Page 1

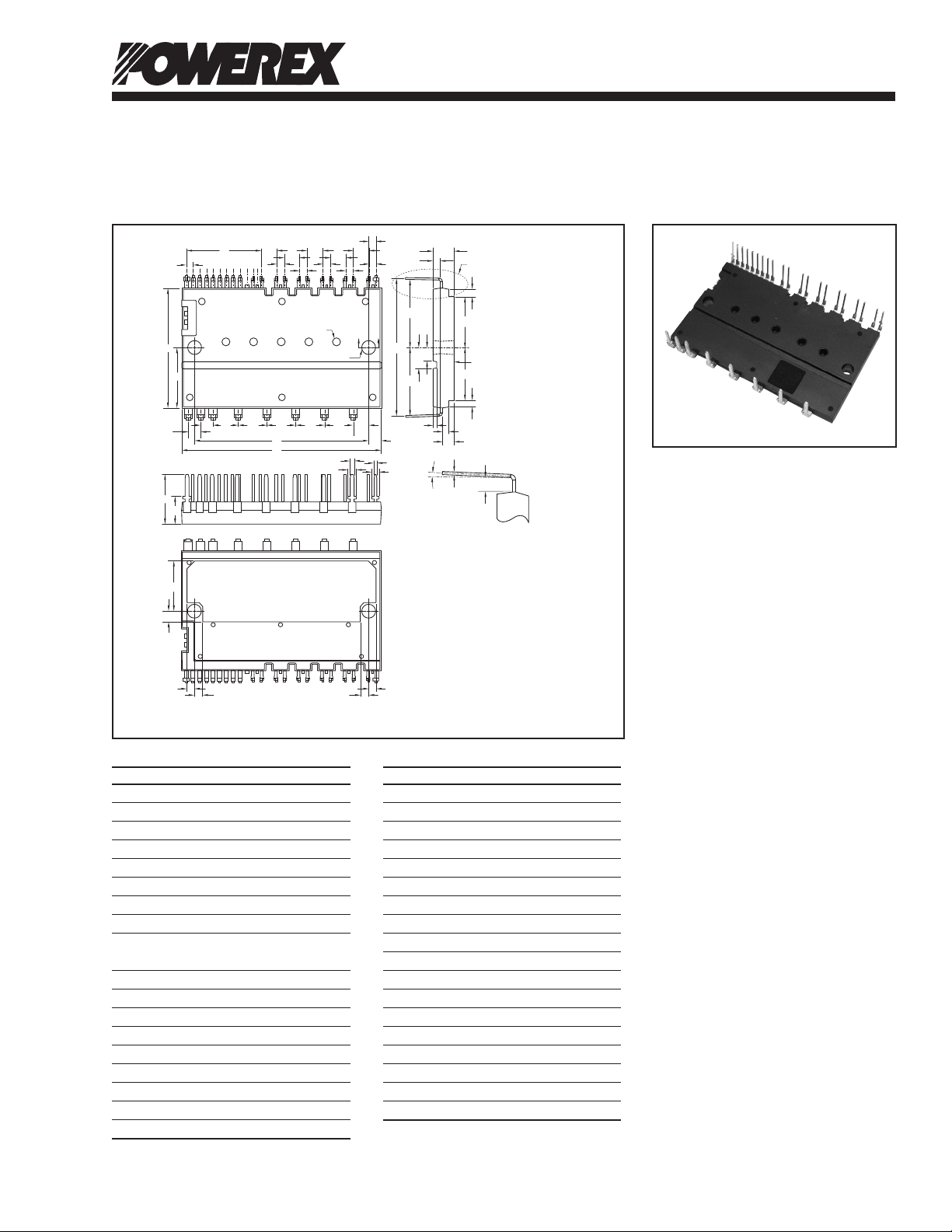

PS51787

HEATSINK

SIDE

E F

F F

F F

L

M

T

S

U

V

W

Y

X

AG

AM

AL

N

P

P

R

Q

D

B

H

Z

Z

AE

AF

W

L

C

AG

V

TT

AJ

AK

AHAH

ACAB ABAB AB

AA

AD

A

D

D

D

D

D

G

K

J

20 VIN

21 VIN

22 GND

23 VD

24 VD

25 RG

26 RG

27 RG

28 RG

29 (VND)

30 (N2)

31 N

32 N

33 N

34 N

35 R

36 S

37 S

38 P

1 N

2

2 (N2)

3 N2

4 N2

5 (N2)

6 N2

7 N2

8 (N2)

9 N

2

10 N2

11 (N2)

12 N2

13 VND

14 (VNO)

15 VND

16 SG

17 (SG)

18 SG

19 (GND)

TERMINAL

CODE

DETAIL "A"

DETAIL "A"

1

1819202122232425262728

1234

567891011121314151617

3837363534333231

29

30

NOTE: Do not connect RG and SG terminal to any wire on the PCB.

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

www.pwrx.com

Intellimod™ Module

Dual-In-Line Intelligent

Power Factor Correction Module

20 Amperes/600 Volts

Description:

DIPPFC™ is an intelligent power

factor correction module that

integrates power devices, drivers

and protection circuitry in an ultracompact dual-in-line package.

Design time is reduced by the

use of application-specific HVIC

and a bridge-less topology.

Overall efficiency and reliability

are increased by use of CSTBT

technology and low thermal

impedance.

Features:

Outline Drawing and Circuit Diagram

Dimensions Inches Millimeters

A 2.07 52.5

B 1.22 31.0

C 1.81±0.008 46.0±0.2

D 0.07±0.008 1.78±0.2

E 0.77 19.58

F 0.17±0.008 4.32±0.2

G 0.08±0.019 2.04±0.3

H 0.61 15.5

J 0.09 Dia. x 2.2 Dia. x

0.1 Depth 2.6 Depth

K 0.13 Dia. 3.3 Dia.

L 0.08 2.0

M 0.22 5.6

N 1.41±0.02 35.9±0.5

P 0.69 17.7

Q 0.216 5.5

R 0.14 3.5

S 0.503 12.78

T 0.09 2.2

Dimensions Inches Millimeters

U 0.53 13.5

V 0.06 1.5

W 0.04 1.0

X 0.12 3.1±0.1

Y 0.06 1.55

Z 0.13±0.019 3.3±0.3

AA 0.26±0.019 6.6±0.3

AB 0.3±0.019 7.62±0.3

AC 0.15±0.019 3.95±0.3

AD 0.13 3.25

AE 0.5 12.7

AF 0.28 7.1

AG 0.02 0.5

AH 0.067 1.7

AJ 0.11 2.8

AK 0.51 13.0

AL 0° ~ 5°

AM 0.078 1.96

Low-loss CSTBT IGBTs

Single Power Supply

Efficient bridge-less Topology

Integrated HVIC

Applications:

HVAC

Compressors

Pumps

Ordering Information:

PS51787 is a 600V, 20 A

RMS

DIPPFC™ Module.

103/10 Rev. 0

Page 2

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272 www.pwrx.com

4.6 mm

25.4mm

IGBT

CONTROL TERMINALS

POWER TERMINALS

TC POINT

PS51787

Intellimod™ Module

Dual-In-Line Intelligent Power Factor Correction Module

20 Amperes/600 Volts

Absolute Maximum Ratings, Tj = 25°C unless otherwise specified

Characteristics Symbol PS51787 Units

Input Supply Voltage (Between S-R Terminals) Vi 264 V

Input Supply Voltage, Surge (Between S-R Terminals) V

500 Volts

i(surge)

Output Voltage (Between P-N Terminals) VO 450 Volts

Output Voltage, Surge (Between P-N Terminals) V

Collector-Emitter Voltage V

Repetative Peak Reverse Voltage V

Input Current, 100% Load (TC ≤ 100°C, Vi = 220V

Input Current, 125% Load (TC ≤ 100°C, Vi = 220V

f

= 20kHz, Non-repetative, within 1 Minute)

PWM

, VO = 390V, f

rms

, VO = 390V, I

rms

= 20kHz) Ii 20 A

PWM

500 Volts

O(surge)

600 Volts

CES

600 Volts

RRM

25 A

i(125%)

I2t for Fusing (Value for 1 Cycle of Surge Current, tw = 8.3ms, Non-repetitive) I2t 120 A2s

Junction Temperature* Tj -20 to 150 °C

Module Case Operation Temperature** TC -20 to 100 °C

Storage Temperature T

-40 to 125 °C

stg

Mounting Torque, M3 Mounting Screws — 8.7 in-lb

Module Weight (Typical) — 21 Grams

Isolation Voltage, AC 1 minute, 60Hz Sinusoidal, Connection Pins to Heatsink Plate V

2500 Vrms

ISO

rms

rms

rms

Control Sector

Control Supply Voltage (Applied between VD-GND) VD 20 Volts

Input Voltage (Applied between VIN-GND) VIN 0 ~ VD+0.5 Volts

*The maximum junction temperature rating of the power chips integrated within the DIPPFC is 150°C (@TC ≤ 100°C). However, to ensure safe operation of the DIPPFC,

the average junction temperature should be limited to T

≤ 125°C (@TC ≤ 100°C).

j(avg)

**TC Measurement Point

2 03/10 Rev. 0

Page 3

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272 www.pwrx.com

PS51787

Intellimod™ Module

Dual-In-Line Intelligent Power Factor Correction Module

20 Amperes/600 Volts

Electrical and Mechanical Characteristics, Tj = 25°C unless otherwise specified

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Collector-Emitter Saturation Voltage V

H-Diode Forward Voltage* V

L-Diode Forward Voltage* V

Switching Times ton — 0.25 0.35 µs

t

t

t

t

Collector-Emitter Cutoff Current I

V

Reverse Current IR V

V

Diode Recovery Current Irr V

V

CE(sat)

I

F(H)

I

F(L)

V

C(on)

I

off

Inductive Load, VIN = 0 ⇔ 5V — 0.18 0.35 µs

C(off)

rr

V

CES

= 15V, VIN = 5V, IC = 30A — 1.9 2.5 Volts

D

= 30A, Applied Between R-P, S-P — 1.9 2.5 Volts

F

= 30A, Applied Between N2-R, N2-S — 1.0 1.3 Volts

F

= 300V, VD = 15V, — 0.14 0.23 µs

CC

= 30A, Tj = 125°C, — 0.40 0.65 µs

C

— 0.11 — µs

= 600V, Tj = 25°C — — 1.0 mA

CE

= 600V, Tj = 125°C — — 10 mA

CE

= 600V, Tj = 25°C — — 1.0 mA

R

= 600V, Tj = 125°C — — 10 mA

R

= 300V, VD = 15V, IC = 30A — 11 — Amperes

CC

Control Sector

Circuit Current I

D

V

Applied Between VD-GND, — 0.7 3.0 mA

V

Input Current IIN V

ON Threshold Voltage V

OFF Threshold Voltage V

Applied Between VIN-GND — 2.1 2.6 Volts

th(on)

Applied Between VIN-GND 0.8 1.3 — Volts

th(off)

Supply Circuit Undervoltage UVDt Trip Level, Tj ≤ 125°C 10.3 — 12.5 Volts

Protection UVDr Reset Level, Tj ≤ 125°C 10.8 — 13.0 Volts

Applied Between VD-GND, — 0.8 3.0 mA

= 15V, VIN = 5V

D

= 15V, VIN = 0V

D

= 15V, VIN = 5V — 0.3 0.45 mA

D

Thermal Characteristics, Tj = 25°C unless otherwise specified

Characteristic Symbol Condition Min. Typ. Max. Units

Thermal Resistance Junction to Case R

Thermal Resistance Junction to Case R

IGBT Part (Per 1 Chip) — — 0.96 °C/Watt

th(j-C)Q

FWDi Part (Per 1 Chip) — — 1.35 °C/Watt

th(j-C)D

Recommended Conditions for Use

Characteristic Symbol Condition Min. Typ. Max. Units

Input Supply Voltage Vi Applied between S-R 90 — 264 V

Control Supply Voltage VD Applied between VD-GND 13.5 15.0 16.5 Volts

Control Supply Variation

PWM Input Frequency f

*H-Diode and L-Diode corresponds to Diode1, Diode 2 and Diode 3, Diode 4 in the Application circuit.

∆VD -1 — 1 V/µs

T

PWM

≤ 100°C, Tj ≤ 125°C — 20 — kHz

C

rms

303/10 Rev. 0

Page 4

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272 www.pwrx.com

V

CC

CONTROL IC

R

OUT

RG

V

D

V

IN

V

NO

GND

SG

MCU

S

OUT

V

NO

V

IN

A

B

N2

N

C2

C1

+

S

R

P

GND

IGBT1

FWDi4 FWDi3

FWDi2 FWDi1

IGBT2

C4

C3

15V

LINE

NOTE:

1. Due to high speed and large surge voltage switching, the area P-C1-N should be a small as possible. (C1: good temperature,

frequency characteristic electrolytic type). Also add a bypass condenser (C2) with good frequency response such as polypropylene

as close as possible to the P and N terminals.

2. To prevent erroneous protection, the wiring of A, B should be as short as possible.

3. It is recommended to insert a high-speed clamp diode between V

NO

-GND terminals to prevent surge destruction.

4. C3 and C4 capacitors should be mounted as close to the terminals of the DIPPFC as possible. C3, good temperature, frequency

characteristic electrolytic type and C4, good temperature, frequency and DC bias characteristic ceramic type are recommended.

5. It is recommended to insert a Zener diode (24V/1W) between each pair of control supply terminals to prevent surge destruction.

6. Please connect adjacent terminals with the same name together on the PCB. (N, N2, V

NO

, VIN, VD, S)

7. Do not connect RG and SG terminals to any wire on the PCB.

PS51787

Intellimod™ Module

Dual-In-Line Intelligent Power Factor Correction Module

20 Amperes/600 Volts

Application Circuit

4 03/10 Rev. 0

Loading...

Loading...