Page 1

6121 Baker Road,

Suite 108

Minnetonka, MN 55345

www.chtechnology.com

Phone (952) 933-6190

Fax (952) 933-6223

1-800-274-4284

Thank you for downloading this document from C&H Technology, Inc.

Please contact the C&H Technology team for the following questions -

Technical

Application

Assembly

Availability

Pricing

Phone – 1-800-274-4284

E-Mail – sales@chtechnology.com

www.chtechnology.com - SPECIALISTS IN POWER ELECTRONIC COMPONENTS AND ASSEMBLIES - www.chtechnology.com

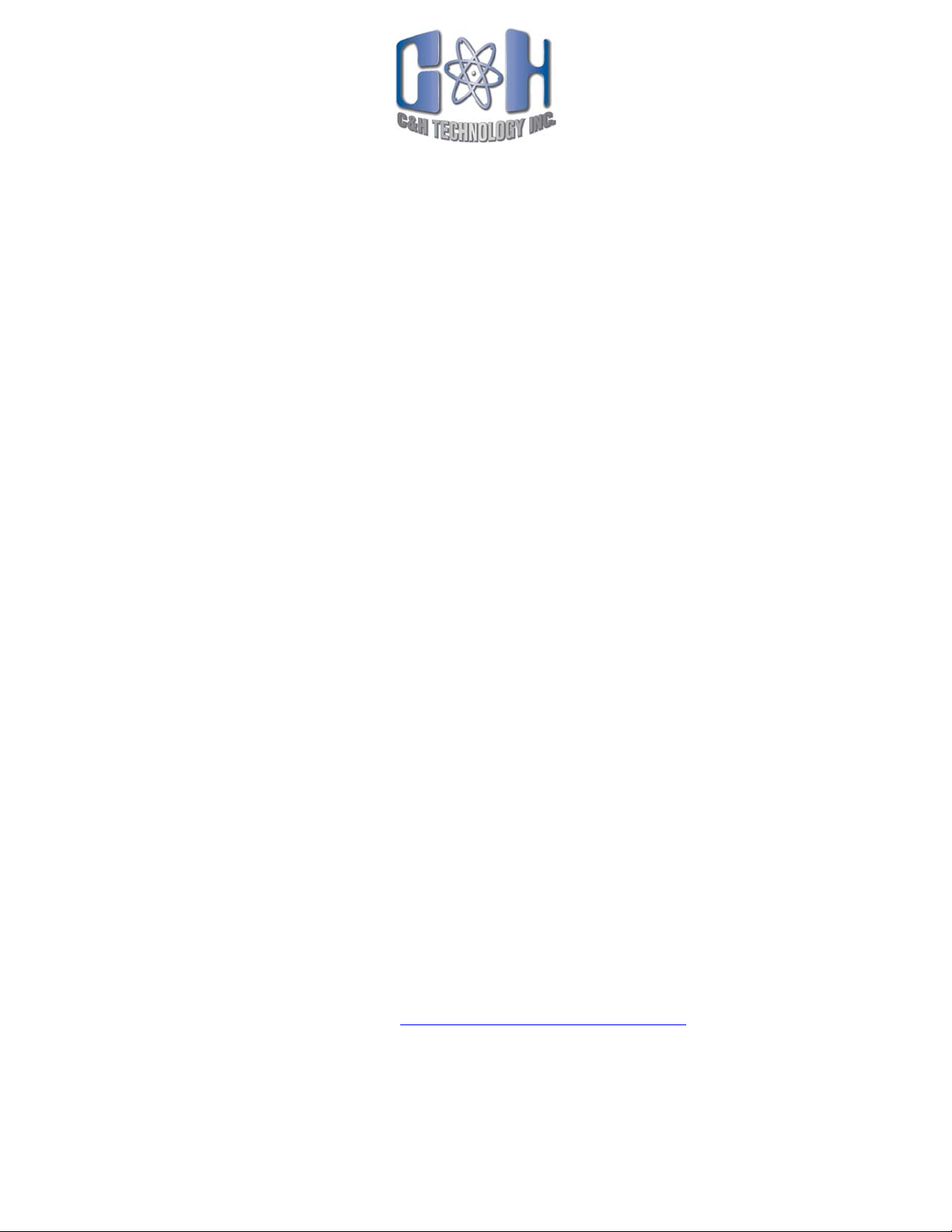

Page 2

PS21A79

C

W

Q

AB

Z

X

Y

B

E

F

A

D

F F F F F

K

G

GG

GGG

GG

HH H

H J

N

R

S

T

W

AB

AC

U

V

Q

AD

HH

L (5 PLACES)

DEPTH 1.6

M (2 PLACES)

1 2 3 4 5 6 7 8 9 1011 12

41 42

13 14 15 16 17 18 19 29

30

31

32

33

3440

6 VUFS

5 (UPG)

3 V

P1

2 (VPC)

26 FO19 V

SC

24 C

IN

23 VOT

22 VNC

21 VN1

25 CFO

20 UNG

28 VN

27 UN

33 W

31 W

NG

30 VNC

29 WN

32 VNG

35 NV

34 NW

40 P

38 V

37 W

36 N

U

39 U

41 U

42 V

7 V

P

9 VP1

11 VPG

10 VVFB

12 VVFS

1 UP

4 VUFB

8 VPC

16 VWFB

15 VPC

17 WPG

18 VWFS

13 WP

14 VP1

TERMINAL CODE

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

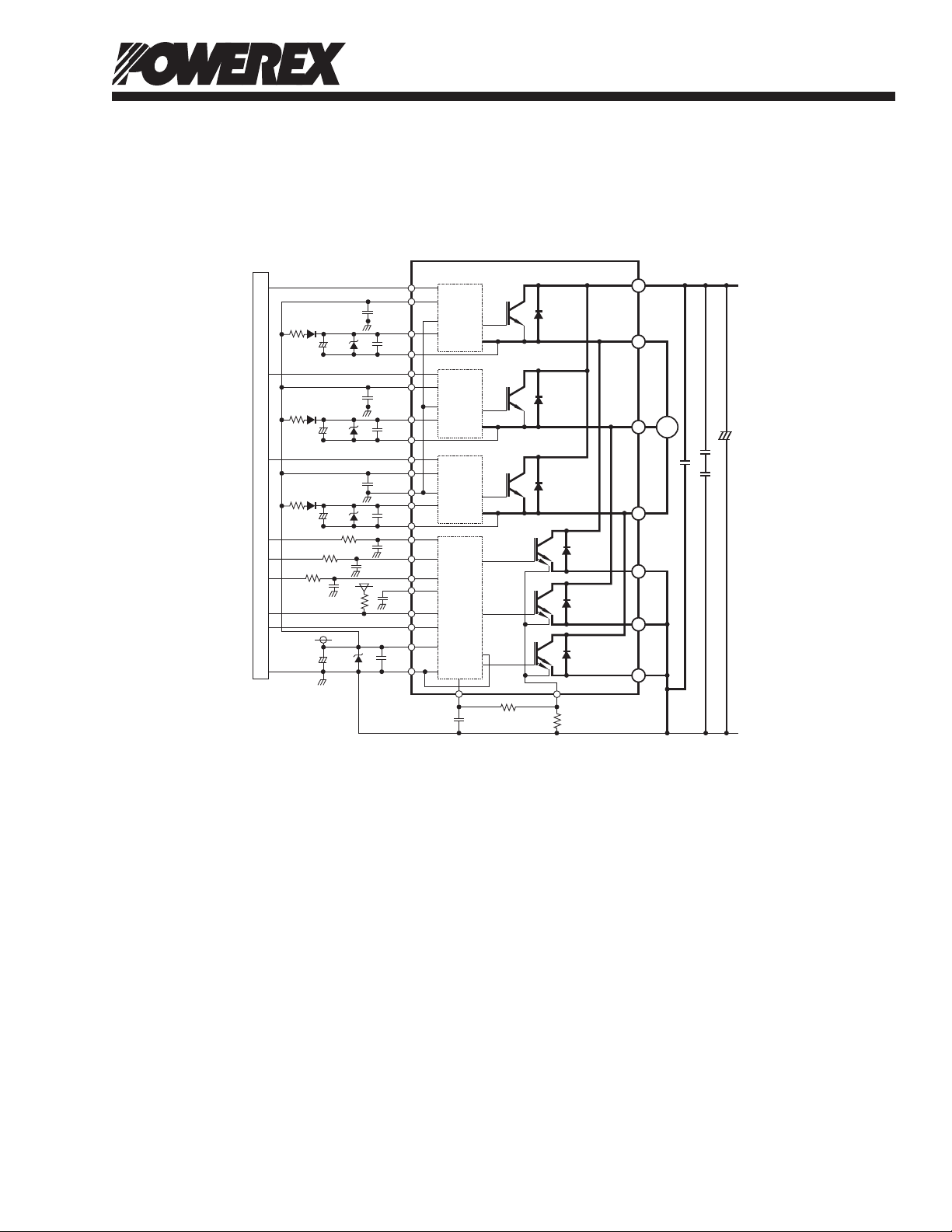

Outline Drawing and Circuit Diagram

Dimensions Inches Millimeters

A 3.11±0.02 79.0±0.5

B 1.22±0.02 31.0±0.5

C 0.63 16.0

D 2.76±0.01 70.0±0.3

E 0.5 12.7

F 0.39±0.01 10.0±0.3

G 0.1±0.01 2.54±0.3

H 0.2±0.01 5.08±0.3

J 1.0 25.4

K 0.11 2.8

L 0.12 Dia. 2.9 Dia.

M 0.18±0.01 Dia. 4.5±0.2 Dia.

N 1.42±0.02 36.2±0.5

P 0.03 0.7

Dimensions Inches Millimeters

Q 0.08 2.0

R 0.66 16.73

S 0.44 11.13

T 015.±0.04 3.8±1.0

U 0.082 2.1

V 0.086 2.2

W 0.31 8.0

X 0.07 1.8

Y 0.34 8.6

Z 0.03 0.8

AA 0.10 2.7

AB 0.48 12.33

AC 0.39 10.12

AD 0.068 1.75

Intellimod™ Module

Dual-In-Line Intelligent

Power Module

50 Amperes/600 Volts

Description:

DIPIPMs are intelligent power

modules that integrate power

devices, drivers, and protection

circuitry. Design time is reduced

by the use of application-specific

HVICs and value-added features

such as linear temperature feedback. Overall efficiency and

reliability are increased by the

use of full gate CSTBT technology

and low thermal impedance.

Features:

Low-loss, Full Gate

CSTBT IGBTs

Single Power Supply

Integrated HVICs

Direct Connection to CPU

Applications:

Variable Speed Pumps

Variable Speed Compressors

Small Motor Control

Ordering Information:

PS21A79 is a 600V, 50 Ampere

DIP Intelligent Power Module.

1Rev. 08/09

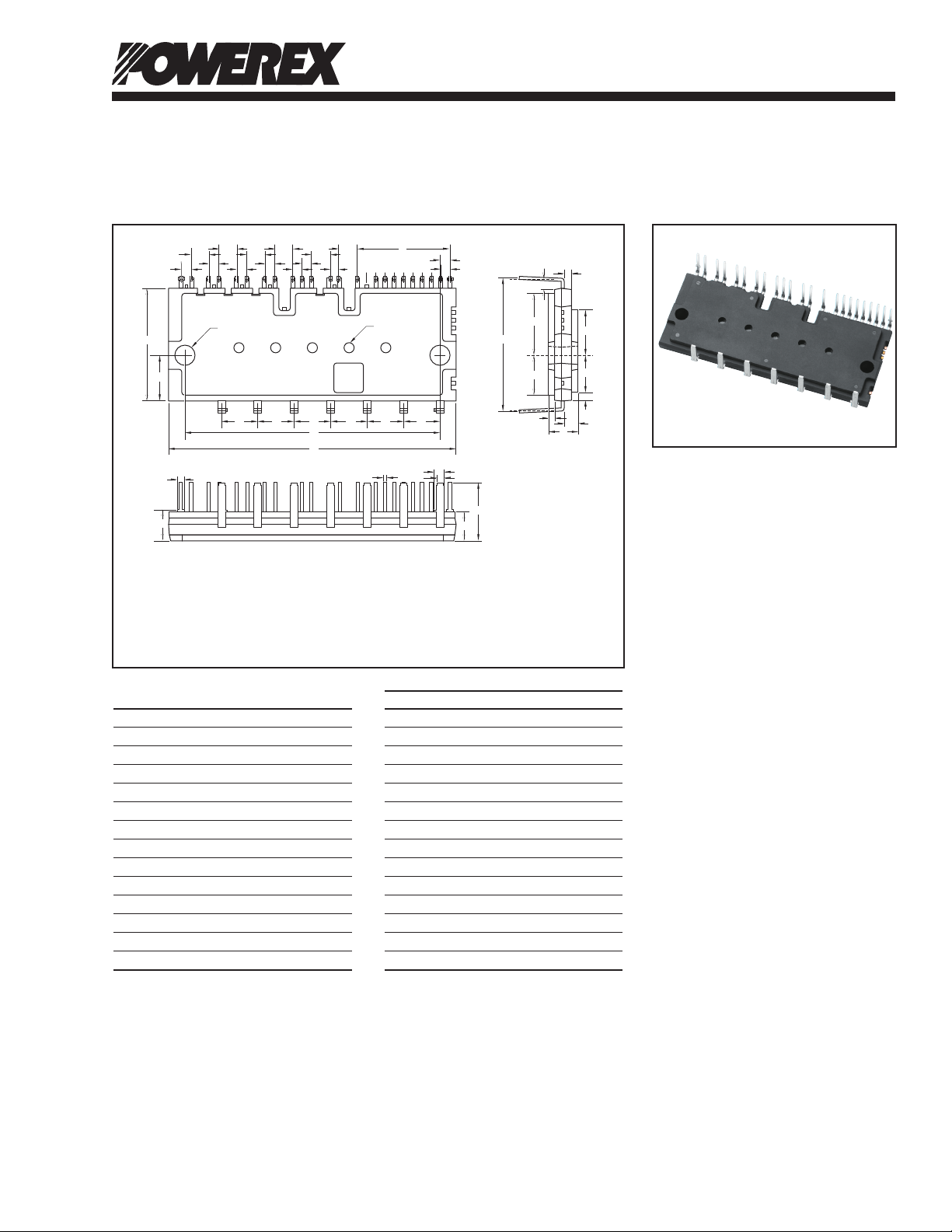

Page 3

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

IGBT CHIP

BUILT-IN HEATSINK

1.2

40.5

TC POINT

PS21A79

Intellimod™ Module

Dual-In-Line Intelligent Power Module

50 Amperes/600 Volts

Absolute Maximum Ratings, Tj = 25°C unless otherwise specified

Characteristics Symbol PS21A79 Units

Self-protection Supply Voltage Limit (Short Circuit Protection Capability)* V

400 Volts

CC(prot.)

Module Case Operation Temperature (See TC Measurement Point Below) TC -20 to 100 °C

Storage Temperature T

-40 to 125 °C

stg

Mounting Torque, M4 Mounting Screws — 13 in-lb

Module Weight (Typical) — 65 Grams

Isolation Voltage, AC 1 minute, 60Hz Sinusoidal, Connection Pins to Heatsink Plate V

2500 Volts

ISO

IGBT Inverter Sector

Supply Voltage (Applied between P-NU, NV, NW) VCC 450 Volts

Supply Voltage, Surge (Applied between P-NU, NV, NW) V

CC(surge)

Collector-Emitter Voltage (TC = 25°C) V

Collector Current (TC = 25°C) ±IC 50 Amperes

Peak Collector Current (TC = 25°C, <1ms) ±ICP 100 Amperes

Collector Dissipation (TC = 25°C, per 1 Chip) PC 142 Watts

Power Device Junction Temperature** Tj -20 to 150 °C

500 Volts

600 Volts

CES

Control Sector

Supply Voltage (Applied between VP1-VPC, VN1-VNC) VD 20 Volts

Supply Voltage (Applied between V

UFB-VUFS, VVFB-VVFS

, V

WFB-VWFS

) VDB 20 Volts

Input Voltage (Applied between UP, VP, WP-VPC, UN, VN, WN-VNC) VIN -0.5 ~ VD+0.5 Volts

Fault Output Supply Voltage (Applied between FO-VNC) VFO -0.5 ~ VD+0.5 Volts

Fault Output Current (Sink Current at FO Terminal) IFO 1 mA

Current Sensing Input Voltage (Applied between CIN-VNC) VSC -0.5 ~ VD+0.5 Volts

*VD = 13.5 ~ 16.5V, Inverter Part, Tj = 125°C, Non-repetitive, Less than 2µs

**The maximum junction temperature rating of the power chips integrated within the DIPIPM is 150°C (@Tf ≤ 100°C). However, to ensure safe operation of the DIPIPM,

the average junction temperature should be limited to T

≤ 125°C (@Tf ≤ 100°C).

j(avg)

TC Measurement Point

2 Rev. 08/09

Page 4

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

PS21A79

Intellimod™ Module

Dual-In-Line Intelligent Power Module

50 Amperes/600 Volts

Electrical and Mechanical Characteristics, Tj = 25°C unless otherwise specified

Characteristics Symbol Test Conditions Min. Typ. Max. Units

IGBT Inverter Sector

Collector-Emitter Saturation Voltage V

IC = 50A, Tj = 125°C, VD = VDB = 15V, VIN = 5V — 1.65 2.10 Volts

Diode Forward Voltage VEC T

Inductive Load Switching Times ton 1.80 2.40 — µs

t

t

t

t

Collector-Emitter Cutoff Current I

V

IC = 50A, Tj = 25°C, VD = VDB = 15V, VIN = 5V — 1.55 2.05 Volts

CE(sat)

= 25°C, -IC = 50A, VIN = 0V — 1.70 2.20 Volts

j

V

rr

I

C(on)

Inductive Load (Upper-Lower Arm) — 3.00 — µs

off

C(off)

V

CES

= 300V, VD = VDB = 15V, — 0.30 — µs

CC

= 50A, Tj = 125°C, VIN = 0 ⇔ 5V, — 0.40 — µs

C

— 0.65 — µs

= V

CE

CE

, Tj = 25°C — — 1.0 mA

CES

= V

, Tj = 125°C — — 10 mA

CES

Control Sector

Circuit Current I

D

Total of VP1-VPC, VN1-V

V

V

Total of VP1-VPC, VN1-V

V

V

Fault Output Voltage V

V

VSC = 0V, FO Terminal Pull-up to 5V by 10kΩ 4.9 — — Volts

FOH

V

FOL

Input Current IIN V

Short-Circuit Trip Level* ISC -20°C ≤ TC ≤ 100°C, VD = 15V, RS = 21.5Ω 85.0 — 150.0 Amps

Supply Circuit Undervoltage UV

Protection UV

Trip Level, TC ≤ 100°C 10.0 — 12.0 Volts

DBt

Reset Level, TC ≤ 100°C 10.5 — 12.5 Volts

DBr

UVDt Trip Level, TC ≤ 100°C 10.3 — 12.5 Volts

UVDr Reset Level, TC ≤ 100°C 10.8 — 13.0 Volts

Fault Output Pulse Width** tFO C

ON Threshold Voltage V

OFF Threshold Voltage V

Applied between UP, VP, WP-V

th(on)

U

th(off)

Temperature Output VOT At LVIC Temperature = 85°C 3.50 3.63 3.76 Volts

* Short-Circuit protection is functioning only at the lower ar ms. Please select the value of the external shunt resistor such that the SC trip level is less than 85A.

**Fault signal is asserted when the lower arm shor t circuit or control supply under-voltage protective functions operate. The fault output pulse-width tFO depends on the capacitance value

of CFO according to the following approximate equation: CFO = (12.2 x 10-6 x tFO [F]).

***When the temperature rises excessively, the controller (MCU) should stop the DIPIPM.

VD = VDB = 15V, VIN = 5V, — — 7.00 mA

NC

= VDB = 15V, VIN = 5V, — — 0.55 mA

D

UFB-VUFS

, V

VFB-VVFS

, V

WFB-VWFS

VD = VDB = 15V, VIN = 0V, — — 7.00 mA

NC

= VDB = 15V, VIN = 0V, — — 0.55 mA

D

UFB-VUFS

, V

VFB-VVFS

= 1V, IFO = 1mA — — 0.95 Volts

SC

IN

FO

, VN, WN-VNC 0.8 1.4 2.1 Volts

N

, V

WFB-VWFS

= 5V 1.0 1.5 2.0 mA

= 22nF 1.0 1.8 — ms

2.1 2.3 2.6 Volts

PC,

3Rev. 08/09

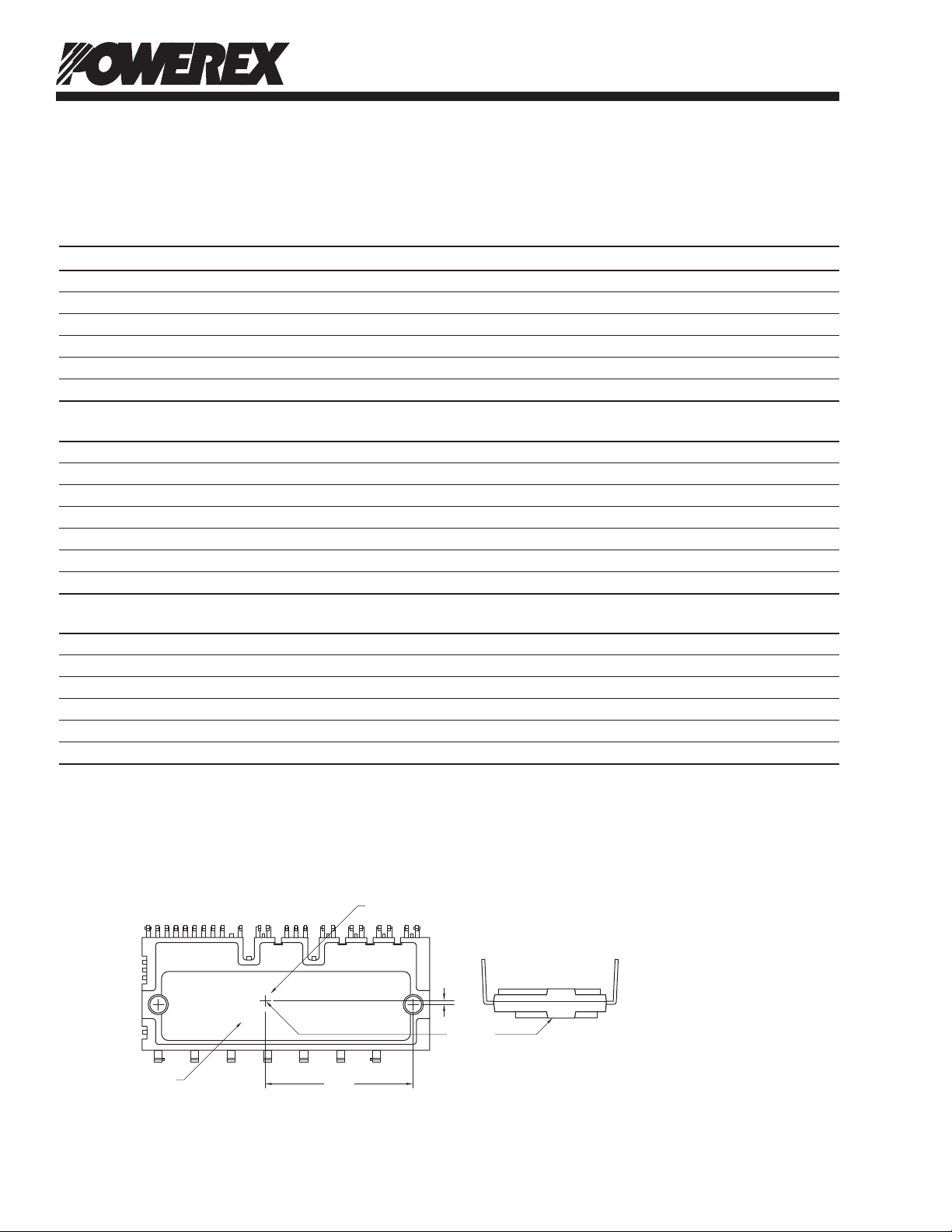

Page 5

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

t2

t1

P-SIDE

CONTROL INPUT

INTERNAL

IGBT GATE

OUTPUT

CURRENT I

C

Solid Line – OFF Pulse Width > P

WIN(off)

: Turn ON time t1.

Dotted Line – OFF Pulse Width < P

WIN(off)

: Turn ON time t2.

PS21A79

Intellimod™ Module

Dual-In-Line Intelligent Power Module

50 Amperes/600 Volts

Thermal Characteristics, Tj = 25°C unless otherwise specified

Characteristic Symbol Condition Min. Typ. Max. Units

Thermal Resistance Junction to Case R

Thermal Resistance Junction to Case R

IGBT Part (Per 1/6 Module) — — 0.88 °C/Watt

th(j-C)Q

FWDi Part (Per 1/6 Module) — — 1.78 °C/Watt

th(j-C)D

Recommended Conditions for Use

Characteristic Symbol Condition Min. Typ. Max. Units

Supply Voltage VCC Applied between P-NU, NV, NW 0 300 400 Volts

Control Supply Voltage VD Applied between VP1-VPC, VN1-VNC 13.5 15.0 16.5 Volts

V

V

Control Supply Variation

ΔVD, ΔVDB -1 — 1 V/µs

Arm Shoot-through t

Blocking Time

PWM Input Frequency f

Allowable rms Current* IO V

f

T

V

f

T

Minimum Input P

Pulse Width P

50 ≤ IC ≤ 85A 13.5 ≤ VDB ≤ 18.5V, -20°C ≤ TC ≤ 100°C, 5.0 — — µs

N-line Wiring Inductance Less Than 10nH

VNC Variation VNC Between VNC-NU, NV, NW (Including Surge) -5.0 — 5.0 Volts

* The allowable rms current value depends on the actual application conditions.

**If input signal ON pulse is less than P

***The IPM may fail to respond to an ON pulse if the preceeding OFF pulse is less than P

WIN(on)

Applied between V

DB

VFB-VVFS

For Each Input Signal, TC ≤ 100°C 2.0 — — µs

DEAD

T

PWM

PWM

PWM

** 0.3 — — µs

WIN(on)

WIN(off)***

≤ 100°C, Tj ≤ 125°C — — 20 kHz

C

= 300V, VD = 15V, — — 23.6 Arms

CC

= 5kHz, PF = 0.8, Sinusoidal PWM,

≤ 125°C, TC ≤ 100°C

j

= 300V, VD = 15V, — — 13.8 Arms

CC

= 15kHz, PF = 0.8, Sinusoidal PWM,

≤ 125°C, TC ≤ 100°C

j

UFB-VUFS,

, V

WFB-VWFS

13.0 15.0 18.5 Volts

IC ≤ 50A 200 ≤ VCC ≤ 350V, 13.5 ≤ VD ≤ 16.5V, 3.0 — — µs

, the device may not respond.

WIN(off)

.

Delayed Response Against Shorter Input OFF Signal Than P

4 Rev. 08/09

WIN

, P-side only

(off)

Page 6

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

Component Selection:

Dsgn. Typ. Value Description

D1 1A, 600V Control and boot strap supply overvoltage suppression

DZ1 24V, 1W Control and boot strap supply over voltage suppression

C1 10-100µF, 50V Boot strap supply reservoir – electrolytic long lifem low impedance, 105°C

C2 0.22-2.0µF, 50V Local decoupling/High frequency noise filters – multilayer ceramic (Note 4)

C3 200 to 2500µF, 450V Main DC bus filter capacitor – electrolytic, long life, high ripple current, 105°C

C4 100pF, 50V Optional input signal noise filter – multilayer ceramic (Note 11)

C5 0.1-0.22µF, 1000V Surge voltage suppression (Note 2)

CSF 1000pF, 50V Shor t circuit detection filter capacitor – multilayer ceramic

RSF 1.8kΩ Short circuit detection filter resistor

R

SHUNT

20ohm-500ohm Current sensing resistor

R1 1-10Ω Boot strap supply inrush limiting resistor – non-inductive, temperature stable, tight tolerance (Note 5)

R2 330Ω Optional input signal noise filter (Note 11)

R3 10kΩ Fault signal pull-up resistor (Note 9)

Notes:

1) If control GND is connected to power GND by broad pattern, it may cause malfunction by power GND fluctuation.

It is recommended to connect control GND at only a point at which NU, NV, NW are connected to power GND line.

2) To prevent surge destruction, the wiring between the smoothing capacitor and the P-N1 terminals should be as short as

possible. Generally inserting a 0.1µ ~ 0.22µF snubber capacitor C3 between the P-N1 terminals is recommended.

3) The time constant R1,C4 of RC filter for preventing the protection circuit malfunction should be selected in the range of 1.5µ ~ 2µs.

SC interrupting time might vary with the wiring pattern. Tight tolerance, temp-compensated type is recommended for R1,C4.

4) All capacitors should be mounted as close to the terminals of the DIPIPM as possible. (C1: good temperature, frequency

characteristics electrolytic type, and C2 : good temperature, frequency and DC bias characteristic ceramic type are recommended.)

5) It is recommended to insert a Zener diode DZ1 (24V/1W) between each pair of control supply terminals to prevent surge destruction.

6) To prevent erroneous SC protection, the wiring from VSC terminals to CIN filter should be divided at the point D that is close

to the terminal of sense resistor and the wiring should be patterned as short as possible.

7) For sense resistor, the variation within 1% (including temperature characteristics), low inductance type is recommended.

1/8W is recommended, but an evaluation of your system is recommended.

8) To prevent erroneous operation, wiring A, B, and C should be as short as possible.

9) FO output is open drain type. It should be pulled up to the positive side of 5V or 15V power supply with a resistor that limits

FO sink current (IFO) under 1mA. (Over 5.1kΩ is needed and 10kΩ is recommended for 5V supply.)

10) Error signal output width (tFO) can be set by the capacitor connected to the CFO terminal. t

FO(typ)

= CFO / 9.1 x 10-6 (s).

11) Input drive is high-active type. There is a 3.3kΩ pull-down resistor integrated in the IC input circuit. To prevent malfunction, the wiring of each input

should be patterned as short as possible. When inserting the RC filter, make sure the input signal level meets the turn-on and turn-off threshold voltage.

Thanks to HVIC inside the module, connection to the MCU may be direct or with an opto-coupler.

V

N1

U

N

F

O

V

OT

V

NC

V

NO

V

SC

D

B

C

A

R

SHUNT

C

IN

C

SF

R

SF

V

N

W

N

CFO

HVIC1

IGBT1

FWDi1

IGBT2

FWDi2

IGBT3

IGBT4

IGBT5

IGBT6

FWDi3

FWDi4

FWDi5

FWDi6

LVIC

P

U

HVIC2

V

V

WFB

V

P1

V

WFS

W

P

V

PC

HVIC3

W

NU

NV

NW

C

2DZ1

C

1

V

D

15V

+

+

C

2

C

4

C

4

C

4

R

3

R

2

R

2

R

2

C

2

DZ

1

C

1

D

1

+

V

VFB

V

P1

V

VFS

V

P

C

2

C

2

DZ

1

C

1

D

1

MCU

+

V

UFB

V

P1

V

UFS

U

P

C

2

C

2

C

3

C

3

C

5

DZ

1

C

1

D

1

+

M

PS21A79

Intellimod™ Module

Dual-In-Line Intelligent Power Module

50 Amperes/600 Volts

Application Circuit

5Rev. 08/09

Page 7

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

a1

SC

SC REFERENCE VOLTAGE

RC CIRCUIT TIME CONSTANT DELAY

a2

a3

a4

a8

a5

a7a6

SET

RESET

N-SIDE

CONTROL INPUT

PROTECTION

CIRCUIT STATE

INTERNAL IGBT GATE

SENSE VOLTAGE OF R

S

OUTPUT CURRENT I

C

FAULT OUTPUT F

O

Short Circuit Protection (N-side Only with External Shunt Resistor and RC Filter)

a1: Normal operation – IGBT turns on and carries current.

a2: Short circuit current is detected (SC trigger).

a3: All N-side IGBT's gate are hard interrupted.

a4: All N-side IGBT's turn off.

a5: FO output wirh a fixed pulse width (determined by the external capacitance CFO).

a6: Input "L" – IGBT off.

a7: Input "H" – IGBT on, but during the FO output perid the IGBT will not turn on.

a8: IGBT turns on when L→H signal is input after FO is reset.

b1

b4

b5

b2

UV

Dt

b7

b3

SET

RESETRESET

UV

Dr

b6

CONTROL INPUT

PROTECTION

CIRCUIT STATE

CONTRO L SUPPLY

VOLTAGE V

D

OUTPUT CURRENT I

C

FAULT OUTPUT F

O

Under-Voltage Protection (N-side , UVD)

b1: Control supply voltage VD rises – After VD level reaches under voltage reset level (UVDr), the circuits

start to operate when next input is applied.

b2 : Normal operation – IGBT turns on and carries current.

b3: VD level dips to under voltage trip level (UVDt).

b4: All N-side IGBT’s turn off in spite of control input condition.

b5: FO is low for a minimum period determined by the capacitance CFO but continuously during UV period.

b6: VD level reaches UVDr.

b7: Normal operation – IGBT turns on and carries current.

PS21A79

Intellimod™ Module

Dual-In-Line Intelligent Power Module

50 Amperes/600 Volts

Protection Function Timing Diagrams

6 Rev. 08/09

Page 8

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272

c1

c5

c6

c3

c2

UV

Dt

c4

SET

RESETRESET

HIGH LEVEL (NO FAULT OUTPUT)

UV

DBr

CONTROL INPUT

PROTECTION

CIRCUIT STATE

CONTROL SUPPLY

VOLTAGE V

DB

OUTPUT CURRENT I

C

FAULT OUTPUT F

O

Under-Voltage Protection (P-side, UVDB)

c1: Control supply voltage VDB rises – After VDB level reaches under voltage reset level (UV

DBr

),

the circuits starts to operate when next input is applied.

c2: Normal operation – IGBT turns on and carries current.

c3: V

DB

level dips to under voltage trip level (UV

DBt

).

c4: P-side IGBT turns off in spite of control input signal level, but there is no FO signal output.

c5: V

DB

level reaches UV

DBr

.

c6: Normal operation – IGBT on and carries current.

UP, VP, WP, UN, VN, W

N

MCU

5V LINE

10kΩ

2.5kΩ (MIN)

F

O

VNC (LOGIC)

DIP-IPM

NOTE: RC coupling at each input

(parts shown dotted) may change

depending on the PWM control

scheme used in the application and

the wiring impedance of the printed

circuit board. The DIPIPM input signal

section integrates a 2.5k

Ω (min)

pull-down resistor. Therefore, when

using an external filtering resistor, care

must be taken to satisfy the turn-on

threshold voltage requirement.

V

NC

NW

NV

NU

DIPIPM

It is recommended to make the inductance under 10nH.

For shunt resistors, it is recommended to use as low

inductance type as possible.

Shunt

Resistors

Connect the wiring from VNC terminal at the point as

close to shunt resistors’ terminal as possible.

It is recommended to divide the wiring to current detecting

circuit at the point as close to shunt resistor’s terminal as

possible.

To Current

Detecting Circuit

PS21A79

Intellimod™ Module

Dual-In-Line Intelligent Power Module

50 Amperes/600 Volts

Protection Function Timing Diagrams

Typical Interface Circuit

Wiring Method Around Shunt Resistor

7Rev. 08/09

Loading...

Loading...