Page 1

6121 Baker Road,

Suite 108

Minnetonka, MN 55345

www.chtechnology.com

Phone (952) 933-6190

Fax (952) 933-6223

1-800-274-4284

Thank you for downloading this document from C&H Technology, Inc.

Please contact the C&H Technology team for the following questions -

Technical

Application

Assembly

Availability

Pricing

Phone – 1-800-274-4284

E-Mail – sales@chtechnology.com

www.chtechnology.com - SPECIALISTS IN POWER ELECTRONIC COMPONENTS AND ASSEMBLIES - www.chtechnology.com

Page 2

MITSUBISHI SEMICONDUCTOR <Application Specific Intelligent Power Module>

MITSUBISHI SEMICONDUCTOR <Application Specific Intelligent Power Module>

PS11011

FLAT-B ASE TYPE

FLA T -B ASE TYPE

INSULA TED TYPE

PS11011

PS11011

INSULA TED TYPE

INTEGRATED FUNCTIONS AND FEATURES

• Converter bridge for 3 phase AC-to-DC power conversion.

• Circuit for dynamic braking of motor regenerative energy.

• 3-phase IGBT inverter bridge configured by the latest 3rd.

generation IGBT and diode technology.

• Inverter output current capability I

Type Name

PS11011

100% load

0.8A (rms)

O (Note 1):

150% over load

1.2A (rms), 1min

(Note 1) : The inverter output current is assumed to be sinu-

soidal and the peak current value of each of the

above loading cases is defined as : I

INTEGRATED DRIVE, PROTECTION AND SYSTEM CONTROL FUNCTIONS:

• For inverter side upper-leg IGBTs : Drive circuit, High voltage isolated high-speed level shifting, Short circuit protection (SC).

• For inverter side lower-leg IGBTs : Drive circuit, Short circuit protection (SC).

• For Brake circuit IGBT : Drive circuit

• Warning and Fault signaling :

F

O1 : Short circuit protection for lower-leg IGBTs and Input interlocking against spurious arm shoot-through.

F

O2 : N-side control supply abnormality locking (OV/UV).

F

O3 : System over-temperature protection (OT).

CL : Warning for inverter current o verload condition

• For system feedback control : Analogue signal feedback reproducing actual inverter output phase currents (3φ).

• Input Interface : 5V CMOS/TTL compatible, Schmitt trigger input, and Arm-Shoot-Through interlock protection.

Bootstrap circuit supply scheme (single drive power supply) and Under voltage protection (UV).

Control supply circuit under- & over- voltage protection (OV/UV).

System over temperature protection (OT). Fault output signaling circuit (F

O) and Current limit warn-

ing signal output (CL).

OP = IO × √2

APPLICATION

Acoustic noise-less 0.1kW/AC200V class 3 phase inverter and other motor control applications

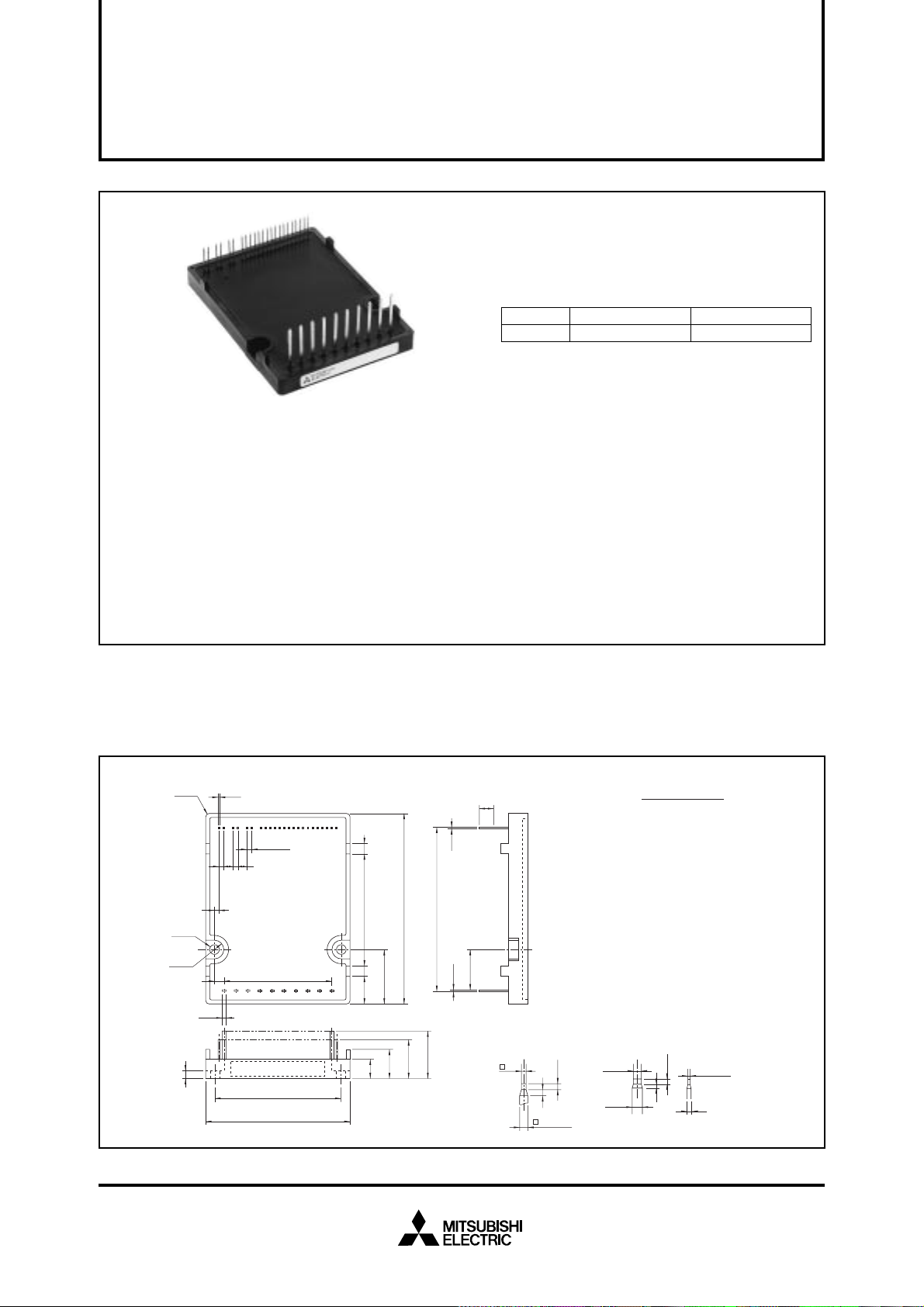

PACKAGE OUTLINES

4-R2

2-φ4

2-R4

3.5

0.5

12 34 56 789

2

2

4.14

31 32 33 34 35 36 37 38 39 40

1.2

22444

5.08

10111213141516 1718 192 021 23

2

± 0.3

± 0.3

✕ 9 = 45.72

LABEL

54

± 0.5

62

± 1

± 0.8

✽

6

22

± 1

20.4

0.5

✽

± 0.8

72

± 0.5

0.6

✽

17.6

✽ Control Pin top

± 1

27

portion details

0.3

0.4

0.5

0~0.8

± 0.03

4

50

4

(12.25)

8.5

± 1

84.2

24

12

1 CBU+

2 CBU–

3 CBV+

4 CBV–

5 CBW+

6 CBW–

7 GND

8 NC

9 VDH

10 CL

11 FO1

12 FO2

13 FO3

14 CU

15 CV

16 CW

17 UP

18 VP

19 WP

20 UN

✽ Main terminal top

portion details

± 0.5

0.8

0

± 0.5

12

0

Terminals Assignment:

21 VN

22 WN

23 Br

31 R

32 S

33 T

34 P1

35 P2

36 N

37 B

38 U

39 V

40 W

0.35MAX

0~0.8

0.5

0.6

(Fig. 1)

Jan. 2000

Page 3

MITSUBISHI SEMICONDUCTOR <Application Specific Intelligent Power Module>

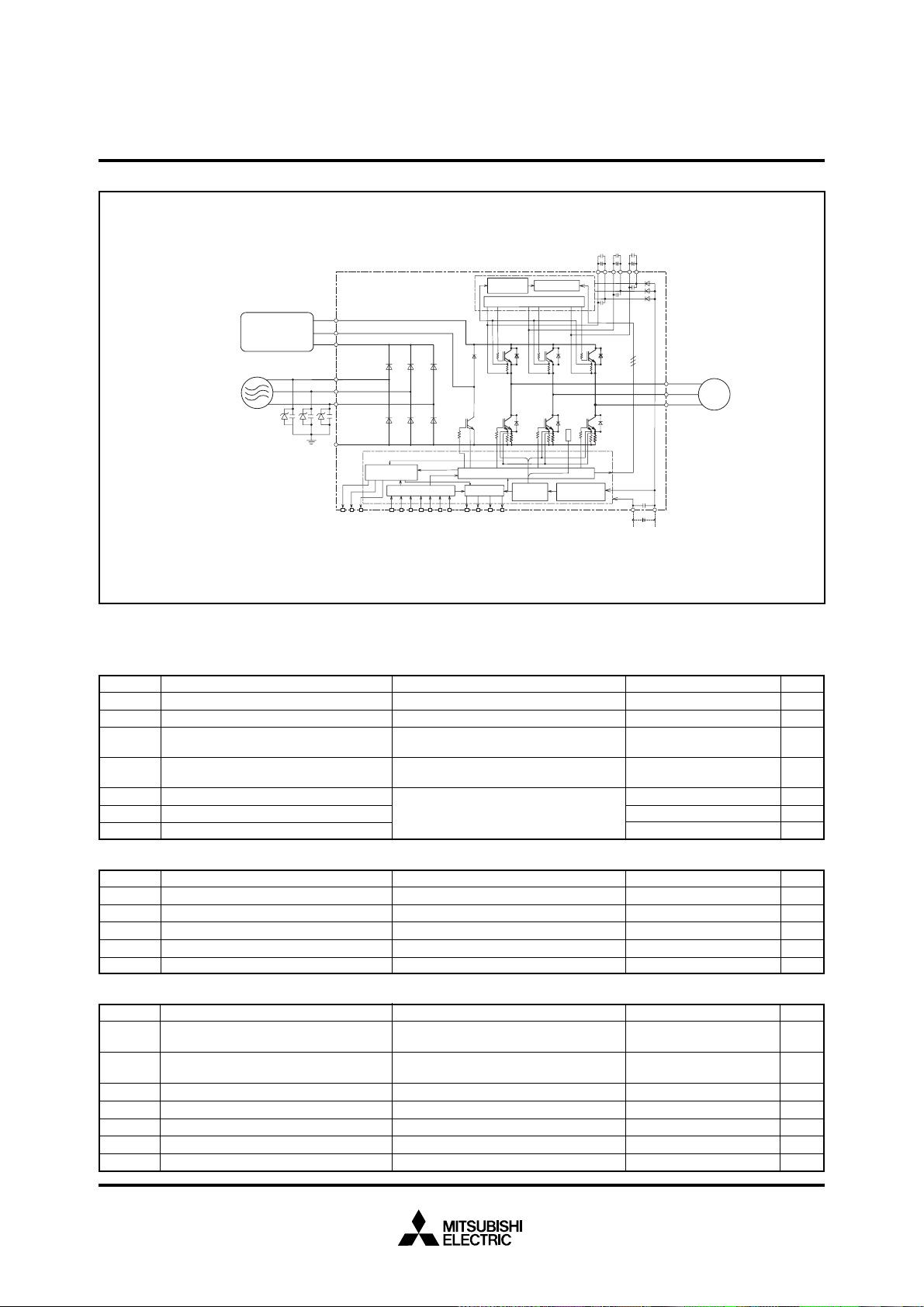

INTERNAL FUNCTIONS BLOCK DIAGRAM

C3 ; 3.3µF or more, tight tolerance, temp-compensated electrolytic type (Note : the value may change

depending on the type PWM control scheme used in the applied system)

C4 ; 2µF R-category ceramic condenser for noise filtering.

Application Specific Intelligent

CZ

P2

B

P1

R

S

T

N

CUCVCW U

Brake resistor

connection,

Inrush prevention

circuit, etc.

AC200V line input

Z : Surge absorber.

C : AC filter (Ceramic condenser 2.2~6.5nF)

[Note : Additionally an appropriate Line-to line

surge absorber circuit maybe necessary

depending on the application environment].

Analogue signal output corresponding to

Note 1) To prevent chances of signal oscillation, an RC coupling at each output is recommended. (see also Fig.10)

Note 2) By virtue of integrating an application specific type HVIC inside the module, direct coupling to CPU, without any opto or transformer isolation ispossible. (see also Fig.10)

Note 3) All these outputs are open collector type. Each signal line should be pulled up to plus side of the 5V power supply with approximately 5.1kΩ resistance. (see also Fig.10)

Note 4) The wiring between power DC link capacitor and P/N terminals should be as short as possible to protect the ASIPM against catastrophic high surge voltage. For extra

precaution, a small film type snubber capacitor (0.1~0.22µF, high voltage type) is recommended to be mounted close to these P and N DC powerinput pins.

each phase current (5V line) Note 1)

Power Module

Current sensing

circuit

Trig signal conditioning

PVPWPUNVNWNBr

Each phase input (PWM)

(5V line) Note 2)

Protection

Circuit

Drive Curcuit

FO Logic

CL FO1 FO2 FO3

Fault output

(5V line) Note 3)

Level shifter

Drive Circuit

Protection

circuit

CBU–

T.S.

Control supply

fault sense

CBU+

CBV–

CBV+

CBW–

CBW+

C4,C3

C2

(15V line)

VDHGND

PS11011

FLAT-B ASE TYPE

INSULA TED TYPE

U

V

M

W

AC 200V line

output

C2 ;

3.3µF or more

(Fig. 2)

MAXIMUM RATINGS (Tj = 25°C)

INVERTER PART (Including Brake Part)

ConditionSymbol Item Ratings Unit

V

CC

VCC(surge)

VP or VN

V

P(S)

±IC(±ICP)

C(ICP)

I

F(IFP)

I

Supply voltage

Supply voltage (surge)

Each output IGBT collector-emitter static voltage

Each output IGBT collector-emitter

or V

N(S)

switching surge voltage

Each output IGBT collector current

Brake IGBT collector current

Brake diode anode current

Applied between P2-N

Applied between P2-N, Surge-value

Applied between P-U, V, W, Br or U, V, W,

Br-N

Applied between P-U, V, W, Br or U, V, W,

Br-N

C = 25°C

T

Note: “( )” means I

C peak value

450

500

600

600

±2 (±4)

2 (4)

2 (4)

CONVERTER PART

Symbol Item Ratings Unit

VRRM

Ea

O

I

IFSM

I2t

Repetitive peak reverse voltage

Recommended AC input voltage

DC output current

Surge (non-repetitive) forward current

2

t for fusing

I

3φ rectifying circuit

1 cycle at 60Hz, peak value non-repetitive

Value for one cycle of surge current

Condition

800

220

25

138

80

CONTROL PAR T

Symbol Item Ratings Unit

DH, VDB

V

VCIN

VFO

IFO

VCL

ICL

ICO

Supply voltage

Input signal voltage –0.5 ~ 7.5

Fault output supply voltage

Fault output current

Current-limit warning (CL) output voltage

CL output current

Analogue current signal output current

Applied between V

C

BV+-CBV–, CBW+-CBW–

Applied between UP · VP · WP · UN · VN ·

W

N · Br-GND

Applied between F

Sink current of F

Applied between CL-GND

Sink current of CL

Sink current of CU · CV · CW

Condition

DH-GND, CBU+-CBU–,

O1 · FO2 · FO3-GND

O1 · FO2 · FO3

20

–0.5 ~ 7

15

–0.5 ~ 7

15

±1

A

mA

mA

mA

V

V

V

V

A

A

A

V

V

A

A

2

s

V

V

V

V

Jan. 2000

Page 4

MITSUBISHI SEMICONDUCTOR <Application Specific Intelligent Power Module>

PS11011

FLAT-B ASE TYPE

INSULA TED TYPE

TOTAL SYSTEM

Symbol

j

T

Tstg

TC

Viso

—

Item

Junction temperature

Storage temperature

Module case operating temperature

Isolation voltage

Mounting torque

60 Hz sinusoidal AC applied between all terminals and

the base plate for 1 minute.

Mounting screw: M3.5

Condition

(Note 2)

—

(Fig. 3)

Note 2) The item defines the maximum junction temperature for the power elements (IGBT/Diode) of the ASIPM to ensure safe operation. How-

ever, these power elements can endure junction temperature as high as 150°C instantaneously . To make use of this additional temperature allowance, a detailed study of the exact application conditions is required and, accordingly, necessary information is requested

to be provided before use.

CASE TEMPERATURE MEASUREMENT POINT (3mm from the base surface)

Ratings Unit

–20 ~ +125

–40 ~ +125

–20 ~ +100

2500

0.78 ~ 1.27

°C

°C

°C

Vrms

kg·cm

TC

(Fig. 3)

THERMAL RESISTANCE

Symbol Item

Q

Rth(j-c)

Rth(j-c)F

Rth(j-c)QB

Rth(j-c)FB

Rth(j-c)

Rth(c-f)

Junction to case Thermal

Resistance

FR

Contact Thermal Resistance

Inverter IGBT (1/6)

Inverter FWDi (1/6)

Brake IGBT

Brake FWDi

Converter Di (1/6)

Case to fin, thermal grease applied (1 Module)

Condition

ELECTRICAL CHARACTERISTICS (Tj = 25°C, VDH = 15V, VDB = 15V unless otherwise noted)

Symbol Item

CE(sat)

V

VEC

V

CE(sat)Br VDH = 15V, Input = ON, Tj = 25°C, IC = 2A

FBr

V

IRRM

VFR

Collector-emitter saturation voltage

FWDi forward voltage

Brake IGBT

Collector-emitter saturation voltage

Brake diode forward voltage

Converter diode reverse current

Converter diode voltage

ton

tc(on)

toff

Switching times

tc(off)

trr

FWD reverse recovery time

Short circuit endurance

(Output, Arm, and Load,

Short Circuit Modes)

Switching SOA

VDH = VDB = 15V, Input = ON, Tj = 25°C, IC = 2A

Tj = 25°C, IC = –2A, Input = OFF

Tj = 25°C, I

R = VRRM, Tj = 125°C

V

Tj = 25°C, I

F = 2A, Input = OFF

F = 5A

1/2 Bridge inductive load, Input = ON

CC = 300V, Ic = 2A, Tj = 125°C

V

DH = 15V, VDB = 15V

V

Note : ton, toff include delay time of the internal control

circuit

CC ≤ 400V, Input = ON (one-shot)

V

Tj = 125°C start

13.5V ≤ V

V

Ic < I

13.5V ≤ V

DH = VDB ≤ 16.5V

CC ≤ 400V, Tj ≤ 125°C,

OL(CL) operation level, Input = ON

DH = VDB ≤ 16.5V

Condition

Ratings

Min.

—

—

—

—

—

—

Typ. Max.

—

—

—

—

—

—

7.3

6.1

7.3

6.1

4.8

0.053

Ratings

Min. Typ. Max.

—

—

—

—

—

—

0.3

—

—

—

—

• No destruction

• F

O output by protection operation

—

—

—

—

—

—

0.6

0.2

1.1

0.35

2.9

2.9

3.5

2.9

8

1.5

1.5

0.6

1.8

1.0

—0.1

• No destruction

• No protecting operation

• No F

O output

Unit

°C/W

°C/W

°C/W

°C/W

°C/W

°C/W

Unit

V

V

V

V

mA

V

µs

µs

µs

µs

µs

Jan. 2000

Page 5

MITSUBISHI SEMICONDUCTOR <Application Specific Intelligent Power Module>

PS11011

FLAT-B ASE TYPE

INSULA TED TYPE

ELECTRICAL CHARACTERISTICS (Tj = 25°C, VDH = 15V, VDB = 15V unless otherwise noted)

ConditionSymbol

C

= –20°C ~ +100°C

DH = 15V

V

C = –20°C ~ +100°C

T

(Fig. 4)

(Fig. 4)

OP(200%) (Fig. 5)

IDH

Vth(on)

Vth(off)

Ri

fPWM

txx

t

dead

tint

VCO

VC+(200%)

C–

(200%)

V

|∆VCO|

C+

V

VC–

∆VC(200%)

CH

r

d(read)

t

±IOL

ICL(H)

ICL(L)

SC

OT

OTr

DH

UV

UVDHr

OVDH

OVDHr

UVDB

UVDBr

tdV

IFO(H)

IFO(L)

Item

Circuit current

Input on threshold voltage

Input off threshold voltage

Input pull-up resistor

PWM input frequency

Allowable input on-pulse width

Allowable input signal dead time for

blocking arm shoot-through

Input inter-lock sensing

Analogue signal linearity with

output current

Offset change area vs temperature

Analogue signal output voltage limit

Analogue signal over all linear variation

Analogue signal data hold accuracy

Analogue signal reading time

Current limit warning (CL) operation level

Signal output current of

CL operation

Idle

Active

Short circuit over current trip level

Over temperature protection

Trip level

Reset level

Trip level

Reset level

Trip level

Supply circuit under &

over voltage protection

Reset level

Trip level

Reset level

Filter time

Fault output current

Idle

Active

DH = 15V, VCIN = 5V

V

Integrated between input terminal-VDH

TC ≤ 100°C, Tj ≤ 125°C

DH = 15V, TC = –20°C ~ +100°C (Note 3)

V

Relates to corresponding input

(Except brake part) T

Relates to corresponding input (Except brake part)

Ic = 0A

Ic = I

OP(200%)

OP(200%)

Ic = –I

VDH = 15V, TC = –20°C ~ +100°C

OP(200%), VDH = 15V

Ic > I

|V

CO-VC±(200%)|

Correspond to max. 500µs data hold period

only, Ic = I

After input signal trigger point (Fig. 8)

VDH =15V, TC = –20°C ~ +100°C (Note 4)

Open collector output

Tj = 25°C (Fig. 7) (Note 5)

VDH =15V

C = –20°C ~ +100°C

T

Tj ≤ 125°C

Open collector output

(Note 3) : (a) Allowable minimum input on-pulse width : This item applies to P-side circuit only.

(b) Allowable maximum input on-pulse width : This item applies to both P-side and N-side circuits excluding the brake circuit.

(Note4) : CL output : The "current limit warning (CL) operation circuit outputs warning signal whenever the arm current exceeds this limit. The

circuit is reset automatically by the next input signal and thus, it operates on a pulse-by-pulse scheme.

(Note5) : The short circuit protection works instantaneously when a high short circuit current flows through an internal IGBT rising up momen-

tarily. The protection function is , thus meant primarily to protect the ASIPM against short circuit distraction. Therefore, this function is

not recommended to be used for any system load current regulation or any over load control as this might, cause a failure due to

excessive temperature rise. Instead, the analogue current output feature or the over load warning feature (CL) should be appropriately used for such current regulation or over load control operation. In other words, the PWM signals to the ASIPM should be shut

down, in principle, and not to be restarted before the junction temperature would recover to normal, as soon as a fault is feed back

from its F

O1 pin of the ASIPM indicating a short circuit situation.

Ratings

Min.

0.8

2.5

2.2

1.87

0.77

2.97

4.0

–5

2.64

3.50

100

11.05

11.55

18.00

16.50

10.0

10.5

Typ. Max.

—mA

150—

1.4

3.0

—

150

2

1

—

—

500

—

—

—

—

65

2.27

1.17

3.37

15

—

100

2.57

1.47

3.67

—

—

1.1

—

—

—

—

—

—

—

—

3

3.10

—

1

6.00

110

90

12.00

12.50

19.20

17.50

11.0

11.5

10

—

1

3.60

9.60

120

12.75

13.25

20.15

18.65

12.0

12.5

2.0

4.0

—

20

—

—

0.7

—

—

—

—

—

—

—

Unit

V

V

kΩ

kHz

µs

µs

ns

V

V

V

mV

V

V

V

5

%

µs

A

1

µA

mA

A

°C

°C

V

V

V

V

V

V

µs

µA

1

mA

RECOMMENDED CONDITIONS

Symbol

VCC

DH, VDB Control supply voltage

V

∆VDH, ∆V

VCIN(on)

VCIN(off)

fPWM

tdead

Supply voltage

DB

Supply voltage ripple

Input on voltage

Input off voltage

PWM Input frequency

Arm shoot-through blocking time

Item Ratings

Applied between V

C

BW+-CBW–

DH-GND, CBU+-CBU–, CBV+-CBV–,

Using application circuit

Using application circuit

Condition

15±1.5

±1 (max.)

0 ~ 0.3

4.8 ~ 5.0

2 ~ 20

2.2 (min.)

Unit

V 400 (max.)Applied across P2-N terminals

V

V/µs

V

V

kHz

µs

Jan. 2000

Page 6

MITSUBISHI SEMICONDUCTOR <Application Specific Intelligent Power Module>

PS11011

FLAT-B ASE TYPE

INSULA TED TYPE

Fig. 4 OUTPUT CURRENT ANALOGUE SIGNALING

LINEARITY

5

C

–

V

max

4

min

V

C

–

(200%)

VDH=15V

T

C

=–20~100˚C

3

C0

V

2

VC(V)

1

Analogue output signal

data hold range

0

Real load current peak value.(%)(Ic=Io✕ 2)

VC+(200%)

200–200

VC+

4003001000–100–300–400

(Fig. 4)

Fig. 6 INPUT INTERLOCK OPERATION TIMING CHART

Input signal V

Input signal V

Gate signal V

(ASIPM internal)

Gate signal V

(ASIPM internal)

CIN(p) of each phase upper arm

CIN(n) of each phase lower arm

o(p) of each phase upper arm

o(n) of each phase upper arm

0V

0V

0V

0V

Fig. 5 OUTPUT CURRENT ANALOGUE SIGNALING

“DATA HOLD” DEFINITION

V

C

500µs

0V

Note ; Ringing happens around the point where the signal output

voltage changes state from “analogue” to “data hold” due

to test circuit arrangement and instrumentational trouble.

Therefore, the rate of change is measured at a 5 µs delayed point.

VCH(5µs) VCH(505µs)

V

CH

rCH=

(505µs)-VCH(5µs)

CH

(5µs)

V

Error output F

O1

0V

Note : Input interlock protection circuit ; It is operated when the input signals for any upper-arm / lower-arm pair of a phase are simulta-

neously in “LOW” level.

By this interlocking, both upper and lower IGBTs of this mal-triggered phase are cut off, and “F

O

interlock” operation the circuit is latched. The “F

” is reset by the high-to-low going edge of either an upper-leg, or a lower-leg input,

O” signal is outputted. After an “input

whichever comes in later.

Fig. 7 TIMING CHART AND SHORT CIRCUIT PROTECTION OPERATION

CIN

Input signal V

upper arm

Short circuit sensing signal V

Gate signal Vo of each phase

upper arm(ASIPM internal)

Note : Short circuit protection operation. The protection operates with “FO” flag and reset on a pulse-by-pulse scheme. The protection by

gate shutdown is given only to the IGBT that senses an overload (excluding the IGBT for the “Brake”).

of each phase

Error output F

0V

S

0V

0V

O1

0V

SC delay time

Jan. 2000

Page 7

MITSUBISHI SEMICONDUCTOR <Application Specific Intelligent Power Module>

Fig. 8 INVERTER OUTPUT ANALOGUE CURRENT SENSING AND SIGNALING TIMING CHART

N-side IGBT Current N-side FWDi Current

CIN

I

off

on

on

off

C

0

+I

CL

0

V

V(hold)

(VS)

PS11011

FLAT-B ASE TYPE

INSULA TED TYPE

–I

CL

Ref

V

C

0

off

V

CL

on

t(hold)

Delay time

td(read)

Fig. 9 START-UP SEQUENCE

Normally at start-up, Fo and CL output signals will be pulled-up

High to Supply voltage (OFF level); however, F

Low (ON) level at the instant of the first ON input pulse to an N-Side

IGBT. This can happen particularly when the boot-strap capacitor is

of large size. F

O1 resetting sequence (together with the boot-strap

charging sequence) is explained in the following graph

DC-Bus voltage

Control voltage supply

Boot-strap voltage

N-Side input signal

P-Side input signal

V

CIN(N)

V

V

V

DH

V

CIN(P)

PN

0

0

DB

0

on

on

O1 output may fall to

PWM starts

a)

b)

Fig. 10 RECOMMENDED I/O INTERFACE CIRCUIT

5V

ASIPM

5.1kΩ

R

CPU

10kΩ

R

UP,VP,WP,UN,VN,WN,Br

F01,F02,F03,CL

CU,CV,CW

0.1nF0.1nF

GND(Logic)

V

Brake input signal

F

O

1 output signal

CIN(Br)

F

on

OI

on

a) Boot-strap charging scheme :

Apply a train of short ON pulses at all N-IGBT input pins for adequate charging (pulse width = approx. 20µs number of pulses =10

~ 500 depending on the boot-strap capacitor size)

b) F

O1 resetting sequence:

Apply ON signals to the following input pins : Br → Un/Vn/Wn →

Up/Vp/Wp in that order.

Jan. 2000

Page 8

This datasheet has been download from:

www.datasheetcatalog.com

Datasheets for electronics components.

Loading...

Loading...