Page 1

VISHAY HIGH POWER PRODUCTS

Modules

Mounting Instructions for MTP Modules

By Marcello Turnaturi, Vishay Semiconductors

This application note introduces Vishay´s MTP

rectifier-switch modules and discusses the assembly and

printed circuit board issues involved in their use.

MTP modules are designed to provide reliable performance

in rugged 20 A to 100 A industri al applications. A single

housing is used to integrate power components, providing

higher power density. Various die selections are available in

several configurations. An integrated thermal sensor is also

offered as an option.

Application Note AN-0801

Important factors in the assembly process are:

• Heatsink design

• PCB design

• Power leads size/area

• Distance from adjacent heating parts

• Solder paste choice

• Reflow profile

• Protection against electrostatic discharge (ESD)

Recommendations for each of these items and requirements

for mounting MTP modules to the PCB are discussed in the

following sections.

Fig. 1 - Example of MTP module

Introduction

Vishay´s MTP modules are distinguished by these key

features:

• Fully isolated

• Compact and easy to mount

• Low profile package suitable for assembly on printed

circuit boards

• Low junction to case thermal resistance

These attributes allow MTP modules to fit into existing

assembly processes using standard reflow profiles.

ESD protection

IGBT and MOSFET modules are sensitive to ESD. All

MTP modules are ESD-protected during shipment with an

antistatic tube. Anyone handling or working with the

modules during the assembly process must wear a

conductive grounded wristband.

Heatsink Specification

The contact surface of the heatsink must be flat, with a

recommended tolerance of < 0.03 mm (< 1.18 mils) and a

levelling depth of < 0.02 mm (< 0.79 mils), according to

DIN/ISO 1302. In general, a milled or machined surface is

satisfactory if prepared with tools in good working

condition. The heatsink mounting surface must be clean,

with no dirt, corrosion, or surface oxide. It is very important

to keep the mounting surface free from particles exceeding

0.05 mm (2 mils) in thickness

APPLICATION NOTE

Document Number: 95002 For technical support, contact ind-modules@vishay.com www.vishay.com

Revision: 02-Jul-08 1

Page 2

Application Note AN-0801

Vishay High Power Products

Mounting Instructions for MTP Modules

Mounting Operation Steps

Inspect the module to insure that the contact surface of the

base is clean, and that there are no lumps or bulges on the

baseplate that could damage the base or reduce heat transfer

across the surfaces.

Make a uniform coat on the heatsink mounting surfaces and

module baseplate with a good quality thermal compo und.

Screen printing of the compound, or direct application with

a roller or spatula, is recommended. The test conditions for

thermal resistance values on the datasheet specify a uniform

layer of thermal compound with a thickness of 0.08 mm.

The thermal conductivity of the compound should not be

less than 1.5 W/mK. Apply uniform pressure on the package

to force the compound to spread over the entire contact area

and check the device bottom surface to verify that coverage

is full and uniform.

Bolt the module to the heatsink using th e two fixing holes.

An even amount of torque should be applied for each

individual mounting screw. An M4 screw should be used

with lock washers. A torque wrench, accurate in the

specified range, must be used to achieve optimum results

when mounting the module. The first mounting screw

should be tightened to one third of the recommended torque,

the second screw should then be tightened to the same

torque. Full tightening of both the screws can then be

completed applying the recommended torque (see data in

bulletins). Over-tightening the mounting screw may result in

deformation of the package, which would hence increase the

thermal resistance and damage the semiconductors. After a

period of three hours, check the torque with a final

tightening in opposite sequence to allow the spread of the

compound.

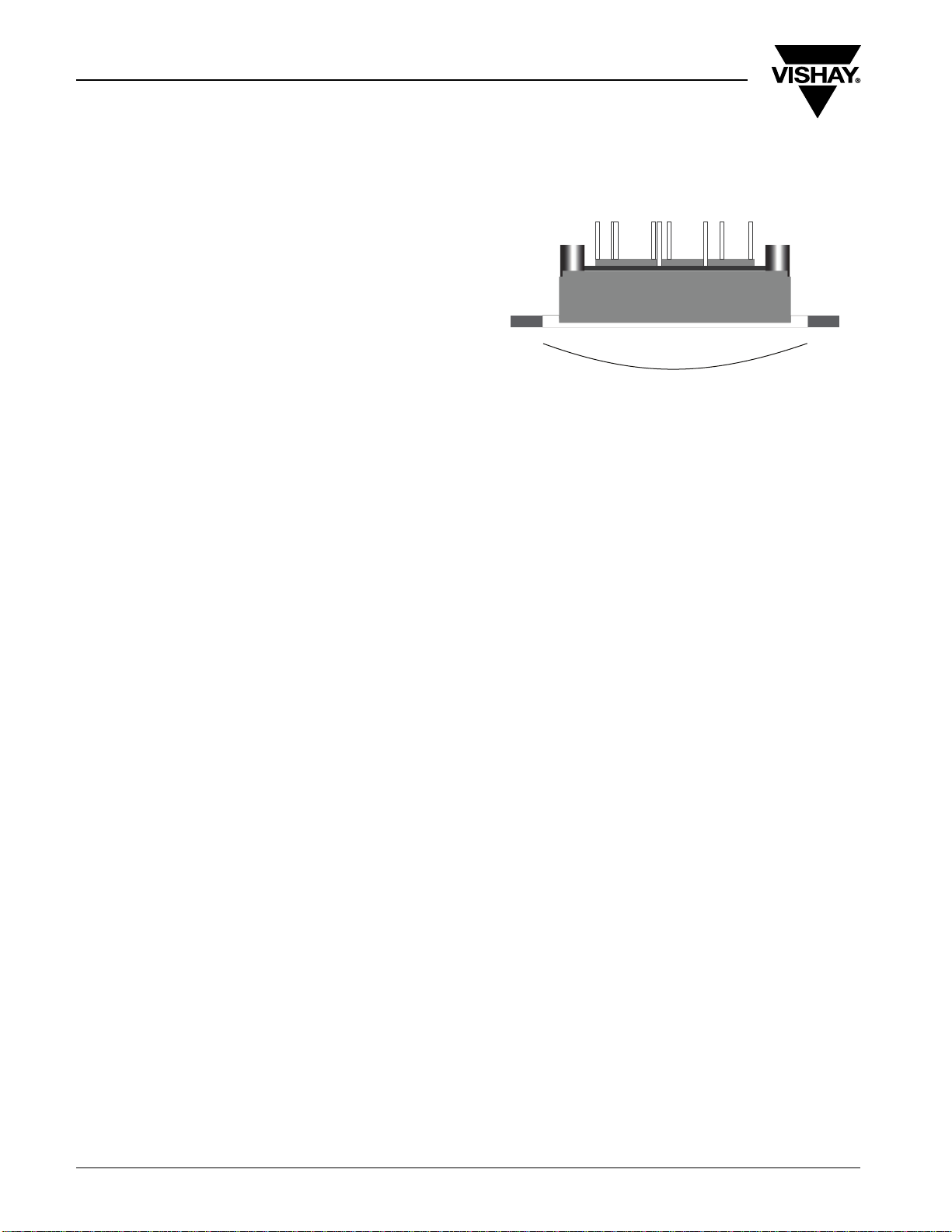

The convexity of the module baseplate ranges from 0.02 to

0.10 mm (0.787 to 3.937 mils) when measured between the

two fixing holes. This provides for an optimal contact area

with the heatsink (Figure 2).

Fig. 2 - Description of “module convexity”

Solder to PCB

The PCB must be designed with appropriate tolerances on

its hole diameters.

Soldering operations must be done so as to avoid in ducing

any mechanical stress from pulling or tensioning the module

pins. The module stand-off can be used to help align the

PCB and keep proper distance.

MTP modules can be soldered to the PCB using hand iron or

wave soldering processes. To prevent overheating of the

device, we suggest that soldering time not exceed 8 to 10

seconds at a temperature of 260 °C.

The mounting of the module on the heatsink can be done

either before or after soldering the module pins onto the

PCB.

APPLICATION NOTE

www.vishay.com For technical support, contact ind-modules@vishay.com Document Number: 95002

2 Revision 02-Jul-08

Loading...

Loading...