Page 1

6121 Baker Road,

Suite 108

Minnetonka, MN 55345

www.chtechnology.com

Phone (952) 933-6190

Fax (952) 933-6223

1-800-274-4284

Thank you for downloading this document from C&H Technology, Inc.

Please contact the C&H Technology team for the following questions -

Technical ● Application ● Assembly ● Availability ● Pricing

Phone – 1-800-274-4284

E-Mail – sales@chtechnology.com

www.chtechnology.com - SPECIALISTS IN POWER ELECTRONIC COMPONENTS AND ASSEMBLIES

-

www.chtechnology.com

Page 2

www.vishay.com

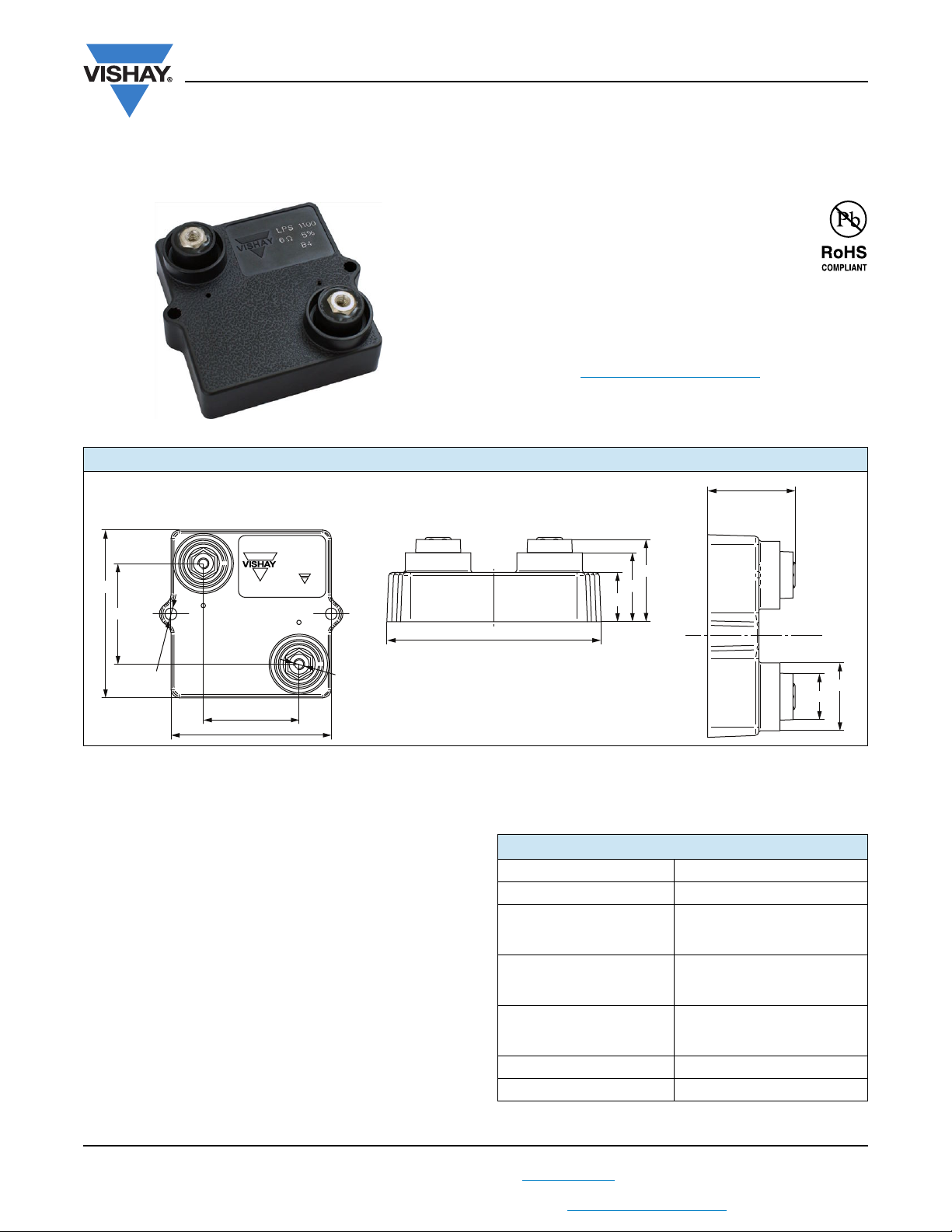

2 x M4 useful depth: 8

57

34

60

36

2 x Ø 4.2

LPS 1100

I5U 5 %

V2

64.7

15.2

21.2

25.2

13.6

Ø 20

25.8 ± 1

Power Resistor for Mounting onto a Heatsink

DIMENSIONS in millimeters

Thick Film Technology

FEATURES

• LPS high power: 1100 W

• Wide resistance range: 1 to 1.3 k

E24 series

•Non inductive

• Easy mounting

• Low thermal radiation of the case

• Material categorization: For definitions of compliance

please see www.vishay.com/doc?99912

LPS 1100

Vishay Sfernice

Notes

• Tolerances unless stated: ± 0.2 mm

• Power dissipation is 1100 W by using a water cooled heatsink at T

onto heatsink) and R

contact estimated at 0.07 °C/W.

th

MECHANICAL SPECIFICATIONS

Mechanical Protection Insulated case and resin for

potting UL 94 V-0

Resistive Element Thick film

End Connections Screws M4

Tightening Torque Connections 2 Nm

Tightening Torque Heatsink 2 Nm

Maximum Torque 2.5 Nm

Weight 79 g ± 10 %

ENVIRONMENTAL SPECIFICATIONS

Temperature Range - 55 °C to + 200 °C

Climatic Category 55/200/56

Revision: 14-Jun-12

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

For technical questions, contact: sfer@vishay.com

= 15 °C of Rth = 0.059 °C/W (25 °C to the nearest point of the resistor

water

ELECTRICAL SPECIFICATIONS

Resistance Range 1 to 1.3 k

Tolerances ± 1 % to ± 10 %

Power Rating and

Thermal Resistance

Temperature Coefficient

(- 55 °C to + 200 °C),

IEC 60115-1

Dielectric Strength

IEC 60115-1,

1 min, 10 mA max.

Insulation 104 M

Inductance 0.1 μH

1

1100 W at + 25 °C

On heatsink

R

: 0.039 °C/W

th(j-c)

± 150 ppm/°C

7 kV

RMS

Document Number: 50059

or 12 kV

RMS

Page 3

P

T

R

th (j - c)

R

th (c - h)

R

th (h - a)

++

---------------------------------------------------------------------------------------------

=

T 200 °C - 18 °C 182 °C=

R

th (j - c)RTH (c - h)RTH (h - a)

+

T

P

-------

182

850

----------

0.214 °C/W== =+

R

th (j - c)

0.039 °C/W=

R

th (c - h)Rth (h - a)

0.214 °C/W - 0.039 °C/W 0.175 °C/W==+

LPS 1100

www.vishay.com

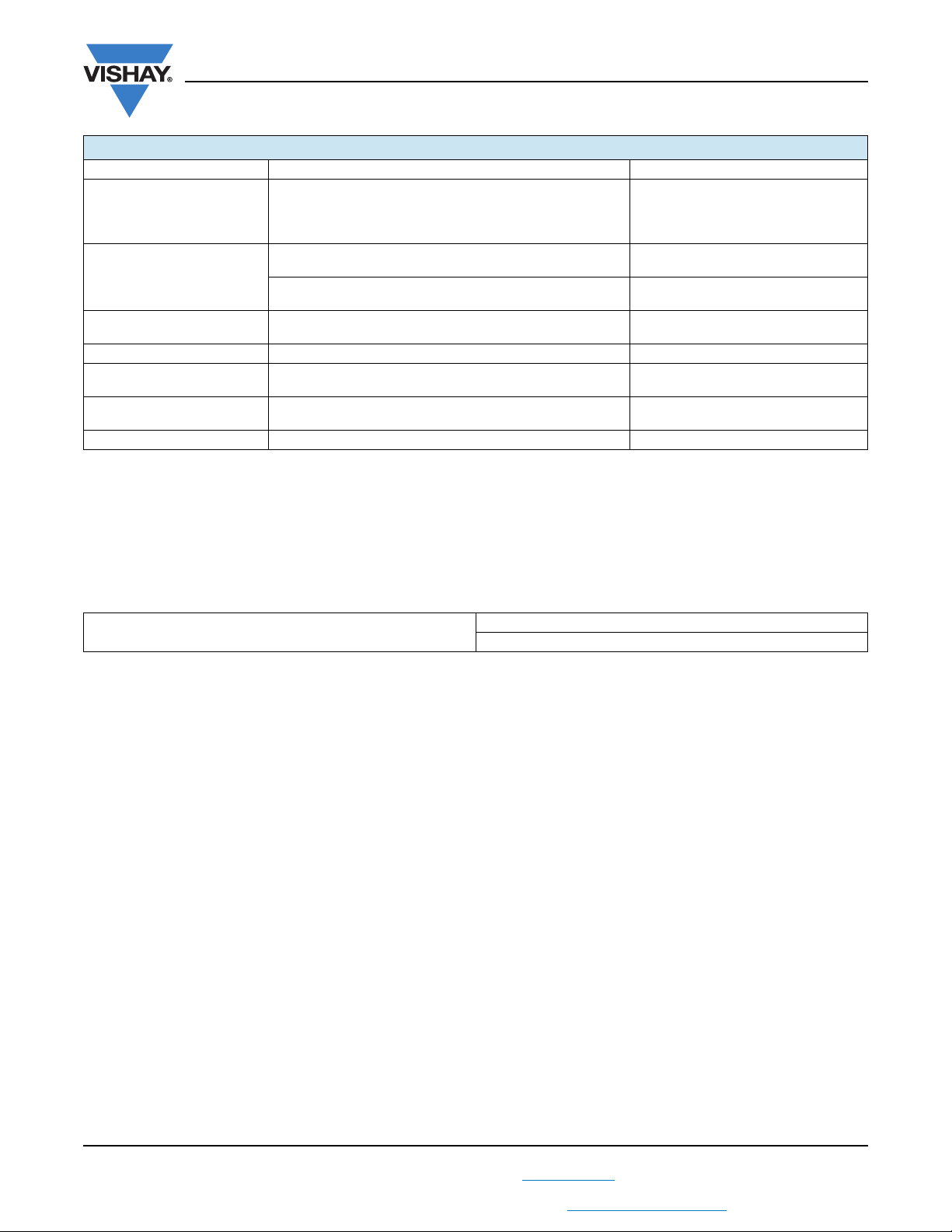

PERFORMANCE

TESTS CONDITIONS REQUIREMENTS

IEC 60115-1: 2 x Pr/10 s for heatsink with

0.26 °C/W (maximum power: 700 W)

R

Momentary Overload

Rapid Temperature Change

Load Life

Humidity (Steady State) AEC-Q200 conditions: IEC 60115-1, 1000 h RH 85 %/85 °C ± (0.5 % + 0.05 )

Mechanical Shock

Vibration

Climatic Sequence AEC-Q200 conditions: IEC 60115-1 (55/200/56) ± (1 % + 0.05 )

1.6 x Pr/1 s for heatsink with 0.26 °C/W >R

AEC-Q200 conditions: IEC 60115-1/IEC 60068-2-14, Test Na

AEC-Q200 conditions: MIL-STD-202 method 213 condition D

AEC-Q200 conditions: MIL-STD-202 method 204 condition D

th(h-a)

(maximum power: 1800 W)

50 cycles (- 55 °C to + 200 °C) ± (0.5 % + 0.05 ) for all the ohmic values

1000 cycles (- 55 °C to + 200 °C)

AEC-Q200 conditions: IEC 60115-1

1000 h (90/30) Pr

(100 g’s/6 ms 3.75 m/s)

(5 g, 20 min 10/2000 Hz)

0.059 °C/W

th(h-a)

± (5 % + 0.05 ) for R < 38 U

± (0.5 % + 0.05 ) for R 38 U

± (5 % + 0.05 ) for R < 38 U

± (0.5 % + 0.05 ) for R 38 U

RECOMMENDATIONS FOR MOUNTING ONTO A HEATSINK

• Surfaces in contact must be carefully cleaned.

• The heatsink must have an acceptable flatness: From 0.05 mm to 0.1 mm/100 mm.

• Roughness of the heatsink must be around 6.3 μm. In order to improve thermal conductivity, surfaces in contact (ceramic,

heatsink) should be coated with a silicone grease (type SI 340 from Blue Star Silicones). Thermal film (type Q-pad II from

Berquist) is also possible, easier and faster to install than grease but with a lower efficiency for the power dissipation.

• The fastening of the resistor to the heatsink is under pressure control of two screws tightened at 2 Nm for full power

availability.

Tightening Torque on Heatsink

• The following accessories are supplied with each product:

- 2 screws CHC M4 x 25 class 8.8 and 2 M4 contact lock washers for heatsink mounting

- 2 screws TH M4 x 6/6 and 2 M4 contact lock washers for connections. 2 off CHC M4 x 16/16 class 8

LPS 1100

2 Nm

Vishay Sfernice

± (0.25 % + 0.05 )

± (1 % + 0.05 )

± (1 % + 0.05 )

CHOICE OF THE HEATSINK AND THE THERMAL INTERFACE

The user must choose the heatsink according to the working conditions of the component (power, room temperature).

Maximum working temperature must not exceed 200 °C. The dissipated power is simply calculated by the following ratio:

P: Expressed in W

T: Difference between maximum working temperature and room temperature or fluid cooling temperature.

R

: Thermal resistance value measured between resistive layer and outer side of the resistor. It is the thermal

th (j - c)

R

th (c - h)

R

th (h - a)

Example:

th (c - h)

+ R

R

Revision: 14-Jun-12

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

resistance of the component: 0.039 °C/W.

: Thermal resistance value measured between outer side of the resistor and upper side of the heatsink. This is the

thermal resistance of the interface (grease, thermal pad), and the quality of the fastening device.

: Thermal resistance of the heatsink.

for LPS 1100 power dissipation 850 W at + 18 °C fluid temperature.

th (h - a)

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

For technical questions, contact: sfer@vishay.com

2

Document Number: 50059

Page 4

www.vishay.com

ENERGY IN J

0.01

0.1

1

10

100

10 000

OVERLOAD DURATION IN s

1

10

-7

10-610

-5

10

-4

10

-3

10-210

-1

1000

LPS 1100

Vishay Sfernice

CONFIG. 1:

WATER COOLING

HEATSINK CP15 AND

THERMAL GREASE SI340

CONFIG. 2:

AIR COOLING

HEATSINK P207/250 AND

THERMAL GREASE SI340

CONFIG. 3:

WATER COOLING

HEATSINK CP15 AND

THERMAL PAD Q-PAD II

CONFIG. 4:

AIR COOLING

HEATSINK P207/250 AND

THERMAL PAD Q-PAD II

Power Dissipation (W) 1100 350 650 285

T° Resistive Element (°C) 200 200 200 200

R

max. (°C/W) 0.039 0.039 0.039 0.039

th(j-c)

R

typ. (°C/W) 0.070 0.201 0.187 0.315

th(c-h)

R

max. (°C/W) 0.059 0.260 0.059 0.260

th(h-a)

Fluid T° (°C) 15 (water) 25 (air) 15 (water) 25 (air)

Note

• Configuration 1: Water cooling heatsink (CP15 from Lytron (304 mm x 95.3 mm x 8 mm) with water flow rate 4LPM and thermal grease Si340

from BlueStar Silicones

Configuration 2: Air cooling heatsink P207/250 from Semikron (250 mm x 200 mm x 72 mm) and thermal grease Si340 from BlueStar

Silicones

Configuration 3: Water cooling heatsink (CP15 from Lytron (304 mm x 95.3 mm x 8 mm) with water flow rate 4LPM and thermal pad

Q-pad II from Berquist

Configuration 4: Air cooling heatsink P207/250 from Semikron (250 mm x 200 mm x 72 mm) and thermal pad Q-pad II from Berquist

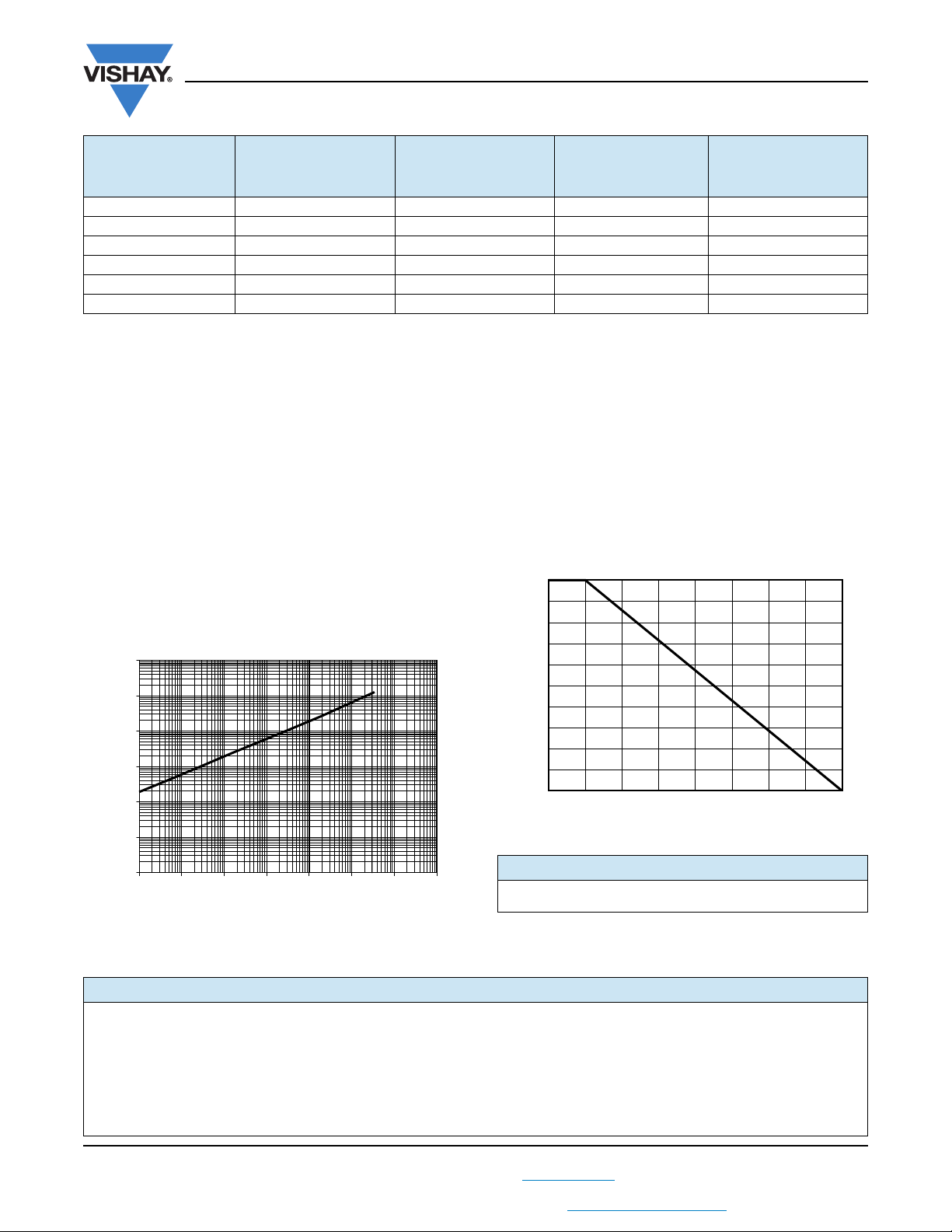

OVERLOAD

In any case the applied voltage must be lower than

= 6600 V.

U

I

Short time overload: 2 x Pr/10 s for heatsink with

R

0.26 °C/W (maximum power: 700 W) and 1.6 x

th(h-a)

Pr/1 s for heatsink with 0.26 °C/W > R

(maximum power: 1800 W).

Accidental overload: The values indicated on the following

0.059 °C/W

th(h-a)

POWER RATING

The temperature of the case should be maintained within

the limit specified in the following figure. To optimize

the thermal conduction, contacting surfaces should be

coated with silicone grease or thermal film, and heatsink

mounting screws tightened to 2 Nm.

100

graph are applicable to resistors in air or mounted onto a

heatsink.

80

ENERGY CURVE

60

40

RATED POWER IN %

20

0

HEATSINK TEMPERATURE IN °C

PACKAGING

Box of 15 units

MARKING

Series, style, ohmic value (in ), tolerance (in %),

manufacturing date, Vishay Sfernice trademark.

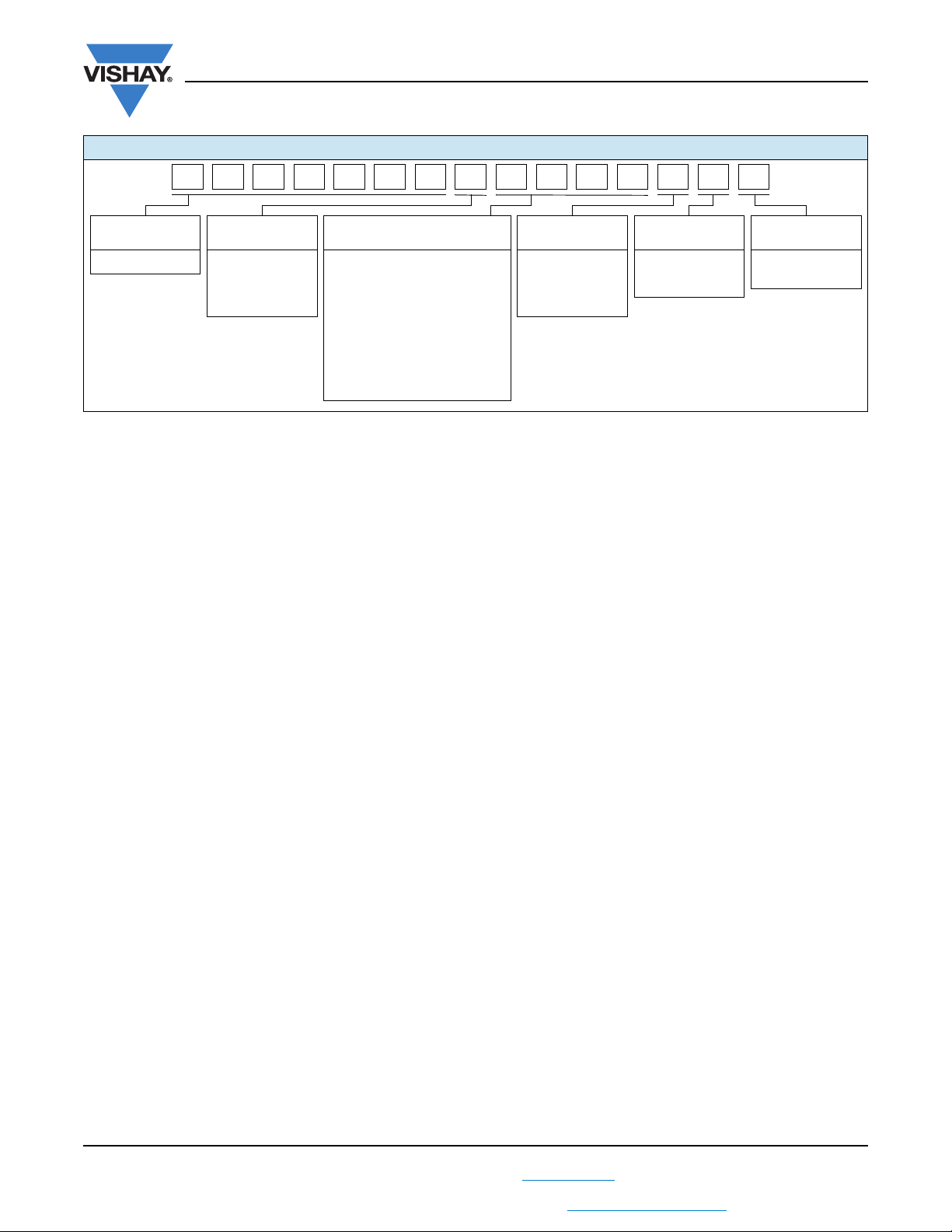

ORDERING INFORMATION

LPS 1100 1 k ± 1 % xxx BO15 e

MODEL STYLE

RESISTANCE

VALUE

TOLERANCE

± 1 %

± 2 %

± 5 %

± 10 %

Revision: 14-Jun-12

3

For technical questions, contact: sfer@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

CUSTOM

DESIGN

Optional on

request:

special TCR,

shape, etc.

PACKAGING LEAD (Pb)-FREE

Document Number: 50059

2000175150125100755025

Page 5

www.vishay.com

GLOBAL PART NUMBER INFORMATION

LPS 1100

Vishay Sfernice

J BS11 00H4 RL P 70

GLOBAL

MODEL

LPS 1100

DIELECTRIC OHMIC VALUE TOLERANCE PACKAGING SPECIAL

L = Dielectric

strengh 7 kV

H = Dielectric

strengh 12 kV

The first three digits are

significant figures and the

last digit specifies the

number of zeros to follow.

R designates decimal point.

48R7 = 48.7

47R0 = 47

1001 = 1 k

4R70 = 4.7

R240 = 0.24

F = 1 %

G = 2 %

J = 5 %

K = 10 %

B = Box 15 pieces

N = Box 15 pieces

n/a

As applicable

ZAx

Revision: 14-Jun-12

For technical questions, contact: sfer@vishay.com

THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. THE PRODUCTS DESCRIBED HEREIN AND THIS DOCUMENT

ARE SUBJECT TO SPECIFIC DISCLAIMERS, SET FORTH AT www.vishay.com/doc?91000

4

Document Number: 50059

Page 6

Legal Disclaimer Notice

www.vishay.com

Vishay

Disclaimer

ALL PRODUCT, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE TO IMPROVE

RELIABILITY, FUNCTION OR DESIGN OR OTHERWISE.

Vishay Intertechnology, Inc., its affiliates, agents, and employees, and all persons acting on its or their behalf (collectively,

“Vishay”), disclaim any and all liability for any errors, inaccuracies or incompleteness contained in any datasheet or in any other

disclosure relating to any product.

Vishay makes no warranty, representation or guarantee regarding the suitability of the products for any particular purpose or

the continuing production of any product. To the maximum extent permitted by applicable law, Vishay disclaims (i) any and all

liability arising out of the application or use of any product, (ii) any and all liability, including without limitation special,

consequential or incidental damages, and (iii) any and all implied warranties, including warranties of fitness for particular

purpose, non-infringement and merchantability.

Statements regarding the suitability of products for certain types of applications are based on Vishay’s knowledge of typical

requirements that are often placed on Vishay products in generic applications. Such statements are not binding statements

about the suitability of products for a particular application. It is the customer’s responsibility to validate that a particular

product with the properties described in the product specification is suitable for use in a particular application. Parameters

provided in datasheets and/or specifications may vary in different applications and performance may vary over time. All

operating parameters, including typical parameters, must be validated for each customer application by the customer’s

technical experts. Product specifications do not expand or otherwise modify Vishay’s terms and conditions of purchase,

including but not limited to the warranty expressed therein.

Except as expressly indicated in writing, Vishay products are not designed for use in medical, life-saving, or life-sustaining

applications or for any other application in which the failure of the Vishay product could result in personal injury or death.

Customers using or selling Vishay products not expressly indicated for use in such applications do so at their own risk and agree

to fully indemnify and hold Vishay and its distributors harmless from and against any and all claims, liabilities, expenses and

damages arising or resulting in connection with such use or sale, including attorneys fees, even if such claim alleges that Vishay

or its distributor was negligent regarding the design or manufacture of the part. Please contact authorized Vishay personnel to

obtain written terms and conditions regarding products designed for such applications.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by this document or by

any conduct of Vishay. Product names and markings noted herein may be trademarks of their respective owners.

Material Category Policy

Vishay Intertechnology, Inc. hereby certifies that all its products that are identified as RoHS-Compliant fulfill the

definitions and restrictions defined under Directive 2011/65/EU of The European Parliament and of the Council

of June 8, 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment

(EEE) - recast, unless otherwise specified as non-compliant.

Please note that some Vishay documentation may still make reference to RoHS Directive 2002/95/EC. We confirm that

all the products identified as being compliant to Directive 2002/95/EC conform to Directive 2011/65/EU.

Revision: 12-Mar-12

1

Document Number: 91000

Loading...

Loading...