Page 1

6121 Baker Road,

Suite 108

Minnetonka, MN 55345

www.chtechnology.com

Phone (952) 933-6190

Fax (952) 933-6223

1-800-274-4284

Thank you for downloading this document from C&H Technology, Inc.

Please contact the C&H Technology team for the following questions -

Technical

Application

Assembly

Availability

Pricing

Phone – 1-800-274-4284

E-Mail – sales@chtechnology.com

www.chtechnology.com - SPECIALISTS IN POWER ELECTRONIC COMPONENTS AND ASSEMBLIES - www.chtechnology.com

Page 2

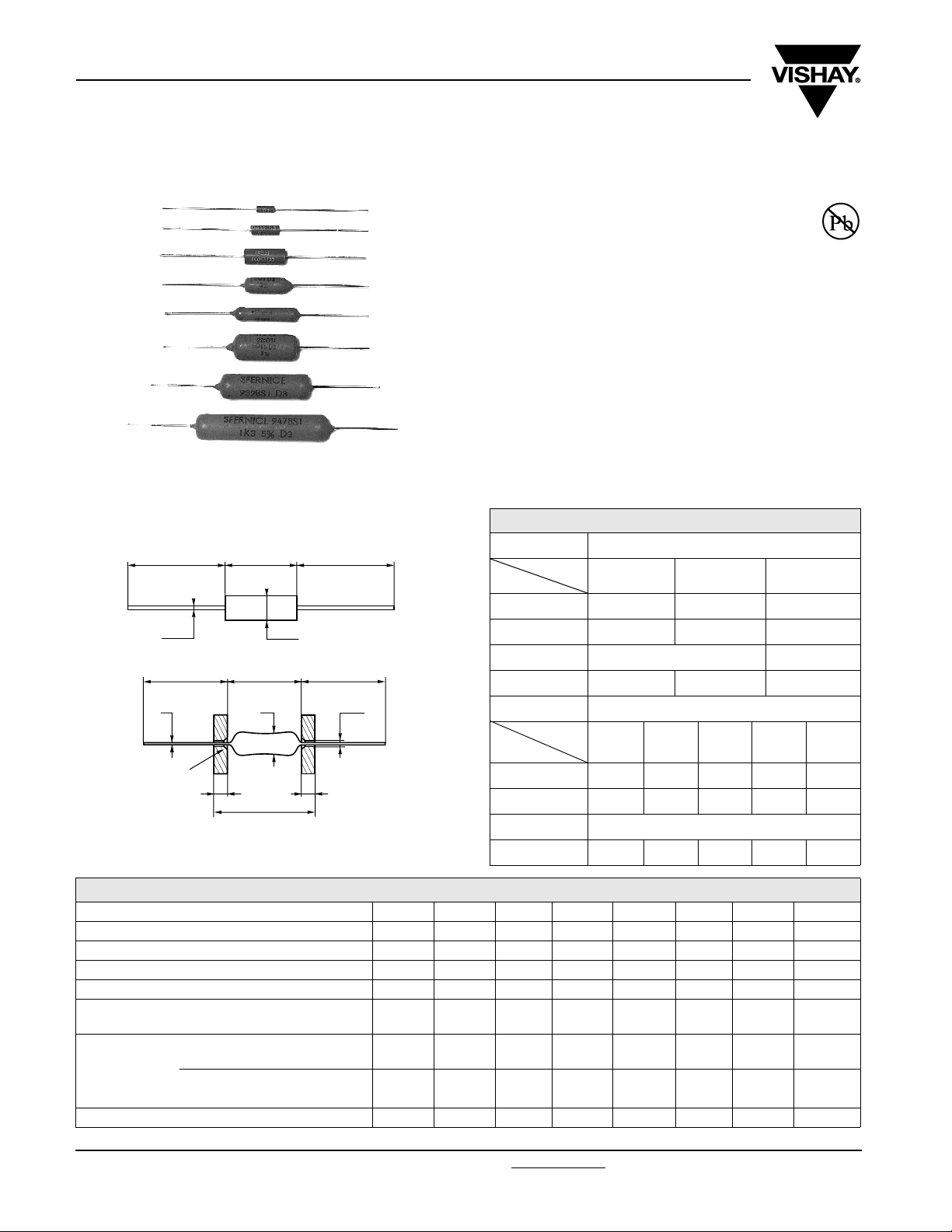

BSI

Vishay Sfernice

Molded and Insulated Wirewound Power

Resistors Axial Leads

FEATURES

• 1 W to 10 W

• NF C 83-210

• GAM T1 LNZ

• Excellent stability = typical drift ± 1 % after 2000 h

• High power = up to 10 W (25 °C)

• Low ohmic values = 0.01 Ω available

• Electrical insulation

• Climatic protection

BSI style resistors comply with the most stringent requirements of the NF C 83-210. 8 styles covering the power range from

1 W to 10 W

DIMENMSIONS in millimeters

MOLDED

25 min.

Ø C

25 min.

Ø E

45° chamfer

max. 0.25 deep

INSULATE D

4

L max.

A

Ø B

A

Ø B

25 min.

25 min.

± 0.02

Ø 1.2

4

DIMENSIONS in millimeters

PROTECTION MOLDED

Style

Dim.

A 6.5 ± 0.2 10 ± 0.2 15 ± 0.5

Ø B 2.4 ± 0.1 3.7 ± 0.1 5.6 ± 0.2

Ø C ± 0.1 0.6 0.8

Weight in g 0.3 0.45 1.3

PROTECTION INSULATED

Style

Dim.

A 16 ± 2 23 ± 2 23 ± 2 32 ± 2 47 ± 2

Ø B 5 ± 1 5 ± 1 9 ± 1 9 ± 1 9 ± 1

Ø C ± 0.1 0.8

Weight in g 1.6 2.5 6 7.5 10

58 BSI 63 BSI 68 BSI

516 BSI 523 BSI 923 BSI 932 BSI 947 BSI

RoHS

COMPLIANT

TECHNICAL SPECIFICATIONS

VISHAY SFERNICE MODEL AND STYLE 58 BSI 63 BSI 68 BSI 516 BSI 523 BSI 923 BSI 932 BSI 947 BSI

NF C 83-210 Conformity RP 8 RP 7 RP 4 - - RP 5 - RP 6

LNZ yes yes yes - - yes - yes

GAM-T-1 yes yes yes - - yes - yes

Power Rating at + 25 °C 1 W 2 W 3 W 4 W 5 W 6 W 8 W 10 W

Ohmic Range

Ohmic Range

in Relation to

Temperature

Coefficient

Limiting Element Voltage 50 V 120 V 200 V 200 V 250 V 300 V 500 V 750 V

www.vishay.com For technical questions, contact: sfer@vishay.com

47 Revision: 25-Mar-07

± 100 ppm/°C

± 300 ppm/°C

± 0.5 %

± 5 %

± 1 %

± 5 %

0.1 Ω

2 kΩ

0.1 Ω

2 kΩ

0.025 Ω

4 kΩ

0.1 Ω

4 kΩ

0.025 Ω

< 0.1 Ω

0.01 Ω

15 kΩ

0.1 Ω

15 kΩ

0.01 Ω

< 0.1 Ω

0.01 Ω

20 kΩ

0.1 Ω

20 kΩ

0.01 Ω

< 0.1 Ω

0.015 Ω

40 kΩ

0.1 Ω

40 kΩ

0.015 Ω

< 0.1 Ω

0.02 Ω

60 kΩ

0.1 Ω

60 kΩ

0.02 Ω

< 0.1 Ω

0.035 Ω

100 kΩ

0.1 Ω

100 kΩ

0.035 Ω

< 0.1 Ω

Document Number: 50011

0.06 Ω

150 kΩ

0.1 Ω

150 kΩ

0.06 Ω

< 0.1 Ω

Page 3

BSI

Molded and Insulated Wirewound Power

Resistors Axial Leads

PERFORMANCE

TESTS CONDITIONS

Dielectric W/s Voltage

Short Time Overload

1000 V

500 V

5 Pn/5 s for Pn < 5 W 10

for 923... 947

RMS

for 58... 523

RMS

Pn/5 s for Pn ≥ 5 W

MIL-R-26 E NF C 83-210

± (0.1 % + 0.05 Ω) - ± (0.1 % + 0.05 Ω)

± (0.2 % + 0.05 Ω) ± 0.25 % + 0.05 Ω ± (0.1 % + 0.05 Ω)

NF C 83-210

Climatic Sequence

fasc. 19 A - 55 °C/+ 200 °C

5 cycles

Humidity (Steady State)

NF C 83-210

fasc. 3 A 56 days 95 % R.H.

Load at 100 % P followed

Thermal Shock

by cold temp. exposure

± (0.2 % + 0.05 Ω) ± 0.25 % + 0.05 Ω ± (0.1 % + 0.05 Ω)

at - 55 °C

MIL-STD-202

Vibration

Method 204 - Test D: 20 g

± (0.1 % + 0.05 Ω) ± 0.25% + 0.05 Ω ± (0.05 % + 0.05 Ω)

10/2000 Hz

Load Life

Moisture Resistance

MIL-STD-202

Method 108PR 2000 h

MIL-STD-202

Method 106

± (0.5 % + 0.05 Ω)

± (0.2 % + 0.05 Ω)

Insulation resistance

> 100 MΩ

High Temperature 250 h at + 275 °C ± (0.5 % + 0.05 Ω)

Shock

MIL-STD-202

100 g Method 205 - Test C

± (0.1 % + 0.05 Ω) ± 0.25 % + 0.05 Ω ± (0.05 % + 0.05 Ω)

REQUIREMENTS

-

-

± 0.5 % + 0.05 Ω

Insulation R >100 MΩ

± 0.5 % + 0.05

Insulation R > 100 M

± 0.5% + 0.05 Ω

Insulation R ≥ 1 GΩ

-

± 0.5 % + 0.05 Ω

Insulation R ≥ 1 GΩ

Vishay Sfernice

TYPICAL VALUES

AND DRIFTS

± (0.3 % + 0.05 Ω) Ins.

resistance > 10

± (0.3 % + 0.05) Ins.

resistance > 10

± (1 % + 0.05 Ω)

± (1 % + 0.05 Ω) Ins.

resistance > 10

± (0.3 % + 0.05 Ω)

3

MΩ

3

MΩ

3

MΩ

POWER RATING CHART TEMPERATURE RISE

8 63 68 516 523 923 932 947

125

100

REWOP

75

DETAR

50

%

37

25

0

0 50 100 150 200 250 275 300 350

AMBIENT TEMPERATURE IN DEGREES CELSIUS

5

250

C° NI

200

E

RUT

A

REP

150

M

E

T

TOPS

100

T

OH

50

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

RATED POWER IN WATTS

MARKING

GEKA trademark, model, style, nominal resistance (in Ω), tolerance (in %), manufacturing date.

Because of lack of space, small styles are marked with ohmic value (in Ω), and tolerance (in %) only.

ORDERING INFORMATION

BSI 63 U22 2 % ± 100 ppm/°C TR300 e1

MODEL STYLE OHMIC VALUE TOLERANCE TEMPERATURE

COEFFICIENT

PACKING LEAD (Pb)-FREE

SAP PART NUMBERING GUIDELINES

BSI 063 R2200 G R22

MODEL STYLE OHMIC VALUE TOLERANCE PACKING

Document Number: 50011 For technical questions, contact: sfer@vishay.com

Revision: 25-Mar-07 48

www.vishay.com

Loading...

Loading...