Page 1

Manual Part No: 11028854

MODEL

EM405D

USER'S MANUAL

ETHERNET

M-MODULE

CARRIER

Page 2

ii

COPYRIGHT

C&H Technologies, Inc. (C&H) provides this manual "as is" without warranty of any kind,

either expressed or implied, including but not limited to the implied warranties of

merchantability and fitness for a particular purpose. C&H may make improvements and/or

changes in the product(s) and/or program(s) described in this manual at any time and without

notice.

This publication could contain technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in new editions

of this publication.

Copyright © 2004 by C&H Technologies, Inc.

The information and/or drawings set forth in this document and all rights in and to inventions

disclosed herein which might be granted thereon disclosing or employing the materials, methods,

techniques or apparatus described herein, are the exclusive property of C&H Technologies, Inc.

A Reader's Comment Form is provided at the back of this publication. If this form has been

removed address comments to:

C&H Technologies, Inc.

Technical Publications

445 Round Rock West Drive

Round Rock, Texas 78681-5012

C&H may use or distribute any of the information you supply in any way that it believes

appropriate without incurring any obligations whatever.

Page 3

iii

DOCUMENT REVISION NOTICE

C&H Technologies, Inc. makes every attempt to provide up-to-date manuals with the associated

equipment. Occasionally, throughout the life of an instrument, changes are deemed necessary to

equipment related documentation. The latest revision of our documentation is available for

download from our web site at http://www.chtech.com

.

NOTE

The contents of any amendment may affect operation,

maintenance, or calibration of the equipment.

Page 4

iv

INTRODUCTION

This manual describes the operation and use of the C&H Model EM405D Ethernet M-Module

Carrier (Part Number 11028850). This instrument is one of a number of M-module carriers

provided by C&H.

Contained within this manual are the physical and electrical specifications, installation and

startup procedures, functional description, and c onfiguration and programming guidelines to

adequately use the product.

Software drivers for an installed M/MA module may b e provided by the M/MA module

manufacturer. Some drivers may require modification to operate correctly with the

communication protocol and the addressing methodology used by the EM405D. To support

initial operation and application software development, C&H provides a software application

called Interactive Mezzanine Control (IMC). The application provides immediate access and

control of any M/MA module residing on an EM405D. IMC can be downloaded from the

support section of C&H’s website www.chtech.com

.

Page 5

v

TABLE OF CONTENTS

1.0 GENERAL DESCRIPTION............................................................................................ 1

1.1 PURPOSE OF EQUIPMENT............................................................................................. 1

1.2 FEATURES AND SPECIFICATIONS..............................................................................1

1.2.1 Key Features ................................................................................................................ 1

1.2.2 Specifications...............................................................................................................2

1.3 ELECTRICAL .................................................................................................................... 3

1.4 MECHANICAL..................................................................................................................3

1.5 ENVIRONMENTAL.......................................................................................................... 3

1.6 BUS COMPLIANCE.......................................................................................................... 3

1.7 APPLICABLE DOCUMENTS...........................................................................................4

2.0 INSTALLATION..............................................................................................................5

2.1 UNPACKING AND INSPECTION...................................................................................5

2.2 HANDLING PRECAUTIONS........................................................................................... 5

2.3 INSTALLATION OF M-MODULES................................................................................ 5

3.0 FUNCTIONAL DESCRIPTION.....................................................................................7

3.1 GENERAL..........................................................................................................................7

3.1.1 Embedded Controller...................................................................................................7

3.1.2 Ethernet Interface......................................................................................................... 7

3.1.3 M-module Interface ..................................................................................................... 8

3.1.4 Power Conversion ........................................................................................................8

3.2 REAR PANEL....................................................................................................................8

3.3 FRONT PANEL..................................................................................................................9

4.0 OPERATING INSTRUCTIONS...................................................................................11

4.1 GENERAL........................................................................................................................11

4.2 CONFIGURING THE ETHERNET INTERFACE.......................................................... 11

4.2.1 IP Address..................................................................................................................11

4.2.2 Subnet Mask...............................................................................................................12

4.2.3 Gateway.....................................................................................................................12

4.2.4 Port Numbers.............................................................................................................12

4.2.5 Wireless Settings........................................................................................................12

4.2.6 Performing the Configuration – Wired Ethernet ....................................................... 13

4.2.6.1 Wed-based Configuration ..................................................................................14

4.2.6.2 Telnet Configuration.......................................................................................... 14

4.2.6.3 Configuring a Device with an Unknown IP address..........................................14

4.2.7 Performing the Configuration – Wireless Ethernet (Wi-Fi)...................................... 15

4.2.7.1 Wed-based Configuration ..................................................................................16

4.2.7.2 Restoring Factory Defaults ................................................................................ 16

4.3 COMMUNICATING WITH THE CARRIER AND M-MODULES..............................17

4.3.1 Error Handling ........................................................................................................... 17

4.3.2 Write Data command ................................................................................................. 19

4.3.3 Read Data command.................................................................................................. 19

4.3.4 Block Access.............................................................................................................. 20

4.3.4.1 Block Write command....................................................................................... 21

4.3.4.2 Block Read command........................................................................................22

Page 6

vi

4.3.5 EM405D Configuration/Status Registers...................................................................23

4.4 CONTROLLING THE TRIGGERS..................................................................................26

4.5 FAN AND TEMPERATURE CONTROL........................................................................27

APPENDIX A - CONNECTORS ............................................................................................ A-1

APPENDIX B – WIRED ETHERNET DEFAULT SETTINGS.......................................... B-1

APPENDIX C – WIRELESS ETHERNET (WI-FI) DEFAULT SETTINGS.................... C-1

LIST OF FIGURES

Figure 1. EM405D Ethernet M-Module Carrier.............................................................................1

Figure 2. M-module Installation.....................................................................................................5

Figure 3. M/MA Configuration Diagram .......................................................................................6

Figure 4. Functional Block Diagram..............................................................................................7

Figure 5. Rear Panel .......................................................................................................................8

Figure 6. Front Panel ......................................................................................................................9

Figure 7. EM405D Registers........................................................................................................24

Figure A-1. 9-Pin DSUB Connector.......................................................................................... A-1

LIST OF TABLES

Table I. Command Summary........................................................................................................17

Table II. Status Code (SC)............................................................................................................17

Table III. Register Summary ........................................................................................................23

Table B-1. Ethernet Interface Default Settings...........................................................................B-1

Table C-1. Wireless Ethernet Configuration Default Settings. ..................................................C-1

Page 7

1.0 GENERAL DESCRIPTION

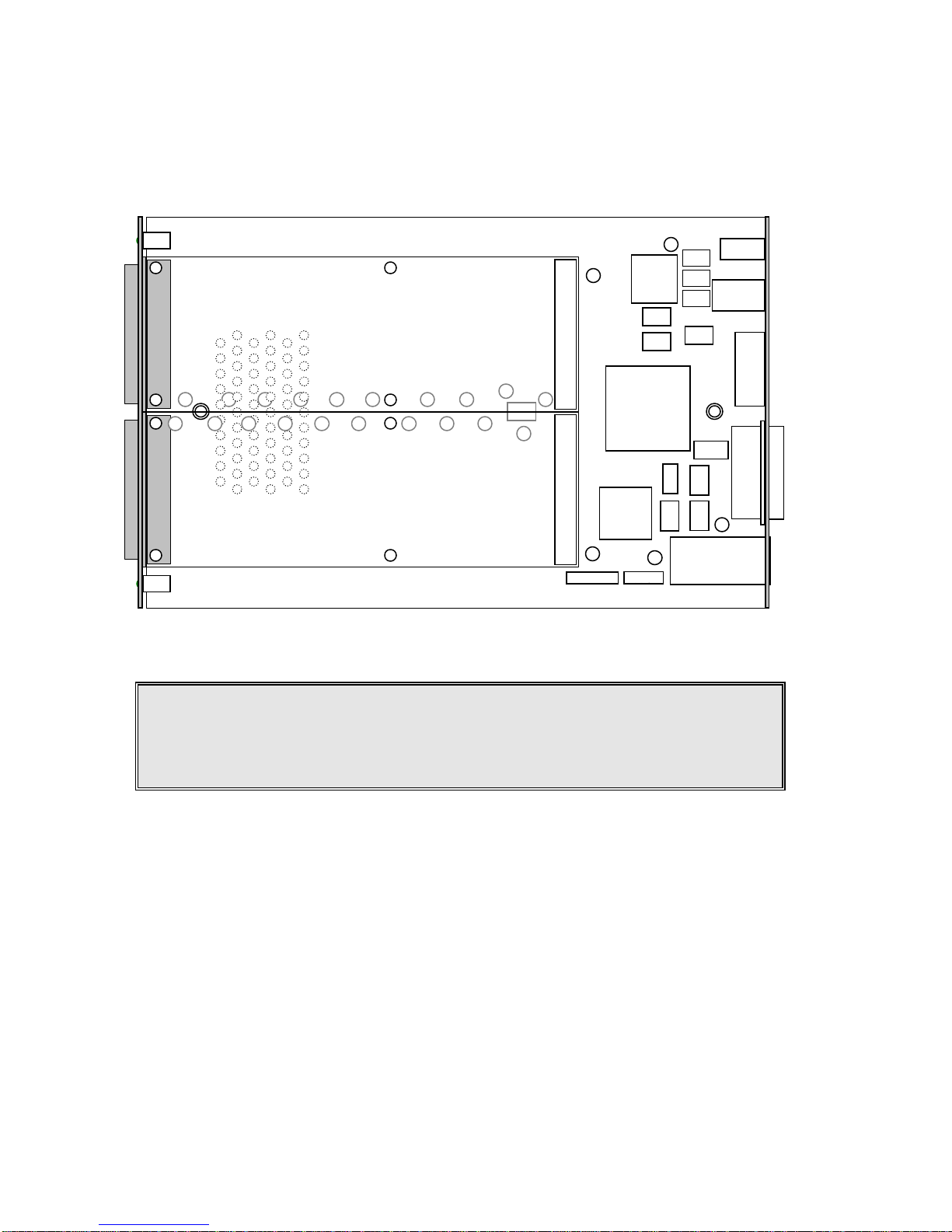

The EM405D Ethernet M-Module carrier provides complete Ethernet connectivity to up to two

industry standard single-wide or one double-wide M or MA modules. The carrier provides full

access to the M/MA module I/O space via the standard TCP/IP networking protocol. M-module

triggers are also fully supported allowing them to be connected externally to a 9-pin DSUB

connector or to an adjacent M-module. A simple command structure eases software integration

and allows reset, identification, control, and configuration of the carrier and M-modules. For a

complete list of M-modules compatible with the EM405D carrier, visit the mezzanine section of

www.mezzanines.org, or www.vita.com.

Figure 1. EM405D Ethernet M-Module Carrier

1.1 PURPOSE OF EQUIPMENT

The EM405 easily interfaces a VITA 12-199x standard M/MA Module to a typical Ethernet

network. The carrier allows the numerous functions available in the M-Module mezzanine

format to be remotely located near the unit-under-test, easing many system integration issues.

Over 100 M/MA modules are available from numerous manufacturers.

1.2 FEATURES AND SPECIFICATIONS

1.2.1 Key Features

Supports two ANSI/VITA 12-1996 compliant single-wide M or MA-modules or one

double-wide module

Ethernet 10Base-T, 100Base-TX (Auto-Sensing) or Wi-Fi 802.11b

Rugged steel/aluminum enclosure (5.6"W 8.5"D 1.5"H)

+12V power input through standard 2.5mm jack or 9-pin DSUB

Variable speed forced air cooling with software temperature status

D16 M-module accesses supported

Flexible block access command provides rapid sequential and FIFO data accesses

External trigger input/output and inter-module triggers supported

Isolated and filtered +5V, +12V, and -12V supplies for each M-module

Interactive Mezzanine Control (IMC) software available

1

Page 8

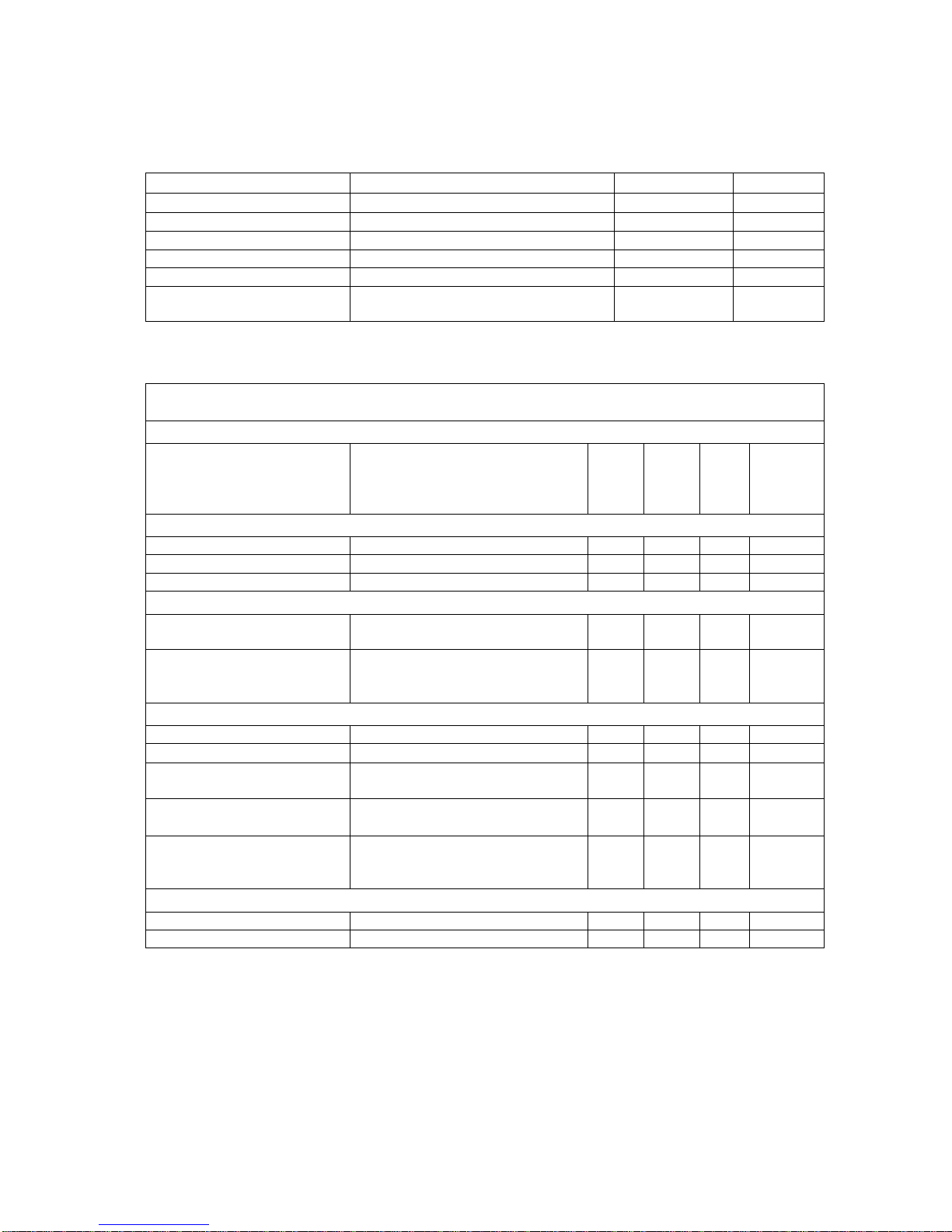

1.2.2 Specifications

MAXIMUM RATINGS

Parameter Condition Rating Units

Operating Temperature 0 to +60

Non-Operating Temperature -40 to +75

Humidity non-condensing 5 to 95 %

Input DC Power Level 12.6 V max.

Power Consumption Support for two M-modules at full power 30 Watts

External Trigger Input Power Off

CHARACTERISTICS

Limit

Parameter Conditions Min Typ. Max Units

Data Transfers

Throughput Wired Ethernet – block read

Input Power Supply

Level DC 11.4 12.0 12.6 V

Current for full M-module support 2.5 A

Ripple/noise 20MHz bandwidth -1.5 +1.5 %

Power Consumption

Ca rrier -0001 wired Ethernet

M-modules (each position) +5V

Triggers

Output Level into a high impedance load 3.8 5.0 5.4 V

Output Impedance 50

Input Level TLVL = 0 4

Input Impedance TIMP = 0 4

External Trigger Delay External connector to M-module

Cooling

Temperature Rise 20 °C

Temperature Accuracy -2 +2 °C

Notes:

1. 12-24ms latency occurs on each command issued. The effect of this latency is reduced by transferring

large amounts of data with a single block read command. Maximum read throughput is achieved by

reading >64K bytes of data from a FIFO type register on an M-module using the Block Read

command. Host software may vary and can limit the maximum throughput.

2. The maximum number of bytes that can be written in a single block write command is 1024.

3. Ethernet is a non-deterministic communications interface. Realized throughput may be significantly

degraded by network activity or other factors that may affect network performance.

4. TLVL and TIMP refer to register bits in the Reset & Trigger Control register. Refer to section 4.3.5.

Power On

1, 3

Wired Ethernet – block write

Wireless Ethernet – block read

Wireless Ethernet – block write

-0002 wireless Ethernet

+12V

-12V

TLVL = 1

TIMP = 1

M-module to external connector

M-module to M-module

2, 3

C

C

± 40

± 36

1, 3

2, 3

90K

460

500

100K

470

510

1.0

2.5

1.4

50

30

30

30

40K

23K

14K

550

590

200

200

V

40

40

40

V

V

bytes/sec

bytes/sec

bytes/sec

bytes/sec

mA

mA

A

mA

mA

V

ns

ns

ns

2

Page 9

1.3 Electrical

The EM405D only requires a +12V DC power input. The +12V input is internally converted to

the +3.3V power required by the carrier and the +5V, +12V, and -12V power required by the Mmodules. A maximum of 30 watts is required to support the carrier and two M-modules

operating at the maximum allowed power consumption. The maximum allowed power

consumption for each M-module is 1A of +5V and 200ma each of +12V and -12V. The

EM405D uses power-off resetable fuses on the incoming +12V supply. If a fault occurs, power

must be removed before the fuse will reset. The fuse is rated at 5 amps.

1.4 Mechanical

The EM405D is contained in a metal chassis with an outside dimension of 5.6 inches wide by 8.5

inches deep by 1.5 inches high. A variable speed fan provides forced air for cooling the Mmodules. The unit weighs approximately 1.7 lbs with no M-modules installed.

1.5 Environmental

The environmental specifications of the module are:

Operating Temperature: 0C to +60C*

Storage Temperature: -40C to +75C

Humidity: <95% without condensation

* The forced air cooling is designed to allow a maximum 20C temperature rise for installed M-

modules. In other words, with two M-modules operating at full dissipation, the M-modules’

temperature can only be maintained within 20C of the ambient air inlet temperature.

Installed M/MAs may differ in environmental specification. Refer to each individual M/MA’s

documentation for information.

1.6 Bus Compliance

The module complies with the ANSI/VITA 12-1996 Specification for single or double-wide MModules and the MA-Module trigger signal extension.

Addressing: A08 only (extended addressing not supported)

Data: D16 only

Interrupts: not supported

DMA: not supported

Triggers: Trig A and Trig B Input/Output

Manufacturer ID: 0FC116

Model Number: 0FDB16

3

Page 10

1.7 APPLICABLE DOCUMENTS

ANSI/VITA 12-1996 American National Standard for The Mezzanine Concept M-

Module Specification, Approved May 20, 1997, VMEbus

International Trade Association, 7825 E. Gelding Dr. Suite 104,

Scottsdale, AZ 85260-3415, E-mail: info@vita.com,

www.vita.com

IEEE-802.3 (ANSI 8802.3), Ethernet Network Standard

IEEE-802.11b, Wireless Ethernet Standard

4

Page 11

2.0 INSTALLATION

M/MA-Module

Carrier

A B C

2.1 UNPACKING AND INSPECTION

Verify that there has been no damage to the shipping container. If damage exists then the

container should be retained, as it will provide evidence of carrier caused problems. Such

problems should be reported to the carrier immediately as well as to C&H. If there is no damage

to the shipping container, carefully remove the instrument from its box and inspect for any signs

of physical damage. If damage exists, report immediately to C&H.

2.2 HANDLING PRECAUTIONS

The components used in the EM405D are static sensitive. Damage may occur if proper static

precautions are not taken. Installation of M-modules should only be done at a properly grounded

static free workstation.

CAUTION: Read the entire User's Manual before proceeding with the

installation and application of power.

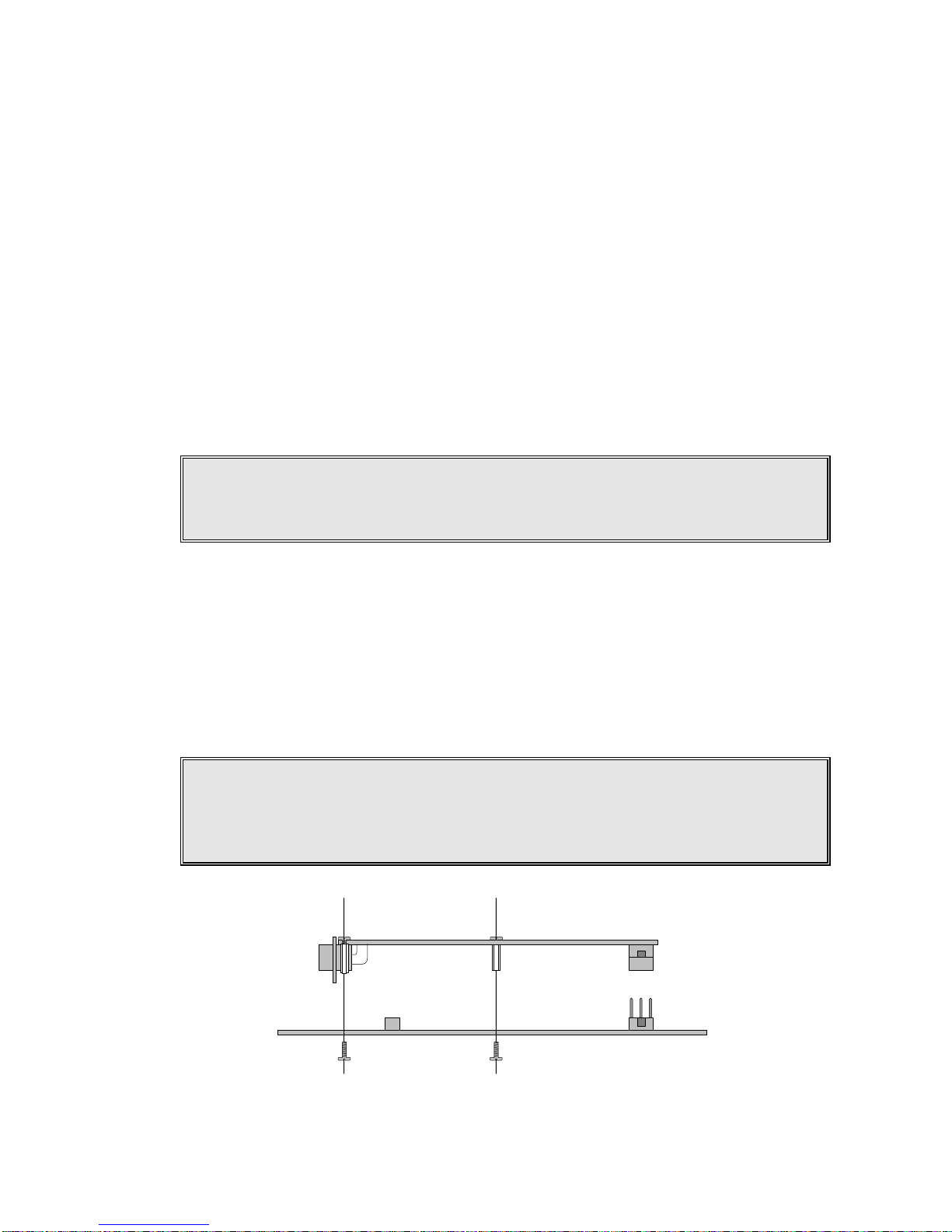

2.3 INSTALLATION OF M-MODULES

To install modules, first remove power from the carrier. Remove the front panel cover by

removing the two screws located at the sides of the panel. Do not remove the screws located on

the bottom of the enclosure. Slide the PCB out of enclosure. Install M-modules by firmly

pressing the connector on the M-module together with the connector on the carrier as shown in

Figure 2. Secure the module through the holes in the PCB using screws provided with the Mmodule.

WARNING: The EM405D supports M-modules that use two or three row

interface connectors. When using M-modules with only two

rows, row C of connector (rear row) is left unconnected.

Figure 2. M-module Installation

5

Page 12

There are two M-module mounting locations on the EM405D. Single-wide M-modules may be

TMP

CPLD

PWR

CNV

uC

CPLD

DSUB

CAP

CAP

CAP

ETHERNET

uC

OSC

BUF

BUF

BUF

SIG

FUSE

FUSE

LED

POWER

FAN

SWITCH

MODULE A

MODULE B

installed in either or both of the positions. A double-wide M-module will occupy both positions.

The EM405D configuration is illustrated in Figure 3.

Figure 3. M/MA Configuration Diagram

CAUTION: M-module connectors are NOT keyed. Use extra caution to

avoid misalignment. Applying power to a misaligned module

can damage the M-module and carrier.

Re-assemble the EM405D by first sliding the carrier into the enclosure. Be careful to align the

edges of the carrier with the guide rails of the enclosure. Improper alignment will cause the back

panel component to not align with the back panel cutouts. Slide the carrier all the way into the

enclosure and re-affix the front panel using the two screw holes located at the sides of the panels.

6

Page 13

3.0 FUNCTIONAL DESCRIPTION

ETHERNET

MICRO

M-MODULE

INTERFACE

POWER

CONVERSION

POSITION A

POSITION B

+12VDC IN

M-MODULE A

M-MODULE B

TRIGGERS

OR

HERE

TRG IN

TRG OUT

10/100 BASE-T

OR WI-FI

9-PIN DSUB

3.1 GENERAL

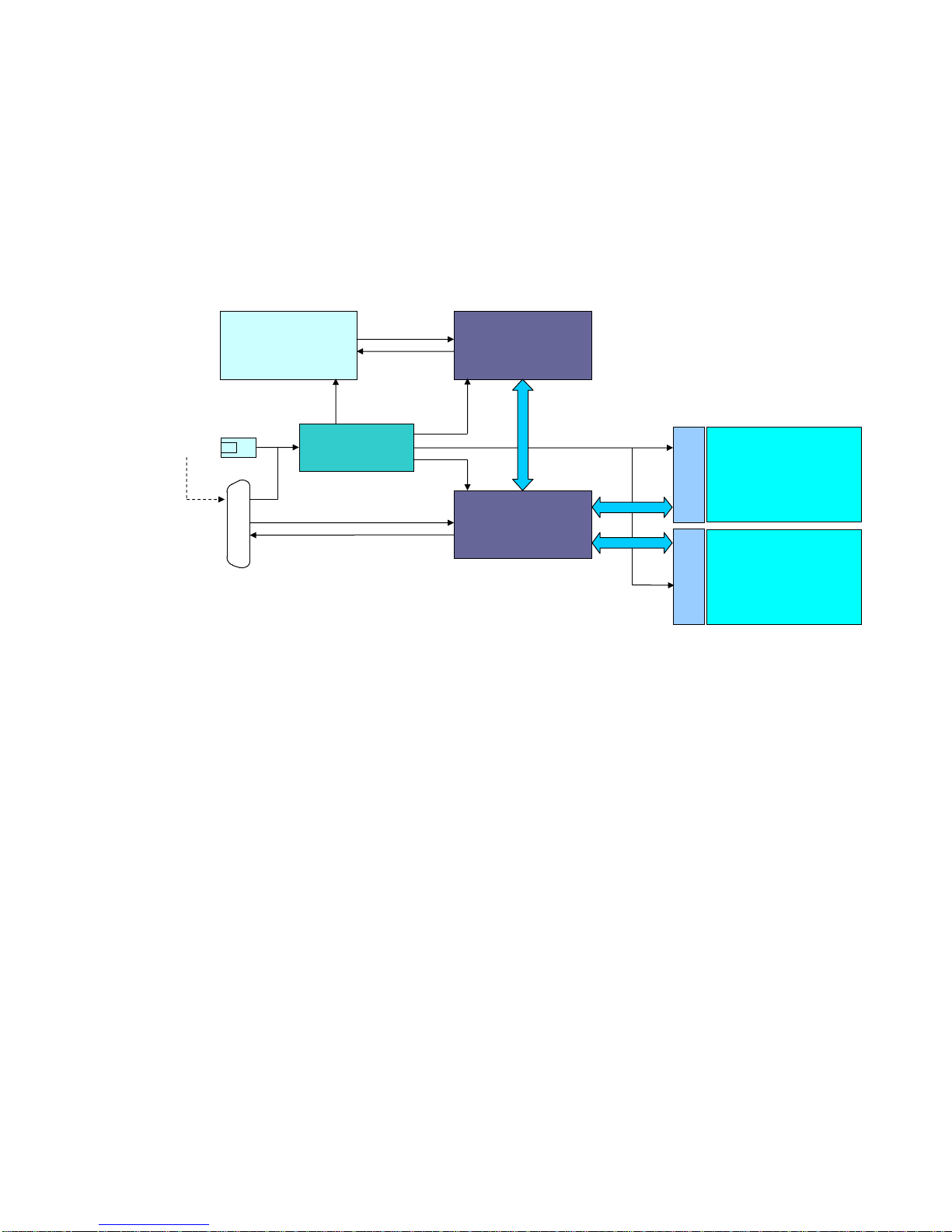

The EM405D provides a mechanical and electrical interface between an Ethernet bus and up to

two M-modules. It utilizes an embedded microcontroller to provide buffering and command

translation between the Ethernet interface and the M-modules. A simplified functional block

diagram is shown in Figure 4.

Figure 4. Functional Block Diagram

3.1.1 Embedded Controller

The embedded controller is implemented using a high-performance microcontroller. The

microcontroller executes system firmware that controls the translation between Ethernet and the

M-module interface. The s ystem firmware implements a s imple command protocol that allows

access to the M-modules I/O space, trigger mapping and carrier information a nd status. It also

provides data buffering and fan control.

3.1.2 Ethernet Interface

The Ethernet interface provides the physical and logical connection to the EM405D allowing

remote control of the M-modules. The EM405D is available with either wired 10/100 Base-T

Ethernet or wireless Ethernet (Wi-Fi). The interface supports the TPC/IP protocol for control of

the M-modules. It also supports DHCP, AutoIP, Telnet, HTTP and other standard protocols for

device configuration and management.

7

Page 14

3.1.3 M-module Interface

ETHERNET

10/100 BASE-T

+12VDC

IN

J1

POWER

ON

OFF

The M-module interface provides the mechanism for the microcontroller to access the Mmodules. It is implemented using programmable logic that emulates a bridge between the

microcontroller and the M-module bus. The logic also provides trigger configuration and

control.

3.1.4 Power Conversion

The +12V input power is converted to the +3.3V power required by the carrier and the +5V,

+12V, and -12V power required by the M-modules. The input p ower can be supplied through

the 2.5mm power jack connector or through pins on the 9-pin DSUB connector.

3.2 REAR PANEL

The rear panel of the EM405D contains a +12V power input connection, an Ethernet connection

or wireless antenna and a 9-pin DSUB connector that provides connection to M-module trigger

lines and an alternate power input connection. Also found on the rear panel are the fan and an

On/Off switch. Figure 5 shows the rear panel of the module. Refer to Appendix A for pin-out

details of the 9-pin DSUB connector.

Figure 5. Rear Panel

8

Page 15

3.3 FRONT PANEL

B

A

EM405D ETHERNET M-MODULE CARRIER

PWR

The front panel of the EM405D contains two openings for access to the M-modules’ front panel

connections and three LED indicators as shown in Figure 6. As mandated by the M-module

specification, each M-module should provide a front panel connector c ontaining the M-module

I/O signals. The two openings on the EM405D’s front panel provide access to these connectors.

The functions of the three front-panel LED indicators are:

PWR: indicates that power is supplied to the module and that the power switch is ON. The units

should be operating normally.

A, B: indicates that M-module A or B is currently being accessed. The LED will illuminate

temporarily each time the module is accessed by the host software.

Figure 6. Front Panel

9

Page 16

10

Page 17

4.0 OPERATING INSTRUCTIONS

4.1 GENERAL

The EM405D is controlled through the Ethernet interface using the TCP/IP protocol to carry a

simple command structure to the module. The carrier contains a set of software controlled

registers that allow the user to request status from the carrier, identify the carrier, and configure

the carrier. All other M/MA controls are dependent on the specific M-module(s) that reside on

the carrier.

4.2 CONFIGURING THE ETHERNET INTERFACE

The Ethernet interface must be properly configured to work on the user’s network. The

flexibility of the EM405D’s Ethernet interface allows it to be used in a large number of possible

network configurations. The unit is delivered with a default configuration that may or may not

be appropriate for the user’s network. It is up to the user and the user’s network administrator to

use the information provided throughout this section to determine what configuration is best for

the given network.

4.2.1 IP Address

The EM405D must have a unique IP address before it can communicate on a network. There are

several options for assigning an IP address to the unit. The option to choose is dependant upon

the type of network for which the EM405D is being configured.

DHCP:

The Dynamic Host Control Protocol (DHCP) allows the module to dynamically retrieve

an IP address from a DHCP server at power-up. If DHCP is used, the EM405D may have a

different IP address assigned each time it is powered on or connected to the network. For the

wired EM405D, DHCP is automatically e nabled if the IP address is set to 0.0.0.0. For the

wireless EM405D, DHCP is a separate setting. DHCP enabled is the default setting.

AutoIP: The AutoIP protocol allows the module to automatically assign itself an IP address on

networks that do not have a DHCP server. If a DHCP server is not found, the EM405D will

select an IP address from t he AutoIP reserved range (168.254.0.1 to 168.254.255.1). The unit

will then send out an address resolution (ARP) request on the network to determine if the chosen

address is already in use. If another device is using the selected IP address then the EM405D

will select another address from the range and repeat the address resolution request. This

continues unit the device finds an IP address that is not in use. For the wired EM405D, manually

setting the IP address to 0.0.0.0 enables AutoIP as well as DHCP and manually setting the IP

address to 0.0.1.0 will disable AutoIP but keep DHCP enabled. For the wireless EM405D both

AutoIP and DHCP have separate enable/disable settings. AutoIP enabled is the default setting.

Static:

For the wired EM405D, manually setting the IP address to something other than 0.0.0.0

will configure the EM405D to use the IP address specified. For the wireless EM405D DHCP

must be disabled and the IP address must be manually set. The configured IP address will

remain static even after power is removed from the module. For proper operation, the IP address

must be chosen according to the network the module is being connected to.

11

Page 18

RECOMMENDATION

The EM405D is an embedded device without an input device or display

that can be used to determine the current configuration of the device. This

can cause difficulties in determining at what IP address to access the

module. For this reason, it is highly recommended, but not required, that

the EM405D be configured to use a static IP address.

4.2.2 Subnet Mask

The subnet mask defines the number of bits that are taken from the IP address to refer to the

given network subsection. The subnet mask allows Ethernet based networks to be separated into

various subnets. The EM405D should be in the same subnet as the controlling PC.

The default subnet mask is: 255.255.255.0

4.2.3 Gateway

The gateway address allows the EM405D to communicate with other network segments. If

communication outside of the given network segment is necessary, the gateway address should

be set to the IP address of the router connecting the local network segment to the outside world.

The gateway address, if needed, must be within the local network.

The default gateway address is: 0.0.0.0

4.2.4 Port Numbers

Every TCP connection to the device is defined by a destination IP address and a port number.

The port number must be known by the software to communicate with the module. The port

number is configurable but it is rarely, if ever, necessary to change it from its default setting.

Port 9999 is reserved for Telnet access to the EM405D’s configuration utility.

The default port number for standard module access is: 10001

4.2.5 Wireless Settings

Wireless EM405D’s have other settings that must be configured for the carrier to work on a

wireless network.

Network Mode:

A wireless network can operate in one of two modes, infrastructure or ad-hoc.

In infrastructure mode, all w ireless network traffic passes through an access point. An access

point can be a bridge, a router, or a combination bridge + router device. The access point may

handle data encryption, bridging to wired networks, assigning IP addresses via DHCP, or a host

12

Page 19

of other tasks. In ad-hoc mode, wireless devices may communicate directly with each other and

an access point is not needed. In this case, all devices on the network must be configured to use

ad-hoc mode. The default network mode is: infrastructure.

SSID:

The Set Service Identifier (SSID) is a name given to a wireless access point to identify

the access point on a wireless network. Most access points can be configured to periodically

broadcast the SSID or to keep it private. Wireless devices can query the network for known

SSID and thus communicate with access points that do not broadcast it. The EM405D can be

configured to communicate with any available SSID or to query for a specific SSID and use the

owning access point if found. The default setting is to use any available SID.

Channel: The 802.11b specification defines a total of 14 frequency channels that can be used for

wireless communication. However, not all channels may be available for use. For example, the

FCC only allows for the use of channels 1 through 11 in the US; whereas most of Europe can use

channels 1 through 13. Other countries or locations may differ. All wireless communication is

done over a common channel. Another consideration in regards to channels is interference.

Interference can occur between access points or may be caused by other equipment such as

microwave ovens and cordless phones. The EM405D can be set to auto-scan mode in which the

device searches for the best wireless channel or it can be configured to use a specific channel.

The default setting is: Auto-Scan.

Country: Some countries restrict certain channel ranges and other transmission properties. The

EM405D should be configured for the country in which the device is being used. The default

setting is: USA.

Security Settings:

The EM405D supports WEP and WPA security protocols. WEP is an

encryption protocol used for secure data transfers. WPA is an authentication protocol used to

authenticate and associate a device and a wireless access point. WPA is not available in ah-hoc

mode. The security settings must be set according to the wireless network being connected to.

The default settings are: WEP disabled and WPA disabled.

4.2.6 Performing the Co nfiguration – Wired Ethernet

There are two ways to configure the wired version of the EM405D: a web-based interface and a

Telnet interface. Both ways work equally as well and the choice of which to use is based solely

on the user’s preferences. In either case, the IP address of the module must be known to perform

the configurations. If the IP address of the module is not known, one can be assigned to the

module as discussed in section 4.2.6.3.

13

Page 20

4.2.6.1 Wed-based Configuration

To use the wed-based interface to configure the wired EM405D, open a Java enabled web

browser and enter the device’s IP address as the web address to open. This will download and

run a Java applet from the device allowing the user to make changes to the devices configuration.

Navigate through the pages of the web interface making the necessary changes to the

configuration. When finished, click on the “Update Settings” button to apply the changes.

Note: If the web page does not display or operate correctly, there may be some incompatibilities

between the Java applet and the Java run-time environment on the PC. This is especially

true for users using Microsoft Internet Explorer and the Microsoft Java Virtual Machine.

It is recommended that the user download the latest Java runtime environment from

www.java.com

and disable the Microsoft Virtual Machine. The java applet served by the

wired EM405D is compatible with Java 1.3.1x or higher.

4.2.6.2 Telnet Configuration

To use the telnet interface, open a telnet session to port 9999 at the device’s IP address. In

Windows, this can b e done by opening a command prompt w indow or going to Run under the

Windows Start menu and in both cases typing the following, where x.x.x.x is the IP address:

telnet x.x.x.x 9999

PC’s running environments other than Windows may require a different instruction but the

concept remains the same. Once a telnet session is opened, the screen will display the

configuration utility. Navigate through the various menu items and follow the instructions to

configure the module. The configurations are not applied until the telnet session is exited with

the Save and Exit menu item.

4.2.6.3 Configuring a Device with an Unknown IP address

To configure the device through either the web-based interface or the telnet interface, the

EM405D must be connected to a network and have a valid IP address known to the user. This

creates an obvious dilemma. How do you configure a device via the network if it is not

configured for the network? The EM405D provides a method to overcome this dilemma using a

process sometimes referred to as address “gleaning.” This method uses the Address Resolution

Protocol (ARP) and telnet to assign a temporary IP address to the device. This temporary

address can then be used to connect to the web-based interface or the telnet interface to configure

the device for the network. To assign a temporary IP address to a device using this method:

1) Locate the device’s hardware (MAC) address and write it down. The address is

displayed on a label inside the EM405D’s cover. View the label by removing the two

screws at the front of the module, removing the front panel, then sliding the top cover of

the enclosure forward, exposing the rear section of the PCB. The MAC address can be

found on the device that the Ethernet cable physically plugs into. It is a six part number

14

Page 21

always starting with 00-20-4A identifying the manufacturer of the device. The last three

parts of the number are unique to each unit.

Example: 00-20-4A-11-68-4C

2) Create an entry in the host computer’s ARP table using the intended temporary IP address

and the hardware address of the EM405D found in step 1. To perform this action on a

Windows-based host, open the command prompt and type (the IP address can be any

available address on your network and xx-xx-xx is the last three numbers in the unit’s

MAC address):

arp –s 192.168.1.7 00-20-4a-xx-xx-xx

View the ARP table to verify that the entry was successful by typing the following:

arp –a

The ARP commands might be slightly different on non Windows based hosts.

Note: On a Windows 95 machine, the ARP command will not work unless at least one IP

address is in the ARP table. To view the ARP table, type: arp –a. If no IP addresses

are found in the table, you must ping an existing IP address on the network. If the ping is

successful, the IP address should be automatically added to the ARP table.

3) Open a Telnet connection to port 1 of the intended temporary IP address. To perform this

action type the following at the command prompt:

telnet 192.168.1.7 1

The connection will fail but will cause the EM05D to temporarily change its IP address to

the one specified.

4) Use the Telnet interface or the wed-based interface to open a session to the module using

the new temporary IP address. At this point the IP address can be configured to a more

permanent setting. The module will retain the temporary IP address until a new

configuration is applied or the module is powered-off.

4.2.7 Performing the Configuration – Wireless Ethernet (Wi-Fi)

The wireless version of the EM405D provides a web-based interface to perform network and

device configuration. A Telnet interface is not supported. To use the web-based interface, the

user must know the carrier’s IP address and the user must be able to connect to the module via a

wireless access point, router, or another wireless device capable of communicating directly with

other wireless devices (ad-hoc). If the EM405D’s configuration is not known, it can be reset to

known defaults as described in section 4.2.7.2.

15

Page 22

4.2.7.1 Wed-based Configuration

To use the wed-based interface to configure the wireless EM405D, open a web browser and enter

the device’s IP address as the web address to open. This will launch the main web page of the

configuration utility. Navigate through the pages of the web interface making the necessary

changes to the configuration. When finished making changes in any given section, click on that

pages “Apply” button to apply the changes. Some changes may require that the wireless

Ethernet interface be rebooted, in which case the user will need to re-connect to the device.

4.2.7.2 Restoring Factory Defaults

Similar to the wired version, the wireless version of the EM405D has a dilemma in which the

carrier must be connected to a network in order to configure its network properties. The

dilemma is made worse in the wireless version by the fact that there is no physical connection to

the device and there are additional configuration settings that must be known in order to connect

to the device, such as the network mode, security settings (WEP, WPA), channel setting, and the

SSID. If the EM405D configuration is not known and thus the user cannot connect to the carrier,

it is possible to reset the configuration settings to known defaults using a small push-button

switch found on the inside the EM405D enclosure.

CAUTION: The following procedure requires opening the EM405D

enclosure and applying power while the PCB is exposed. Use

extreme caution when attempting to perform the procedure as

to not damage the carrier or any of its components.

To restore the factory defaults:

1) Turn power Off.

2) Remove the front panel cover by removing the two screws located at the sides of the

panel. Do not remove the screws located on the bottom of the enclosure.

3) Slide the top cover of the enclosure forward exposing the rear portion of the PCB.

4) Locate the tiny push button switch near the Ethernet device (bottom right hand corner of

the PCB when the carrier is oriented as shown in Figure 3).

5) Using a finger or a tool, such as the eraser end of a pencil, press and hold the button.

6) While holding the button down, turn the device On.

7) Continue holding the button pressed until the amber colored LED on the back of the

Ethernet device flashes a 1-5-1 sequence.

8) Once the 1-5-1 sequence is complete, the device has been reset to its factory defaults and

the user may release the button.

9) Re-assemble the EM405D by sliding the top cover back into place and re-installing the

front panel.

16

Page 23

The defaults that are restored using the above procedure are those set by the manufacturer of

the Ethernet device and not by C&H Technologies, Inc. The default settings of the carrier as

received from the factory at C&H are different in several key areas. The user must manually

return these settings to the default as set by C&H in order for the carrier to operate properly.

Refer to APPENDIX C or details on the factory default settings as received from C&H

Technologies, Inc.

4.3 COMMUNICATING WITH THE CARRIER AND M-MODULES

The EM405D uses a simple binary command structure to communicate with the host s oftware.

The commands allow the user to either write or read registers residing on the EM405D or on

each M-module. By writing regis ters residing on the EM405D, the user can identify the module,

perform device configuration, and receive status. The registers residing on each M-module are

specific to the particular M-module. Refer to the M-module’s documentation for register details.

Each command consists of a command-id byte, a module number on which the command is to be

executed and parameters, if required. The commands are listed in Table I. Details of each

command are found throughout the rest of this section.

Table I. Command Summary

Binary

Command-id Function

0x20 Write Data

0x30 Read Data

0x40 Block Write

0x50 Block Read

4.3.1 Error Handling

Each command will return a status code as the last byte returned. This status code will indicate

whether the command completed successfully or whether an error occurred while the EM405D

was performing the command. Table II shows a list of potential status codes that may be

returned.

Table II. Status Code (SC)

Value

0x00 Successful

0x01 Invalid Command

0x02 Invalid Parameter

0x03 Module did not respond*

* Note: Applies to M-module requests only.

Meaning

17

Page 24

Successful (0x00): The command completed successfully without error.

Invalid Command

(0x01): The first byte received was not a valid command-id value from the

list in Table I.

Invalid Parameter (0x02): The EM405D received a valid command however the command could

not be completed because one of the command parameters was invalid or out of range. Refer to

the description of each individual command for parameter details.

Module D id Not Respond (0x03): The EM405D received a valid command with valid

parameters; however, the specified module did not respond to the access. This error code applies

to M-module accesses only. The error code could result from the specified M-module being

absent, the specified address being outside the range of addresses supported by the particular Mmodule, or more serious hardware problems with the M-module itself.

Once any of the above status codes are returned, the EM405D will set the Reset Error (RERR)

status bit in t he EM405D Reset Error and Manufacturer ID register (refer to section 4.3.5 for

details on this register) and cease responding to further commands except the Read Data and

Write Data commands to the Reset Error and Manufacturer ID register. To recover from this

condition, the user must clear the RERR bit by writing a ‘1’ to that bit location in the Reset Error

and Manufacturer ID register.

This functionality is implemented so that when the EM405D recognizes an error at the beginning

of a command, it can search the buffer for the next command without having to send a status

code response for each byte remaining in the buffer. For example, assume this functionality

didn’t exist and the user wanted to perform a block write with a 1024 byte block. The full

command for this action, including data, requires 1033 bytes to be placed into the EM405D’s

buffer. If the third byte in the command is an invalid parameter, the EM405D would return an

Invalid Parameter (0x02) status code followed by one thousand and thirty Invalid Command

(0x01) status codes, one for each byte in the buffer after the invalid parameter. By implementing

this functionality, the EM405D will ignore the one thousand and thirty bytes and any following

bytes in the buffer unless the command is a Read Data or Write Data of the Reset Error and

Manufacturer ID register or until the RERR bit is reset to ‘0’.

The software must be written such that it checks for error conditions and performs the

appropriate action to reset the RERR bit. In most cases error conditions are generated by

errors in the software source code, therefore, once the software has been debugged and

verified, error codes will rarely, if ever be received.

18

Page 25

4.3.2 Write Data command

The Write Data command writes data to an EM405D control register or to a register residing on

an M-module. The command consists of seven bytes including the command-id, the module to

which the data should be written, an address space selector, the access width, the address, and

two data bytes. The return value consists of a single status byte.

Command Syntax:

0x20 md as ws ad dh dl

Return:

SC

where

md = module (0 = EM405D control, 1 = M-module A, 2 = M-module B)

as = address space (0 = I/O, 1 = future use)

ws = word size (2 = 16-bit word, other values for future use)

ad = address (0 to FF)

dh = data (MSB)

dl = data (LSB)

SC = Status Code

Example (values shown hex):

To write the data value 0x1234 to M-module A, send the following command:

Command: cd md as ws ad dh dl

Send: 20 01 00 02 06 12 34

Receive: 00 (if successful)

4.3.3 Read Data command

The Read Data command reads data from an EM405D control/status register or from a register

residing on an M-module. The command consists of five bytes including the command-id, the

module from which the data should be read, as address space selector, the access width and the

address from which to read. The return value consists of two data bytes followed by a single

status byte.

Command Syntax:

0x30 md as ws ad

Return:

dh dl SC

where

md = module (0 = EM405D control, 1 = M-module A, 2 = M-module B)

as = address space (0 = I/O, 1 = future use)

ws = word size (2 = 16-bit word, other values for future use)

ad = address (0 to FF)

dh = data (MSB)

dl = data (LSB)

SC = Status Code

19

Page 26

Example (values shown hex):

To read the Device Identification Register on the EM405D, send the following command:

Command: cd md as ws ad

Send: 30 00 00 02 02

Receive: 0F DB 00 (if successful)

4.3.4 Block Access

The EM405D provides a flexible block access feature that can be used to significantly improve

data throughput. Both a block read and a block write command is implemented. The flexibility

of the bock access feature is in the command protocol. The protocol allows the user to specify

four parameters in addition to the standard parameters also found in the single data read and

write commands: starting address, block size, number of blocks, and address increment.

The EM405D firmware will execute the command by reading or writing a block of data the size

of the block size parameter, starting from the starting address and ending at:

starting address + (block size * word size)

The firmware will then repeat this process N number of times depending on the number of blocks

parameter. If the address increment parameter is not equal to 0, the firmware will increment the

starting address by the specified amount after each read or write of a single block.

The M-module I/O space is a maximum of 256 bytes. Care must be taken when performing a

block access that an address greater than 0xFF is never accessed. Otherwise, an error will occur

and the block access will terminate immediately.

The following examples further illustrate the block access feature.

Example 1:

starting address = 0x4

block size = 32

number of blocks = 1

address increment = don’t care

Read a single block of 32 words (64 bytes) starting at address 0x4.

Example 2: Read 32 words (64 bytes) from a FIFO at address 0x8.

starting address = 0x8

block size = 1

number of blocks = 32

address increment = 0

Example 3: Read 32 words from two FIFOs one at address 0x8 and another at address 0xA

starting address = 0x8

block size = 2

number of blocks = 32

address increment = 0

20

Page 27

Example 4: Read 32 words starting at address 0x0 followed by 32 words starting at address 0x80

starting address = 0x0

block size = 32

number of blocks = 2

address increment = 128

4.3.4.1 Block Write command

The Block Write command writes a block of data to an M-module. A maximum of 1024 bytes

can be written in a single command. The number of bytes written in any given command is

equal to:

number of bytes = number of blocks * block size * word size

The block write command consists of nine command bytes and any number (up to 1024) of data

bytes. The return value is a single status byte indicating the success of the command.

Command Syntax:

0x40 md as ws ad ai nh nl bs d1 d0 …

Return:

SC

where

md = module (0 = invalid, 1 = M-module A, 2 = M-module B)

as = address space (0 = I/O, 1 = future use)

ws = word size (2 = 16-bit word, other values for future use)

ad = starting address (0 to FF)

ai = address increment (number to increment address by after each write)

nh = number of blocks to read (upper 4 bits)

nl = number of blocks to read (lower 8 bits)

bs = block size in words (i.e., number of words

d1 = data (MSB)

d0 = data (LSB)

… = the number of data bytes = ws bs nb

SC = Status Code

Example (values shown hex):

To write the data values 0x1234, 0x5678, 0x9ABC to M-module A starting at I/O Register 4, send the

following command:

Command: cd md as ws ad ai nh nl bs dh1 dl1 dh2 dl2 dh3 dl3

Send: 40 01 00 02 04 02 00 03 01 12 34 56 78 9A BC

Receive: 00 (if successful)

per block)

21

Page 28

4.3.4.2 Block Read command

The Block Read command reads a block of data from an M-module. Unlike the block write

command, block read does not have a restriction on the number of bytes that can be read with a

single command. The number of bytes read in any given command is equal to:

number of bytes = number of blocks * block size * word size

The block read command consists of nine command bytes. The return value is any number of

data bytes followed by a single status byte indicating the success of the command.

Command Syntax:

0x50 md as ws ad ai nh nl bs

Return:

d1 d0 ... SC

where

md = module (0 = invalid, 1 = M-module A, 2 = M-module B)

as = address space (0 = I/O, 1 = future use)

ws = word size (2 = 16-bit word, other values for future use)

ad = starting address (0 to FF)

ai = address increment (number to increment address by after each write)

nh = number of blocks to read (upper 4 bits)

nl = number of blocks to read (lower 8 bits)

bs = block size in words (i.e., number of words

d1 = data (MSB)

d0 = data (LSB)

… = the number of data bytes = ws bs number of blocks (nh:nl)

SC = Status Code

Example (values shown hex):

To read three data values from a 32-bit FIFO located at I/O Register 6 and 8 on M-module B, send

the following command:

Command: cd md as ws ad ai nh nl bs

Send: 50 02 00 02 06 00 00 03 02

Receive: da1 db1 dc1 dd1 da2 db2 dc2 dd2 da3 db3 dc3 dd3 00 (if successful)

where

dax = MSB of register 6

dbx = LSB of register 6

dcx = MSB of register 8

ddx = LSB of register 8

Note: x = 1 is first read, x = 2 is second read, x = 3 is third read

per block)

22

Page 29

4.3.5 EM405D Configuration/Status Registers

The EM405D contains a set of registers that are used to identify the carrier, configure the carrier,

and retrieve status from the carrier. These registers are independent of the M-modules r esiding

on the board. Table III summarizes the register map. Bit level details of each register can be

found in Figure 7. These registers are accessed using the Read Data and Write Data commands

with the module field of the command set to ‘0’.

Table III. Register Summary

Offset

0x00 Reset Error & Manufacturer Identification

0x02 Device Identification

0x04 Hardware Version

0x06 Firmware Version

0x08 Reset & Trigger Control

0x0A Fan Control & Temperature Status

Register

Reset Error & Manufacturer Identification

(0x00): A read of this register will return the 12-bit

manufacturer ID value of the EM405D and the reset error bit. The manufacturer ID field is readonly. Writing a ‘1’ to the reset error bit will clear the error condition. Refer to section 4.3.1 for

details on error handling.

Device Identification (0x02): This read-only register returns the device ID value of the EM405D

and a bit indicating whether the EM405D is a wired or wireless (Wi-Fi) version.

Hardware Version

(0x04): This read-only register returns the hardware version number of the

EM405D being accessed.

Firmware Version (0x06): This read-only register returns the firmware version number of the

EM405D being accessed.

Reset & Trigger Control

(0x08): This read/write register can be used to reset the M-modules

residing on the EM405D and to control the triggers. An independent reset bit is available for

each module as well as numerous bits that allow the user to configure the external trigger lines

and to map each M-module trigger.

Fan Control & Temperature Status (0x0A): A read of this register will return a value

representative of the current temperature inside the EM405D casing and will return the current

setting of the fan c ontrol bit. The t emperature field of this register is read only. By writing to

the fan control bit, the user can select whether the fan is set to full-on or variable speed.

23

Page 30

Reg. 00

Byte 1 0

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Write RERR - - - Read Only

Read RERR 0 0 0 MID

Reset Error & Manufacturer Identification

RERR Reset Error (writing a 1 clears the error condition) 1

MID Manufacturer ID (always FC116 - C&H)

Notes:

1. This bit is set if a command error occurs. If an error exists, only reads or writes to this register are

allowed. The RERR bit must be cleared by writing a 1 to this bit before normal command operation

will resume. See 4.3.1 for further details.

Reg. 02

Byte 3 2

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Write - - - - Read Only

Read ETH 0 0 0 DID

Device Identification

ETH Ethernet Type (0 = wired, 1 = wireless (Wi-Fi))

DID Device ID (always FDB16 - EM405D)

Reg. 04

Byte 5 4

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Write Read Only Read Only

Read HW Major HW Minor

Hardware Version

HW Major Major Version Level of EM405D Hardware

HW Minor Minor Version Level of EM405D Hardware

Reg. 06

Byte 7 6

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Write Read Only Read Only

Read FW Major FW Minor

Firmware Version

FW Major Major Version Level of EM405D Firmware

FW Minor Minor Version Level of EM405D Firmware

Figure 7. EM405D Registers

24

Page 31

Reg. 08

Byte 9 8

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Write RSTB RSTA TLVL TIMP BTBD BTBM BTAD BTAM ATBD ATBM ATAD ATAM

Read RSTB RSTA TLVL TIMP BTBD BTBM BTAD BTAM ATBD ATBM ATAD ATAM

Reset & Trigger Control

RSTB Reset M-module B (0 = normal, 1 = reset) 1

RSTA Reset M-module A (0 = normal, 1 = reset) 1

TLVL External Trigger Input Threshold Level (0 = +2.5V, 1 = +1.4V)

TIMP External Trigger Input Impedance (0 = high (>100K), 1 = 50)

BTBD Module B Trigger B Direction (0 = input, 1 = output) 2

BTBM Module B Trigger B Mode

0 0 Disabled

0 1 to/from External Trigger

1 0 to/from Module A Trigger A

1 1 to/from Module A Trigger B

BTAD Module B Trigger A Direction (0 = input, 1 = output) 2

BTAM Module B Trigger A Mode

0 0 Disabled

0 1 to/from External Trigger

1 0 to/from Module A Trigger A

1 1 to/from Module A Trigger B

ATBD Module A Trigger B Direction (0 = input, 1 = output) 2

ATBM Module A Trigger B Mode

0 0 Disabled

0 1 to/from External Trigger

1 0 to/from Module B Trigger A

1 1 to/from Module B Trigger B

ATAD Module A Trigger A Direction (0 = input, 1 = output) 2

ATAM Module A Trigger A Mode

0 0 Disabled

0 1 to/from External Trigger

1 0 to/from Module B Trigger A

1 1 to/from Module B Trigger B

Notes:

1. This bit must be cleared by user software to return the M-module to normal operation. The reset bit

need only be set to a 1 for a minimum of 1s to properly reset an M-module.

2. The direction is with respect to the M-module specified. For intermodule triggers, the M-module

trigger directions must be set opposite one another for proper operation.

Reg. 0A

Byte B A

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Write VARF - - - Read Only

Read VARF 0 0 0 TEMP

Fan Control & Temperature Status

VARF Variable Speed Fan (0 = variable, 1 = full ON)

TEMP Enclosure Temperature (°C = (TEMP – 281) / 4.6)

Figure 7. EM405D Registers (continued)

25

Page 32

4.4 CONTROLLING THE TRIGGERS

The carrier implements flexible trigger control capabilities providing the user with many options

for using triggers. Each M-module can support two trigger lines (labeled A & B) which can be

mapped to one of two external trigger lines (one input and one output) available on the carrier or

to the trigger lines of the adjacent M-module.

The carrier’s external trigger lines can be accessed at the 9-pin DSUB connector on the back

panel of the EM405D. Refer to Appendix A for pin-out details of the 9-pin DSUB connector.

The input trigger line has a software configurable threshold and input impedance. The input

threshold is configurable using the TLVL bit in the Reset & Trigger Control register and can be

set to either +1.4 volts or +2.5 volts. The input impedance is configurable using the TIMP bit in

the Reset & Trigger Control register and can be set to either high impedance (>100K) or 50.

The output trigger line has a set output impedance of 50and a set output drive level of +5V

(typical) into a high impedance load.

Each M-module trigger line can be configured to be either an input or an output and can be

mapped to either the external trigger lines or to one of the trigger lines on the other M-module.

Each trigger line contains two bit fields in the Reset & Trigger Control register. The xTzD bit

controls the trigger direction and the xTzM controls the trigger mapping, where x specifies the

module and z specifies the trigge r (for example ATBM is module A trigger B). If the xTzM bit

field is set to map the trigger line to the external trigger, the trigger is connected to either the

external input or the external output depending on the value of the xTzD bit. If the xTzM bit

field is set to map the trigger line to another M-module trigger line, then the two triggers must be

configured to be opposite directions. Also the second M-module trigger line must be mapped to

the first M-module trigger line. For example, if module A trigger B is to be outputted to module

B trigger A then the corresponding bit fields must be set as follows:

ATBD = output

ATBM = to/from Module B Trigger A

BTAD = input

BTAM = to/from Module A Trigger B

The following values would be invalid:

ATBD = output

ATBM = to/from Module B Trigger A

BTAD = output

BTAM = to/from Module A Trigger B

or

ATBD = output

ATBM = to/from Module B Trigger A

BTAD = input

BTAM = to/from external trigger

26

Page 33

The function of each M-module trigger line is fully dependent upon the M-module. Refer to the

particular M-module’s documentation for further details.

4.5 FAN AND TEMPERATURE CONTROL

The EM405D contains an on-board temperature sensor placed near the M-module positions. The

current temperature inside the EM405D case can be determined by reading the Fan &

Temperature Control register of the EM405D. The TEMP field inside this register represents the

current temperature as read by the temperature sensor. To translate the TEMP value in to

degrees Celsius use the following equation:

°C = (TEMP – 281) / 4.6

The temperature sensor is also read by the firmware and used to control the variable speed fan.

When the fan is set to variable, the firmware constantly monitors the temperature and speeds up

the fan as the temperature rises. The variable fan is designed to maintain a maximum 20° C rise

in temperature from the ambient inlet air. The user may select the fan to remain full on at all

times by setting the VARF bit in the Fan & temperature Control register to a ‘1’.

27

Page 34

28

Page 35

A-1

PIN DESCRIPTION

1 +12V INPUT

2 +12V INPUT

3 +12V INPUT

4 TRIGGER OUT

5 TRIGGER IN

6 GND

7 GND

8 GND

9 GND

5 4 3 2 1

9 8 7

6

APPENDIX A - CONNECTORS

Figure A-1. 9-Pin DSUB Connector

Page 36

A-2

Page 37

B-1

APPENDIX B – WIRED ETHERNET DEFAULT SETTINGS

The Ethernet interface device on the wired version of the EM405D contains many configurable

settings that allow it to be used in a large number of applications. Many of these settings must be

set to certain values in order for the EM405D to operate normally. Other settings are not

applicable to the EM405D. When the user tries to configure the network settings via the webinterface or the telnet interface, he/she will see options to change many of these settings.

Changing some of these may make the EM405D inoperable. For this reason, it is highly

recommended that the user does not change any settings other than the following:

IP Address

Subnet Mask

Gateway Address

Table B-1 lists the various settings and their default values as set my C&H during manufacturing

of the EM405D. If the carrier fails to operate, verify that these settings are set to their default

values prior to calling C&H for technical support. Settings that are emphasized in bold italics

are required settings that if changed will render the carrier inoperable.

Table B-1. Ethernet Interface Default Settings.

Server Properties

IP Address 0.0.0.0

Subnet Mask 0.0.0.0

Gateway Address 0.0.0.0

Serial Settings

Baud Rate 921600

Data bits 8

Parity None

Stop bits 1

Flow control None

UDP Datagram Mode

Datagram Mode False

Datagram Type N/A

Passive Connection

Password Required False

Port Password N/A

Accept Passive Connection Yes

Local Port** 10001

Auto Increment Source Port False

** The EM405D will operate with any port number; however, many software applications

expect the port to be set to the default as shown in this table. Changing the port number will

not render the EM405D inoperable but may render these software applications inoperable.

Page 38

B-2

Table B-1. Ethernet Interface Default Settings. (continued)

Active Connection

Active Connection None

Telnet Mod N/A

Terminal Type N/A

Remote Port N/A

Connection Response None

Modem Emulation Mode None

Use Host List N/A

Remote Host N/A

Disconnection

Disconnect with EOT N/A

Disconnect with DTRDrop False

Disable Hard Disconnect False

Inactivity Timeout 00:00

Connection

Connection LED Blink

Buffer Flushing

Flush Output Buffer

- At Time of Disconnect False

- On Passive Connection True

- On Active Connection False

Flush Input Buffer

- At Time of Disconnect False

- On Passive Connection True

- On Active Connection False

Packing

Enable Packing True

Send Trailing Bytes None

Send Frame Only False

Match Two Byte Sequence False

Idle Time Force Transmit 12ms

Match Byte 2 00

Match Byte 1 00

Device

Firmware Type N/A

Firmware Version N/A

Product Type N/A

Page 39

B-3

Table B-1. Ethernet Interface Default Settings. (continued)

Email Notification

Domain Name blank

Mail Server 0.0.0.0

Recipients (Collection)

Triggers (Collection)

Unit Name blank

Host List

Host List (Collection)

Retry Counter 3

Retry Timeout 250

OEM Configurable Pins

Pin 1 IN1

Pin 2 IN2

Pin 3 IN3

User IO ActiveLow

XPort-03

CPU Performance High

Page 40

B-4

Page 41

C-1

APPENDIX C – WIRELESS ETHERNET (Wi-Fi) DEFAULT SETTINGS

The Ethernet interface device on the Wireless version of the EM405D contains many

configurable settings that allow it to be used in a large number of applications. Many of these

settings must be set to certain values in order for the EM405D to operate normally. Other

settings are not applicable to the EM405D. When the user tries to configure the network settings

via the web-interface, he/she will see options to change many of these settings. Changing some

of these may make the EM405D inoperable. For this reason, it is highly recommended that the

user does not change any settings other than the following:

IP Address

Subnet Mask

Gateway Address

Wireless LAN Settings

Wireless Security Settings

Table C-1 lists the various settings and their default values as set my C&H during manufacturing

of the EM405D. If the carrier fails to operate, verify that these settings are set to their default

values prior to calling C&H for technical support. Settings that are emphasized in bold italics

are required settings that if changed will render the carrier inoperable.

Table C-1. Wireless Ethernet Configuration Default Settings.

Network

IP Settings

Obtain an IP address autom atically using DHCP True

Wireless LAN Settings

Connect to wireless access points (infrastructure) True

Connect to any available wireless network True

Country United States

Channel Auto-Scan

Wireless Security Settings

Enable WEP security False

Enable WPA authentication False

Network Services Settings

Enable ADDP True

- Port 2362

Enable Encrypted RealPort True

- Port 1027

Enable HTTP & HTTPS True

- HTTP Port 80

- HTTPS Port 443

Page 42

C-2

Table C-1. Wireless Ethernet Configuration Default Settings. (continued)

Enable Line Printer Daemon (LPD) True

- Port 515

Enable RealPort True

- Port 771

Enable Remote Login (rlogin) True

- Port 513

Enable Remote Shell (rsh) True

- Port 514

Enable SNMP True

- Port 161

Enable Telnet True

- Port 23

Advanced Network Settings

Enable AutoIP address assignment True

RTS Threshold 2347

Fragmentation Threshold 2346

Serial Port

Port Profile Settings

Current Port Profile TCP Sockets

TCP Server Settings

Enable Telnet access using TCP Port False

- Port N/A

Enable Raw TCP access using TCP Port True

- Port** 10001

Enable Secure Socket access using TCP Port False

- Port N/A

TCP Client Settings

Automatically establish TCP connections False

Basic Serial Settings

Description blank

Baud Rate 230400

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

** The EM405D will operate with any port number; however, many software applications

expect the port to be set to the default as shown in this table. Changing the port number will

not render the EM405D inoperable but may render these software applications inoperable.

Page 43

C-3

Table C-1. Wireless Ethernet Configuration Default Settings. (continued)

Advanced Serial Settings

Enable Port Logging False

Enable RTS Toggle False

Enable RCI over Serial (DSR) False

Send Socket ID False

Send data only under any of the following conditions True

- Send when data is present on the serial line False

- Send after the following number of idle milliseconds True - 12 ms

- Send after the following number of bytes 1024

- Close connection after the following number of idle

False

seconds

- Close connection when DCD goes low False

- Close connection when DSR goes low False

GPIO

General Purpose Input/Output Pins

Pin 1 In

Pin 2 In

Pin 3 In

Pin 4 In

Pin 5 In

Alarms

Alarm Notification Settings

Enable Alarm Notifications False

Alarm Conditions

Alarm 1 …Alarm 32 False

Security

Administrator Password

Enable Password Authentication False

System

System Settings

Description blank

Contact blank

Location blank

Simple Network Management Protocol (SNMP) Settings

Enable Simple Network Management Protocol (SNMP) True

- Public community public

- Private community private

- Allow SNMP clients to set device settings through SNMP False

Enable Simple Network Management Protocol (SNMP) traps False

Page 44

C-4

Page 45

N O T E S:

Page 46

.

Page 47

READER'S COMMENT FORM

Your comments assist us in improving t he use fulness of C&H's publications; they ar e an

important part of the inputs used for revision.

C&H Technologies, Inc. may use and distribute any of the information that you supply in any

way that it believes to be appropriate without incurring any obligation whatsoever. You may, of

course, continue to use the information, which you supply.

Please refrain from using t his form for technical questions or for requests for additional

publications; this will only delay the response. Instead, please direct your technical questions to

your authorized C&H representative.

COMMENTS:

Thank you for helping C&H to deliver the best possible product. Your support is appreciated.

Sincerely,

F. R. Harrison

President and CEO

Page 48

Place

Stamp

Here

INSTRUCTIONS

In its continuing effort to improve documentation, C&H Technologies, Inc. provides this form

for use in submitting any comments or suggestions that the user may have. This form may be

detached, folded along the lines indicated, taped along the loose edge (DO NOT STAPLE), and

mailed. Please try to be as specific as possible and reference applicable sections of the manual or

drawings if appropriate. Also, indicate if you would like an acknowledgment mailed to you

stating whether or not your comments were being incorporated.

NOTE: T his form may not be used to request copies of documents or to request

waivers, deviations, or clarification of specification requirements on current

contracts. Comments submitted on this form do not constitute or imply

authorization to waive any portion of the referenced document(s) or to amend

contractual requirements.

(Fold along this line)

(Fold along this line)

______________________

______________________

______________________

C&H Technologies, Inc.

Technical Publications

445 Round Rock West Drive

Round Rock, Texas 78681-5012

Loading...

Loading...