Page 1

GROUP TAB LOCATOR

Maintenance Schedules

0

Cooling 2.5L Turbo Diesel

7

Electronic Control Modules

8E

Engine Systems

8F

Ignition Control

8I

Engine

9

Exhaust System and Turbocharger

11

Fuel System

14

Emissions Control 2.5L Turbo Diesel

25

Service Manual Comment Forms (Rear of Manual)

Page 2

RG MAINTENANCE SCHEDULES 0-1

MAINTENANCE SCHEDULES

TABLE OF CONTENTS

page

MAINTENANCE SCHEDULES FOR ALL

MARKETS EXCEPT U.S., CANADA and

MEXICO

DESCRIPTION — DIESEL ENGINES .........1

MAINTENANCE SCHEDULES

FOR ALL MARKETS EXCEPT

U.S., CANADA and MEXICO

DESCRIPTION — DIESEL ENGINES

Maintenance Schedule Information not included in

this section, is located in the appropriate Owner’s

Manual.

There are two maintenance schedules that show

the required service for your vehicle.

First is Schedule “B”. It is for vehicles that are

operated under the conditions that are listed below

and at the beginning of the schedule.

• Extensive engine idling.

• Driving in dusty conditions.

• More than 50% of your driving is at sustained

high speeds during hot weather, above 32° C (90° F).

• Trailer towing.

• Taxi, police, or delivery service (commercial ser-

vice).

NOTE: Most vehicles are operated under the conditions listed for Schedule ⴖBⴖ.

Second is Schedule “A”. It is for vehicles that are

not operated under any of the conditions listed under

Schedule ⬙B⬙.

Use the schedule that best describes your driving

conditions. Where time and mileage are listed, follow

the interval that occurs first.

CAUTION: Failure to perform the required maintenance items may result in damage to the vehicle.

At Each Stop for Fuel

• Check the engine oil level about 5 minutes after

a fully warmed engine is shut off. Checking the oil

level while the vehicle is on level ground will

improve the accuracy of the oil level reading. Add oil

only when the level is at or below the ADD or MIN

mark.

• Check the windshield washer solvent and add if

required.

Once a Month

• Check the tire pressure and look for unusual

wear or damage.

• Inspect the battery and clean and tighten the

terminals as required.

• Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission

and add as needed.

• Check all lights and all other electrical items for

correct operation.

At Each Oil Change

• Change the engine oil filter.

• Inspect the exhaust system.

• Inspect the brake hoses.

• Inspect the CV joints and front suspension com-

ponents.

• Check the manual transmission fluid level.

• Check the coolant level, hoses, and clamps.

• Inspect engine accessory drive belts. Replace as

necessary.

• Inspect for the presence of water in the fuel filter/water separator unit.

• Rotate the tires at each oil change interval (20

000 km).

SCHEDULE “B”

Follow schedule “B” if you usually operate your

vehicle under one or more of the following conditions.

• Extensive engine idling.

• Driving in dusty conditions.

• More than 50% of your driving is at sustained

high speeds during hot weather, above 32° C (90° F).

• Trailer towing.

• Taxi, police, or delivery service (commercial ser-

vice).

Page 3

0 - 2 MAINTENANCE SCHEDULES RG

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

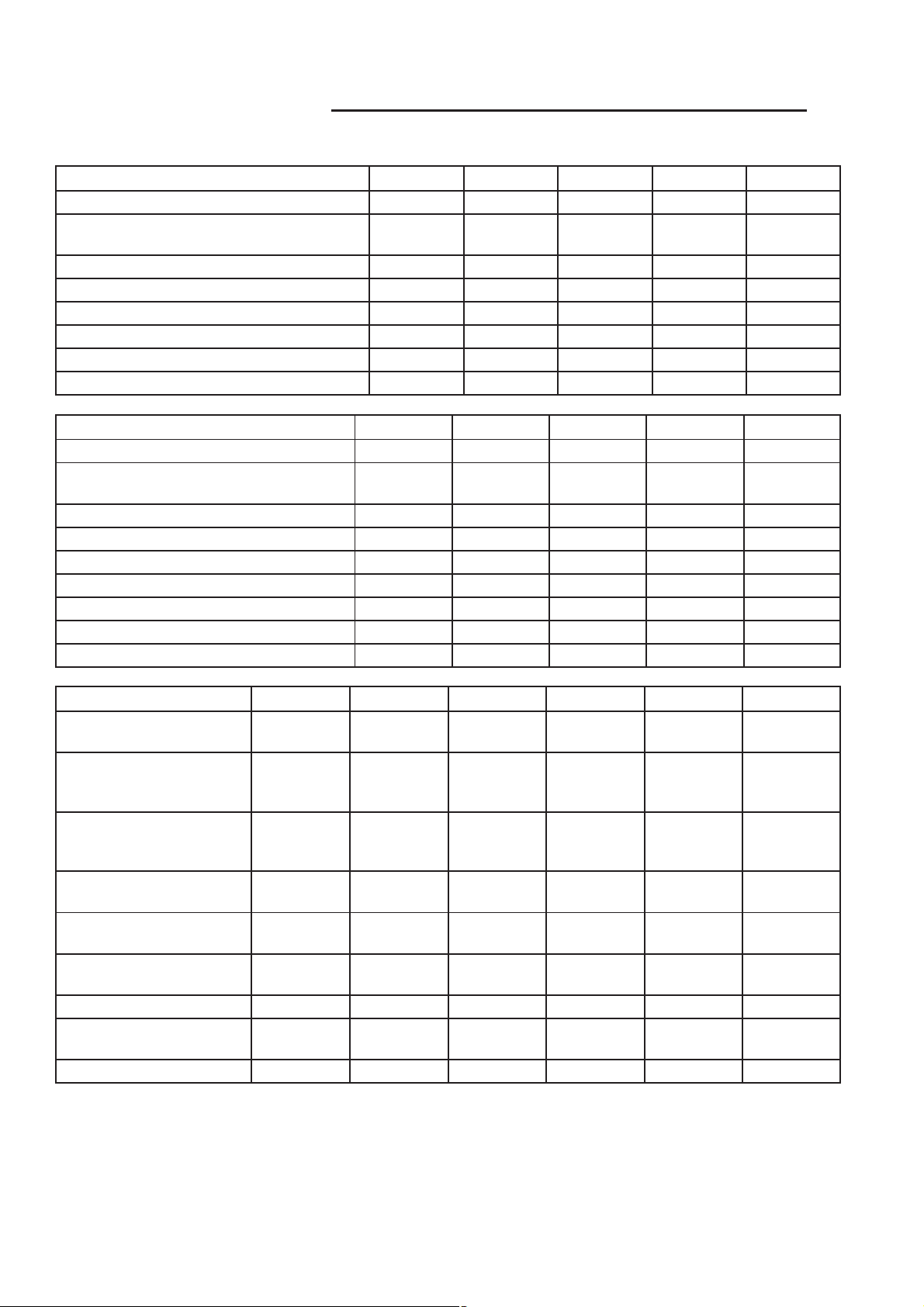

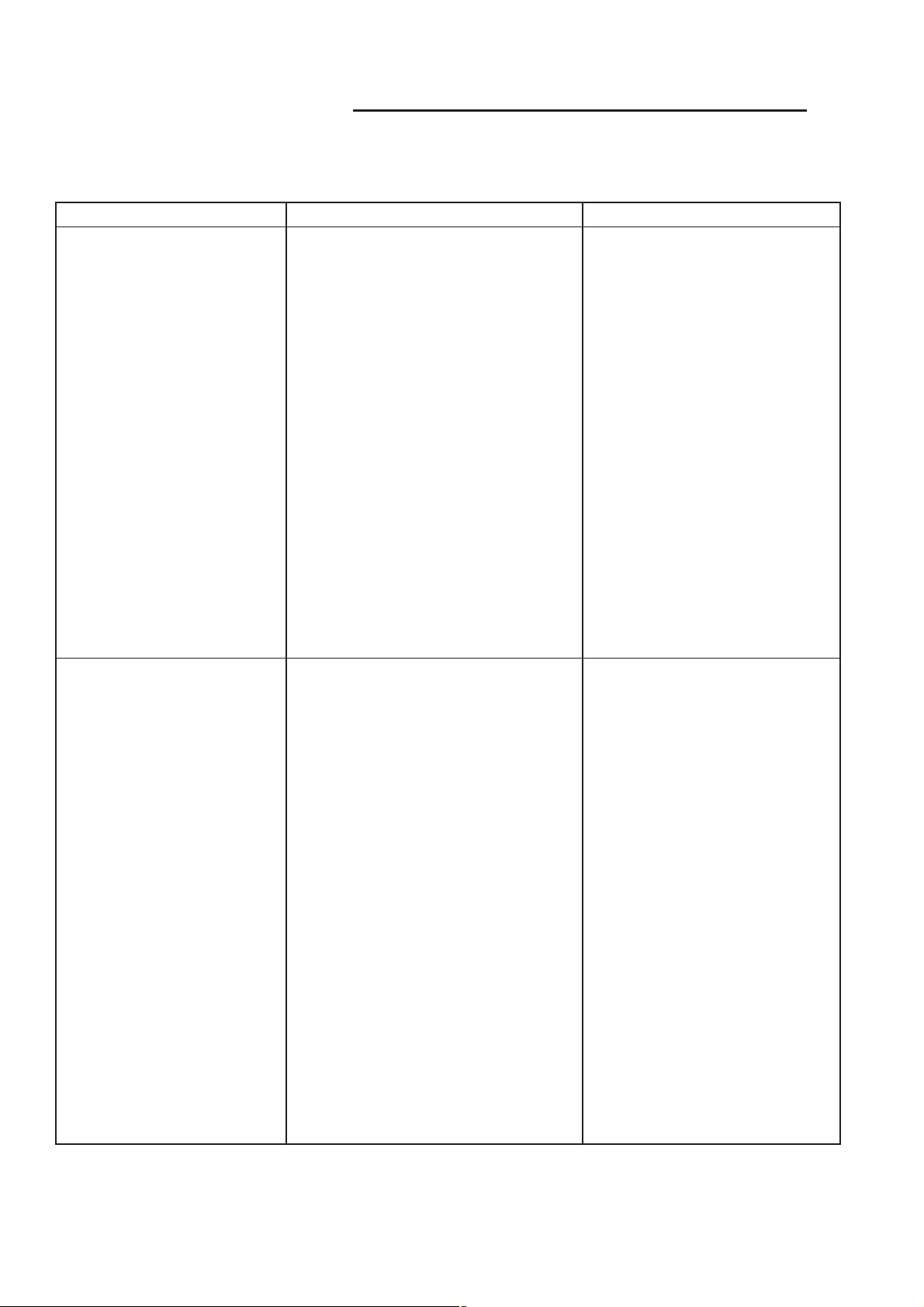

Kilometers 10 000 km 20 000 km 30 000 km 40 000 km 50 000 km

Change engine oil and engine oil filter. XXXXX

Inspect engine air filter element. Replace as

necessary.

Replace engine air filter element X X

Replace fuel filter/water separator unit. X X

Check front end alignment. X X

Change the manual transaxle fluid. X

Inspect the tie rod ends and boot seals. X

Inspect the brake linings. XXXXX

Kilometers 60 000 km 70 000 km 80 000 km 90 000 km 100 000 km

Change engine oil and engine oil filter. XXXXX

Inspect engine air filter element. Replace

as necessary.

Replace engine air filter element X X X

Replace fuel filter/water separator unit. X X X

Replace engine timing belt. X

Check front end alignment. X X

Change the manual transaxle fluid. X X

Inspect the tie rod ends and boot seals. X

Inspect the brake linings. XXXXX

XXX

XX

Kilometers 110 000 km 120 000 km 130 000 km 140 000 km 150 000 km 160 000 km

Change engine oil and

engine oil filter.

Inspect engine air filter

element. Replace as

necessary.

Inspect accessory drive

belts and replace if

necessary.

Replace engine air filter

element

Replace fuel filter/water

separator unit.

Flush and replace engine

coolant.

Check front end alignment. X X X

Inspect the tie rod ends and

boot seals.

Inspect the brake linings. XXXXXX

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

XXXXXX

XXX

X

XXX

XXX

X

XX

Page 4

RG MAINTENANCE SCHEDULES 0-3

MAINTENANCE SCHEDULES FOR ALL MARKETS EXCEPT U.S., CANADA and MEXICO (Continued)

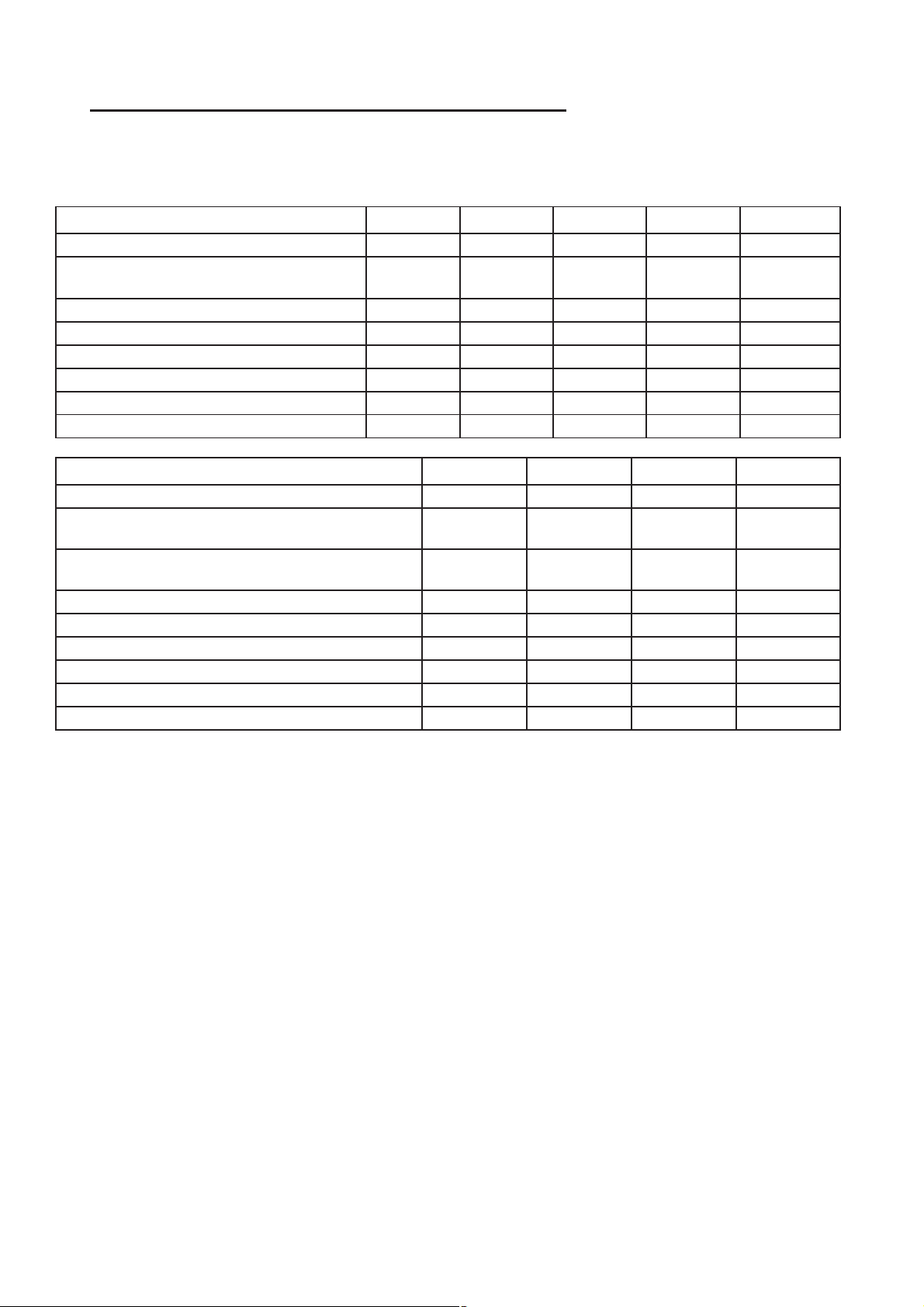

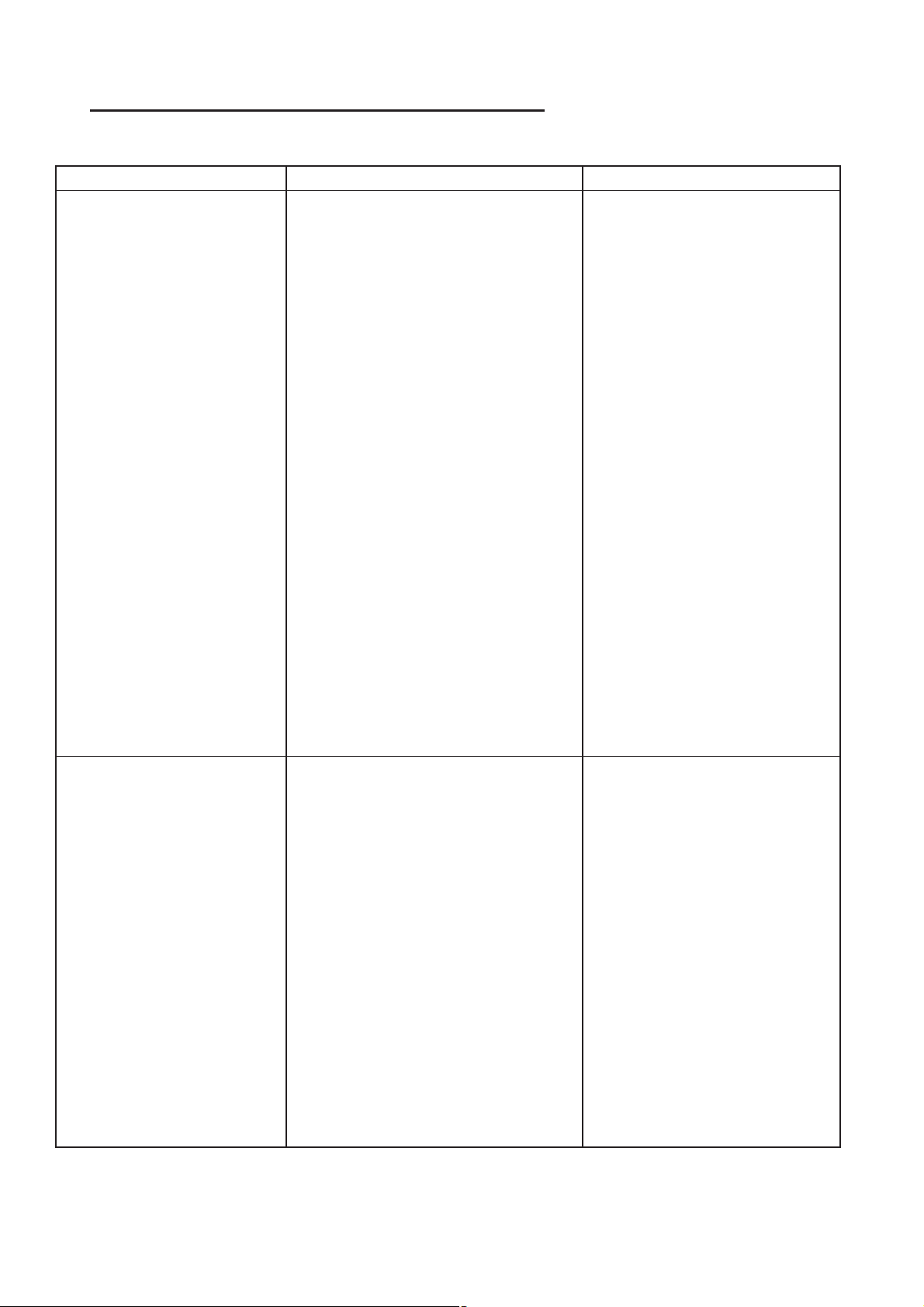

SCHEDULE “A”

Kilometers 20 000 km 40 000 km 60 000 km 80 000 km 100 000 km

Change engine oil and engine oil filter. XXXX X

Inspect engine air filter element. Replace

as necessary.

Replace engine air filter element X X

Replace fuel filter/water separator unit. XXXX X

Replace engine timing belt. X

Check front end alignment. X X

Inspect the tie rod ends and boot seals. X X

Inspect the brake linings. XXXX X

Kilometers 120 000 km 140 000 km 160 000 km 180 000 km

Change engine oil and engine oil filter. X X X X

Inspect engine air filter element. Replace as

necessary.

Inspect accessory drive belts and replace if

necessary.

Replace engine air filter element X X

Replace fuel filter/water separator unit. X X X X

Flush and replace engine coolant. X

Check front end alignment. X X

Inspect the tie rod ends and boot seals. X X

Inspect the brake linings. X X X X

XX X

XX

X

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the right

equipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

Page 5

Page 6

RG COOLING 2.5L TURBO DIESEL 7-1

COOLING 2.5L TURBO DIESEL

TABLE OF CONTENTS

page page

COOLING 2.5L TURBO DIESEL

DESCRIPTION - COOLING SYSTEM .........1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING

SYSTEM .............................1

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAK TEST....................6

DIAGNOSIS AND TESTING - COOLING

SYSTEM FLOW CHECK .................7

DIAGNOSIS AND TESTING - COOLING

SYSTEM AERATION ....................7

COOLING 2.5L TURBO DIESEL

DESCRIPTION - COOLING SYSTEM

The cooling system regulates engine operating temperature. It allows the engine to reach normal operating temperature as quickly as possible, maintains

normal operating temperature and prevents overheating.

The cooling system also provides a means of heating the passenger compartment. The cooling system

is pressurized and uses a centrifugal water pump to

circulate coolant throughout the system. A separate

and remotely mounted, pressurized coolant tank

using a pressure/vent cap is used.

COOLING SYSTEM COMPONENTS

The cooling system consists of:

• Charge Air Cooler

• Electric Cooling Fans

• A aluminum-core radiator with plastic side

tanks

• A separate pressurized coolant tank

• A pressure/vent cap on the coolant tank

• Fan shroud

• Thermostat

• Coolant

• Low coolant warning lamp

• Coolant temperature gauge

• Water pump

• Hoses and hose clamps

CLEANING .............................7

INSPECTION ...........................7

SPECIFICATIONS

SPECIFICATIONS - TORQUE .............8

SPECIFICATIONS - COOLING SYSTEM

CAPACITY............................8

ACCESSORY DRIVE .......................9

ENGINE ...............................14

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING SYSTEM

Establish what driving conditions caused the complaint. Abnormal loads on the cooling system such as

the following may be the cause:

(1) PROLONGED IDLE, VERY HIGH AMBIENT

TEMPERATURE, SLIGHT TAIL WIND AT IDLE,

SLOW TRAFFIC, TRAFFIC JAMS, HIGH SPEED

OR STEEP GRADES.

• Idle with A/C off when temperature gauge is at

end of normal range.

(2) TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

(3) RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been performed on vehicle that may effect cooling system.

This may be:

• Engine adjustments (incorrect timing)

• Slipping engine accessory drive belt

• Brakes (possibly dragging)

• Changed parts (incorrect water pump)

• Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating complaint, refer to following Cooling System Diagnosis

charts.

These charts are to be used as a quick-reference

only.

Page 7

7 - 2 COOLING 2.5L TURBO DIESEL RG

COOLING 2.5L TURBO DIESEL (Continued)

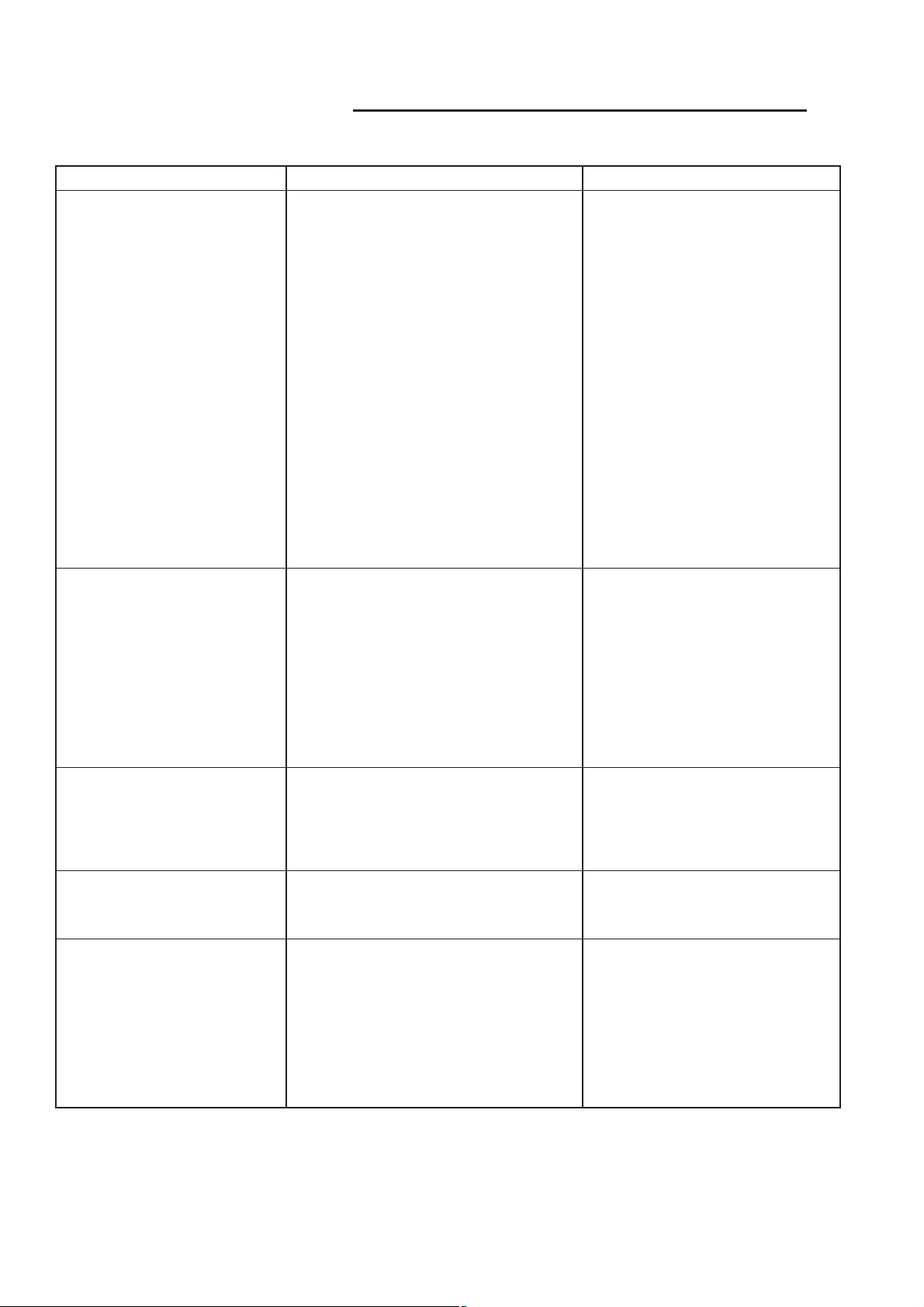

COOLING SYSTEM DIAGNOSIS-DIESEL ENGINE

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE

READS LOW

TEMPERATURE GAUGE

READS HIGH. COOLANT

MAY OR MAY NOT BE

LOST OR LEAKING FROM

COOLING SYSTEM

1. Diesel engines, due to their

inherent efficiency are slower to

warm up than gasoline powered

engines, and will operate at lower

temperatures when the vehicle is

unloaded.

2. Is the temperature gauge

connected to the temperature gauge

coolant sensor on the engine?

3. Is the temperature gauge

operating OK?

4. Coolant level low in cold ambient

temperatures accompanied with poor

heater performance.

5. Improper operation of internal

heater doors or heater controls.

1. Trailer is being towed, a steep hill

is being climbed, vehicle is operated

in slow moving traffic, or engine is

being idled with very high ambient

(outside) temperature and the air

conditioning is on. Higher altitudes

could aggravate these conditions.

2. Temperature gauge reading

incorrectly.

3. Coolant low in coolant tank and

radiator.

4. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered.

5. Poor seals at pressure/vent cap. 5. (a) Check condition of cap

1. The low gauge reading may

be normal. Refer to thermostats

in the manual text for

information. See Thermostat

Diagnosis-Diesel Engine.

2. Check, the engine

temperature sensor connector

in the engine compartment.

3. Check gauge operation.

Repair as necessary.

4. Check coolant level in the

coolant tank. Inspect system for

leaks. Repair leaks as

necessary. Refer to the Coolant

section for WARNINGS and

precautions before removing

the pressure cap.

5. Inspect heater and repair as

necessary. Refer to Heating

and Air Conditioning for

procedures.

1. This may be a temporary

condition and repair is not

necessary. Turn off the air

conditioning and attempt to

drive the vehicle without any of

the previous conditions.

Observe the temperature

gauge. The gauge should return

to the normal range. If the

gauge does not return to

normal range, determine the

cause for the overheating and

repair.

2. Check gauge. Refer to I/P

group.

3. Check for coolant leaks and

repair as necessary.

4. Tighten cap.

and cap seals. (b) Check

condition of coolant tank filler

neck. Make sure it does not

leak pressure.

Page 8

RG COOLING 2.5L TURBO DIESEL 7-3

COOLING 2.5L TURBO DIESEL (Continued)

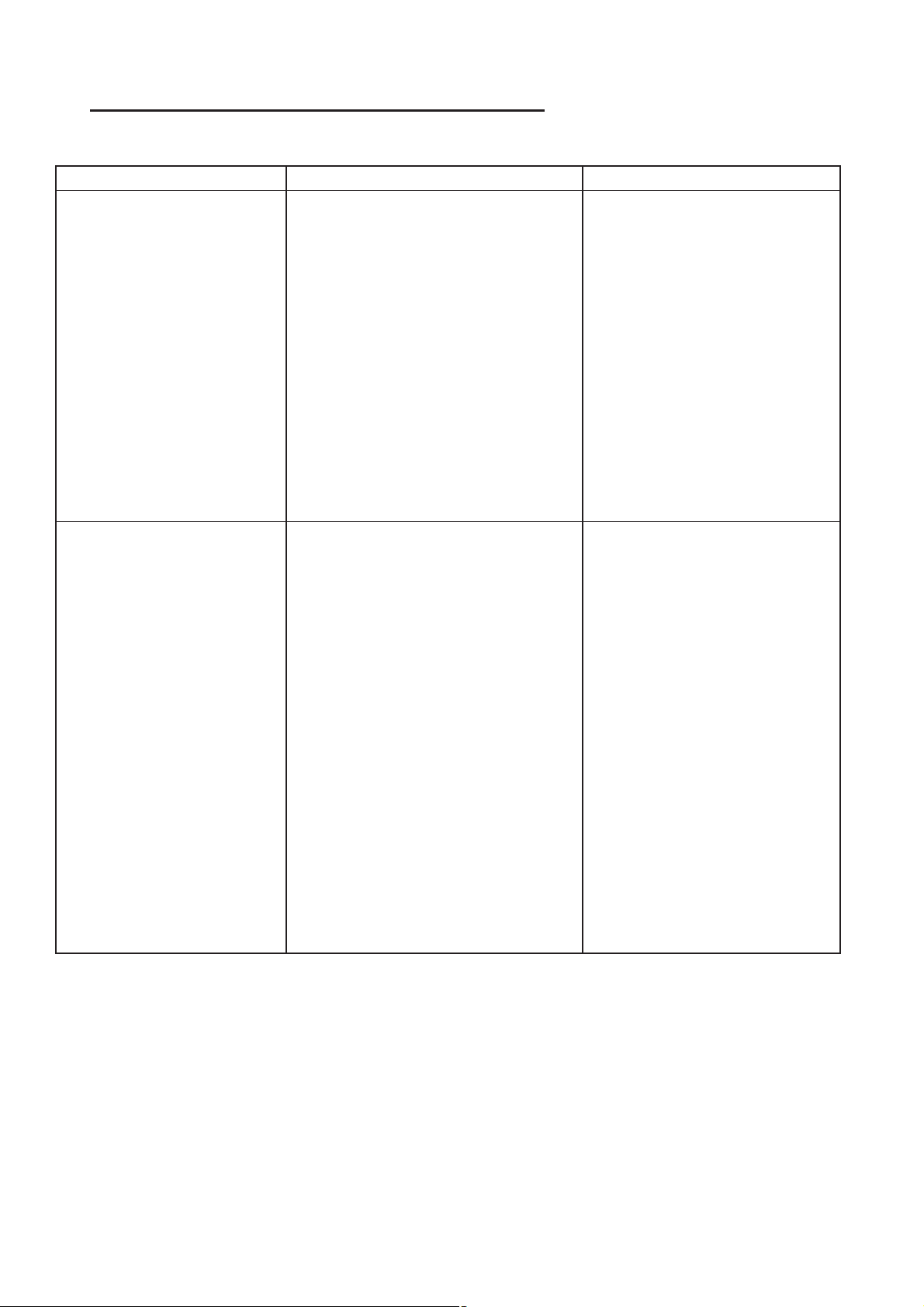

CONDITION POSSIBLE CAUSES CORRECTION

6. Freeze point of antifreeze not

correct. Mixture may be too rich.

7. Coolant not flowing through

system.

8. Radiator or A/C condenser fins

are dirty or clogged.

9. Radiator core is corroded or

plugged.

10. Aftermarket A/C installed without

proper A/C condenser.

11. Dragging Brakes. 11. Check and correct as

12. Non-factory bug screen is being

used reducing air flow.

13. Thermostat partially or

completely shut. This is more

prevalent on high mileage vehicles.

14. Cylinder head gasket leaking. 14. Check cylinder head gasket

15. Heater core leaking. 15. Check heater core for

6. Check antifreeze. Adjust

antifreeze-to-water ratio as

required.

7. Check for coolant flow in

coolant tank with engine warm

and thermostat open. Coolant

should be observed flowing

through the tank. If flow is not

observed, determine reason for

lack of flow and repair as

necessary.

8. Clean debris from radiator or

A/C condenser

9. Have radiator re-cored or

replaced.

10. Install proper A/C

condenser.

necessary.

12. Only a factory screen

should be used.

13. Check thermostat and

replace if necessary.

for leaks.

leaks. Repair as necessary.

TEMPERATURE GAUGE

READING IS

INCONSISTENT

(FLUCTUATES, CYCLES

OR IS ERRATIC)

1. During cold weather operation,

with the heater blower in the high

position, the gauge reading may

drop slightly. Fluctuation is also

influenced by loads, outside

temperature and extended idle time

with diesel engines.

2. Temperature gauge or engine

mounted gauge sensor defective or

shorted. Also, corroded or loose

wiring in this circuit.

3. Gauge reading rises when vehicle

is brought to a stop after heavy use

(engine still running).

4. Gauge reading high after starting

a warm-up (hot) engine.

1. A normal condition. No

correction is necessary.

2. Check operation of gauge

and repair as necessary.

3. A normal condition. No

correction needed. Gauge

should return to normal range

after vehicle is driven.

4. A normal condition. No

correction needed. Gauge

should return to normal after a

few minutes of engine

operation.

Page 9

7 - 4 COOLING 2.5L TURBO DIESEL RG

COOLING 2.5L TURBO DIESEL (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

PRESSURE CAP IS

BLOWING OFF STEAM

AND/OR COOLANT.

TEMPERATURE GAUGE

READING MAY BE ABOVE

NORMAL BUT NOT HIGH.

COOLANT LEVEL MAY BE

HIGH IN COOLANT TANK

5. Coolant level low in the coolant

tank (air will build up in the cooling

system causing the thermostat to

open late).

6. Cylinder head gasket leaking

allowing exhaust gases to enter the

cooling system causing the

thermostat to open late.

7. Water pump impeller loose on

shaft.

8. Loose accessory drive belt (water

pump slipping).

9. Air leak on the suction side of the

water pump allowing air to build up

in the cooling system causing the

thermostat to open late.

1. Pressure relief valve in pressure/

vent cap is defective.

2. Head gasket leak or cracked

cylinder head.

5. Check and correct coolant

leaks.

6. (a) Check for cylinder head

gasket leaks with a

commercially available leak

tester. (b) Check for coolant in

engine oil. Inspect for white

steam emitting from exhaust

system. Repair as necessary.

7. Check water pump and

replace as necessary.

8. Check and correct as

necessary.

9. Locate leak and repair as

necessary.

1. Check condition of

pressure/vent cap and cap

seals.

2. Repair as necessary.

COOLANT LOSS TO THE

GROUND WITHOUT

PRESSURE CAP

BLOWOFF. GAUGE IS

READING HIGH OR HOT

HOSE OR HOSES

COLLAPSE WHEN

ENGINE IS COOLING

NOISY FAN 1. Cooling fan blades loose. 1. Replace cooling fan

1. Coolant leaks in radiator, cooling

system hoses, water pump, or

engine.

1. Vacuum created in cooling system

on engine cool-down is not being

relieved through pressure/vent cap.

2. Cooling fan blades striking a

surrounding object.

3. Air obstructions at radiator or A/C

condenser.

1. Pressure test cooling system

and repair as necessary.

1. Cap relief valve stuck.

Replace if necessary.

assembly.

2. Locate point of fan blade

contact and repair as

necessary.

3. Remove obstructions or

clean debris from radiator or

A/C condenser.

Page 10

RG COOLING 2.5L TURBO DIESEL 7-5

COOLING 2.5L TURBO DIESEL (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

INADEQUATE AIR

CONDITIONER

PERFORMANCE

(COOLING SYSTEM

SUSPECTED)

INADEQUATE HEATER

PERFORMANCE. MAY BE

ACCOMPANIED BY LOW

GAUGE READING

1. Radiator and/or A/C condenser is

restricted, obstructed or dirty

(insects, leaves, etc.)

2. Engine is overheating (heat may

be transferred from radiator to A/C

condenser. High Under hood

temperatures due to engine

overheating may also transfer heat

to A/C condenser).

3. The cooling system is equipped

with air seals at the radiator and/or

A/C condenser. If these seals are

missing or damaged, not enough air

flow will be pulled through the

radiator and A/C condenser.

1. Diesel engines, due to their

inherent efficiency are slower to

warm up than gasoline powered

engines, and will operate at lower

temperatures when the vehicle is

unloaded.

2. Coolant level low. 2. Pressure test cooling system.

3. Obstruction in heater hose fitting

at engine.

4. Heater hose kinked. 4. Locate kinked area. Repair

5. Water pump is not pumping water

to heater core. When the engine is

fully warmed up, both heater hoses

should be hot to the touch. If only

one of the hoses is hot the water

pump may not be operating correctly.

The accessory drive belt may also

be slipping causing poor water pump

operation.

1. Remove restriction or clean

debris from radiator or A/C

condenser.

2. Correct overheating

condition.

3. Check for missing or

damaged air seals. Repair as

necessary.

1. The lower gauge reading

may be normal.

Repair leaks as necessary.

3. Remove heater hoses and

check for obstructions. Repair

as necessary.

as necessary.

5. Refer to water pumps in this

group. Repair as necessary. If a

slipping belt is detected, refer to

Engine Accessory Drive Belts in

this group. Repair as

necessary.

Page 11

7 - 6 COOLING 2.5L TURBO DIESEL RG

COOLING 2.5L TURBO DIESEL (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

HEAT ODOR 1. Various heat shields are used at

certain drive line components. One

or more of these shields may be

missing.

2. Is temperature gauge reading

above the normal range?

3. Is the Cooling fan operating

correctly?

4. Has undercoating been applied to

any unnecessary components?

STEAM IS COMING FROM

FRONT OF VEHICLE

NEAR GRILL AREA WHEN

WEATHER IS WET,

ENGINE IS WARMED UP

AND RUNNING, AND

VEHICLE IS STATIONARY.

TEMPERATURE GAUGE

IS IN NORMAL RANGE

COOLANT ODOR 1. Coolant color is not necessarily an

1. During wet weather, moisture

(snow, ice, or rain condensation) on

the radiator will evaporate when the

thermostat opens. This opening

allows heated water into the radiator.

When the moisture contacts the hot

radiator, steam may be emitted. This

usually occurs in cold weather with

no fan or air flow to blow it away.

indication of adequate corrosion or

temperature protection. Do not rely

on coolant color for determining

condition of coolant.

1. Locate missing shields.

Repair or replace as necessary.

2. Refer to the previous

Temperature Gauge Reads

High in these Diagnostic

Charts. Repair as necessary.

3. Refer to Cooling System Fan

in this group for diagnosis.

Repair as necessary.

4. Clean undercoating as

necessary.

1. Occasional steam emitting

from this area is normal. No

repair is necessary.

1. Refer to Coolant in this group

for antifreeze tests. Adjust

antifreeze-to-water ratio as

necessary.

COOLANT LEVEL

CHANGES IN COOLANT

TANK. TEMPERATURE

GAUGEISINNORMAL

RANGE

1. Level changes are to be expected

as coolant volume fluctuates with

engine temperature. If the level in

the tank was between the HOT and

COLD marks at normal engine

operating temperature, the level

should return to within that range

after operation at elevated

temperatures.

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAK TEST

WARNING: THE WARNING WORDS “DO NOT OPEN

HOT” ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

1. This a normal condition. No

repair necessary.

With engine not running, remove pressure/vent cap

from the coolant recovery pressure container and

wipe the filler neck sealing seat clean. The coolant

recovery pressure container should be full.

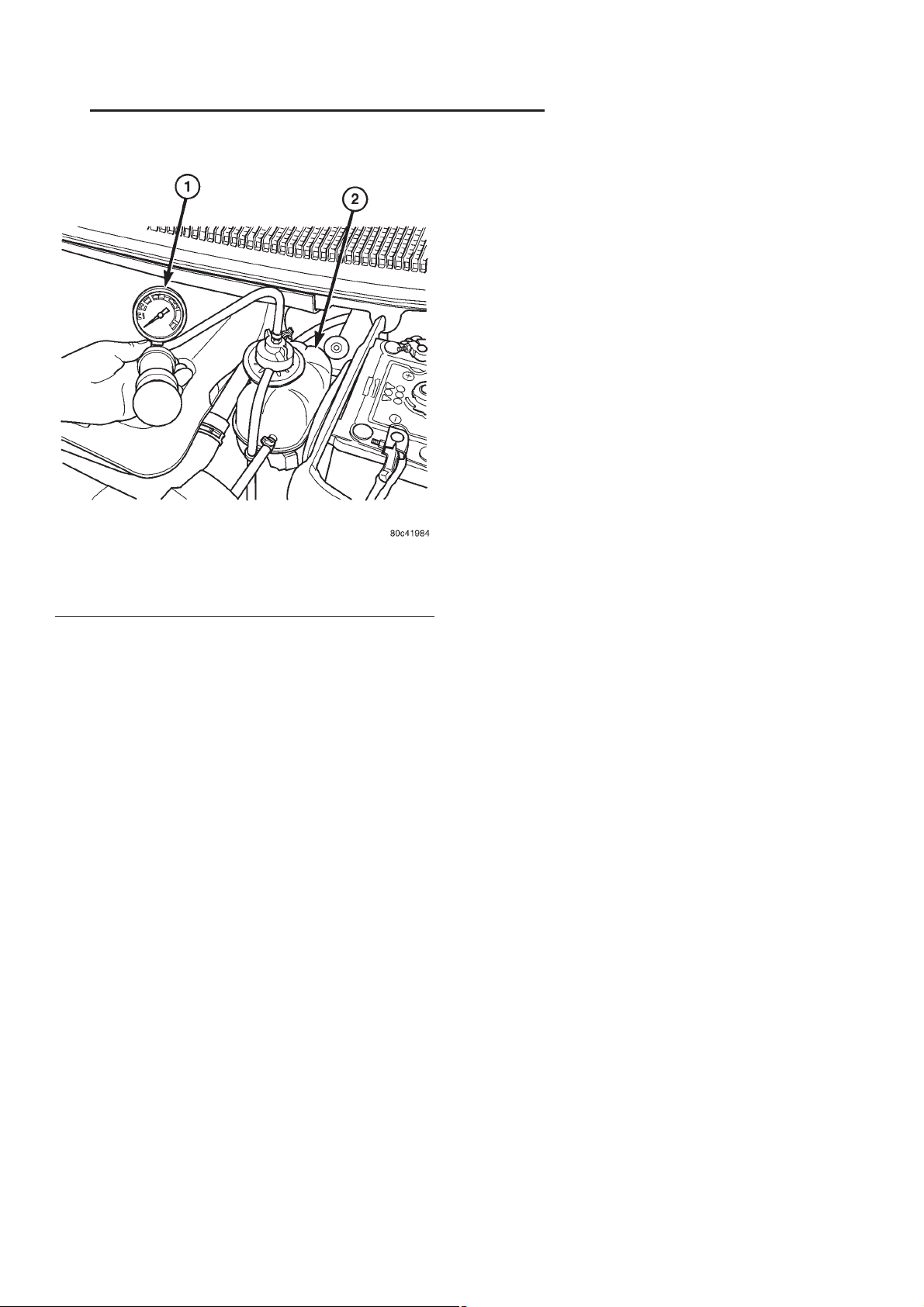

Attach the Cooling System Tester 7700 or equivalent to the radiator, as shown in (Fig. 1) and apply

104 kPa (15 psi) pressure. If the pressure drops more

than 13.8 kPa (2 psi) in 2 minutes, inspect all points

for external leaks.

All radiator and heater hoses should be shaken

while at 104 kPa (15 psi), since some leaks occur only

while driving due to engine movement.

Page 12

RG COOLING 2.5L TURBO DIESEL 7-7

COOLING 2.5L TURBO DIESEL (Continued)

DIAGNOSIS AND TESTING - COOLING SYSTEM

FLOW CHECK

To determine whether coolant is flowing through

the cooling system, use the following procedures:

(1) If engine is cold, idle engine until normal operating temperature is reached. Then feel the upper

radiator hose. If it is hot, coolant is circulating.

WARNING: DO NOT REMOVE THE COOLING SYSTEM PRESSURE CAP WITH THE SYSTEM HOT AND

UNDER PRESSURE BECAUSE SERIOUS BURNS

FROM COOLANT CAN OCCUR.

(2) Remove pressure/vent cap when engine is cold,

idle engine until thermostat opens, you should

observe coolant flow while looking down in the coolant recovery pressure container. Once flow is

detected install the pressure/vent cap.

DIAGNOSIS AND TESTING - COOLING SYSTEM

AERATION

Fig. 1 PRESSURE TESTING COOLING SYSTEM

1 - COOLING SYSTEM PRESSURE TESTER

2 - COOLANT RECOVERY PRESSURE CONTAINER

If there are no external leaks, after the gauge dial

shows a drop in pressure, detach the tester. Start

engine and run until the thermostat opens, allowing

the coolant to expand. Reattach the cooling system

tester. If the needle on the dial fluctuates it indicates

a combustion leak, usually a head gasket leak.

WARNING: WITH TOOL IN PLACE, PRESSURE WILL

BUILD UP FAST. EXCESSIVE PRESSURE BUILT UP,

BY CONTINUOUS ENGINE OPERATION, MUST BE

RELEASED TO A SAFE PRESSURE POINT. NEVER

PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, raise

the engine rpm a few times. If an abnormal amount

of coolant or steam emits from the tailpipe, it may

indicate a coolant leak caused by a faulty head gasket, cracked engine block, or cracked cylinder head.

There may be internal leaks that can be determined by removing the oil dipstick. If water globules

appear intermixed with the oil it will indicate an

internal leak in the engine. If there is an internal

leak, the engine must be disassembled for repair.

Low coolant level in a cross flow radiator will

equalize in both tanks with engine off. With engine

at running and at operating temperature, the high

pressure inlet tank runs full and the low pressure

outlet tank drops, resulting in cooling system aeration. Aeration will draw air into the water pump

resulting in the following:

• High reading shown on the temperature gauge.

• Loss of coolant flow through the heater core.

• Corrosion in the cooling system.

• Water pump seal may run dry, increasing the

risk of premature seal failure.

• Combustion gas leaks into the coolant can also

cause aeration.

CLEANING

Drain cooling system and refill with clean water.

Refer to procedures in this section. Run engine with

pressure/vent cap installed until upper radiator hose

is hot. Stop engine and drain water from system. If

water is dirty; fill, run, and drain system again, until

water runs clear.

INSPECTION

After performing a cleaning/flush procedure,

inspect all hoses, clamps and connections for deterioration and leaks. Inspect radiator and heater core for

leaks.

Page 13

7 - 8 COOLING 2.5L TURBO DIESEL RG

COOLING 2.5L TURBO DIESEL (Continued)

SPECIFICATIONS

SPECIFICATIONS - TORQUE

2.5L DIESEL - TORQUE SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Water Pump Housing Nuts 24.4 18 215

Thermostat Housing Bolts 27.5 21 —

Accessory Drive Belt

Tensioner Bolt

Accessory Drive Belt Idler

Bolt

47.1 35 —

53 39 —

SPECIFICATIONS - COOLING SYSTEM

CAPACITY

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Cooling System With

Auxiliary Heater

Cooling System With Out

Auxiliary Heater

16.6 Liters (17.5 qts.)

13.8 Liters (14.6 qts.)

Page 14

RG ACCESSORY DRIVE 7-9

ACCESSORY DRIVE

TABLE OF CONTENTS

page page

ACCESSORY DRIVE

SPECIFICATIONS - ACCESSORY BELT

TENSION .............................9

BELT TENSIONER

REMOVAL .............................9

INSTALLATION ..........................9

IDLER PULLEY

REMOVAL .............................10

INSTALLATION .........................10

DRIVE BELTS

DESCRIPTION

DESCRIPTION - ACCESSORY DRIVE BELT . 10

ACCESSORY DRIVE

SPECIFICATIONS - ACCESSORY BELT TENSION

ACCESSORY DRIVE

BELT

2.5L DIESEL ENGINE

A/C Compressor/

Generator

Power Steering Belt 300 N (67 lbs.)

GAUGE

Dynamic Tensioner

DESCRIPTION - POWER STEERING BELT . . 10

OPERATION

OPERATION-ACCESSORY DRIVE BELT ....10

OPERATION-POWER STEERING BELT .....11

DIAGNOSIS AND TESTING - ACCESSORY

DRIVEBELT .........................11

REMOVAL

REMOVAL-ACCESSORY DRIVE BELT ......11

REMOVAL ...........................11

INSTALLATION

INSTALLATION-ACCESSORY DRIVE BELT . . 13

INSTALLATION-POWER STEERING BELT . . . 13

BELT TENSIONER

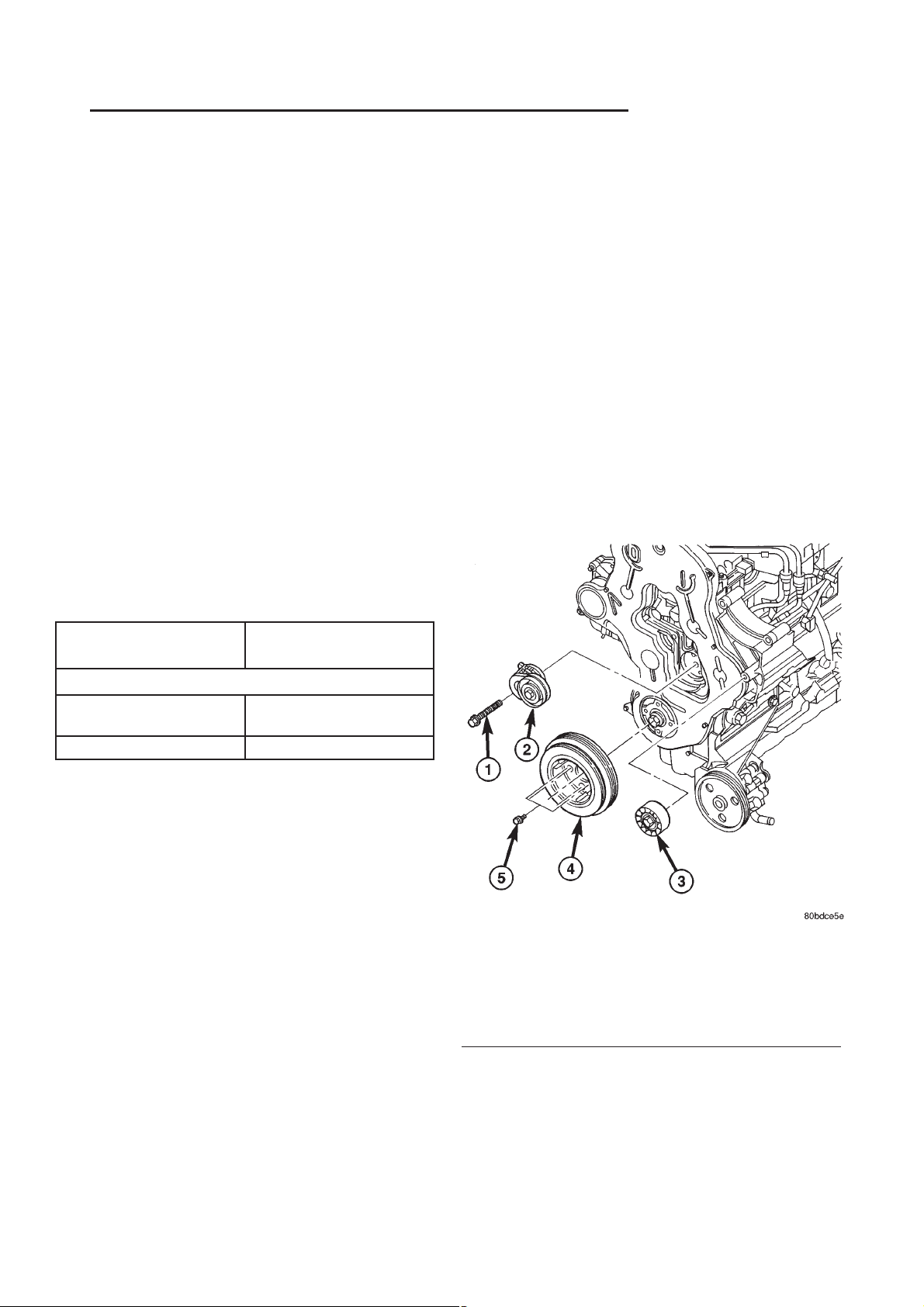

REMOVAL

WARNING:: BECAUSE OF HIGH SPRING TENSION,

DO NOT ATTEMPT TO DISASSEMBLE THE AUTOMATIC BELT TENSIONER. THE TENSIONER IS SERVICED AS AN ASSEMBLY.

(1) Remove the power steering belt (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS REMOVAL).

(2) Remove the accessory drive belt (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS INSTALLATION).

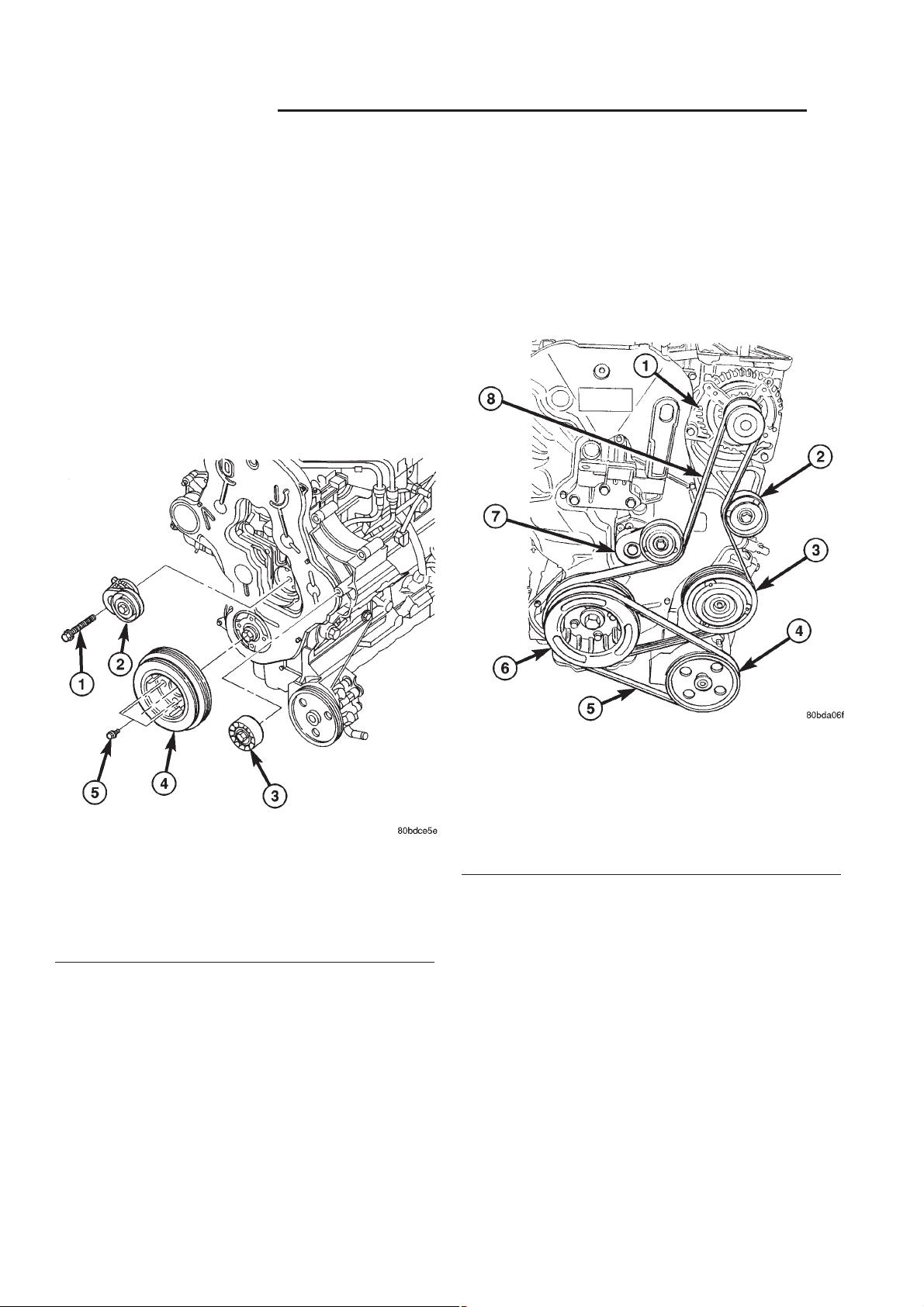

(3) Remove the belt tensioner retaining bolt and

remove tensioner (Fig. 1).

Fig. 1 BELT TENSIONER AND IDLER PULLEY

1 - BELT TENSIONER RETAINING BOLT

2 - BELT TENSIONER

3 - IDLER PULLEY

4 - VIBRATION DAMPER/CRANKSHAFT PULLEY

5 - VIBRATION DAMPER/CRANKSHAFT PULLEY RETAINING

BOLTS

INSTALLATION

(1) Install belt tensioner and retaining bolt (Fig.

1). Torque bolt to 47 N·m (35ft. lbs.).

(2) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS INSTALLATION).

Page 15

7 - 10 ACCESSORY DRIVE RG

BELT TENSIONER (Continued)

(3) Install the power steering belt (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS INSTALLATION).

IDLER PULLEY

REMOVAL

(1) Remove the accessory drive belt (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS REMOVAL).

CAUTION: IDLER PULLEY RETAINING BOLT HAS

LEFT HAND THREAD

(2) Remove the idler pulley (Fig. 2).

DRIVE BELTS

DESCRIPTION

DESCRIPTION - ACCESSORY DRIVE BELT

The accessory drive belt is a serpentine type belt

(Fig. 3). Satisfactory performance of these belts

depends on belt condition and proper belt tension.

Fig. 2 BELT TENSIONER AND IDLER PULLEY

1 - BELT TENSIONER RETAINING BOLT

2 - BELT TENSIONER

3 - IDLER PULLEY

4 - VIBRATION DAMPER/CRANKSHAFT PULLEY

5 - VIBRATION DAMPER/CRANKSHAFT PULLEY RETAINING

BOLTS

INSTALLATION

(1) Install the idler pulley (Fig. 2). Torque retain-

ing bolt to 22 N·m (16 ft. lbs.).

(2) Install the accessory drive belt (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS INSTALLATION).

(3) Install the power steering belt (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS INSTALLATION).

Fig. 3 ACCESSORY DRIVE BELT ROUTING

1 - GENERATOR

2 - IDLER PULLEY

3 - A/C COMPRESSOR CLUTCH

4 - POWER STEERING PUMP PULLEY

5 - POWER STEERING BELT

6 - CRANKSHAFT DAMPER/PULLEY

7 - BELT TENSIONER

8 - ACCESSORY DRIVE BELT

DESCRIPTION - POWER STEERING BELT

The power steering belt is a serpentine type belt

(Fig. 3). Satisfactory performance of this belt depends

on condition of the belt.

OPERATION

OPERATION-ACCESSORY DRIVE BELT

The accessory drive belts form the link between

the engine crankshaft and the engine driven accessories.

Page 16

RG ACCESSORY DRIVE 7-11

DRIVE BELTS (Continued)

OPERATION-POWER STEERING BELT

The power steering belt forms a link between the

engine crankshaft and the power steering pump.

DIAGNOSIS AND TESTING - ACCESSORY DRIVE BELT

CONDITION POSSIBLE CAUSES CORRECTIONS

INSUFFICIENT ACCESSORY

OUTPUT DUE TO BELT SLIPPAGE

BELT SQUEAL WHEN

ACCELERATING ENGINE

BELT SQUEAK AT IDLE 1. Belts too loose 1. Replace belt

BELT ROLLED OVER IN GROOVE

OR BELT JUMPS OFF

1. Belt too loose 1. Replace belt (auto-tensioned

belts)

2. Faulty belt tensioner 2. Replace tensioner as necessary

3. Belt excessively glazed or worn 3. Replace belt

1. Belts too loose 1. Check and replace belt tensioner

if necessary

2. Belt glazed 2. Replace belt

2. Dirt or paint imbedded in belt or

pulley

3. Non-uniform belt 3. Replace belt

4. Misaligned pulleys 4. Align accessories

5. Non-uniform groove or eccentric

pulley

1. Broken cord in belt 1. Replace belt

2. Belt too loose, or too tight 2. Replace belt

3. Misaligned pulleys 3. Align accessories

4. Non-uniform groove or eccentric

pulley

2. Replace belt, clean pulley

5. Replace pulley

4. Replace pulley

REMOVAL

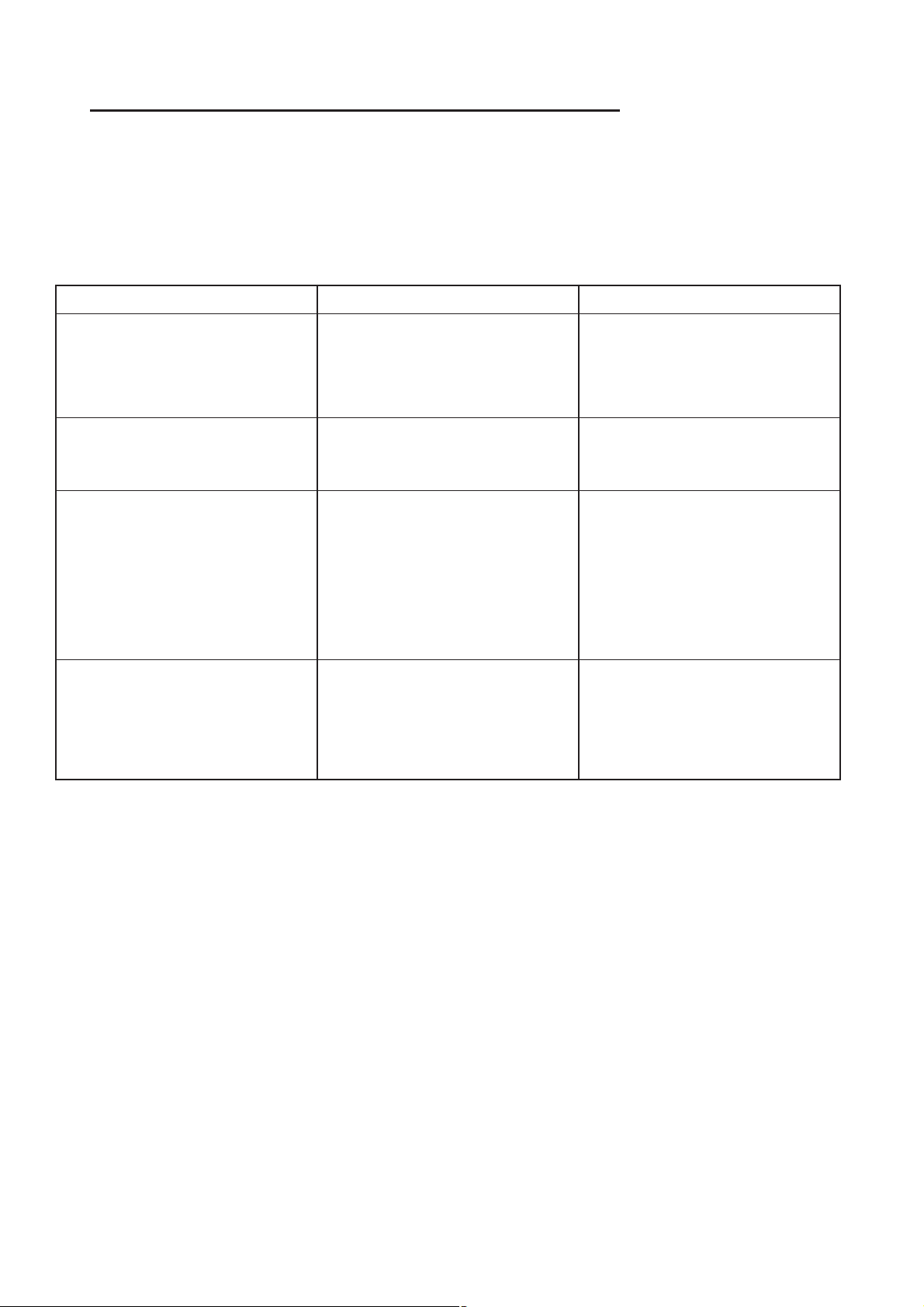

REMOVAL-ACCESSORY DRIVE BELT

(1) Remove the power steering belt (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS REMOVAL).

(2) Relieve tension on belt tensioner using a suitable wrench (Fig. 4) and lock tensioner with a drift

punch (Fig. 5).

(3) Remove the accessory drive belt.

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove right front fender inner splash shield.

(3) Install power steering belt remover tool on

crankshaft damper (Fig. 6).

(4) Rotate engine clockwise to remove belt (Fig. 7).

Page 17

7 - 12 ACCESSORY DRIVE RG

DRIVE BELTS (Continued)

Fig. 4 ACCESSORY DRIVE BELT REMOVAL

1 - BELT TENSIONER

2 - ACCESSORY DRIVE BELT

3 - IDLER PULLEY

4 - A/C COMPRESSOR CLUTCH

5 - CRANKSHAFT DAMPER/PULLEY

6 - WRENCH

Fig. 6 POWER STEERING BELT REMOVAL TOOL

1 - VIBRATION DAMPER

2 - POWER STEERING PULLEY

3 - POWER STEERING BELT

4 - POWER STEERING BELT REMOVER

Fig. 5 LOCKING/LOCKING BELT TENSIONER

Fig. 7 POWER STEERING BELT REMOVAL

1 - VIBRATION DAMPER

2 - POWER STEERING BELT

3 - POPWER STEERING BELT REMOVER

Page 18

RG ACCESSORY DRIVE 7-13

DRIVE BELTS (Continued)

INSTALLATION

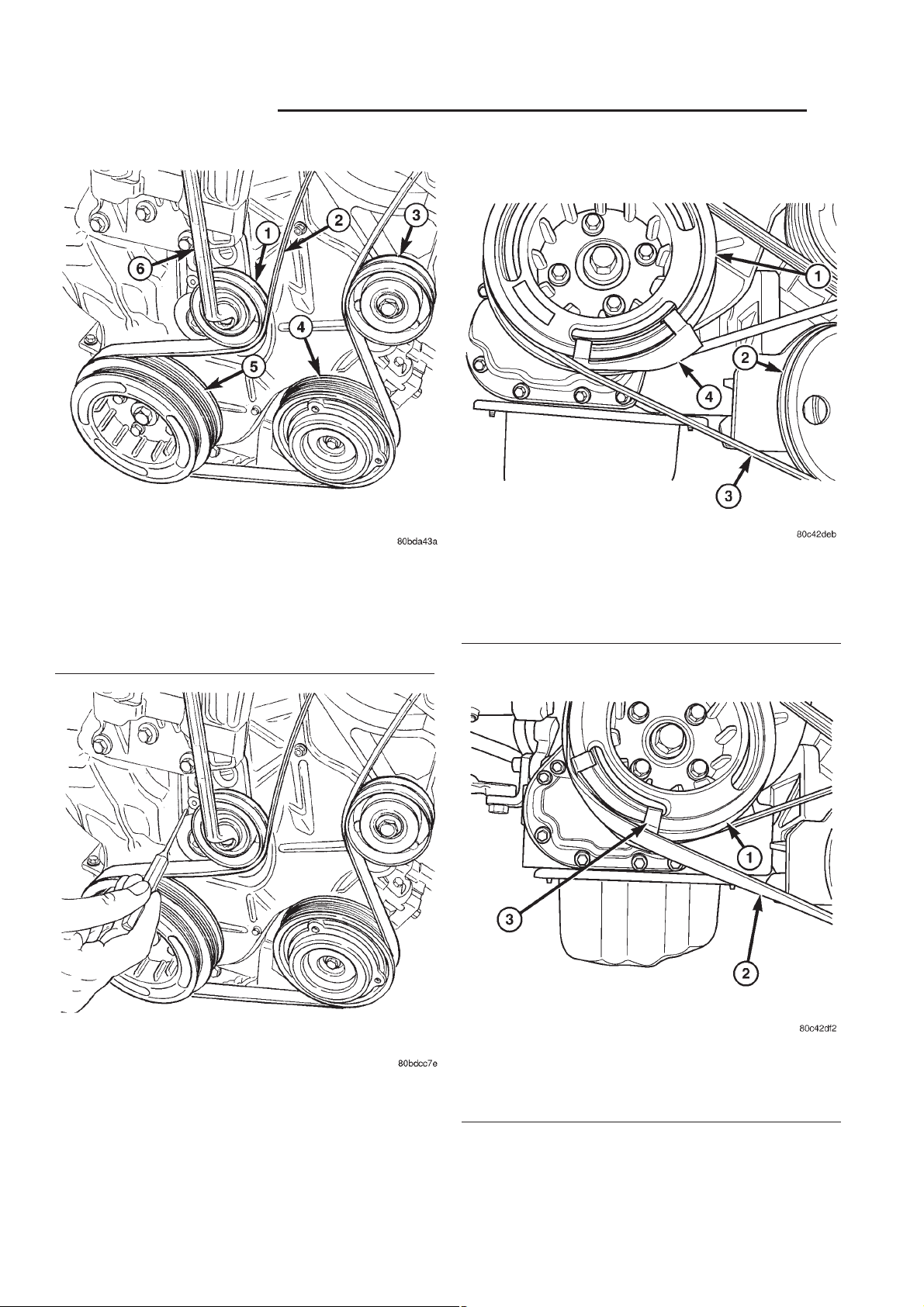

INSTALLATION-ACCESSORY DRIVE BELT

(1) Install the accessory drive belt in proper popsition (Fig. 8).

Fig. 8 ACCESSORY DRIVE BELT ROUTING

1 - GENERATOR

2 - IDLER PULLEY

3 - A/C COMPRESSOR CLUTCH

4 - POWER STEERING PUMP PULLEY

5 - POWER STEERING BELT

6 - CRANKSHAFT DAMPER/PULLEY

7 - BELT TENSIONER

8 - ACCESSORY DRIVE BELT

(2) Unlock belt tensioner by removing punch and

apply tension to accessory drive belt (Fig. 9).

(3) Install the power steering belt (Refer to 7 COOLING/ACCESSORY DRIVE/DRIVE BELTS INSTALLATION).

INSTALLATION-POWER STEERING BELT

(1) Install power steering belt installation tool

(Fig. 10).

(2) Install power steering belt on crankshaft and

rotate crankshaft clockwise until belt is fully

installed on crankshaft (Fig. 10).

(3) Remove installation tool from crankshaft.

(4) Install right front fender inner splash shield.

(5) Lower vehicle from hoist.

Fig. 9 LOCKING/UNLOCKING BELT TENSIONER

Fig. 10 POWER STEERING BELT INSTALLATION

1 - POWER STEERING BELT

2 - HOLDING HOOK

3 - POWER STEERING PUMP PULLEY

4 - VIBRATION DAMPER

5 - POWER STEERING BELT INSTALLATION TOOL

Page 19

7 - 14 ENGINE RG

ENGINE

TABLE OF CONTENTS

page page

COOLANT

DESCRIPTION .........................15

DIAGNOSIS AND TESTING - COOLANT

CONCENTRATION TESTING .............15

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLANT

SERVICE............................16

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................16

STANDARD PROCEDURE - COOLANT

LEVEL CHECK........................16

STANDARD PROCEDURE - COOLING

SYSTEM FILLING .....................16

STANDARD PROCEDURE - COOLING

SYSTEM DRAINING....................17

COOLANT RECOVERY PRESS CONTAINER

DESCRIPTION .........................17

OPERATION ...........................17

REMOVAL .............................18

INSTALLATION .........................18

ENGINE COOLANT TEMP SENSOR

DESCRIPTION .........................18

OPERATION ...........................18

REMOVAL .............................19

INSTALLATION .........................19

ENGINE COOLANT THERMOSTAT

DESCRIPTION .........................20

OPERATION ...........................20

REMOVAL .............................20

INSTALLATION .........................20

RADIATOR

DESCRIPTION .........................21

OPERATION ...........................21

REMOVAL .............................21

INSTALLATION .........................21

RADIATOR DRAINCOCK

REMOVAL .............................22

INSTALLATION .........................22

WATER PUMP

DESCRIPTION .........................22

OPERATION ...........................22

REMOVAL

REMOVAL-WATERPUMP ..............22

REMOVAL-WATERPUMPHOUSING ......22

CLEANING ............................23

INSTALLATION

INSTALLATION-WATERPUMP ..........23

INSTALLATION - WATER PUMP HOUSING . . 23

RADIATOR PRESSURE CAP

DESCRIPTION .........................23

OPERATION ...........................24

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING

SYSTEM PRESSURE CAP...............25

DIAGNOSIS AND TESTING - PRESSURE

RELIEFTEST ........................25

CLEANING ............................26

INSPECTION ..........................26

RADIATOR FAN

DESCRIPTION .........................26

OPERATION ...........................26

DIAGNOSIS AND TESTING - RADIATOR FAN

MOTOR .............................27

REMOVAL .............................27

INSTALLATION .........................27

HOSE CLAMPS

DESCRIPTION - HOSE CLAMPS ...........28

OPERATION - HOSE CLAMPS .............28

RADIATOR FAN RELAY

DESCRIPTION .........................28

OPERATION ...........................28

COOLANT SYSTEM HOSES

REMOVAL

REMOVAL - UPPER RADIATOR HOSE .....29

REMOVAL-LOWERRADIATORHOSE .....29

REMOVAL-COOLANTBYPASSHOSE .....29

INSTALLATION

INSTALLATION - UPPER RADIATOR HOSE . . 29

INSTALLATION - LOWER RADIATOR HOSE . 29

INSTALLATION - COOLANT BYPASS HOSE . 29

Page 20

RG ENGINE 7-15

COOLANT

DESCRIPTION

Coolant flows through the engine water jackets

and cylinder heads absorbing heat produced by the

engine during operation. The coolant carries heat to

the radiator and heater core. Here it is transferred to

ambient air passing through the radiator and heater

core fins.

The required ethylene-glycol (antifreeze) and water

mixture depends upon the climate and vehicle operating conditions. The recommended mixture of 50/50

ethylene-glycol and water will provide protection

against freezing to -37 deg. C (-35 deg. F). The antifreeze concentration must always be a minimum of

44 percent, year-round in all climates. If percentage

is lower than 44 percent, engine parts may be

eroded by cavitation, and cooling system components may be severely damaged by corrosion.

Maximum protection against freezing is provided

with a 68 percent antifreeze concentration, which

prevents freezing down to -67.7 deg. C (-90 deg. F). A

higher percentage will freeze at a warmer temperature. Also, a higher percentage of antifreeze can

cause the engine to overheat because the specific

heat of antifreeze is lower than that of water.

100 Percent Ethylene-Glycol—Should Not Be Used in

Chrysler Vehicles

Use of 100 percent ethylene-glycol will cause formation of additive deposits in the system, as the corrosion inhibitive additives in ethylene-glycol require

the presence of water to dissolve. The deposits act as

insulation, causing temperatures to rise to as high as

149 deg. C (300 deg. F). This temperature is hot

enough to melt plastic and soften solder. The

increased temperature can result in engine detonation. In addition, 100 percent ethylene-glycol freezes

at -22 deg. C (-8 deg. F ).

Propylene-glycol Formulations—Should Not Be Used in

Chrysler Vehicles

Propylene-glycol formulations do not meet

Chrysler coolant specifications. It’s overall effec-

tive temperature range is smaller than that of ethylene-glycol. The freeze point of 50/50 propylene-glycol

and water is -32 deg. C (-26 deg. F). 5 deg. C higher

than ethylene-glycol’s freeze point. The boiling point

(protection against summer boil-over) of propyleneglycol is 125 deg. C (257 deg.F)at96.5 kPa (14 psi),

compared to 128 deg. C (263 deg. F) for ethylene-glycol. Use of propylene-glycol can result in boil-over or

freeze-up in Chrysler vehicles, which are designed for

ethylene-glycol. Propylene glycol also has poorer heat

transfer characteristics than ethylene glycol. This

can increase cylinder head temperatures under certain conditions.

Propylene-glycol/Ethylene-glycol Mixtures—Should Not Be

Used in Chrysler Vehicles

Propylene-glycol/ethylene-glycol Mixtures can

cause the destabilization of various corrosion inhibitors, causing damage to the various cooling system

components. Also, once ethylene-glycol and propylene-glycol based coolants are mixed in the vehicle,

conventional methods of determining freeze point will

not be accurate. Both the refractive index and specific gravity differ between ethylene glycol and propylene glycol.

CAUTION: Richer antifreeze mixtures cannot be

measured with normal field equipment and can

cause problems associated with 100 percent ethylene-glycol.

DIAGNOSIS AND TESTING - COOLANT

CONCENTRATION TESTING

Coolant concentration should be checked when any

additional coolant was added to system or after a

coolant drain, flush and refill. The coolant mixture

offers optimum engine cooling and protection against

corrosion when mixed to a freeze point of -37°C

(-34°F) to -59°C (-50°F). The use of a hydrometer or a

refractometer can be used to test coolant concentration.

A hydrometer will test the amount of glycol in a

mixture by measuring the specific gravity of the mixture. The higher the concentration of ethylene glycol,

the larger the number of balls that will float, and

higher the freeze protection (up to a maximum of

60% by volume glycol).

A refractometer will test the amount of glycol in a

coolant mixture by measuring the amount a beam of

light bends as it passes through the fluid.

Some coolant manufactures use other types of glycols into their coolant formulations. Propylene glycol

is the most common new coolant. However, propylene

glycol based coolants do not provide the same freezing protection and corrosion protection and is not recommended.

CAUTION: Do not mix types of coolant—corrosion

protection will be severely reduced.

Page 21

7 - 16 ENGINE RG

COOLANT (Continued)

STANDARD PROCEDURE

STANDARD PROCEDURE - COOLANT SERVICE

For engine coolant recommended service schedule,

(Refer to LUBRICATION & MAINTENANCE/MAINTENANCE SCHEDULES - DESCRIPTION).

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The pressure/vent cap should not be removed

from the coolant recovery pressure container

when the engine is hot. When additional coolant is

needed to maintain this level, it should be added to

the coolant recovery pressure container (Fig. 1). Use

only 50/50 mix of ethylene glycol type antifreeze and

distilled water. For the recommeded antifreeze/coolant type (Refer to LUBRICATION & MAINTENANCE/FLUID TYPES - DESCRIPTION).

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended. For the

recommeded antifreeze/coolant type (Refer to

LUBRICATION & MAINTENANCE/FLUID TYPES DESCRIPTION).

STANDARD PROCEDURE - COOLANT LEVEL

CHECK

NOTE: Do not remove pressure/vent cap for routine

coolant level inspections.

The coolant reserve system provides a quick visual

method for determining the coolant level without

removing the pressure/vent cap. With the engine

cold and not running, simply observe the level of

the coolant in the coolant recovery pressure container

(Fig. 2). The coolant level should be between the MIN

and MAX marks.

STANDARD PROCEDURE - COOLING SYSTEM

FILLING

(1) Remove pressure vent cap from coolant recovery pressure container.

(2) Loosen air bleed screw on the thermostat housing.

(3) Slowly fill the cooling through the coolant

recovery pressure container until a steady stream of

coolant comes out of the air bleed.

(4) Tighten the air bleed screw.

(5) Continue filling coolant recovery pressure container until level reaches the full line.

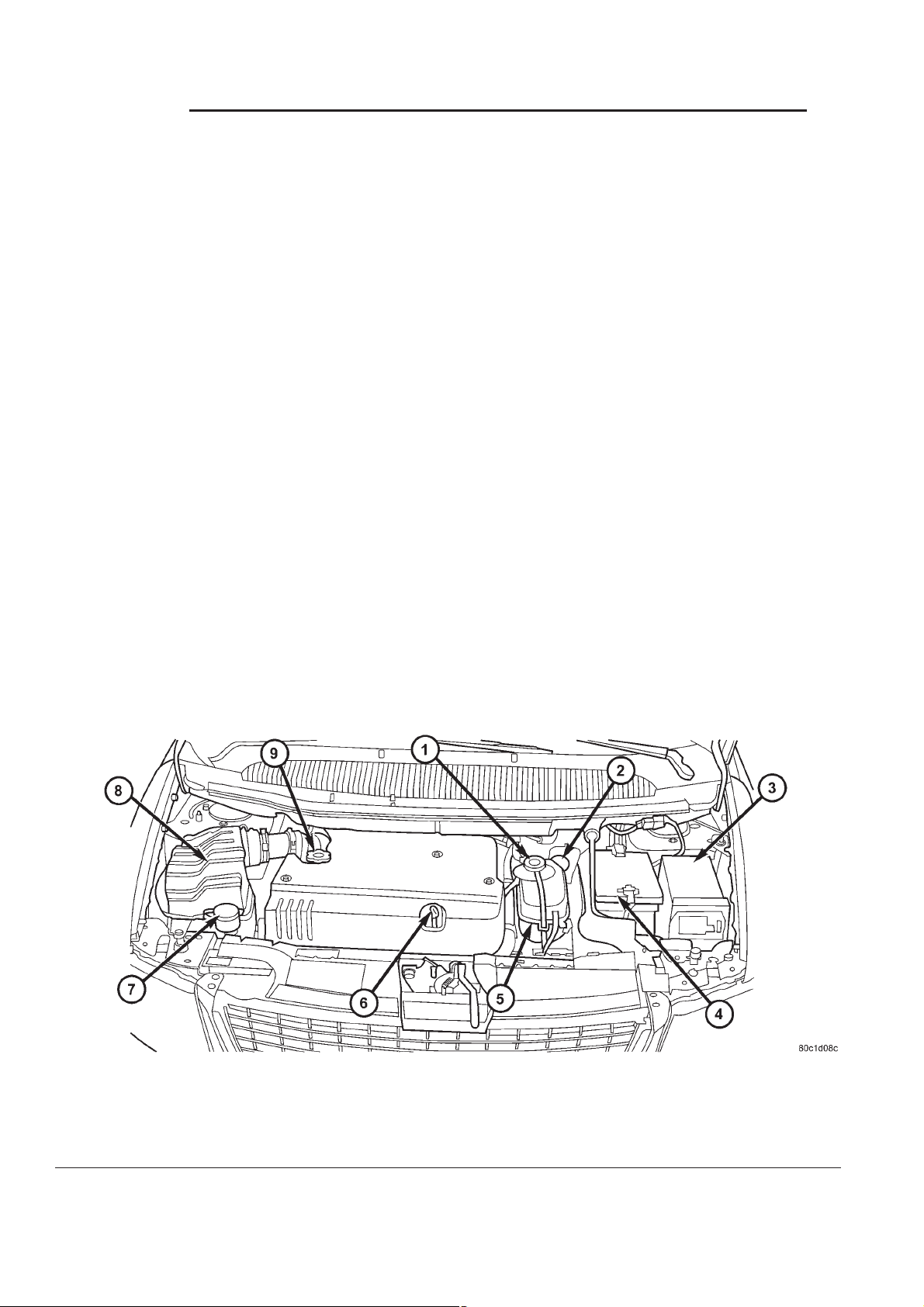

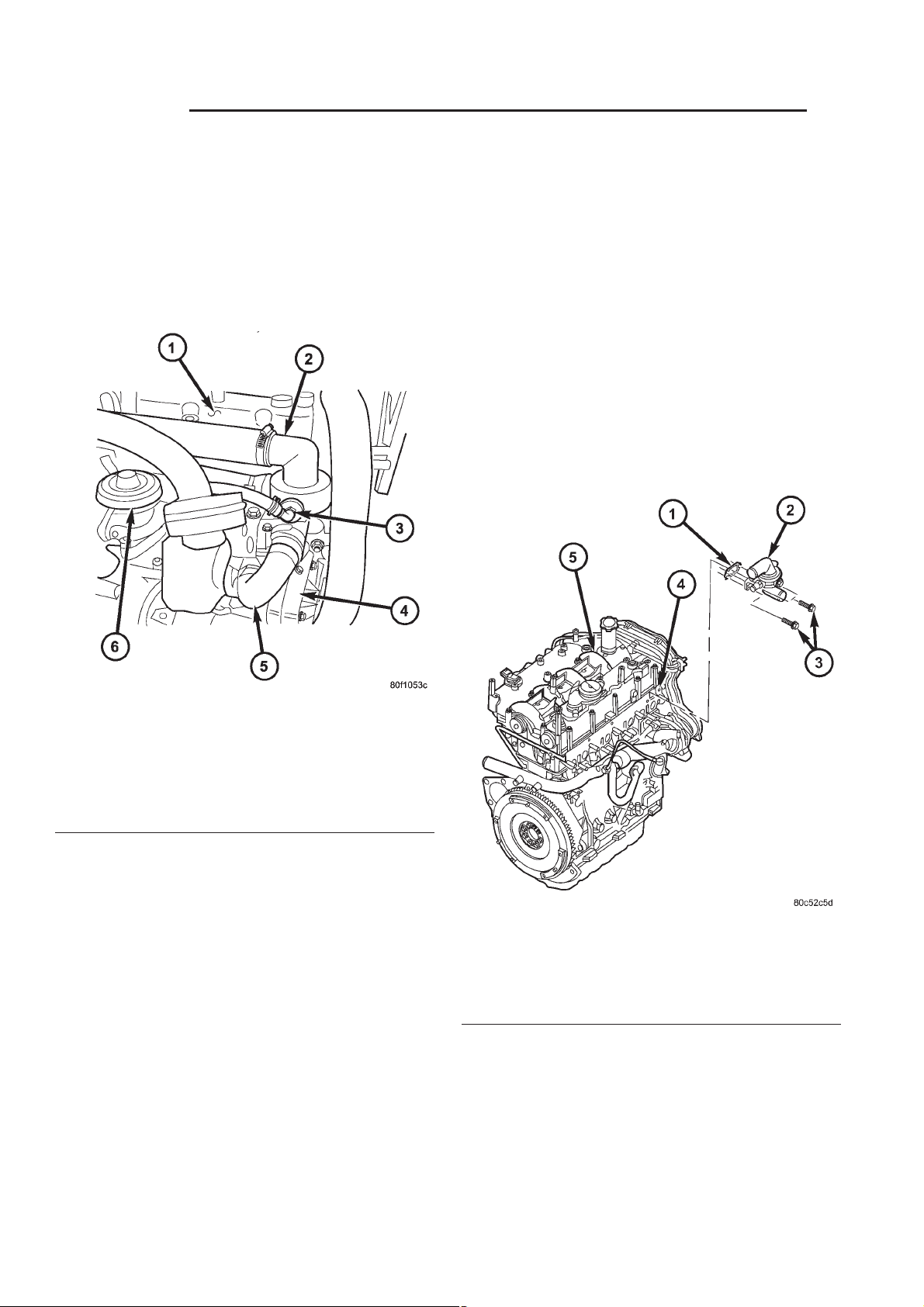

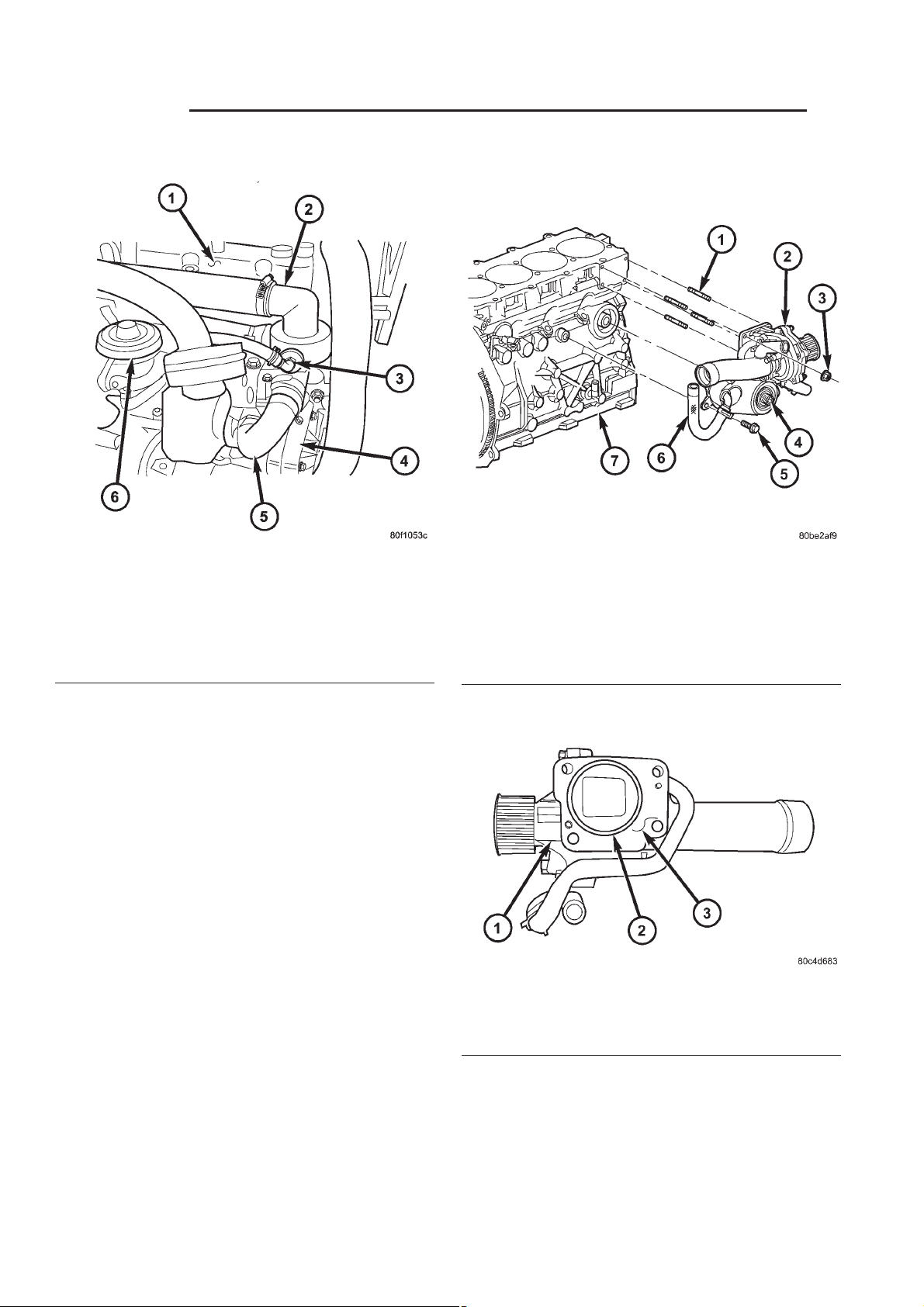

Fig. 1 UNDERHOOD FLUID FILL LOCATIONS

1 - COOLANT PRESSURE/VENT CAP

2 - BRAKE MASTER CYLINDER

3 - INTELLIGENT POWER MODULE

4 - BATTERY

5 - COOLANT RECOVERY PRESSURE CONTAINER

6 - OIL DIPSTICK

7 - WINDSHIELD SOLVENT RESEVOIR

8-AIRFILTERHOUSING

9 - ENGINE OIL FILL CAP

Page 22

RG ENGINE 7-17

COOLANT (Continued)

(1) Without removing pressure/vent cap and

with system not under pressure, open the drain-

cock. The draincock is located on the lower right side

of radiator (Fig. 3).

(2) After the coolant recovery pressure container is

empty, then remove coolant pressure/vent cap.

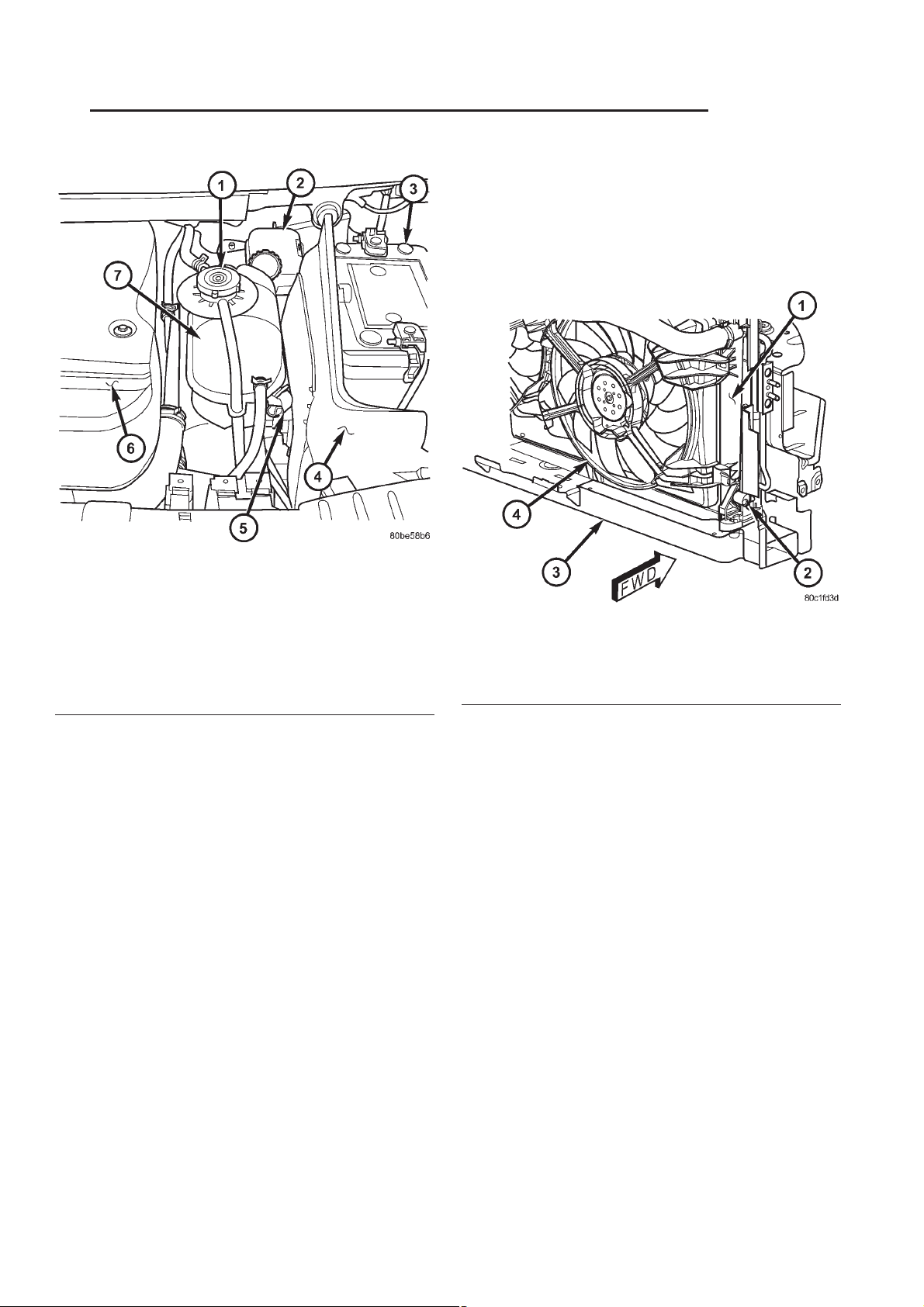

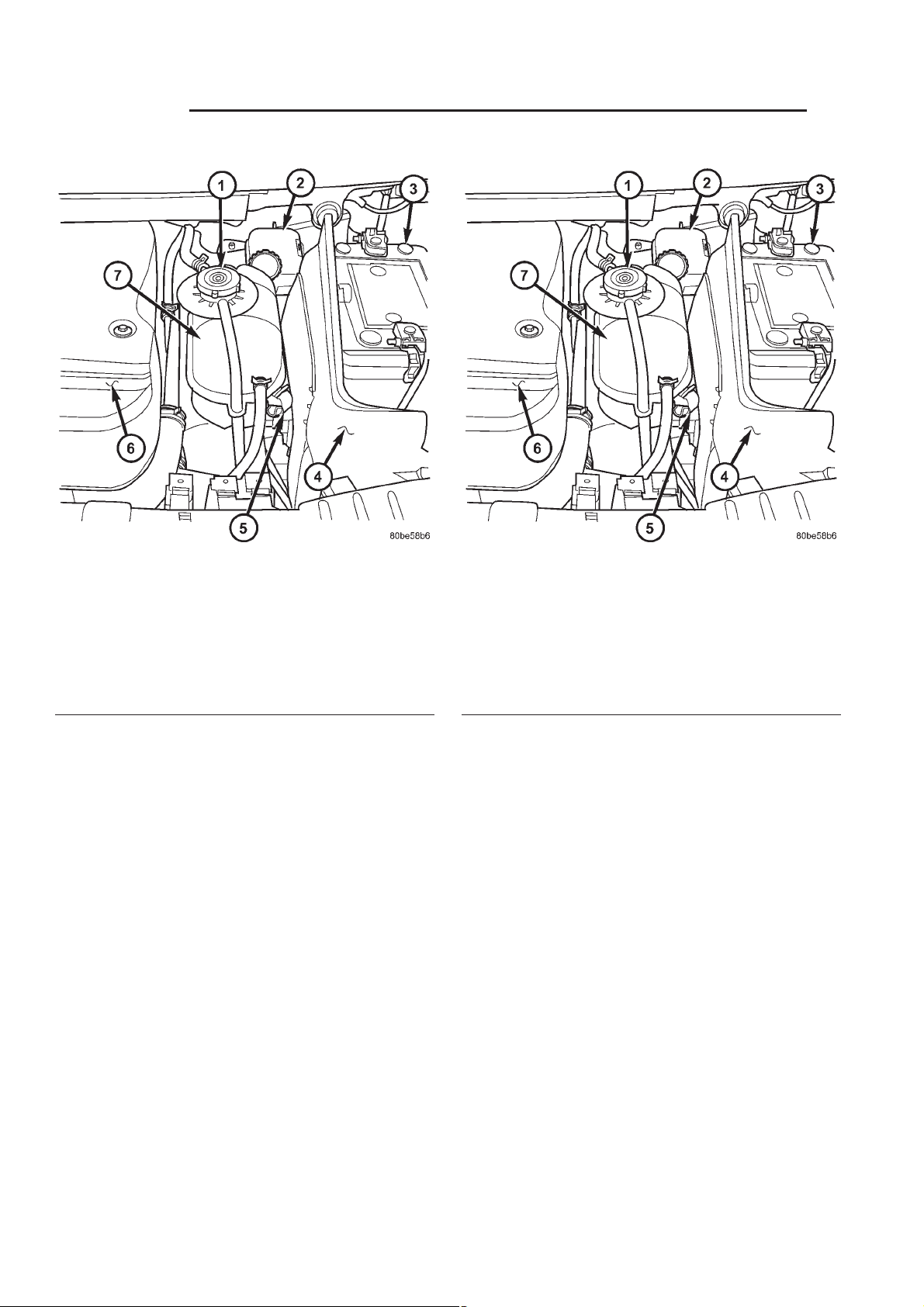

Fig. 2 COOLANT RECOVERY PRESSURE

CONTAINER LOCATION

1 - PRESSURE/VENT CAP

2 - BRAKE MASTER CYLINDER

3 - BATTERY

4 - BATTERY SHIELD

5 - COOLANT RECOVERY PRESSURE CONTAINER RETAING

CLIP

6 - ENGINE COVER

7 - COOLANT RECOVERY PRESSURE CONTAINER

(6) Without installing the pressure/vent cap, start

and run engine at idle for a couple minutes.

(7) Recheck coolant level and fill as necessary.

(8) Install pressure/vent cap and drive vehicle for

approx. 10 km to reach normal operating temperatures.

(9) Allow vehicle to cool. Check and fill coolant as

needed.

STANDARD PROCEDURE - COOLING SYSTEM

DRAINING

WARNING: DO NOT REMOVE OR LOOSEN THE

COOLANT PRESSURE/VENT CAP, CYLINDER

BLOCK DRAIN PLUGS, OR THE DRAINCOCK WHEN

THE SYSTEM IS HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

Fig. 3 DRAINCOCK LOCATION

1 - RADIATOR

2 - DRAINCOCK

3-LOWERRADIATORSUPPORT

4 - ELECTRIC COOLING FAN

COOLANT RECOVERY PRESS

CONTAINER

DESCRIPTION

The coolant recovery pressure container is

mounted in the engine compartment next to the battery. The coolant recovery pressure container is made

of plastic (Fig. 4).

OPERATION

The coolant recovery pressure container works

with the pressure/vent cap to use thermal expansion

and contraction of the coolant to keep the coolant

free of trapped air. Provides a convenient and safe

method for checking coolant level and adjusting level

at atmospheric pressure without removing the pressure/vent cap. It also provides some reserve coolant

to cover deaeration, evaporation, or boiling losses.

Page 23

7 - 18 ENGINE RG

COOLANT RECOVERY PRESS CONTAINER (Continued)

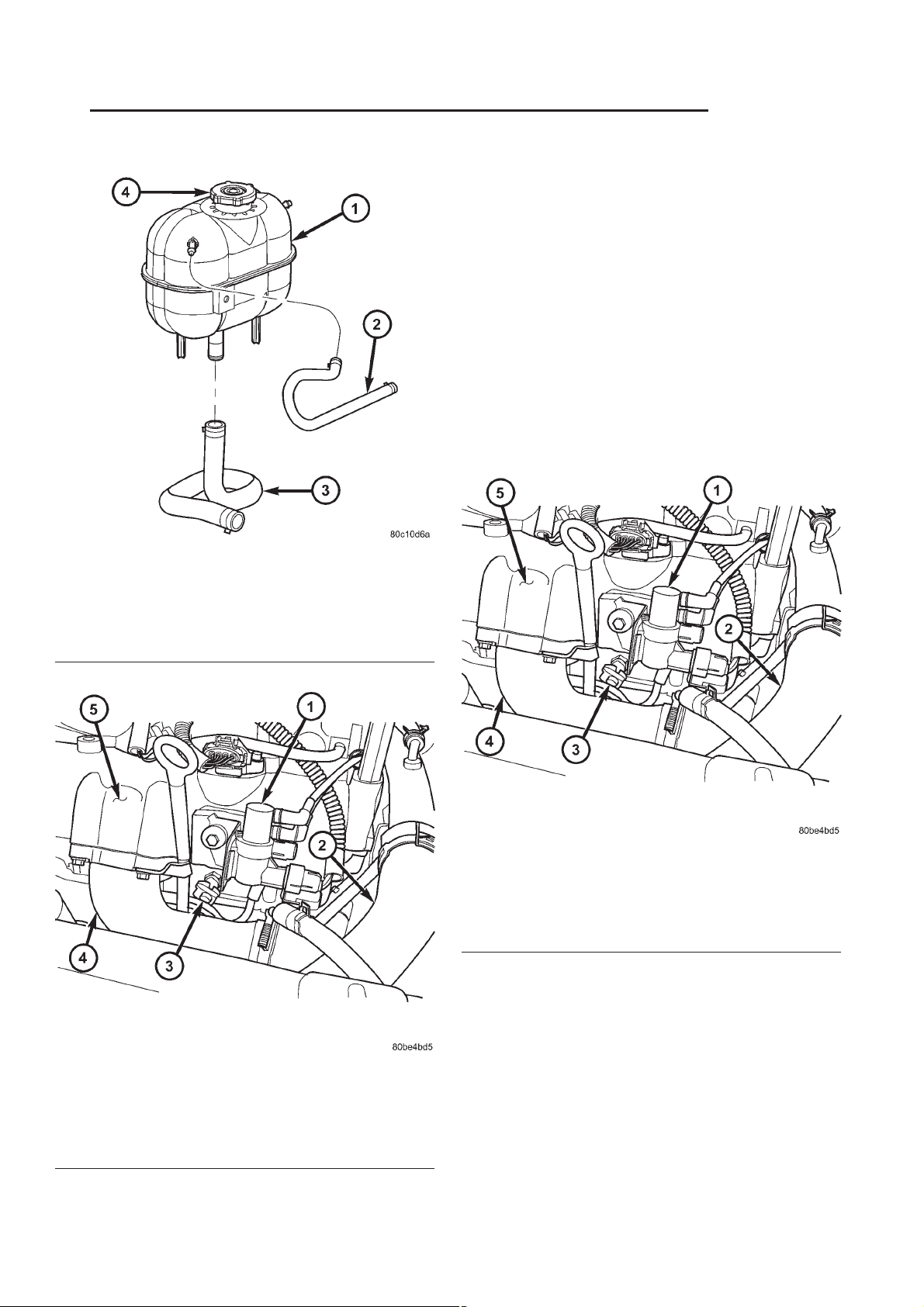

Fig. 4 COOLANT RECOVERY PRESSURE

CONTAINER LOCATION

1 - PRESSURE/VENT CAP

2 - BRAKE MASTER CYLINDER

3 - BATTERY

4 - BATTERY SHIELD

5 - COOLANT RECOVERY PRESSURE CONTAINER RETAING

CLIP

6 - ENGINE COVER

7 - COOLANT RECOVERY PRESSURE CONTAINER

REMOVAL

(1) Drain cooling system below level of coolant

recovery pressure bottle. (Refer to 7 - COOLING/ENGINE/COOLANT - STANDARD PROCEDURE)

(2) Disconnect coolant bypass and overflow hoses

from coolant recovery pressure container (Fig. 6).

(3) Unclip the coolant recovery pressure container

retaining clip (Fig. 5).

(4) Raise coolant recovery pressure container from

mounting bracket and disconnect coolant hose from

bottom of container (Fig. 6).

(5) Remove coolant recovery pressure bottle.

INSTALLATION

(1) Connect coolant hose at bottom of coolant

recovery pressure container (Fig. 6) and install in

mounting bracket.

(2) Connect coolant recovery pressure container

retaining clip (Fig. 5).

(3) Connect coolant bypass and overflow hoses to

coolant recovery pressure container.

Fig. 5 COOLANT RECOVERY PRESSURE

CONTAINER LOCATION

1 - PRESSURE/VENT CAP

2 - BRAKE MASTER CYLINDER

3 - BATTERY

4 - BATTERY SHIELD

5 - COOLANT RECOVERY PRESSURE CONTAINER RETAING

CLIP

6 - ENGINE COVER

7 - COOLANT RECOVERY PRESSURE CONTAINER

(4) Refill cooling system. (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE)

ENGINE COOLANT TEMP

SENSOR

DESCRIPTION

The engine coolant temperature sensor threads

into a coolant passage in the cylinder head (Fig. 7).

New sensors have sealant applied to the threads.

OPERATION

The coolant temperature (ECT) sensor is a negative temperature coefficient (NTC) thermistor (resistance varies inversley with temperature). This means

at cold tempertures its resistance is high so the voltage signal will be high. As coolant temperture

increases, resistance decreases and the signal voltage

will be low. This allows the sensor to provide an analog voltage signal to the ECM.

Page 24

RG ENGINE 7-19

ENGINE COOLANT TEMP SENSOR (Continued)

REMOVAL

WARNING: DO NOT REMOVE OR LOOSEN THE

COOLANT PRESSURE/VENT CAP, CYLINDER

BLOCK DRAIN PLUGS, OR THE DRAINCOCK WHEN

THE SYSTEM IS HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

(1) Drain the cooling system. (Refer to 7 - COOLING/ENGINE/COOLANT - STANDARD PROCEDURE)

(2) Disconnect coolant temperature sensor electrical connector (Fig. 8).

(3) Remove coolant temperature sensor from cylinder head (Fig. 8).

Fig. 6 COOLANT RECOVERY PRESSURE

CONTAINER

1 - COOLANT RECOVERY PRESSURE CONTAINER

2 - COOLANT BYPASS HOSE

3 - OUTLET HOSE

4 - PRESSURE/VENT CAP

Fig. 7 COOLANT TEMPERATURE SENSOR

LOCATION

1 - EGR SOLENOID

2 - UPPER RADIATOR HOSE

3 - COOLANT TEMPERATURE SENSOR

4 - INTAKE MANIFOLD INLET

5 - INTAKE MANIFOLD/CYLINDER HEAD COVER

Fig. 8 COOLANT TEMPERATURE SENSOR

LOCATION

1 - EGR SOLENOID

2 - UPPER RADIATOR HOSE

3 - COOLANT TEMPERATURE SENSOR

4 - INTAKE MANIFOLD INLET

5 - INTAKE MANIFOLD/CYLINDER HEAD COVER

INSTALLATION

(1) Install coolant temperature sensor in cylinder

head (Fig. 8).

(2) Connect coolant temperature sensor electrical

connector (Fig. 8).

(3) Refill the cooling system. (Refer to 7 - COOLING/ENGINE/COOLANT - STANDARD PROCEDURE)

(4) Connect the negative battery cable.

Page 25

7 - 20 ENGINE RG

ENGINE COOLANT

THERMOSTAT

DESCRIPTION

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator (Fig. 9).

REMOVAL

NOTE: The thermostat is not serviced separately.

The thermostat and housing must be replaced as

an assembly.

(1) Disconnect negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove front wiper unit to gain access to thermostat housing(Refer to 8 - ELECTRICAL/WIPERS/

WASHERS/WIPER MODULE - REMOVAL).

(4) Disconnect upper radiator hose adapter tube,

water pump hose, and EGR hose at thermostat housing.

(5) Remove both thermostat housing attaching

bolts and housing (Fig. 10).

Fig. 9 THERMOSTAT HOUSING

1 - CYLINDER HEAD COVER

2 - THERMOSTAT HOUSING

3 - AIR BLEED

4-WATERPUMP

5 - WATER PUMP HOUSING TO THERMOSTAT HOUSING

BYPASS HOSE

6 - EGR VALVE

OPERATION

The thermostat starts to open at 88°C (190°F).

Above this temperature, coolant is allowed to flow to

the radiator. This provides quicker engine warmup

and overall temperature control.

The same thermostat is used for winter and summer seasons. An engine should not be operated without a thermostat, except for servicing or testing.

Operating without a thermostat causes other problems. These are: longer engine warmup time, unreliable warmup performance, increased exhaust

emissions and crankcase condensation. This condensation can result in sludge formation.

Fig. 10 THERMOSTAT HOUSING ASSEMBLY

1 - THERMOSTAT HOUSING GASKET

2 - THERMOSTAT HOUSING

3 - RETAINING BOLTS

4 - CYLINDER HEAD

5 - CYLINDER HEAD COVER/INTAKE MANIFOLD

INSTALLATION

(1) Install thermostat housing, gasket, and retain-

ing bolts (Fig. 10). Torque bolts to 27.5N·m.

(2) Connect upper radiator hose adapter tube,

water pump hose, and EGR cooler hose to thermostat

housing.

Page 26

RG ENGINE 7-21

ENGINE COOLANT THERMOSTAT (Continued)

(3) Install front wiper unit (Refer to 8 - ELECTRICAL/WIPERS/WASHERS/WIPER MODULE INSTALLATION).

(4) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(5) Connect negative battery cable.

RADIATOR

DESCRIPTION

The radiator is a cross-flow type (horizontal tubes)

with design features that provide greater strength

along with sufficient heat transfer capabilities to

keep the engine satisfactorily cooled. The radiator

has plastic side tanks and aluminum cooling tubes.

OPERATION

The radiator functions as a heat exchanger, using

air flow across the exterior of the radiator tubes. This

heat is then transferred from the coolant and into

the passing air.

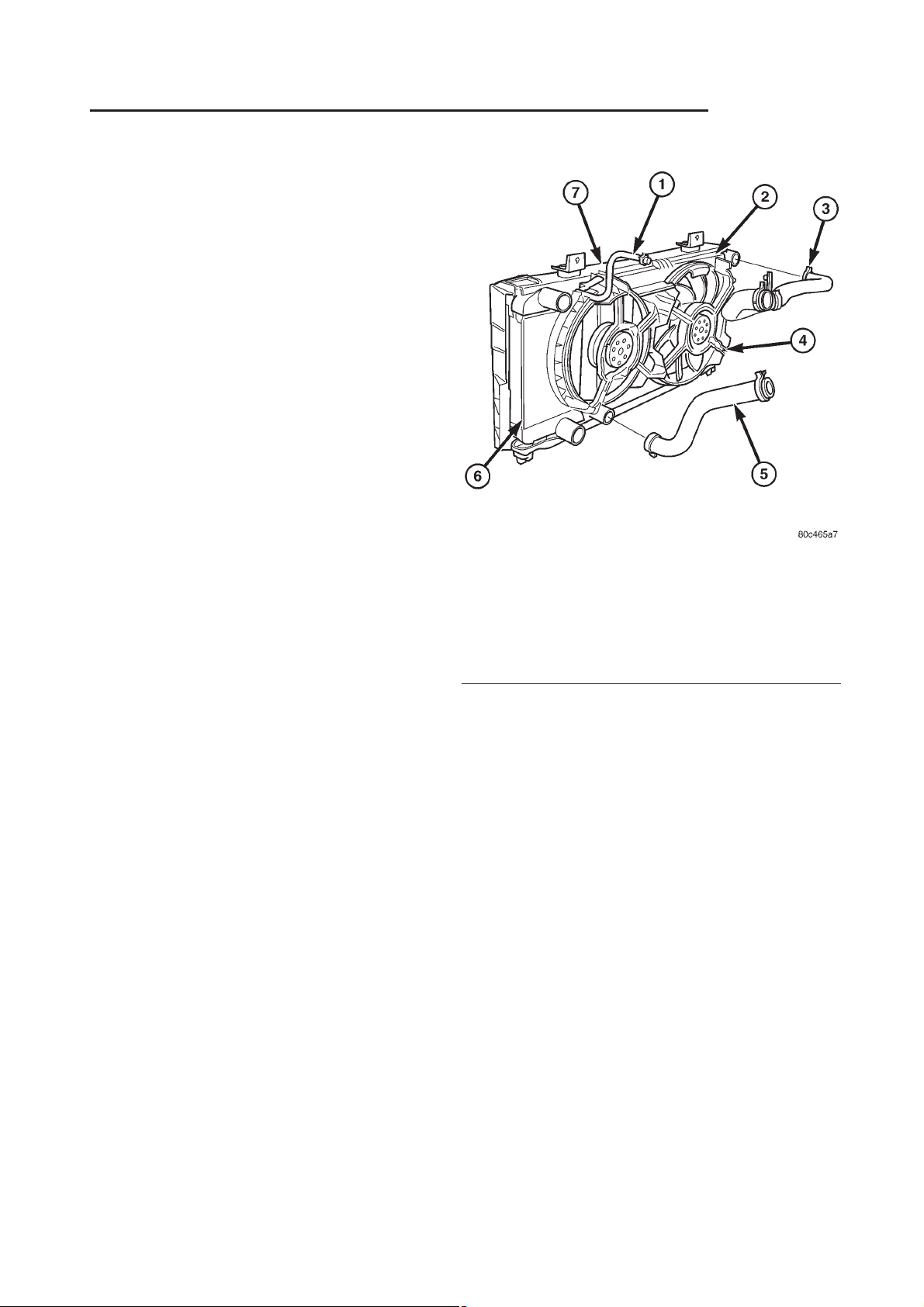

Fig. 11 UPPER AND LOWER RADIATOR HOSES

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove radiator upper crossmember support.

(Refer to 23 - BODY/EXTERIOR/GRILLE OPENING

REINFORCEMENT - REMOVAL)

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(3) Drain the cooling system (Refer to 7 - COOLING/ENGINE/COOLANT - STANDARD PROCEDURE).

(4) Remove the radiator fans. (Refer to 7 - COOLING/ENGINE/RADIATOR FAN - REMOVAL)

(5) Disconnect coolant bypass hose (Fig. 11).

(6) Disconnect upper and lower hoses from the

radiator (Fig. 11).

(7) Remove the A/C condenser side brackets to

radiator attaching screws (Fig. 12). Separate the condenser from the radiator by lifting upward to disengage from lower mounts (Fig. 12). Allow the

condenser to rest in front of radiator.

(8) Radiator can now be lifted free from engine

compartment. Care should be taken not to dam-

age radiator cooling fins or water tubes during

removal.

1 - COOLANT BYPASS HOSE

2 - RADIATOR ASSEMBLY

3 - UPPER RADIATOR HOSE

4 - COOLING FAN

5-LOWERRADIATORHOSE

6 - CHARGE AIR COOLER

7 - RADIATOR BRACKET

INSTALLATION

(1) Be sure the air seal is in position before

radiator is installed. Slide radiator down into posi-

tion. Seat the radiator with the rubber isolators into

the mounting holes provided, with a 10 lbs. force.

(2) Position air conditioning condenser onto the

radiator lower mounts and install upper screws (Fig.

12). Tighten fasteners to 5 N·m (45 in. lbs.).

(3) Install the radiator upper and lower hoses (Fig.

11).

(4) Connect the coolant bypass hose.

(5) Install the radiator fans. (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION)

(6) Install the radiator upper crossmember sup-

port. (Refer to 23 - BODY/EXTERIOR/GRILLE

OPENING REINFORCEMENT - INSTALLATION)

(7) Fill the cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(8) Connect negative cable to battery.

Page 27

7 - 22 ENGINE RG

RADIATOR (Continued)

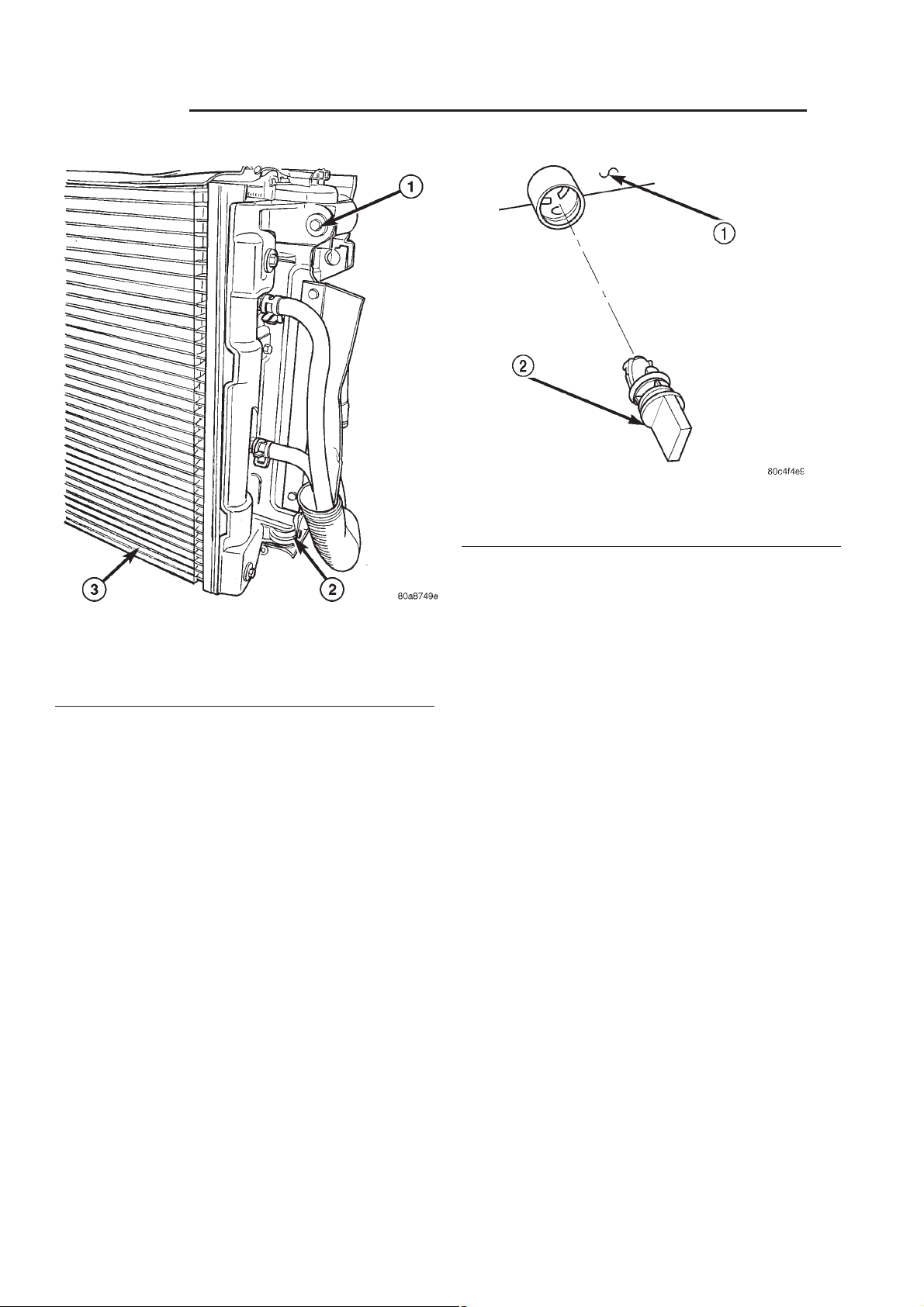

Fig. 13 Draincock

1 - RADIATOR TANK

2 - DRAINCOCK

Fig. 12 Radiator to A/C Condenser Mounting (left

mount shown, right similar)

1 - SCREW - A/C CONDENSER SIDE BRACKET TO RADIATOR

2 - LOWER MOUNT

3 - A/C CONDENSER

RADIATOR DRAINCOCK

REMOVAL

CAUTION: Use of pliers on draincock is not recommended. Damage may occur to radiator or draincock.

NOTE: It is not necessary to remove draincock during a routine coolant drain.

(1) Drain the cooling system (Refer to 7 - COOLING/ENGINE/COOLANT - STANDARD PROCEDURE).

(2) Open the draincock by turning it counterclockwise until it stops.

(3) Turn the draincock back (clockwise) 1/8 turn.

(4) Pull the draincock (Fig. 13) from the radiator

tank.

(4) Fill the cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

WATER PUMP

DESCRIPTION

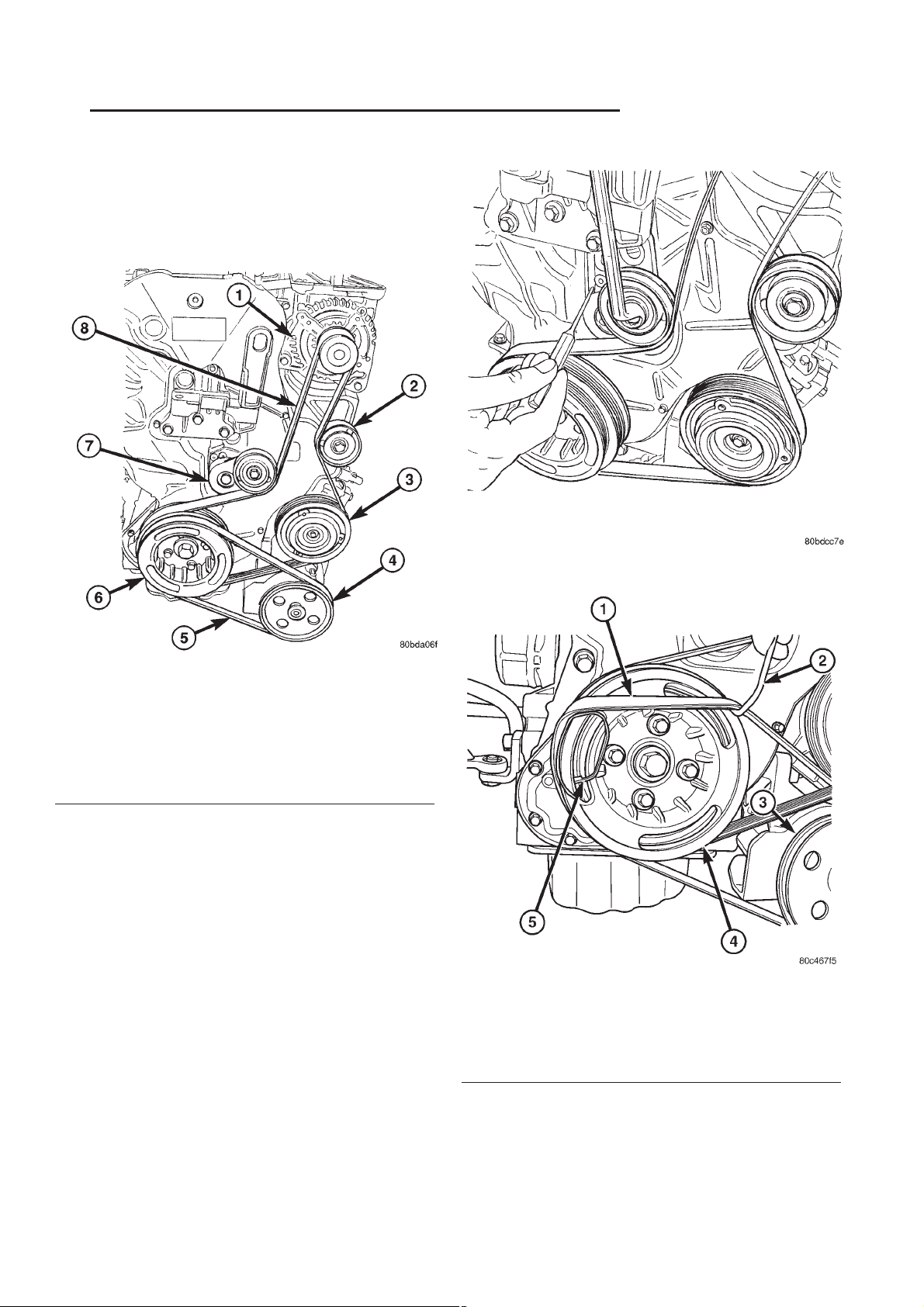

The water pump on the 2.5L CRD diesel has a die

cast aluminum housing. It bolts to a aluminum housing which attaches to the engine block (Fig. 14).

OPERATION

The water pump is used to circulate coolant

through the cooling system. The coolant is pumped

through the engine block, cylinder head, heater core,

EGR cooler, cabin heater, and radiator.

REMOVAL

REMOVAL - WATER PUMP

(1) Disconnect negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove timing belt inner and outer covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

(4) Remove water pump retaining bolts and pump

(Fig. 15).

INSTALLATION

(1) Align draincock stem to radiator tank opening.

(2) Push draincock into the radiator tank opening.

(3) Tighten the draincock by turning clockwise

until it stops.

REMOVAL - WATER PUMP HOUSING

(1) Disconnect negative battery cable.

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

Page 28

RG ENGINE 7-23

WATER PUMP (Continued)

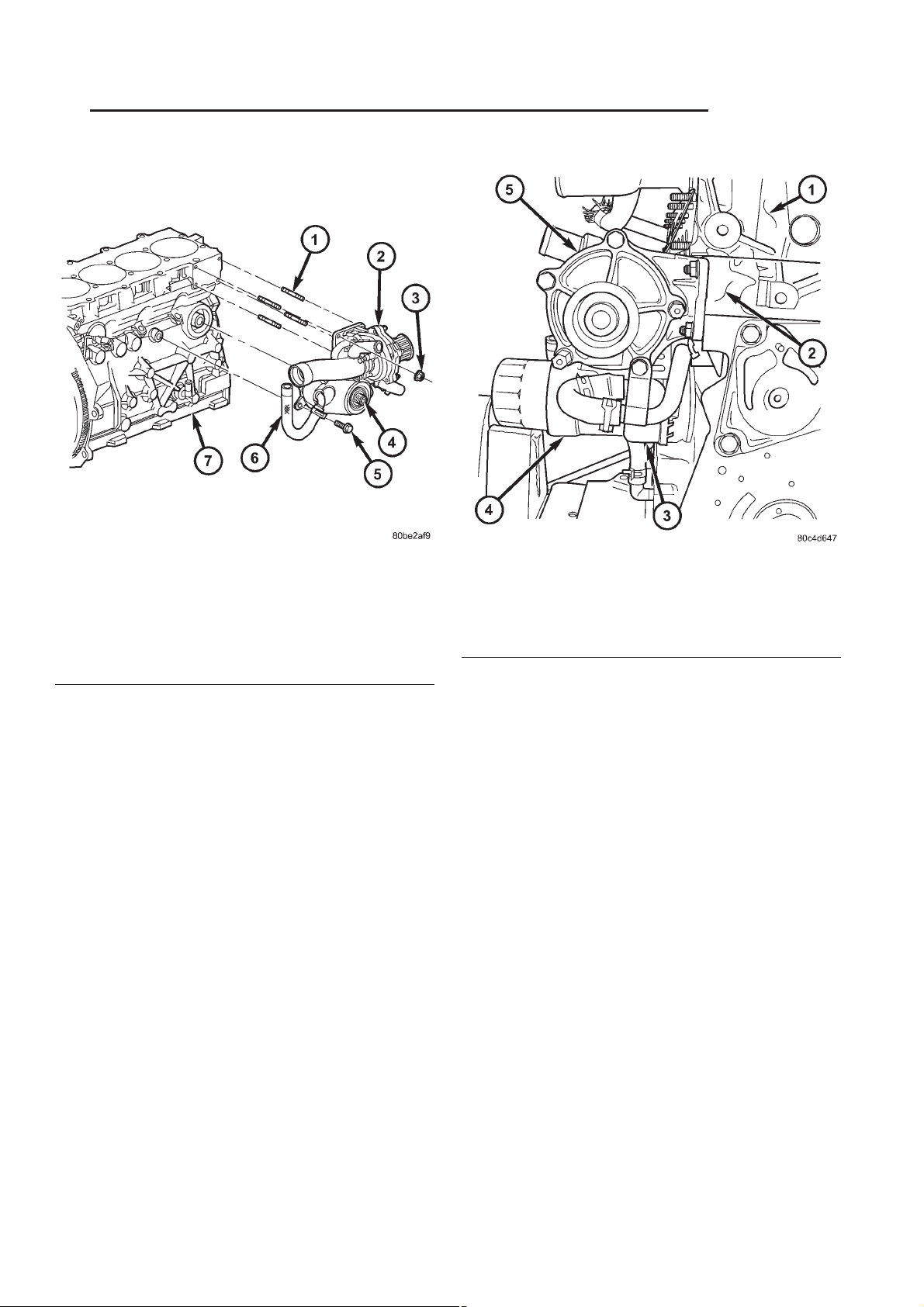

Fig. 14 WATER PUMP

1 - WATER PUMP HOUSING STUDS

2-WATERPUMP

3 - RETAINING NUTS

4 - OIL COOLER RETAINING STUD

5 - OIL COOLER TO ENGINE BLOCK RETAINING BOLT

6 - OIL COOLER COOLANT HOSE

7 - ENGINE BLOCK

(3) Remove both outer and inner timing belt covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - REMOVAL).

(4) Disconnect water pump housing to thermostat

housing bypass hose (Fig. 16).

(5) Remove the water pump housing retaining

nuts (Fig. 17).

(6) Remove water pump housing from engine block

(Fig. 17).

CLEANING

Clean gasket mating surfaces as necessary.

INSTALLATION

INSTALLATION - WATER PUMP

(1) Clean gasket mating surfaces as necessary.

(2) Place water pump and gasket in place. Install

water pump retaining bolts (Fig. 15). Torque bolts to

24.4N·m.

(3) Install both inner and outer timing belt covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - INSTALLATION).

(4) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(5) Connect negative battery cable.

Fig. 15 WATER PUMP LOCATION

1 - CYLINDER HEAD

2 - ENGINE BLOCK

3 - OIL COOLER

4 - OIL FILTER HOUSING

5-WATERPUMP

INSTALLATION - WATER PUMP HOUSING

(1) Clean mating surfaces of water pump housing

and engine block as necessary.

(2) Place new o-ring in groove in water pump

housing (Fig. 18).

(3) Be sure lower radiator hose tube o-ring is in

place.

(4) Install water pump housing on lower radiator

hose tube and push on mounting studs (Fig. 17).

Torque retaining nuts to 24.4N·m.

(5) Connect water pump housing to thermostat

housing bypass hose (Fig. 16).

(6) Install both inner and outer timing belt covers

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - INSTALLATION).

(7) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(8) Connect negative battery cable.

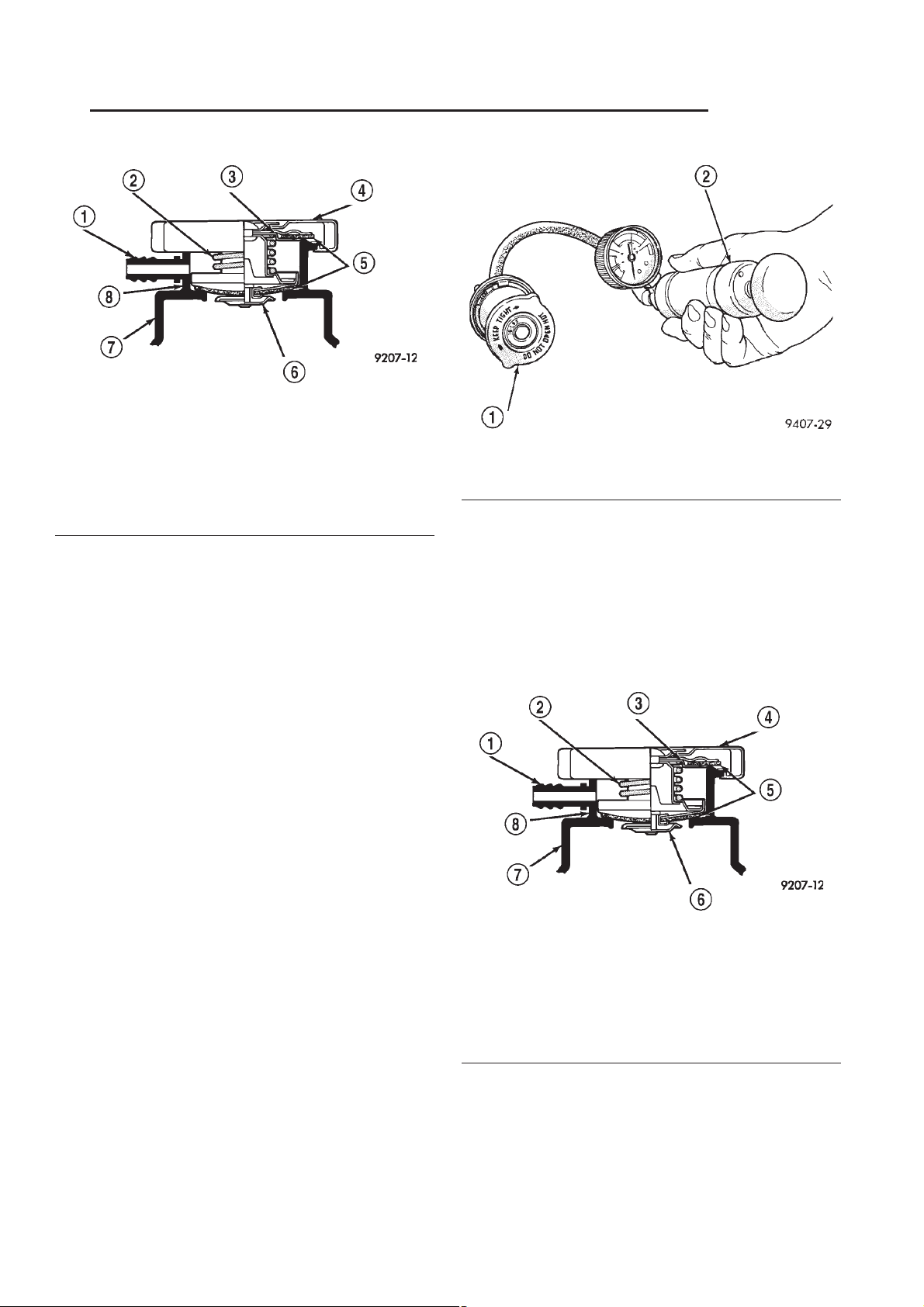

RADIATOR PRESSURE CAP

DESCRIPTION

The cooling system pressure cap is located on the

coolant recovery pressure container. The cap construction includes; stainless steel swivel top, rubber

seals, and retainer, main spring, and a spring loaded

valve (Fig. 19).

Page 29

7 - 24 ENGINE RG

RADIATOR PRESSURE CAP (Continued)

Fig. 16 THERMOSTAT HOUSING LOCATION

1 - CYLINDER HEAD COVER

2 - THERMOSTAT HOUSING

3 - AIR BLEED

4-WATERPUMP

5 - WATER PUMP HOUSING TO THERMOSTAT HOUSING

BYPASS HOSE

6 - EGR VALVE

OPERATION

The cooling system is equipped with a pressure cap

that releases excessive pressure; maintaining a range

of 97-124 kPa (14-18 psi).

The cooling system will operate at higher than

atmospheric pressure. The higher pressure raises the

coolant boiling point thus, allowing increased radiator cooling capacity.

There is also a vent valve in the center of the cap.

This valve also opens when coolant is cooling and

contracting, allowing the coolant to return to cooling

system from coolant reserve system tank by vacuum

through a connecting hose. If valve is stuck shut,

or the coolant recovery hose is pinched, the

radiator hoses will be collapsed on cool down.

Clean the vent valve (Fig. 19) and inspect coolant recovery hose routing, to ensure proper

sealing when boiling point is reached.

The gasket in the cap seals the filler neck, so that

vacuum can be maintained, allowing coolant to be

drawn back into the radiator from the reserve tank.

If the gasket is dirty or damaged, a vacuum

may not be achieved, resulting is loss of coolant

and eventual overheating due to low coolant

level in radiator and engine.

Fig. 17 WATER PUMP ASSEMBLY

1 - WATER PUMP HOUSING STUDS

2-WATERPUMP

3 - RETAINING NUTS

4 - OIL COOLER RETAINING STUD

5 - OIL COOLER TO ENGINE BLOCK RETAINING BOLT

6 - OIL COOLER COOLANT HOSE

7 - ENGINE BLOCK

Fig. 18 WATER PUMP HOUSING O-RING

1-WATERPUMP

2 - WATER PUMP HOUSING O-RING

3-WATERPUMPHOUSING

Page 30

RG ENGINE 7-25

RADIATOR PRESSURE CAP (Continued)

Fig. 19 Cooling System Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - PRESSURE BOTTLE

8-FILLERNECK

Fig. 20 Testing Cooling System Pressure Cap

1 - PRESSURE CAP

2 - PRESSURE TESTER

DIAGNOSIS AND TESTING - PRESSURE

RELIEF TEST

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING SYSTEM

PRESSURE CAP

Dip the pressure cap in water. Clean any deposits

off the vent valve or its seat and apply cap to end of

the Pressure Cap Test Adaptor that is included with

the Cooling System Tester 7700. Working the

plunger, bring the pressure to 104 kPa (15 psi) on the

gauge. If the pressure cap fails to hold pressure of at

least 97 kPa (14 psi), replace the pressure cap.

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 21). Attach the

Radiator Pressure Tool to the filler neck nipple and

pump air into the radiator. Pressure cap upper gasket should relieve at 69-124 kPa (10-18 psi) and hold

pressure at 55 kPa (8 psi) minimum.

CAUTION: The Cooling System Tester Tool is very

sensitive to small air leaks that will not cause cooling system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to the tool. Turn tool

upside down and recheck pressure cap to confirm

that cap is bad.

If the pressure cap tests properly while positioned

on Cooling System Tester (Fig. 20), but will not hold

pressure or vacuum when positioned on the filler

neck. Inspect the filler neck and cap top gasket for

irregularities that may prevent the cap from sealing

properly.

Fig. 21 Radiator Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - PRESSURE BOTTLE

8-FILLERNECK

Page 31

7 - 26 ENGINE RG

RADIATOR PRESSURE CAP (Continued)

WARNING: THE WARNING WORDS “DO NOT OPEN

HOT” ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

time except for the following purposes:

(1) Check and adjust coolant freeze point.

(2) Refill system with new coolant.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN

PLACE A SHOP TOWEL OVER THE CAP AND WITHOUT PUSHING DOWN ROTATE COUNTERCLOCKWISE TO THE FIRST STOP. ALLOW FLUIDS TO

ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COMPLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE)

BEFORE AND AFTER TURNING TO THE FIRST

STOP IS RECOMMENDED.

CLEANING

Use only a mild soap to clean the pressure cap.

INSPECTION

Hold the cap in your hand, top side up (Fig. 21).

The vent valve at the bottom of the cap should open.

If the rubber gasket has swollen, preventing the

valve from opening, replace the cap.

Hold the cleaned cap in your hand, upside down.

If any light can be seen between vent valve and the

rubber gasket, replace the cap. Do not use a

replacement cap that has a spring to hold the

vent shut.

A replacement cap must be of the type designed for

coolant reserve systems. This design ensures coolant

return to the radiator.

RADIATOR FAN

DESCRIPTION

The dual radiator fans are mounted to the back

side of the radiator (Fig. 22). The radiator fan consist

of the fan blade, electric motor and a support shroud

which are all serviced as an assembly.

OPERATION

Fan Operation

Speeds:

RADIATOR FAN OPERATION CHART

COOLANT TEMPERATURE A/C PRESSURE

Initial Max Initial Max

Fan On: 104°C (220°F) 110°C (230°F) Fan

Speed Duty-Cycles

(Ramps-up) from

30% to 99%

Fan Off: 101°C (214°F) Fan Speed

Duty-Cycles

(Ramps-down) from

99% to 30%

1,724 Kpa (250 psi) 2,068 Kpa (300 psi)

1,710 Kpa (248 psi) Fan Speed

Fan Speed

Duty-Cycles

(Ramps-up) from

30% to 99%

Duty-Cycles

(Ramps-down) from

99% to 30%

Page 32

RG ENGINE 7-27

RADIATOR FAN (Continued)

DIAGNOSIS AND TESTING - RADIATOR FAN

MOTOR

RADIATOR FAN DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

NOISY RADIATOR FAN 1. Fan blade loose. 1. Replace fan assembly. (Refer to

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

2. Fan blade striking a surrounding

object.

3. Air obstructions at radiator or A/C

condenser.

4. Electric fan motor defective. 4. Replace fan assembly. (Refer to

2. Locate point of fan blade contact

and repair as necessary.

3. Remove obstructions and/or

clean debris.

7 - COOLING/ENGINE/RADIATOR

FAN - REMOVAL)

ELECTRIC FAN MOTOR DOES

NOT OPERATE

ELECTRIC RADIATOR FAN

OPERATES ALL THE TIME

1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor, or wiring defective.

2. Defective A/C pressure

transducer.

1. Fan relay, powertrain control

module (PCM), coolant temperature

sensor or wiring defective.

2. Check for low coolant level. 2. Add coolant as necessary.

3. Defective A/C pressure

transducer.

REMOVAL

There are no repairs to be made to the fan or

shroud assembly. If the fan is warped, cracked, or

otherwise damaged, it must be replaced as an assembly (Fig. 22).

(1) Remove the radiator upper crossmember. (Refer

to 23 - BODY/EXTERIOR/GRILLE OPENING REINFORCEMENT - REMOVAL)

(2) Disconnect the radiator fan electrical connectors.

(3) Remove radiator fan(s) retaining screw (Fig.

22).

(4) Remove the radiator fan(s) by lifting upward to

release from mounts.

INSTALLATION

(1) Install the radiator fan(s) into mounts and

attaching clips on the radiator.

(2) Install radiator fan(s) attaching screws (Fig.

22). Tighten to 5 N·m (45 in. lbs.).

(3) Connect the radiator fan(s) electrical connectors.

1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

2. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

1. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

3. (Refer to Appropriate Diagnostic

Information) Repair as necessary.

Fig. 22 Radiator Fans

1 - SCREWS - RADIATOR FAN ATTACHING

2 - RADIATOR FAN - RIGHT

3 - MOUNT - RIGHT RADIATOR FAN

4 - CLIPS - RADIATOR FAN LOWER

5 - MOUNT - LEFT RADIATOR FAN

6 - RADIATOR FAN - LEFT

(4) Install the radiator upper support crossmember. (Refer to 23 - BODY/EXTERIOR/GRILLE OPENING REINFORCEMENT - INSTALLATION)

Page 33

7 - 28 ENGINE RG

RADIATOR FAN (Continued)

(5) Install the upper radiator mounts to the crossmember bolts, if removed. Tighten to 8 N·m (70 in.

lbs.).

(6) Install the radiator upper hose to the support

clip (2.4L engine).

HOSE CLAMPS

DESCRIPTION - HOSE CLAMPS

The cooling system uses spring type hose clamps.

If a spring type clamp replacement is necessary,

replace with the original Mopar威 equipment spring

type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 23).

Fig. 23 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

OPERATION - HOSE CLAMPS

The spring type hose clamp applies constant tension on a hose connection. To remove a spring type

hose clamp, use Special Tool 6094 or equivalent, constant tension clamp pliers (Fig. 24) to compress the

hose clamp.

RADIATOR FAN RELAY

DESCRIPTION

The low and high speed fan relays are mounted to

the upper radiator support above the charge air

cooler (Fig. 25).

Fig. 24 Hose Clamp Tool

1 - HOSE CLAMP TOOL 6094

2 - HOSE CLAMP

Fig. 25 RELAY LOCATIONS

1 - GLOW PLUG RELAY

2 - UPPER RADIATOR SUPPORT

3 - CHARGE AIR COOLER OUTLET HOSE

4 - RADIATOR FAN RELAYS

5 - UPPER RADIATOR HOSE

6 - EGR SOLENOID

OPERATION

The cooling system uses two fans. Both fans operate at two different speeds, low and high. Depending

on engine coolant temperature and A/C system high

side pressure, the fans operate at either low or high.

The ignition switch supplies voltage to the coil side of

the relay. When the ECM grounds the coil side of the

relay, the contacts close and the battery supplies

power to the fans.

Page 34

RG ENGINE 7-29

COOLANT SYSTEM HOSES

REMOVAL

REMOVAL - UPPER RADIATOR HOSE

WARNING: THE WARNING WORDS “DO NOT OPEN

HOT” ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

(1) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(2) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Remove upper radiator hose (Fig. 26).

REMOVAL - LOWER RADIATOR HOSE

WARNING: THE WARNING WORDS “DO NOT OPEN

HOT” ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

(1) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(2) Remove lower radiator hose (Fig. 26).

REMOVAL - COOLANT BYPASS HOSE

WARNING: THE WARNING WORDS “DO NOT OPEN

HOT” ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

(1) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(2) Remove the coolant bypass hose (Fig. 26).

Fig. 26 UPPER AND LOWER RADIATOR HOSES

1 - COOLANT BYPASS HOSE

2 - RADIATOR ASSEMBLY

3 - UPPER RADIATOR HOSE

4 - COOLING FAN

5-LOWERRADIATORHOSE

6 - CHARGE AIR COOLER

7 - RADIATOR BRACKET

INSTALLATION

INSTALLATION - UPPER RADIATOR HOSE

(1) Install upper radiator hose (Fig. 26).

(2) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(3) Install engine cover (Refer to 9 - ENGINE INSTALLATION).

INSTALLATION - LOWER RADIATOR HOSE

(1) Install lower radiator hose (Fig. 26).

(2) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

INSTALLATION - COOLANT BYPASS HOSE

(1) Install cooling system bypass hose (Fig. 26).

(2) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

Page 35

Page 36

RG ELECTRONIC CONTROL MODULES 8E-1

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ENGINE CONTROL MODULE

DESCRIPTION ..........................1

OPERATION ............................1

STANDARD PROCEDURE - PCM/ECM/SKIM

PROGRAMMING - DIESEL ...............2

ENGINE CONTROL MODULE

DESCRIPTION

The ECM is located in the left front corner of the

engine compartment attached to the radiator support

(Fig. 1).

REMOVAL .............................4

INSTALLATION ..........................4

entered into the ECM memory. The criteria may be a

range of: engine rpm, engine temperature, time or

other input signals to the ECM. If all of the criteria

for monitoring a system or circuit are met, and a

problem is sensed, then a DTC will be stored in the

ECM memory. It is possible that a DTC for a monitored circuit may not be entered into the ECM memory, even though a malfunction has occurred. This

may happen when the monitoring criteria have not

been met. The ECM compares input signal voltages

from each input device with specifications (the established high and low limits of the input range) that

are programmed into it for that device. If the input

voltage is not within the specifications and other

trouble code criteria are met, a DTC will be stored in

the ECM memory.

ECM OPERATING MODES

As input signals to the ECM change, the ECM

adjusts its response to the output devices. For example, the ECM must calculate a different fuel quantity

and fuel timing for engine idle condition than it

would for a wide open throttle condition. There are

several different modes of operation that determine

how the ECM responds to the various input signals.

Fig. 1 ENGINE CONTROL MODULE LOCATION-

TYPICAL

1 - BATTERY

2 - IPM (INTEGRATED POWER MODULE)

3 - ECM (ENGINE CONTROL MODULE)

4 - RETAINING BOLT

5 - RADIATOR SUPPORT

6 - CLUTCH CABLE BRACKET (LHD)

7 - CLUTCH CABLE BRACKET RETAINING BOLT (LHD)

OPERATION

The ECM has been programmed to monitor different circuits of the diesel fuel injection system. This

monitoring is called on-board diagnostics. Certain criteria must be met for a diagnostic trouble code to be

Ignition Switch On (Engine Off)