Page 1

(Supersedes PF424-3)

PF424-4

UB

161-027049-001

JULY, 2002

4

and

Installation, Operation

RENEWAL PARTS IDENTIFICATION

Type UB-3502A, UB-4002A, UB-4502A, UB-5002A

Forced-Air Heater

© 2010 Chromalox, Inc.

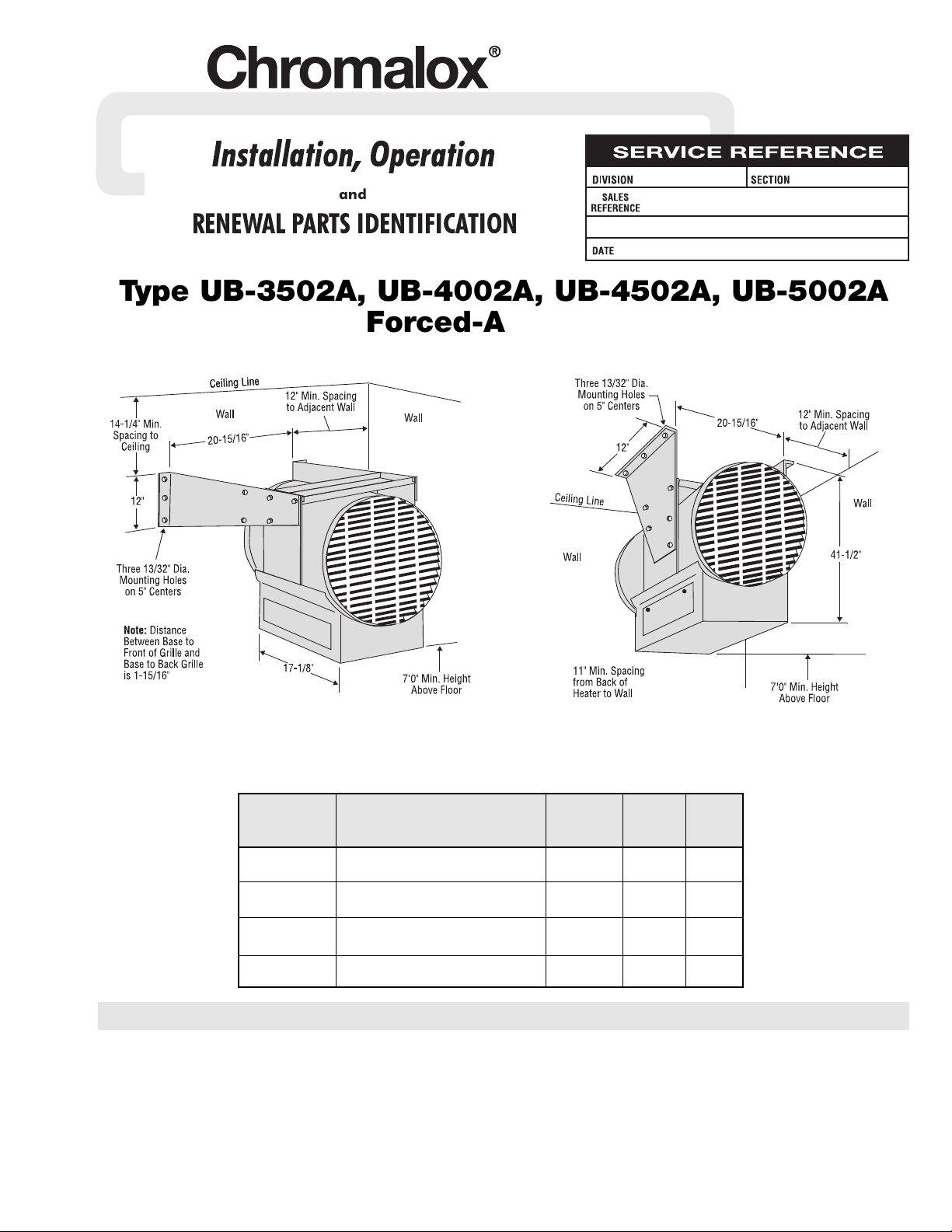

Horizontal

Air

Wt.

Model Volts and Phase kW

Discharge

(Lbs.)

UB-3502A

240V, 550V, 575V, 600V (3ø)

35 54’ 210

480V (1ø or 3ø)

UB-4002A

480V (1ø or 3ø)

40 54’ 210

550V, 575V, 600V (3ø)

UB-4502A

480V (1ø or 3ø)

45 54’ 210

550V, 575V, 600V (3ø)

UB-5002A 480V, 550V, 575V, 600V (3ø) 50 54’ 210

Specifications – Table A

IMPORTANT

WARNING: Hazard of Electric Shock. Disconnect

all power before installing heater.

WARNING: This heater is not intended for use in

hazardous atmospheres where flammable vapors,

gases, liquids or other combustible atmospheres

are present as defined in the National Electrical

Code. Failure to comply can result in explosion or

fire. For these applications see PDS CXH-EP

(PF305).

WARNING: Users should install adequate back-up

controls and safety devices with their electric

heating equipment. Where the consequences of

failure may be severe, back-up controls are essential. Although the safety of installation is the

responsibility of the user, Chromalox will be glad to

make equipment recommendations.

Figure 1

(Wall Mounted)

Figure 2

(Ceiling Mounted)

Page 2

MOUNTING

Note: All wiring should be done in accordance with local codes

and the National Electrical Code by a qualified person.

WARNING: Hazard of Electric Shock. Any installation involving electric heaters must be effectively

grounded in accordance with the National

Electrical Code to eliminate shock hazard.

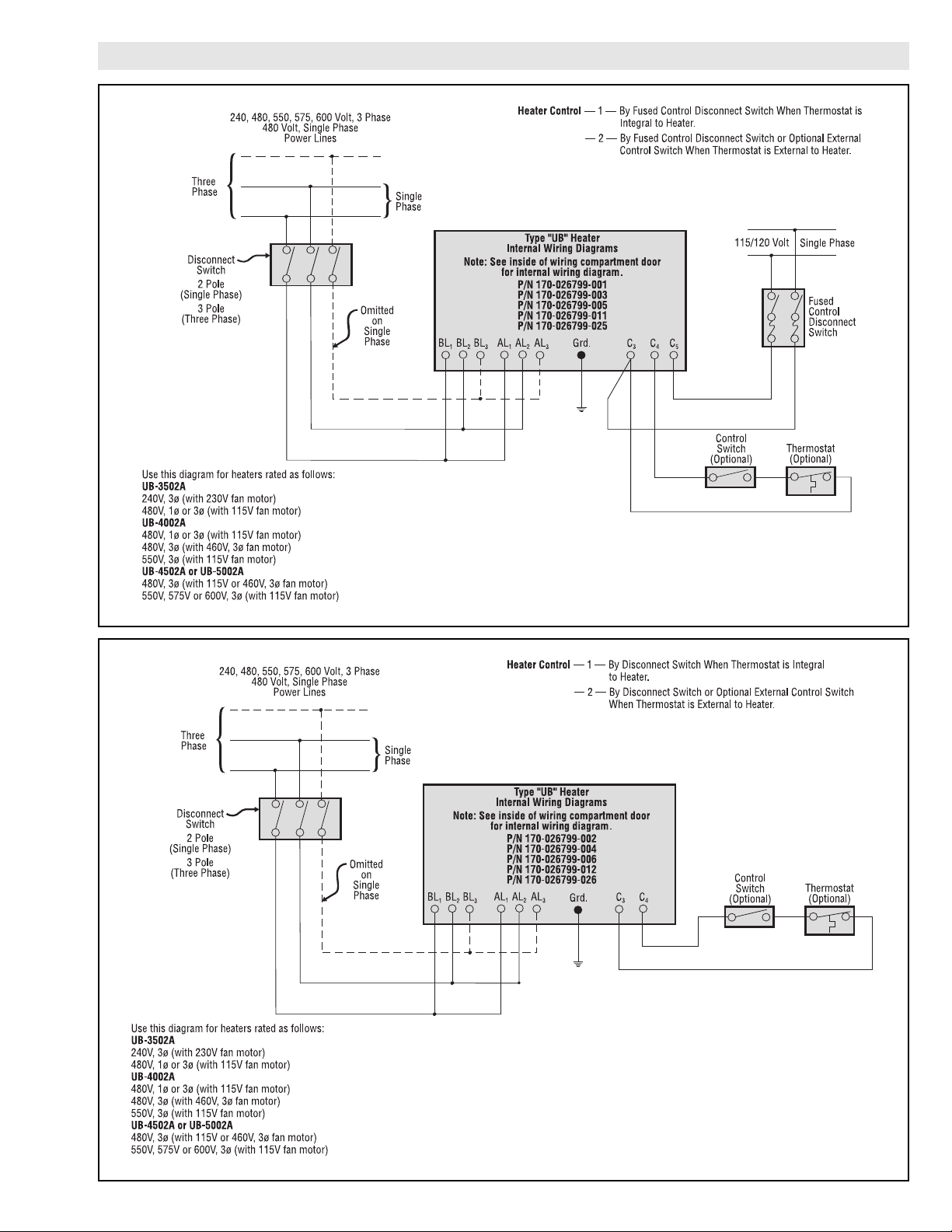

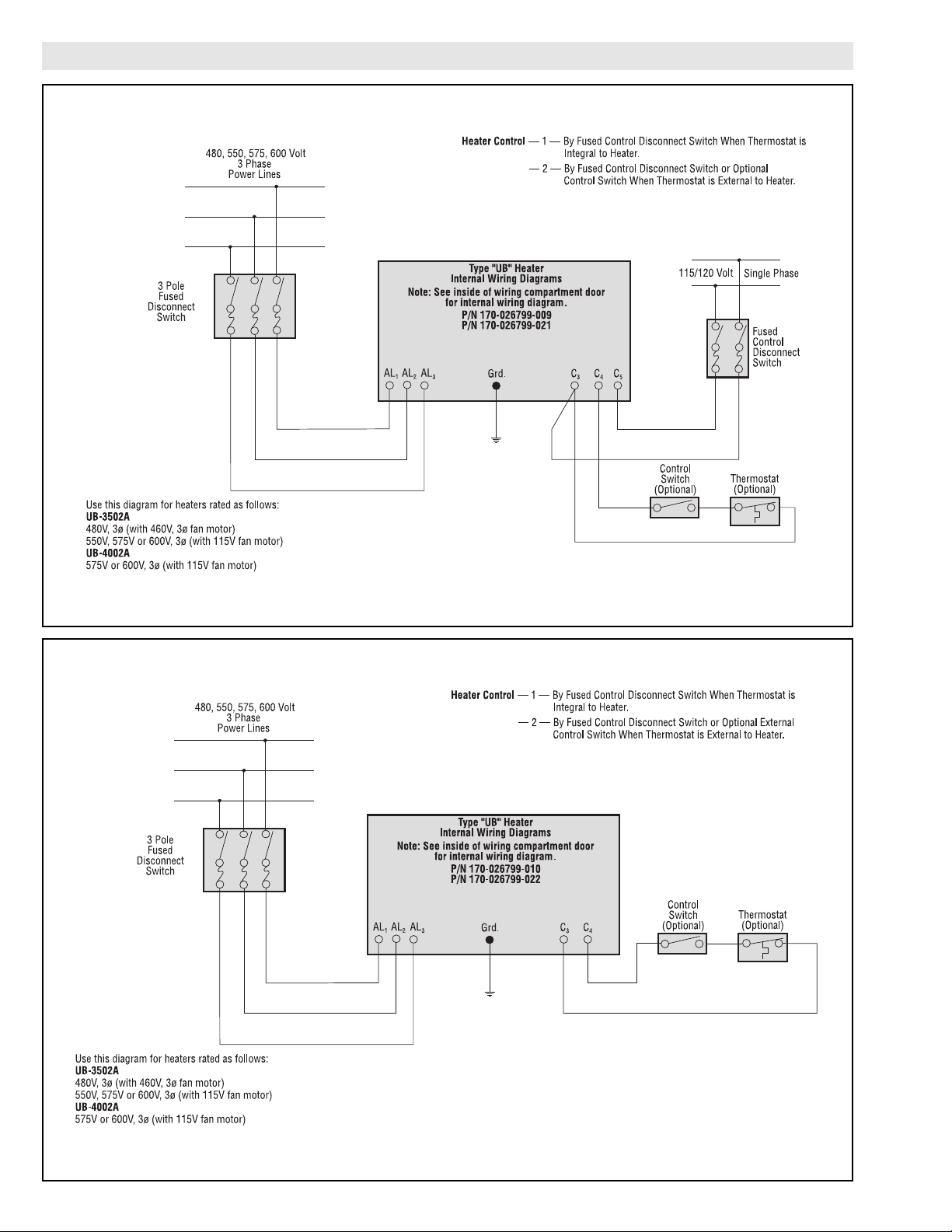

1. Connect heater according to the voltage and frequency speci-

fied on the nameplate and using the appropriate wiring diagram

(Figures 3 thru 14).

Note: Be sure to check the voltage rating of the fan motor since

it is not necessarily the same as the heater circuit.

2. If an external transformer is used to step down the voltage for

operating the fan motor, use appropriate wiring diagram (Figures

7 thru 14).

3. Heaters are not provided with a control switch and should be

controlled by externally mounted disconnect switches and/or

separately mounted thermostat and control switch as recommended in appropriate wiring diagrams (Figures 3 thru 14).

Key to proper wiring diagram is the part number (P/N) of internal wiring diagram located on inside of the hinged cover of the

terminal box.

4. Protection against overheating is provided by an internal auto-

matic thermal cutout which opens the electric circuit if the normal air-flow is restricted or stopped. Cutout automatically

energizes heater on removal of the obstruction.

WARNING: Hazard of Electric Shock. Disconnect all

power before installing heater.

WARNING: These heaters are designed for wall or ceiling mounting only. Other modes of mounting voids factory warranty.

1. Height above floor

A. In areas where ceiling height is more than 12 feet, recom-

mended mounting height is approximately 10 feet to underside of heater.

B. For ceiling heights of 12 feet or less, maximum mounting

height is determined by use of ceiling mounting brackets

offered with these heaters. Minimum spacing to ceiling is

14-1/4”.

C. In either case the minimum mounting height is 7 feet from

floor to bottom of heater. (See Figures 1 and 2.)

2. Spacing to adjacent walls

A. Rear of case to back wall 11” minimum.

B. Side of case to side wall 12” minimum.

3. If two or more units are operated in the same enclosed space,

their discharges should be directed to aid in development of

mass air movement for uniform heat dispersal.

4. Controlling thermostats to individual heaters should be mounted at shoulder height on inside walls or columns.

IMPORTANT

WIRING

Do not mount mercury type thermostat directly on unit. Vibration

could cause heater to malfunction.

The heater must be mounted at least 7’ above the floor to prevent

accidental contact with the heating elements or fan blade which

could cause injury.

Keep at least 5’ clearance in front of the heater. Refer to Figures 1

and 2 for side, top, and back clearance requirements.

The wall or ceiling mounting structure and the anchoring provision

must be of sufficient strength to support the combined weight of

the heater and mounting bracket. (Refer to Table A for weights of

heater and bracket).

Fan blade rotation must be checked. If airflow is not moving out

through the louvers, interchange any two of the three customer

power leads on three-phase units only.

2

Page 3

WIRING DIAGRAMS

Figure 4

Figure 3

3

Page 4

4

WIRING DIAGRAMS

Figure 6

Figure 5

Page 5

5

WIRING DIAGRAMS

Figure 8

Figure 7

Page 6

6

WIRING DIAGRAMS

Figure 10

Figure 9

Page 7

7

WIRING DIAGRAMS

Figure 12

Figure 11

Page 8

8

WIRING DIAGRAMS

Figure 14

Figure 13

Page 9

9

OPERATION

MAINTENANCE

1. DANGER: Hazard of Fire.

A. Do not restrict air flow through heater by placing fabric or

other obstructions in front of or behind the heater. Increased

discharge temperatures can discolor or ignite some heat

sensitive combustible materials.

B. Do not operate heater in areas where combustible lint, dust

or flammable vapors, gases or liquids are present.

2. Do not operate heater in corrosive atmosphere conditions to

avoid destructive damage to heater.

3. Avoid operating heater in dusty environment which can foul

heater fins to dissipate heat or impair motor ventilation leading

to excessive operating temperatures.

4. Do not operate heater in ambient temperatures exceeding 90

O

F.

WARNING: Turn off all power to service heater. Do

not attempt to service heater while unit is operating as there is hazard of electric shock, injury from

operating fan, and burns from hot heating elements.

1. Fan motors in these heaters are provided with sealed ball bear-

ings, factory lubricated, requiring no further lubrication under

normal service conditions.

2. Vacuum heater before activating heater for next heating season

to remove accumulated dust or lint which otherwise may

smoke or incinerate on initial heat up.

3. Periodically inspect all electrical connections and terminals to

avoid electrical wiring difficulties. Inspect all wiring for frayed

or worn insulation.

Page 10

10

RENEWAL PARTS IDENTIFICATION

Model Voltage Phase Heating Element Model Voltage Phase Heating Element

240 3 118-117481-001 (6) 480 1 or 3 118-117481-010 (6)

480 1 or 3 118-117481-002 (6)

UB-4502A

550 3 118-117481-011 (6)

UB-3502A 550 3 118-117481-003 (6) 575 3 118-117481-012 (6)

575 3 118-117481-004 (6) 600 3 118-117481-013 (6)

600 3 118-117481-005 (6) 480 3 118-117481-014 (6)

480 1 or 3 118-117481-006 (6)

UB-5002A

550 3 118-117481-015 (6)

UB-4002A

550 3 118-117481-007 (6) 575 3 118-117481-016 (6)

575 3 118-117481-008 (6) 600 3 118-117481-017(6)

600 3 118-117481-009 (6)

1

1

HEATING ELEMENTS

1

Page 11

11

RENEWAL PARTS IDENTIFICATION

Motors Capacitors

Manufacturer’s

Specifications

Manufacturer’s

Specifications

Part No.

Cat. No.

Volts Amps Phase Cycles RPM HP

Part No.

Cat. No.

Type Vac Cap.

193-025776-001 HF2K007N 115 5.4 1 60 1625 1/3 040-025779-001 1270 Oil 370 5 MFD

193-025776-002 HF2K006N 230 2.54 1 60 1625 1/3 040-025779-002 1271 Oil 370 6 MFD

193-302120-011 P55YYBYV-887 460 0.9 3 60 1725 1/3 — — — — —

Voltages

Size Part Number V.A. Rating

Primary Secondary

Large

315-052169-011

970

220, 230, 240, 440, 460, 480 110, 115, 120

315-052169-012 550, 575, 600 110, 115, 120

Small

315-304252-001

40

240 & 480 120

315-304252-003 575 120

Fuses — 600 Volt Fuseholders

Manufacturer’s

Part Number Amps

Cat. No.

Use Part Number Description

128-026510-003 30 JKS 30 Power 129-025643-002 600 Volt, 30 Amp, 3 Pole

128-026510-001 35 JKS 35

128-026510-004 40 JKS 40

Power 129-025643-001 600 Volt, 60 Amp, 3 Pole

128-026510-006 50 JKS 50

128-026510-007 60 JKS 60

128-027590-001 1 KTK-R-1

Control/

129-048473-001 2, 3, 4, 5 poles contact section

128-027590-008 8 KTK-R-8

Motor

129-048475-001

End barrier section for use

128-027590-010 15 KTK-R-15

with 129-048473-001

PARTS COMMON TO ALL HEATERS

Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112-027568-001

Fan Delay . . . . . . . . . . . . . . . . . . . . . . . . . . 300-048038-001

Cutout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300-049602-008

Manual Reset Cutout (Optional) . . . . . . . . . 300-117647-006

Grille . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134-119147-004

Louver Assembly . . . . . . . . . . . . . . . . . . . . 182-047073-009

Mounting Bracket - (Right Hand) . . . . . . . . 027-025836-001

(Left Hand) . . . . . . . . . 027-025836-002

Thermostat (Optional) . . . . . . . . . . . . . . . . 300-026604-001

Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . 072-304551-008

Auxiliary Contact . . . . . . . . . . . . . . . . . . . . 072-304551-101

16

11

12

13

10

14

15

9

8

7

3

MOTORS AND CAPACITORS

TRANSFORMERS

6

FUSES

2

5

4

3

2

5

4

Page 12

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...