Page 1

Tubular Heaters

Application Guidelines

Components

• Upto172"Lengths(Std.)

• 75-10,000Watts(Std.)

• 120,240and480Volt(Std.)

• 3-53W/In2(Std.)

• Max.SheathTemp.

• Copper—350°F

• Steel—750°F

• StainlessSteel—1200°F

• INCOLOY®—1600°F

Applications

Extremely Versatile Heat Source — Highly

adaptable, the tubular element, in its many

forms and as a component of Chromalox

packaged heaters and systems, has vastly

increased the scale of electric heating applications. The heaters' mechanical and electrical

flexibility are important to process engineers

and product designers alike, as heating

requirements can be matched accurately

by proper selection from a great variety of

element lengths, sheaths, diameters and watt

densities.

Product Uniformity — Electric tubular heating

elements provide a method of applying the

exact amount of heat required at a specific

area. When used with appropriate temperature

control, product repeatability is assured.

Increased Production — Adding heat to a

process often leads to increased production.

For example, drying time may be reduced by

heating the air or the product being dried.

Chemical and cleaning processes are often

more efficient when heated and a more consistent finished product results.

Less Down Time — Chromalox quality tubular

elements with properly applied watt density

and sheath material will provide long life, less

down time and little or no maintenance.

Construction

Chromalox tubular elements are used for practically the entire range of electric resistance

heating applications.

A metal sheath material is selected. The

proper size resistance wire for the heating

element is carefully selected and verified by

computer calculations to ensure the longest

service life possible. The high quality resistor

wire is carefully tested and inspected to meet

rigid specifications prior to being coiled. The

resistance wire is then welded to a terminal

pin to assure positive connection. The wire is

centered in a metal sheath and insulated with

high quality magnesium oxide which is highly

compacted around it and acts as an electrical insulator. This material readily conducts

the heat from the coiled resistor to the metal

sheath and puts the heat where it is required,

which results in maximum heater life.

The highly compacted magnesium oxide holds

the terminal pin securely allowing maximum

torque of eight inch pounds when tightening

terminal hardware

Terminal Pin

Cold Length

Helically Coiled Resistor Wire

Metal

Sheath

Compacted

Magnesium Oxide

Typical Installations

In Free Air — For applications like ovens and

drying cabinets, tubular elements are compact, rugged heat sources. Their formability

permits fitting around other oven components

and work protrusions, concentrating heat at

any point.

In Free Air

In Moving Air — Compression

fittings, factory mounted fittings or

brackets will mount a tubular element

in a duct or air heating chamber.

In Moving Air

In Transferring Heat to Metal Parts - Dies,

Molds, Platens — The available diameters,

lengths, ratings, watt densities, cross-sections, and maximum temperatures provide the

solution for a given job.

Transferring Heat to Metal

In Liquids — Tubular elements listed may be

mounted through the side wall of a tank with

compression fittings or by factory mounted

fittings.

In Liquids

A-4

Page 2

Tubular Heaters

Components

Application

Guidelines (cont’d.)

Liquid Heating

Direct Immersion — Water and water solutions can generally be heated to any desired

temperature. If liquid is under pressure,

temperatures should not exceed the maximum

sheath temperature of the element minus

100°F.

Note — Heated section of element must be

immersed at all times when energized. Longer

cold ends can be provided, if required.

Threaded fittings are available for mounting

through tank walls.

Oil Heating

Steel sheath elements can be used for heating

oils, heat transfer oils and other solutions not

corrosive to steel sheath.

Air & Gas Heating

Use watt densities compatible with work

temperatures. Refer to Technical section of

this catalog. Heaters mounted horizontally

must be supported to avoid sagging at high

temperatures.

Proper spacing of supports may vary with

application temperature, element diameter and

sheath material. Generally 12 to 18" spacing of

supports is adequate.

Max. Sheath Temperatures

To assure maximum life, tubular elements

should not be operated beyond the temperatures in this tabulation:

Max. Allowable

Sheath Material

Copper 350

Steel 750

®

MONEL

Stainless Steel 1200

INCOLOY

INCONEL

®

®

Metric Diameter Equivalents

Inches (±0.005) Millimeter

0.5 12.7

0.475 12.07

0.43 10.92

0.375 9.53

0.315 8

0.26 6.6

0.246 6.25

0.2 5.08

Sheath Temp. (°F)

900

1600

1600

Where air flowing over elements permits use

of higher watt densities, make sure air flow is

evenly distributed.

Allow approximately 1/8" per foot of element

length for expansion and contraction of elements (i.e., 24" long element could expand

1/4" when energized).

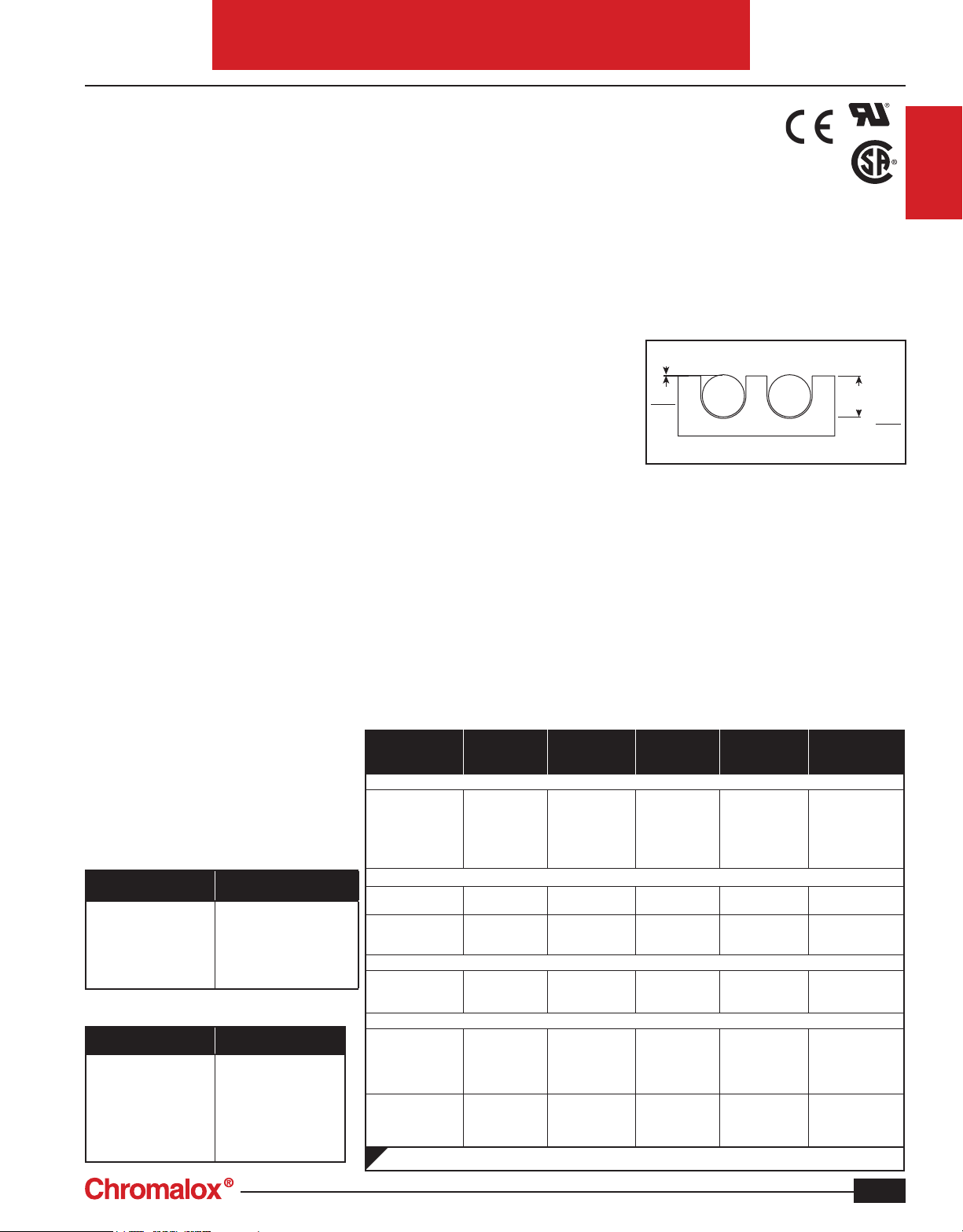

Note — Depth of groove should never exceed

element diameter to assure positive clamping.

Grooves should be machined to the following

tolerences:

Clamp-On Heating

Clamp-On Heating

Use watt densities compatible with work

temperatures. Refer to Application Guide for

Tubular Heating of Solids, Liquids, Air & Gas

or use curve G-175S in Technical section.

Heaters should be clamped tightly for good

heat transfer but should be allowed to expand

as they heat up. Heaters clamped too tightly

will bow away from the heated surface which

results in poor heating efficiency and possible

heater failure. It is generally best to tighten the

middle clamp first to hold the element. Other

clamps should be tightened enough to hold,

but back off 1/2 turn to allow for expansion

and contraction.

Heaters should be spaced on approximately

two inch centers minimum.

Heaters are commonly installed by clamping

into machined grooves for better heat transfer.

0.003

0.015

WARNING — When insulation is used over

elements, an air space must be provided between the elements and insulation. Insulation

should never be in direct contact with heated

section of elements.

Application Engineering

Is available from direct sales and engineering

representatives. The largest, most experienced

organization of field engineers in the country

is ready to help solve any heating problem.

Contact your Local Chromalox Sales office.

(See back of catalog.)

Tubular Heating Application Guidelines

Product To

Be Heated

Solids

Molds, Platens,

Dies, Pipes,

Tanks

Liquids

Water, Clean Up to 250

Water Solutions,

Mild Corrosion

Corrosive

Oil

Low Viscosity

Med. Viscosity

High Viscosity

Air&Gases

Moving, 9'/sec

Velocity

Still Up to 1500 Ovens INCOLOY

1

1. See Corrosion Guide in Technical section. 2.VDE - 50 W/In

Temperature

Desired

(°F)

Up to 1400 Clamp-On INCOLOY

Up to 550

Up to 200

1

,

Up to 200

Up to 180 Immersion Steel Up to 180 23

Up to 1500 In Ducts INCOLOY

Suggested

Application

Immersion

Immersion

Immersion

Immersion

Sheath

Material

Copper

INCOLOY

304SS

INCOLOY

®

®

®

®

®

Work

Temperature

(°F)

Up to 300

Up to 500

Up to 800

Up to 1000

Up to 1200

Up to 1400

250

550

200

200

500

800

1000

1200

1500

700

1000

1200

1500

Element

Dia. Less

0.008

0.010

Allowable

Watt Density

(W/In2)

30

20

15

10

7

2.5

Up to 80

40

50

50

15

6.5

40

32

25

15

2

30

20

10

2

2

max.

Tubular

2

A-5

Loading...

Loading...