Chromalox Tubular Heaters Accessories Catalog

Tubular Heaters

Customer Bending &

Accessories

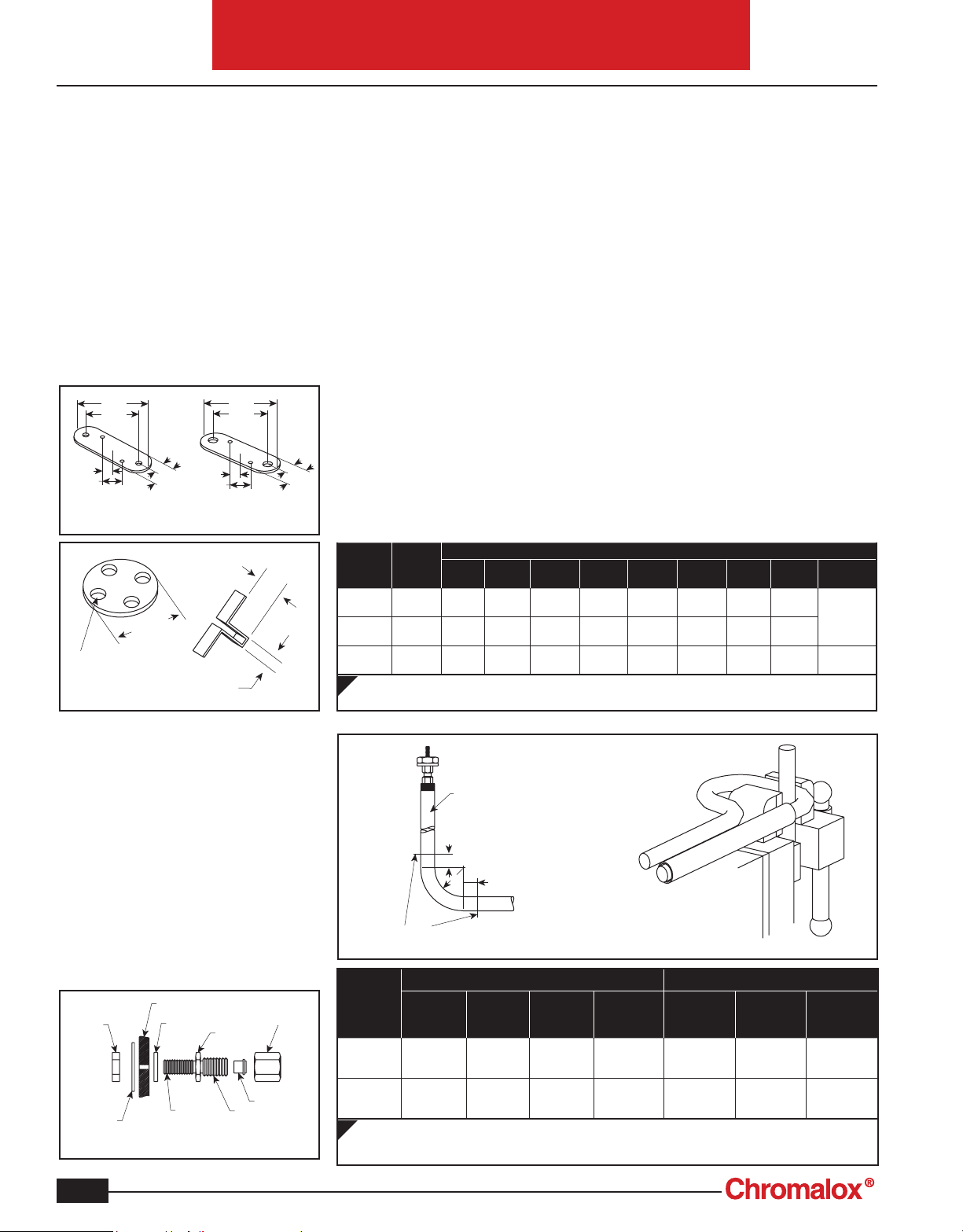

Brackets, Discs & Clips

Brackets, Discs and Clips — Various types

of brackets and clips can be fastened to the

heaters to facilitate installation. The following

are typical.

For other brackets to meet your installation

requirements, contact your Local Chromalox

Sales office.

31/32"

1-15/16"

Flange - Support

0.475" Element

5/32"

4-1/2"

3-3/8"

7/16"

Clip-Anchor

3/4"

1-1/2"

4-1/2"

3-3/8"

31/32"

1-15/16"

Flange - Support

0.315" Element

Elements are on

1" Dia. Bolt Circle

Disc

3/4"

1-7/16"

1-1/2" O.D.

Components

Customer Bending

Simple element configurations can be made

easily in the field from stocked tubulars

listed in this catalog. If copper or stainless

sheaths are selected, specify “To be fully

annealed for bending.” Elements can be bent

around any round, smooth surface of the right

diameter.

Three precuations should be observed to

prevent damage to the element:

1. Radius of the round object, around which

the element is bent, should be no smaller

than the minimum radius for the element,

as shown in the table below.

2. Sharp edges of tools should not be

permitted to gouge the element sheath

while bending.

3. End of cold section of the element should

not fall within the bend nor come within

1/4" of either side of the bend. To locate

Customer Bending — Min. Inside Radius (In.)

Sheath

Material

Copper 90

Steel 90

Alloy 90

Degree

of Bend 1/2" 0.475" 0.430" 3/8" 0.375" 0.315" 0.26" 0.246" 0.2"

3-1/2

1-1/2

180

180

180

1. For radii smaller than shown, special processing is required to achieve good life

qualities.ContactyourLocalChromaloxSalesofce.

3-1/2

2-1/2

2-1/2

2-1/2

2-1/2

1-1/2

1-1/2

1-1/2

1-1/2

1-1/2

1-5/16

1-5/16

1-5/16

1-5/16

1-5/16

1-5/16

end of cold section, see dimensions for the

element on its catalog page and determine

as follows:

Example — To locate end of cold section

of TRI-1645 tubular element, refer to

the individual product page.

Sheath length: 16"

Less heated length: 9-1/8"

Total cold length: 6-7/8"

Cold length of each end

(6-7/8" ÷ 2) = 3-7/16"

Terminal end bending can be done with pipe

section of slightly larger diameter than sheath.

A minimum 1" straight section should be left

at the end. Note — To protect sheath, copper

sheet can be bolted to vise jaws and end of

pipe can be filed to remove sharp edge.

Before bending, it is best to lay out and dimension the configuration. Also, it is best to start

bending from the center of the heater and

work toward the terminal ends.

2-5/16

2-5/16

1-7/8

1-7/8

1-7/8

1-7/8

1-1/8

1-1/8

1-1/8

1-1/8

1-1/8

1-1/8

15/16

15/16

15/16

15/16

15/16

15/16

7/8

7/8

7/8

7/8

7/8

7/8

3/4

3/4

3/4

3/4

3/4

3/4

Not Std.

Mat.

in this

Dia.

5/8

5/8

Compression Fittings

Field Installed Compression Fittings — For

0.475, 0.315 and 0.246" diameter elements.

Available in both brass and steel, these fittings

have been tested to 600 psi hydrostatic pressures and may be used in tank walls for liquid

immersion as well as in air ducts and a variety

of other applications.

Compression fittings do not require brazing

and can be field mounted in minutes. They

may be positioned anywhere along the cold

section of the heating element. Do not position

over heated section. Cannot be installed over

terminal Type #26 (Hermetic Seal), and some

other terminals wider than sheath diameter.

Tank Wall

Hex Nut

Washer

Compression Fittings for 0.475, 0.315 and 0.246"

Diameter Elements for Installation in the Field.

Gasket

Thread F

Fitting

Thread G

Compression

Nut

Ferrule

Leave 1" Min.

Straight Section

at Terminal End

1/4

1/4

R

End of Heated Section Must Not Be Within These Two Points

1

Material

Brass

Brass

Brass

Steel

Steel

Steel

ToOrder—Specify PCN, material, element diameter and quantity. Available in pairs only.

1. Available only in brass and steel at this time.

Elem.

Dia.

0.246

0.315

0.475

0.246

0.315

0.475

Terminal End

Dimensions (In.) Thread Size

Mtg. Hole

Dia.

13/32

15/32

21/32

13/32

15/32

21/32

Max. Wall

Thickness

7/32

5/16

5/16

7/32

5/16

5/16

Assembled

Overall

Length F G PCN

1-7/16

1-1/2

2

1-3/4

1-3/4

2-1/8

3/8-24

7/16-28

5/8-24

3/8-24

7/16-28

5/8-24

Bending

1/2-24

1/2-24

3/4-24

1/2-24

1/2-24

3/4-24

144151

144143

144135

143474

143466

143458

A-12

Loading...

Loading...