Tubular Heaters

Components

Modifications

World Leader in the Manufacture of Electric

Heating Elements — Chromalox offers the

most complete line of tubular heaters available. Standard diameters are:

Standard

Diameters

0.2

0.246

0.260

0.315

0.375

0.43

0.475

3/8”

1/2”

3/8”

7/16”

}

}

}

Round

Triangular

(heart shape)

Flat Pressed

Round Cross Section — Highly adaptable

where elements must be bent — particularly if

bending is performed in the field.

Triangular Cross Section — Patented process

produces elements with the closest possible

dimensional control.

Triangulated Cross Section — Flat pressed.

Patented process provides large contact area

for clamp-on applications. This means more

efficient heat transfer, fewer elements since

higher element ratings may be employed.

Voltage or Wattage — Heaters can be made

for operation on any voltage and rated at any

wattage suitable for the application within

practical limits. For voltages higher than 480V,

specify high voltage terminal construction.

See Component section Tubular Heater (0.475

or 1/2" diameter only).

Special Wattage Distribution — Heaters can

be made with higher wattages toward the end

of the heated section to help offset losses in

certain applications. Check with your Local

Chromalox Sales office for additional

information.

Tubing — Standard industrial grade wall

thickness:

Cross-Section

Views

Repressed Bends — Tubulars can be bent

to tighter radii at the factory. Bends are then

repressed to ensure re-compaction of insulation for long life. Customer bending on larger

radii does not require repressing. (See Factory

Bending Guidelines in this section).

Sheath Length — Larger diameter heaters can

be made in unspliced lengths up to 51 feet.

This eliminates the need for a spliced joint

which is always a possible weak point that

might cause premature heater failure.

Element Dia. (In.)

0.2 10

0.246 40

0.375 40

0.315 40

0.43 40

0.475 51

3/8 17±1/8"

1/2 17±1/8

Note— Single-end elements have a

maximum sheath length of 10 feet.

Max. Heater

Length (Ft. ± 1%)

Terminal Construction — Many choices to

suit your application. Tubular elements generally have a terminal for electrical connection

at each end. Single end construction has both

terminals at the same end.

UL and CSA — Chromalox tubular heaters

can be furnished as UL Recognized and CSA

Certified components with the addition of a

terminal end seal. Terminal end seals can be

added to stock elements and shipped in one

week. (UL File E198480, Guide UBJY2, CSA

File 40859). Use “end seal/moisture barrier” in

place of end seal.

VDE and CE — Chromalox tubular heaters can

be furnished as VDE Certified and CE certified.

Contact your Local Chromalox Sales office.

Wide Choice of Sheath Materials — Available

to meet a wide variety of applications. Standard sheath materials are: INCOLOY

type 304 and 316 stainless

steel, copper, INCONEL

Element

Dia. (In.)

0.246

0.315

3/8

1/2-0.475

0.246

0.315

3/8

1/2-0.475

0.246

0.315

3/8

1/2-0.475

®

and MONEL®.

Fitting

Material

Brass

Brass

Brass

Brass

Steel

Steel

Steel

Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

®

, steel,

Mtg. Hole

Dia. (In.)

13/32

15/32

17/32

21/32

13/32

15/32

17/32

21/32

13/32

15/32

17/32

21/32

In addition, titanium and other 300

series stainless steel sheaths are

available upon request. For applications requiring other materials,

contact your Local Chromalox Sales

office.

Cold Section — Longer cold ends can be supplied, as required, up to 20 inches. For longer

cold ends, contact your Local Chromalox

Sales office.

Factory Bending — Tighter bends can be

made at the factory.

Tubular heaters can be formed to many different shapes to suit your application. This is

done by specially designed bending tools and

repressing dies for bending on many different

radii.

Additional Features — Many additional features are available for the difficult jobs which

require custom designed elements employing

Chromalox's vast engineering experience.

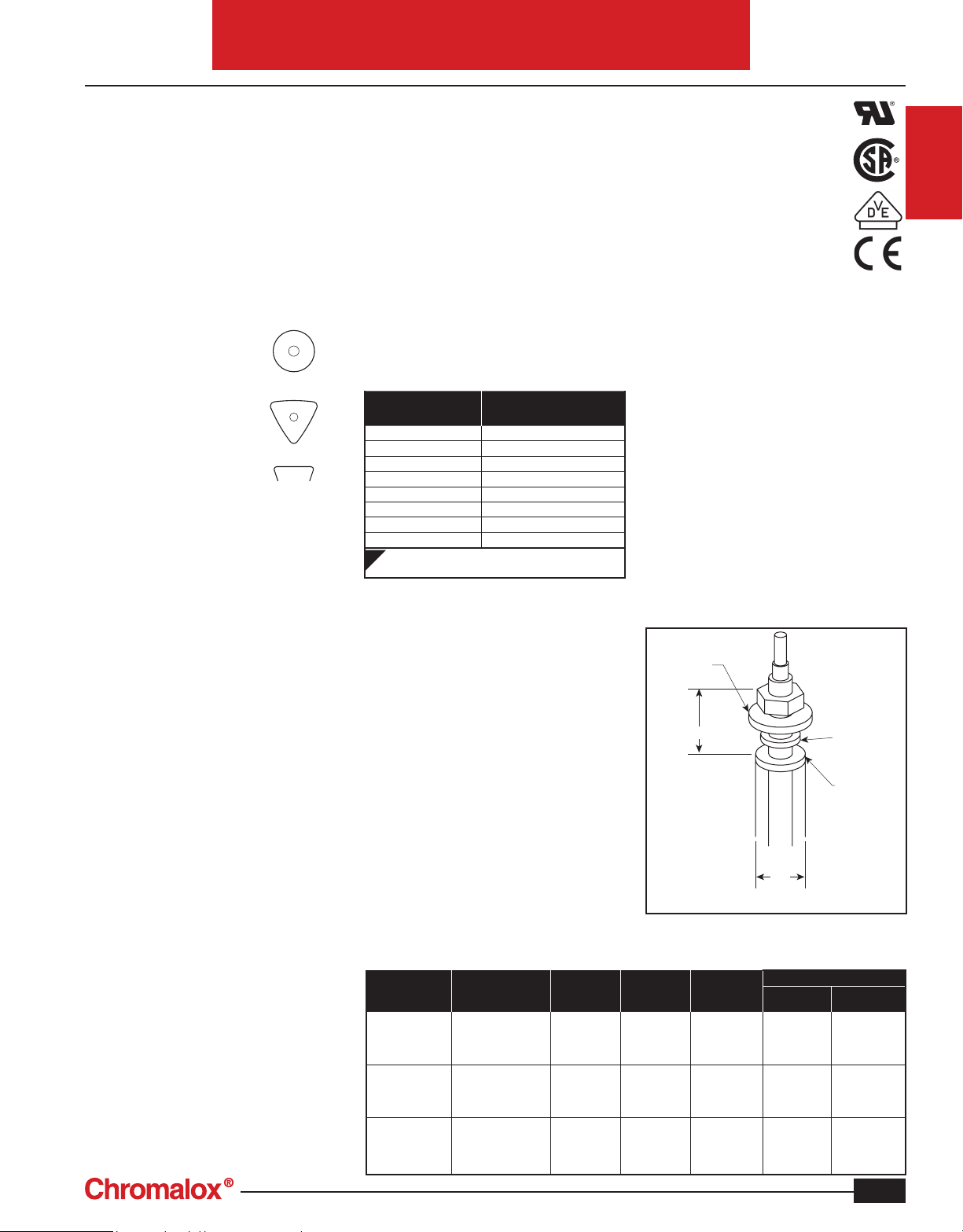

Threaded Fittings

Nickel Plated

Steel Washer

Max. Wall

Thickness

(In.)

7/32

5/16

5/16

5/16

7/32

5/16

5/16

5/16

7/32

5/16

5/16

5/16

A

Thrd. Size

F

3/8 - 24

7/16 - 28

1/2 - 28

5/8 - 24

3/8 - 24

7/16 - 28

1/2 - 28

5/8 - 24

3/8 - 24

7/16 - 28

1/2 - 28

5/8 - 24

B

15/32

13/16

13/16

13/16

15/32

13/16

13/16

13/16

15/32

13/16

13/16

13/16

Gasket Washer

Welded or

Brazed Ring

Dimensions (In.)

A B

7/8

7/8

7/8

1

7/8

7/8

7/8

1

7/8

7/8

7/8

1

Tubular

A-7

Loading...

Loading...