Chromalox TLC-210, TLC-318, TLC-315, TLC-212, TLC-220 Installation, Operating, & Maintenance Instructions

...Page 1

Chromalox

®

DIVISION 4 SECTION

TL

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation, Operation,

Maintenance Instructions

and

RENEWAL PARTS IDENTIFICATION

PD411-10

AUGUST, 2008

(Supersedes PD411-9)

161-048529-001

Incorporates PD410-8 and PD413-6.

These manuals have been discontinued.

Type TLC, TLO, TLS, TLI, KTLC, KTLO, KTLS,

KTLI, KBLC, KBLS, BLCK, & BLCS Series

Industrial Over-The-Side Immersion Heaters

© 2010 Chromalox, Inc.

Safety Guidelines

The safety and performance of this heater is dependent on proper

handling, installation, control and maintenance. As Chromalox can not

anticipate all conditions under which this information and heater, or

this heater in combination with other manufacturer’s products may be

used, it is advised that you conduct your own tests to determine the

safety and suitability of this heater in combination with other products

in your application. Where the consequences of overheating or failure

could result in personal injury or property damage, back-up controls

and safety devices are essential.

The Safety Alert Symbol: is found throughout these installation instructions to identify potential hazards that can result in personal injury. The seriousness of the potential risk is identified by one of

these three words:

– will result in serious injury or death.

– could result in serious injury or death.

– may result in minor or moderate injury.

Read and follow these instructions to minimize risks of electric

shock or fire. Save these instructions for future reference.

Chromalox Type TLC, TLO,TLS,TLI, KTLC, KTLO, KTLS,

KTLI, KBLC, KBLS, BLCK, & BLCS series industrial Over-TheSide immersion heaters are designed for a wide variety of heating

applications.

1. Heater Construction Characteristics

A. High quality resistance wire held in place by compacted

Magnesium Oxide Refractory or compacted proprietary

cement enclosed in a wide variety of sheath materials.

B. Low to high watt densities.

C. Standard selection of sheath materials include copper, steel,

INCOLOY

®

alloy and stainless steel. This broad selection of

sheath materials will operate successfully in many corrosive

solutions.

GENERAL

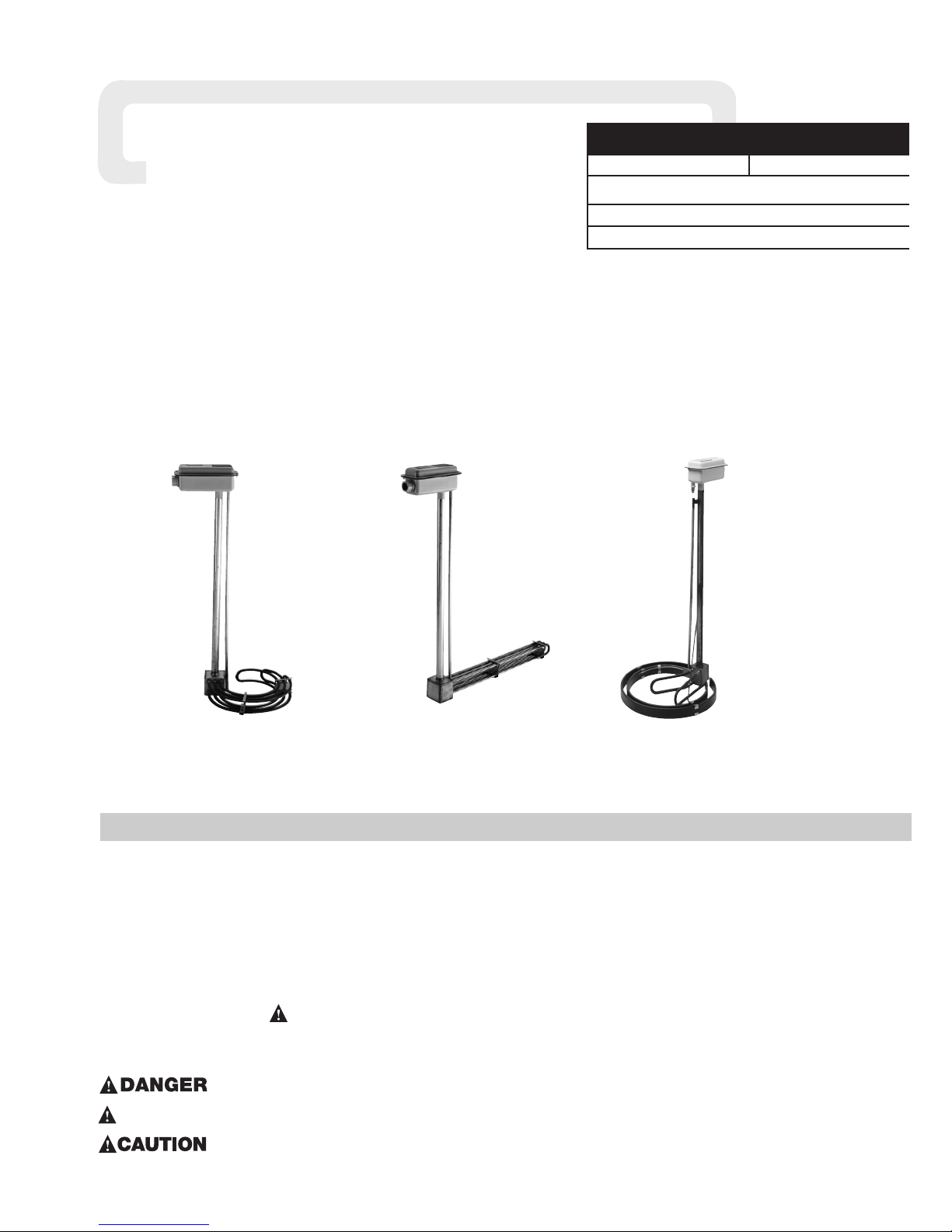

Type KTLC

Type TLC

Type KBLS

Shown above are Moisture Resistant Terminal Enclosures. Explosion Resistant Terminal Enclosure not shown.

Note: Consult factory for specific installation instructions for heaters with additional features not detailed in this installation guide.

Such additional features may include thermocouples supplied as a special order modification.

!

!

WARNING

Page 2

2

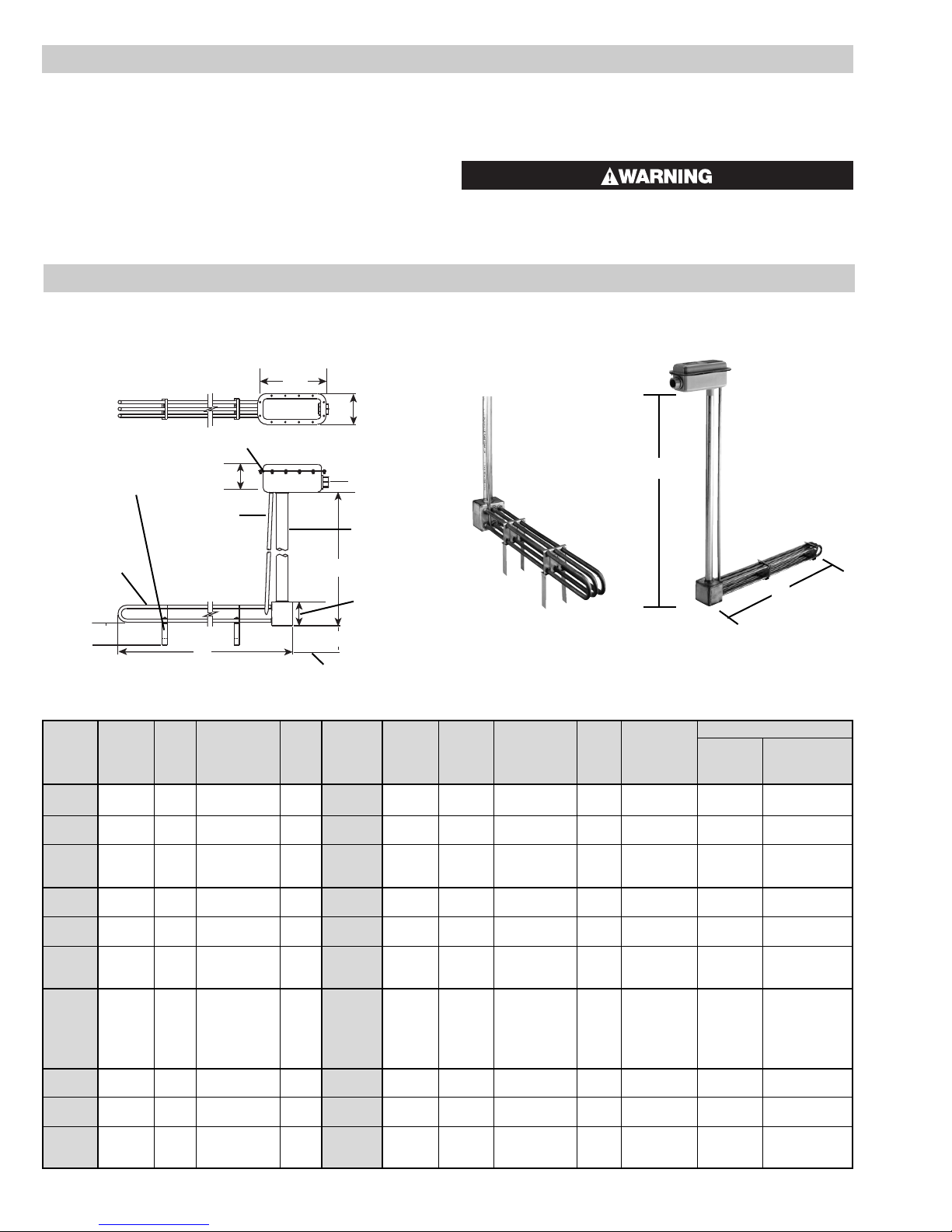

Specifications –

Dimensions (In.)

(A) (B)

No. No. Sheath Min. Tank

Model Elements Phase Volts kW Model Elements Phase Volts kW Material Riser Height Opening Clearance

TLC-210 2 1 240-480 10 TLC-315 3 1 or 3Δ 240-480 15 Copper 48 45

TLC-212 2 1 240-480 12 TLC-318 3 1 or 3Δ 240-480 18 Copper 48 52-1/2

TLC-220 2 1 120-240-480 2 TLC-330 3

1 or 3Δ 120-240

3 Copper 36 12-1/4

1 or 3Y 480

TLC-240 2 1 120-240-480 4 TLC-360 3 1 or 3Δ 120-240-480 6 Copper 36 22-1/4

TLC-260 2 1 120-240-480 6 TLC-390 3 1 or 3Δ 120-240-480 9 Copper 36 29-1/2

TLC-280 2 1 240-480 8 TLC-312 3 1 or 3Δ 240-480 12 Cooper 36, 48 37-3/8

TLI-210 2 1 240-480 10 TLI-315 3 1 or 3Δ 240-480 15 Incoloy 48 45

TLI-212 2 1 240-480 12 TLI-318 3 1 or 3Δ 240-480 18 Incoloy 48 52-1/2

TLI-220 2 1 120-240-480 2 TLI-330 3

1 or 3Δ 120-240

3 Incoloy 36 12-1/4

1 or 3Y 480

TLI-240 2 1 120-240-480 4 TLI-360 3 1 or 3Δ 120-240-480 6 Incoloy 36 22-1/4

TLI-260 2 1 120-240-480 6 TLI-390 3 1 or 3Δ 120-240-480 9 Incoloy 36 29-1/2

TLI-280 2 1 240-480 8 TLI-312 3 1 or 3Δ 240-480 12 Incoloy 36, 48 37-3/8

TLO-220 2 1 120-240-480 2 TLO-330 3 1 or 3Δ 120-240-480 3 Steel 36 22-1/4

TLO-230 2 1 120-240-480 3 TLO-345 3 1 or 3Δ 120-240-480 4.5 Steel 36 29-1/2

TLO-240 2 1 120-240-480 4 TLO-360 3 1 or 3Δ 120-240-480 6 Steel 36, 48 37-3/8

TLO-250 2 1 120-240-480 5 TLO-375 3 1 or 3Δ 120-240-480 7.5 Steel 48 45

TLO-260 2 1 120-240-480 6 TLO-390 3 1 or 3Δ 120-240-480 9 Steel 48 52-1/2

TLO-270 2 1 240-480 7 TLO-310 3 1 or 3Δ 240-480 10 Steel 48 56-1/2

TLS-210 2 1 240-480 10 TLS-315 3 1 or 3Δ 240-480 15 Stainless Steel 48 45

TLS-212 2 1 240-480 12 TLS-318 3 1 or 3Δ 240-480 18 Stainless Steel 48 52-1/2

TLS-220 2 1 120-240-480 2 TLS-330 3

1 or 3Δ 120-240

3 Stainless Steel 36 12-1/4

1 or 3Y 480

TLS-240 2 1 120-240-480 4 TLS-360 3 1 or 3Δ 120-240-480 6 Stainless Steel 36 22-1/4

TLS-260 2 1 120-240-480 6 TLS-390 3 1 or 3Δ 120-240-480 9 Stainless Steel 36 29-1/2

TLS-280 2 1 240-480 8 TLS-312 3 1 or 3Δ 240-480 12 Stainless Steel 36, 48 37-3/8

(A)

(B)

Note: Thermostat shipped separately in kit. See page

with renewal parts for ordering information.

(10)

(A)

(B)

(4)

(4-1/2)

(3-1/2)

3-1/2 approx.

Tank Bottom

1”–11-1/2 NPT

Tube Riser

Gasket

Thermostat Well

Heating Elements

Sludge Leg/s

Assemble

As Shown

(See Installation)

(4-1/16)

TLC, TLO, TLS, TLI

SPECIFICATIONS

GENERAL (cont’d.)

D. Riser type construction puts the heat at the bottom inducing

natural “stirring action” and evenly distributed temperatures.

E. Units are available with E1 General Purpose, E4 Moisture

Resistant, E2 Explosion/Moisture Resistant and E3 Explosion

Resistant terminal enclosures.

IMPORTANT: It is the responsibility of the purchaser of

the heater to make the ultimate choice of sheath

material based upon his knowledge of the chemical

composition of the corrosive solution, character of

the materials entering the solution, and controls

which he maintains on the process. CHROMALOX

cannot warrant any electric immersion heater against

failure by sheath corrosion if such failure is the result

of operating conditions beyond our control.

Sheath corrosion can result in a ground fault which,

depending upon the solution being heated, can cause

an explosion or fire.

Page 3

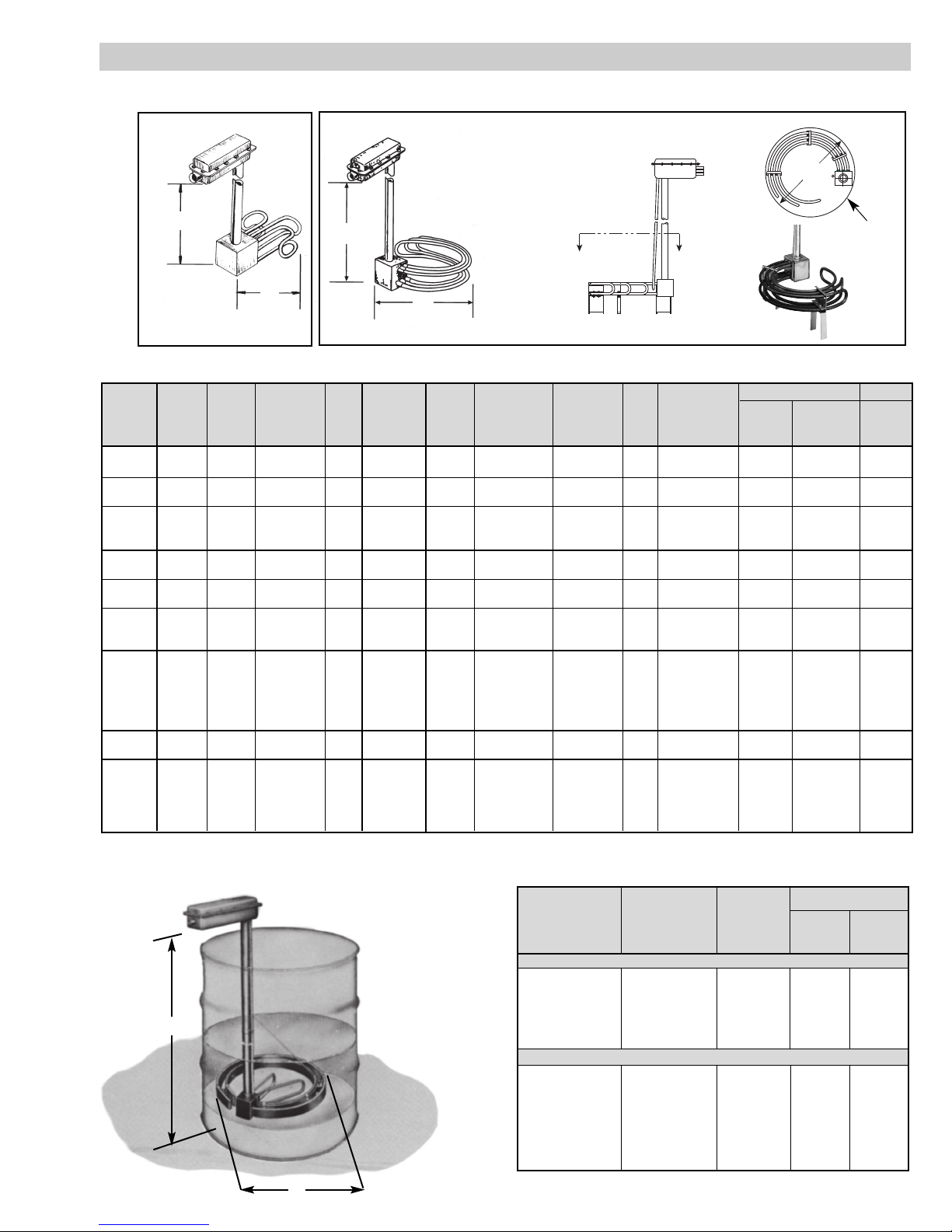

DIMENSIONS

Inches

(A) (B)

Kw Riser

Min. Opening

Model Volts (11 WPSI) Height Clearance

Type KBLC – Steel Construction

KBLC-24 120 or 240 2.2 36 12-3/4

KBLC-24T2 120 or 240 2.2 36 12-3/4

KBLC-24T3 120 or 240 2.2 36 12-3/4

KBLC-28 240 only 4.4 36 17-3/4

KBLC-28T2 240 only 4.4 36 17-3/4

KBLC-28T3 240 only 4.4 36 17-3/4

Type KBLS – Stainless Steel Construction

KBLS-244 120 or 240 2.2 36 12-3/4

KBLS-244T1 120 or 240 2.2 36 12-3/4

KBLS-244T2 120 or 240 2.2 36 12-3/4

KBLS-244T3 120 or 240 2.2 36 12-3/4

KBLS-288 240 only 4.4 36 17-3/4

KBLS-288T1 240 only 4.4 36 17-3/4

KBLS-288T2 240 only 4.4 36 17-3/4

KBLS-288T3 240 only 4.4 36 17-3/4

3

Specifications –

(A)

(B)

KBLC, KBLS

KTLC, KTLI, KTLO, KTLS

Specifications –

Dimensions (In.)

(A) Standard

(B) Min. Element

No. No. Sheath Riser Tank Opening Arrange-

Model Elements Phase Volts kW Model Elements Phase Volts kW Material Height Clearance ment

KTLC-210 2 1 240-480 10 KTLC-315 3 1 or 3Δz 240-480 15 Copper 48 21-1/4 Fig. 2

KTLC-212 2 1 240-480 12 KTLC-318 3 1 or 3Δz 240-480 18 Copper 48 23-1/2 Fig. 2

KTLC-220 2 1 120-240-480 2 KTLC-330 3

1 or 3Δz 120-240

3 Copper 36 10-5/8 Fig. 1

1 or 3Y 480

KTLC-240 2 1 120-240-480 4 KTLC-360 3 1 or 3Δ 120-240-480 6 Copper 36 13-3/4 Fig. 2

KTLC-260 2 1 120-240-480 6 KTLC-390 3 1 or 3Δ 120-240-480 9 Copper 36 16-1/8 Fig. 2

KTLC-280 2 1 240-480 8 KTLC-312 3 1 or 3Δ 240-480 12 Cooper 36, 48 18-5/8 Fig. 2

KTLI-210 2 1 240-480 10 KTLI-315 3 1 or 3Δ 240-480 15 Incoloy 48 21-1/4 Fig. 2

KTLI-212 2 1 240-480 12 KTLI-318 3 1 or 3Δ 240-480 18 Incoloy 48 23-1/2 Fig. 2

KTLI-220 2 1 120-240-480 2 KTLI-330 3

1 or 3Δ 120-240

3 Incoloy 36 10-5/8 Fig. 1

1 or 3Y 480

KTLI-240 2 1 120-240-480 4 KTLI-360 3 1 or 3Δ 120-240-480 6 Incoloy 36 13-3/4 Fig. 2

KTLI-260 2 1 120-240-480 6 KTLI-390 3 1 or 3Δ 120-240-480 9 Incoloy 36 16-1/8 Fig. 2

KTLI-280 2 1 240-480 8 KTLI-312 3 1 or 3Δ 240-480 12 Incoloy 36, 48 18-5/8 Fig. 2

KTLO-220 2 1 120-240-480 2 KTLO-330 3 1 or 3Δ 120-240-480 3 Steel 36 13-3/4 Fig. 2

KTLO-230 2 1 120-240-480 3 KTLO-345 3 1 or 3Δ 120-240-480 4.5 Steel 36 16-1/8 Fig. 2

KTLO-240 2 1 120-240-480 4 KTLO-360 3 1 or 3Δ 120-240-480 6 Steel 36, 48 18-5/8 Fig. 2

KTLO-250 2 1 120-240-480 5 KTLO-375 3 1 or 3Δ 120-240-480 7.5 Steel 48 21-1/4 Fig. 2

KTLO-260 2 1 120-240-480 6 KTLO-390 3 1 or 3Δ 120-240-480 9 Steel 48 23-1/2 Fig. 2

KTLO-270 2 1 240-480 7 KTLO-310 3 1 or 3Δ 240-480 10 Steel 48 24-7/8 Fig. 2

KTLS-210 2 1 240-480 10 KTLS-315 3 1 or 3Δ 240-480 15 Stainless Steel 48 21-1/4 Fig. 2

KTLS-212 2 1 240-480 12 KTLS-318 3 1 or 3Δ 240-480 18 Stainless Steel 48 23-1/2 Fig. 2

KTLS-220 2 1 120-240-480 2 KTLS-330 3

1 or 3Δ 120-240

3 Stainless Steel 36 10-5/8 Fig. 1

1 or 3Y 480

KTLS-240 2 1 120-240-480 4 KTLS-360 3 1 or 3Δ 120-240-480 6 Stainless Steel 36 13-3/4 Fig. 2

KTLS-260 2 1 120-240-480 6 KTLS-390 3 1 or 3Δ 120-240-480 9 Stainless Steel 36 16-1/8 Fig. 2

KTLS-280 2 1 240-480 8 KTLS-312 3 1 or 3Δ 240-480 12 Stainless Steel 36, 48 18-5/8 Fig. 2

(A)

(A)

(B)

(B)

Figure 1

Figure 2

A

(B)

A

Section A-A

Min. Tank

Clearance

SPECIFICATIONS (cont’d.)

Page 4

FIRE HAZARD. An integral thermostat, if provided,

is designed for temperature control service only.

Because the thermostat does not fail safe, it should

not be used for temperature limiting duty. Wiring to

this device is the responsibility of the user.

The system designer is responsible for the safety

of this equipment and should install adequate

back-up controls and safety devices with their

electric heating equipment. Where the consequences of failure could result in personal injury or

property damage, back-up controls are essential.

FIRE/EXPLOSION HAZARD. Use only Explosion

Resistant Enclosures (E2, E3 or ER) in hazardous

atmospheres where flammable vapors, gases, liquids

or other combustible atmospheres are present as

defined in the National Electrical Code (NFPA 70).

Failure to comply could result in personal injury or

property damage.

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed by a qualified person

in accordance with the National Electrical Code,

NFPA 70.

1. Before installing, check your Over-The-Side heater for any dam-

age that may have occurred during shipment. Also, check to ensure

that the line voltage is the same as that stamped on the nameplate.

2.

Do not bend heating elements. If bending is necessary, consult factory.

3. IMPORTANT: Mount the heater in the tank so that the liquid

level will always be above the effective heated portion of the

heater. If the heater is not properly submerged, it will overheat and

damage the heating elements and create a possible fire hazard due

to excessive sheath temperatures. See “Warning” under

“Installation” section. (see Figure 3).

4. Heater must be supported from tank bottom. Heater must not be

operated in sludge. Sludge legs can be provided. Assemble as

shown in Figure 3.

5. Where work will pass over or near equipment, additional protec-

tion, such as a metal guard, may be needed.

6. In the electroplating operation the heaters are not, under any cir-

cumstance, to be placed between the electrodes and the work.

7. When melting solids by direct immersion, a surface vent should be

provided to allow gases to escape. Operate the heater on half voltage until melted material completely covers the heater area.

8. A drip loop is recommended to minimize passage of moisture

along wiring into terminal enclosure and connections.

FIRE HAZARD. Since heaters are capable of developing

high temperatures, extreme care should be taken to:

A. Use explosion-resistant terminal enclosures in hazardous loca-

tions. Consult Chromalox for selection of explosion-resistant

terminal enclosures for hazardous locations.

B. Avoid contact between heater and combustible materials.

C. Keep combustible materials far enough away to be free of the

effects of high temperatures.

FREEZE HAZARD. Some Over-The-Side heaters are

equipped with a thermowell for process control or

over-temperature control. Do not allow moisture to

accumulate in thermowell. Freezing temperatures

can cause damage that may result in the heated

medium leaking into terminal enclosure.

INSTALLATION

4

Specifications –

Kilowats Dimensions (In.)

No. Regular Oil Fuel Oil (A) (B) Min. Tank

Model Blades Phase 18 W/in

2

12 W/in

2

40 W/in

2

Voltage Riser Height

Opening Clearance

(C)

BLCK-MH618 6 1 or 3 ⌬ 12 7.5 – 240 or 480 144 16-1/2 8-7/8

BLCK-MH824 8 1 or 3 ⌬ 16 10 – 240 or 480 144 16-1/2 12

BLCK-MH103 10 1 or 3 ⌬ 20 12.5 – 240 or 480 144 16-1/2 15-1/8

BLCK-MH236 12 1 or 3 ⌬ 24 15 – 240 or 480 144 16-1/2 18-1/4

BLCS-618 6 1 or 3 ⌬ 12 7.5 – 240 or 480 144 34 8-7/8

BLCS-824 8 1 or 3 ⌬ 16 10 – 240 or 480 144 34 12

BLCS-1030 10 1 or 3 ⌬ 20 12.5 – 240 or 480 144 34 15-1/8

BLCS-1236 12 1 or 3 ⌬ 24 15 – 240 or 480 144 34 18-1/4

BLCK, BLCS

4 to 12 Blades

Type BLCK-MH

1-1/4” Ground Joint

Malleable Iron Union

1-1/4” Round

Floor Flange

Malleable Iron

1-1/4” Steel

Pipe Riser

Type BLCS

1-1/4” Pipe Opening

(4-5/32)

of Mtg. Hole

same as Dim. “A”

Suspension Bracket

4 to 12 Blades

C

L

(C)

(B)

(A)

(A)

(C)

(B)

!

SPECIFICATIONS (cont’d.)

Page 5

ELECTRIC SHOCK HAZARD. Any installation involving electric heaters must be performed by a qualified person and must be effectively grounded in

accordance with the National Electrical Code to

eliminate shock hazard.

1. Electric wiring to heater must be installed in accordance with the

National Electrical Code and with local codes by a qualified person. CAUTION: Use copper conductors only.

2. When element wattages are not equal, heaters must not be con-

nected in series.

3. Electrical wiring to heater should be contained in rigid conduit or

in sealed flexible conduit to keep corrosive vapors and liquids out

of the terminal enclosure. If high humidity is encountered, the conduit should slope away from the heater.

4. If flexible cord is employed, a watertight connector should be used

for entry of the cord into the terminal enclosure. Outdoor applications require liquid-tight conduit and connectors.

5. Bring the power line wires through the opening in the terminal

enclosure.

6. Heaters are prewired and tagged for easy installation of electrical

wiring to the heater. Tagging of the individual circuits of

Chromalox Industrial Over-The-Side Immersion heaters is shown

in the following tabulations. Refers to Type TLC, TLO, TLS, TLI,

KTLC, KTLO, KTLS, KTLI, KBLC, KBLS, BLCK, and BLCS

Series heaters.

7. Make sure heater, is grounded by attaching ground conductor,

traceable back to service entrance, to the ground terminal located

inside the terminal enclosure. If heater is used in an electroplating

tank, the heater should be grounded externally to the tank wall to

minimize stray plating currents in heater sheath that may cause

sheath corrosion.

8. Check for loose terminal connections and tighten if necessary.

Made to order items are prewired and tagged at the factory. Wiring

of made to order items may differ from those shown in the tabulations. Carefully check voltage and phase on the heater name-

plate and select either the appropriate wiring shown above or

check for the appropriate wiring diagram in the heater terminal enclosure. For reference purposes, some typical wiring dia-

grams are shown in the following figures.

5

WIRING

WIRING DIAGRAMS – TLC, TLO, TLS, TLI

120V 120V 240V 240V 480V 480V 480V 120V 120V 240V 240V 480V 480V 480V

Model 1ø 3øΔz 1ø 3øΔz 1ø 3øΔz 3øY Model 1ø 3øΔz 1ø 3øΔz 1ø 3øΔz 3øY

Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig.

TLC, TLI and TLS 210 — — 1 — 1 — — TLO 310 — — 3 4 3 4 —

TLC, TLI and TLS 212 — — 1 — 1 — — TLC, TLI and TLS 312 — — 3 4 3 4 —

TLC, TLI, TLO and TLS 220 1 — 1 — 2 — — TLC, TLI and TLS 315 — — 3 4 3 4 —

TLO 230 1 — 1 — 1 — — TLC, TLI and TLS 318 — 3 4 3 4 —

TLC, TLI, TLO and TLS 240 1 — 1 — 1 — — TLC, TLI, TLO and TLS 330 3 4 3 4 5 4 6

TLO 250 1 — 1 — 1 — — TLO 345 3 4 3 4 3 4 —

TLC, TLI, TLO and TLS 260 1 — 1 — 1 — — TLC, TLI, TLO and TLS 360 3 4 3 4 3 4 —

TLO 270 — — 1 — 1 — — TLO 375 3 4 3 4 3 4 —

TLC, TLI and TLS 280 — — 1 — 1 — — TLC, TLI, TLO and TLS 390 3 4 3 4 3 4 —

Note: Use wire size and type specified by NEC.

480V heaters require 600V wire per NEC.

480V heaters require a contactor.

Contactor and wiring supplied by customer.

INSTALLATION (cont’d.)

9. To prevent moisture accumulation in cryogenic applications or

when heater is exposed to freezing temperatures:

A. Slope conduit away from enclosure (drip loop).

B. Seal all conduit openings to moisture/explosion resistant ter-

minal enclosure.

C. Insulate terminal enclosure.

FIRE OR SHOCK HAZARD. Moisture accumulation

in the element refractory material, element overtemperature, or sheath corrosion can cause

ground fault to the element sheath, generating arcing and molten metal. Install Ground Fault CircuitInterrupter (GFCI) to prevent personal injury or

Equipment Ground Fault Protection to prevent

property damage.

10. Heaters with floor flange:

A. Remove electrical enclosure.

B. Mount heater to tank or manhole cover.

C. Install electrical enclosure.

Fittings into electrical enclosure must be properly

sealed to prevent contamination of electrical contacts from vapors.

FIRE OR EXPLOSION HAZARD. If the heater is not

properly submerged, the heating elements will overheat and could result in a fire or damaged equipment.

NOTE: If heating in closed vessels, controls and

backup controls must be used to prevent buildup of

temperature and/or pressure. Maximum pressure

rating is 50 PSI.

Drip Loop recommended to

minimize passage of moisture

along wiring into terminal

wiring connections.

Expected Low Liquid Level

Always maintain a minimum of

6 to 8" of liquid above the heated

portion of the element to prevent

exposure of the effective

heated length.

Expected maximum

sediment level

Sludge Legs

NOTE: Locate the heater as low as possible for maximum

heated liquid storage capacity. Heat does not move downward.

6 to 8"

Minimum

Suitable Wiring

FIGURE 3 Open Tank Illustration

!

Page 6

6

120V

or

240V

Contactor

Thermostat

Low

Liquid

Control

L1

L2

Term. Block

Junction Box

Factory

Field

120V

or

240V

Contactor

Thermostat

Low

Liquid

Control

L1

L2

Term. Block

Junction Box

L3

Factory

Field

WIRING DIAGRAM 3

WIRING DIAGRAM 4

120V

or

240V

Contactor

Thermostat

Low

Liquid

Control

L1

L2

Term. Block

Junction Box

Factory

Field

120V

or

240V

Contactor

Thermostat

Low

Liquid

Control

L1

L2

Term. Block

Junction Box

Factory

Field

WIRING DIAGRAM 2

WIRING DIAGRAM 1

120V 120V 240V 240V 480V 480V 480V 120V 120V 240V 240V 480V 480V 480V

Model 1ø 3øΔz 1ø 3øΔz 1ø 3øΔz 3øY Model 1ø 3øΔz 1ø 3øΔz 1ø 3øΔz 3øY

Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig.

KTLC, KTLI and KTLS 210 — — 1 — 1 — — KTLO 310 — — 3 4 3 4 —

KTLC, KTLI and KTLS 212 — — 1 — 1 — — KTLC, KTLI and KTLS 312 — — 3 4 3 4 —

KTLC, KTLI, KTLO and KTLS 220 1 — 1 — 2 — — KTLC, KTLI and KTLS 315 — — 3 4 3 4 —

KTLO 230 1 — 1 — 1 — — KTLC, KTLI and KTLS 318 — 3 4 3 4 —

KTLC, KTLI, KTLO and KTLS 240 1 — 1 — 1 — — KTLC, KTLI, KTLO and KTLS 330 3 4 3 4 5 4 6

KTLO 250 1 — 1 — 1 — — KTLO 345 3 4 3 4 3 4 —

KTLC, KTLI, KTLO and KTLS 260 1 — 1 — 1 — — KTLC, KTLI, KTLO and KTLS 360 3 4 3 4 3 4 —

KTLO 270 — — 1 — 1 — — KTLO 375 3 4 3 4 3 4 —

KTLC, KTLI and KTLS 280 — — 1 — 1 — — KTLC, KTLI, KTLO and KTLS 390 3 4 3 4 3 4 —

Note: Use wire size and type specified by NEC.

480V heaters require 600V wire per NEC.

480V heaters require a contactor.

Contactor and wiring supplied by customer.

WIRING DIAGRAMS – KTLC, KTLO, KTLS, KTLI

120V 120V 240V 240V 480V 480V 480V 120V 120V 240V 240V 480V 480V 480V

Model 1ø 3øΔz 1ø 3øΔz 1ø 3øΔz 3øY Model 1ø 3øΔz 1ø 3øΔz 1ø 3øΔz 3øY

Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig. Fig.

BLCK — — 1 4 1 4 — BLCS — — 7 8 7 8 —

Note: Use wire size and type specified by NEC.

480V heaters require 600V wire per NEC.

480V heaters require a contactor.

Contactor and wiring supplied by customer.

WIRING DIAGRAMS – BLCK, BLCS

Page 7

7

1. Do not operate heater at voltages in excess of that stamped on the

heater since excess voltage will shorten heater life.

2. Always maintain a minimum of 6 to 8” of liquid above the heated

portion of the element to prevent exposure of the effective heated

length. If the heater is not properly submerged, it will overheat and

shorten heater life. DO NOT OPERATE HEATER IF DRY.

3. Keep heating elements above sediment deposits.

4. Low Megohm Condition — The refractory material used in elec-

tric heaters may absorb moisture during transit, storage or when

subject to humid environments that will reduce the cold insulation

resistance (low megohm). Low megohm may result in a high leakage current to ground and nuisance trips of ground fault protection

equipment. Normally, the megohm value increases after heat-up.

Typical insulation valves are 5 megohm or greater on complete

assemblies or 20 megohm on individual unsealed elements. It is

recommended that heaters with 1 megohm or less be dried out

before applying full power. If dried properly, low megohm will not

effect heater life or efficiency.

To correct a low megohm condition, remove terminal enclosure

cover, gaskets, and terminal hardware. Bake heaters in an oven at

300 to 500˚F for several hours or preferably overnight.

An alternate procedure is to cycle the heater in 10 to 15 minute

periods at low voltage until megohm values are normal. Sheath

temperatures should not exceed 350˚F.

NOTE: Low megohm on heating elements with epoxy or hermetic

seals cannot be serviced in the field. Typical resistance values when sealed are 200 megohm or greater. Contact Chromalox service center at number listed.

OPERATION

Term. Block

Contactor

L1

L2

Thermostat

Junction Box

120V

or

240V

Low

Liquid

Control

Factory

Field

Term. Block

Contactor

L1

L2

Thermostat

Junction Box

120V

or

240V

Low

Liquid

Control

Factory

Field

L3

WIRING DIAGRAM 7

WIRING DIAGRAM 8

Factory

Field

120V

or

240V

Contactor

Thermostat

Low

Liquid

Control

L1

L2

Term. Block

Junction Box

L3

120V

or

240V

Contactor

Thermostat

Low

Liquid

Control

L1

L2

Term. Block

Junction Box

Factory

Field

WIRING DIAGRAM 6

WIRING DIAGRAM 5

Page 8

TA -V7 - EF

Litho in U.S.A.

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

MAINTENANCE

RENEWAL PARTS

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do so

could result in personal injury or property damage.

1. Heaters should be checked periodically for coatings and corrosion

and cleaned if necessary.

2. The tank should be checked regularly for sediment around the

heater as sediment can act as an insulator and shorten heater life.

Note: Applies to all items, not just #2.

Note: User is responsible for maintenance schedule based on their

knowledge of the heated medium and operating conditions.

3. Remove any accumulated sludge deposits from heater and from

tank.

4. Check for loose terminal connections.

5. If corrosion is indicated in the terminal enclosure, check termi-

nal enclosure gasket and replace if necessary. Check conduit

layout to correct conditions that allow corrosion to enter the terminal enclosure.

6. Clean terminal ends of all contamination.

1. Thermostat Kit (order by PCN):

A. 0-100°F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PCN 277835

B. 60-250°F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .PCN 277819

2. Thermostat Knob:

A. 0-100°F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169-019605-002

B. 60-250°F . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169-019604-001

C. 200-550˚F . . . . . . . . . . . . . . . . . . . . . . . . . . . .169-019604-002

3. Sludge Legs:

A. TLC, KTLC Series . . . . . . . . . . . . . . . . . . . . . .176-114713-001

B. TLI, KTLI Series . . . . . . . . . . . . . . . . . . . . . . .176-114713-001

C. TLO, KTLO Series . . . . . . . . . . . . . . . . . . . . . .176-114713-002

D.TLS, KTLS Series . . . . . . . . . . . . . . . . . . . . . .176-114713-003

Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132-012603-004

Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .080-012602-001

4 Post Terminal Block . . . . . . . . . . . . . . . . . . . . . . .303-001843-001

3 Post Terminal Block . . . . . . . . . . . . . . . . . . . . . . .303-006621-003

Thermostat Mounting Bracket . . . . . . . . . . . . . . . . .027-072456-001

4. Thermostat

A. 0-100°F (84” Capillary) . . . . . . . . . . . . . . . . . .300-048518-005

B. 60-250°F (84” Capillary) . . . . . . . . . . . . . . . . .300-048518-002

C. 200-550˚F (84” Capillary) . . . . . . . . . . . . . . . .300-048518-004

D.0-100°F (144” Capillary) . . . . . . . . . . . . . . . . .300-048518-019

E. 60-250°F (180” Capillary) . . . . . . . . . . . . . . . .300-048518-022

F. 200-550˚F (180” Capillary) . . . . . . . . . . . . . . .300-048518-023

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...