Page 1

TDH

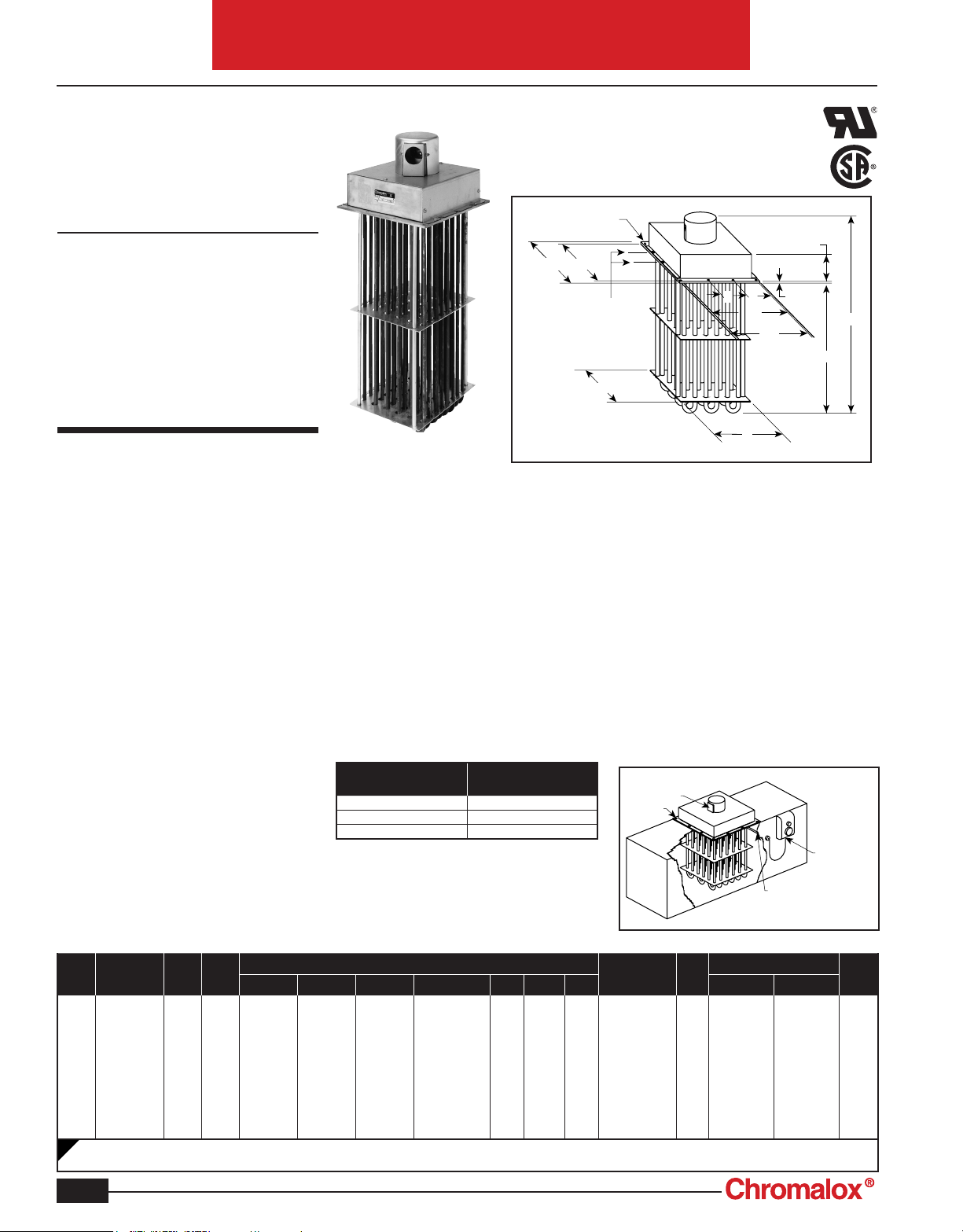

Process Air and Radiant

Medium Temperature

Air Duct Heater

• 6 - 60 kW

• 240 and 480 Volt

• Three Phase

• INCOLOY® Sheath Elements

• 750°F Max. Outlet Air Temp.

Applications

Heat Air for Drying and Curing Operations up

to 750°F Air Temperature, Heat Treating, Reheating or Dehumidification, Booster Heater

in Heating Ducts and Ovens.

Construction

U-Shaped Tubular Elements with INCOLOY®

sheath are mounted in a heavy gauge steel

flange with 9/32" diameter mounting holes for

attaching to duct work. All terminal connections are of high-temperature alloy construction and are enclosed in an aluminum painted

steel housing.

Features

Steel flange is equipped with special holes to

permit easy replacement of individual element.

Sheet steel terminal box may be removed to

facilitate wiring during installation.

All Heaters can be mounted in any position;

top, side or bottom entry. In high ambient

temperature operations, least corrosive action

and least oxidation to the terminals will occur

if heaters are mounted with terminals in the

coolest possible ambient, usually on bottom

Dimensions (Inches)

9/32" Dia.

Mtg. Holes

10-1/2

11-1/8

8-11/16

or side of duct. Minimum duct size is

A dimension plus 3/8" or 11-1/8" plus 3/8"

and B dimension plus 1-5/8".

Wiring — Terminals on field wiring con-

nections are located in circular junction box

outside of heating zone. Alloy wire or buss bar

must be used for power connections.

Maximum Sheath Temperature — 1150°F.

Application & Selection Guidelines

Maximum Work Temperatures — Type TDH

heaters can generally be used at the following

maximum temperatures, without exceeding

their capability, if properly installed according

to instructions packed with heaters.

Air Velocity

(Ft./Sec.)

6 650

9 700

16 750

Note — Maximum work temperatures are

based on 22 W/In

2

. If elements have a lower

watt density, output air temperature may

Max. Output

Air Temp. (°F)

3-5/8

X

3-1/2

(Typ.)

X

F

M

A

D

be increased but not to exceed 750°F. If watt

density is higher, output air temperature

should be lower.

Note — See Allowable Watt Density & Heater

Selection Graphs and Pressure Drop Curve

G-227-2 in the Technical section of this

catalog.

Options

Replacement Elements — Order model number TI-43X752, 240V, 1000W (PCN 282781).

Explosion-Resistant Terminal Enclosure is

available for hazardous area applications.

Overtemperature Protection

Connections

Bolts

ARC

Thermal

Cutout

Probe

Downstream

C

B

Specifications and Ordering Information

No.

kW Volts W/In

6 240/480 22 6 2-1/2 5-5/8 20-3/8 26-15/16 4 1/4 5 TDH-6C AS 260785

12 240/480 22 12 3-1/2 7-5/8 20-3/8 26-15/16 6 1/4 7 TDH-12C AS 260822

18 240/480 22 18 3 9-5/8 20-3/8 26-15/16 8 1/4 9 TDH-18C AS 260865

24 240/480 22 24 2-3/4 11-5/8 20-3/8 26-15/16 10 1/4 11 TDH-24C AS 260902 260929

30 240/480 22 30 3-1/4 13-5/8 20-3/8 26-15/16 12 1/4 13 TDH-30C AS 260945 260961

36 240/480 22 36 3-3/4 15-5/8 20-3/8 27-5/8 14 3/8 15 TDH-36C AS 260970 260988

42 240/480 22 42 4-1/4 17-5/8 20-3/8 27-5/8 16 3/8 17 TDH-42C AS 260996 261008 69

48 240/480 22 48 4-3/4 19-5/8 20-3/8 27-5/8 18 3/8 19 TDH-48C AS 261016 261024 78

54 240/480 22 54 5-1/4 21-5/8 20-3/8 27-5/8 20 3/8 21 TDH-54C AS 261032 261040 87

60 240/480 22 60 5-3/4 23-5/8 20-3/8 27-5/8 22 3/8 23 TDH-60C AS 261059 261067 96

Stock Status: S = stock AS = assembly stock NS = non-stock

To Order—Specify model, PCN, kW, volts and quantity.

2

Elem.

Dimensions (In.)

Model Stock

1. Heater has UL component recognition;

UL versions of larger sizes are available.

E-16

PCN

1

260806119

1

260849126

1

260881134

1

1

1

Wt.

(Lbs.)X A B C D F M 240V 480V

42

51

60

Loading...

Loading...