Page 1

Chromalox

®

DIVISION 4 SECTION

RT

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation Instructions

PJ451-11

161-562762-001

MARCH, 2009

(Supersedes PJ451-10)

RTPC Power Connection Kit for Self-Regulating

and Constant Wattage Rapid-Trace Heating Cable

RTPC Power Connection Kit Parts:

1 - Molded Junction Box consisting of:

Base - Box - Lid - Hardware

1 - Three Position Terminal Block

1 - Mounting Screw for Terminal Block

1 - Black Cable Grommet

1 - Orange Cable Grommet

1 - Cover Gasket

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heating cable and

accessories. A qualified person must perform

installation and service of heating cable and

accessories. Heating cable must be effectively

grounded in accordance with the National

Electrical Code. Failure to comply can result in

personal injury or property damage.

NOTE: All electrical wiring, including GFCI (Ground Fault

Circuit Interrupters), must be done according to National

Electrical or local codes by a qualified person.

The RTPC Kit is used to connect base, braided (-C) and overcoated (-CR or -CT) versions of Self-Regulating and Fluoropolymer

insulated Constant Wattage Rapid-Trace Heating Cables to power.

© 2010 Chromalox, Inc.

GENERAL

The cable grommet is furnished with this kit, such that the black

grommet is used for self-regulating cables SRL, SRF, SRM/E,

SRL/S, SRMF/S and the orange grommet is used for constant

wattage cable CWM and self-regulating cable SRS.

Each kit contains enough material to make one power connection point. It is possible to connect up to three Self-Regulating or

two Constant Wattage Cables in the same box. (One grommet

required for each cable.)

Materials required for installation include: standard electrical

cutters, screwdriver, sharp utility knife and a pipe strap

(Chromalox PS or equal).

Wipe inside lip of cover with a clean cloth. Remove protective

backing from the gasket and affix it to the cover lip. Press firmly

all around for proper adhesion.

Page 2

INSTALLATION

NOTE: These instructions are for all Self-Regulating and

Constant Wattage heating cables in ordinary locations. Consult

factory for installation of braided cable in hazardous locations.

Not all instructions are for all cables. Each step of the instructions

will have a heading in boldface stating what type of cable each

instruction is intended for.

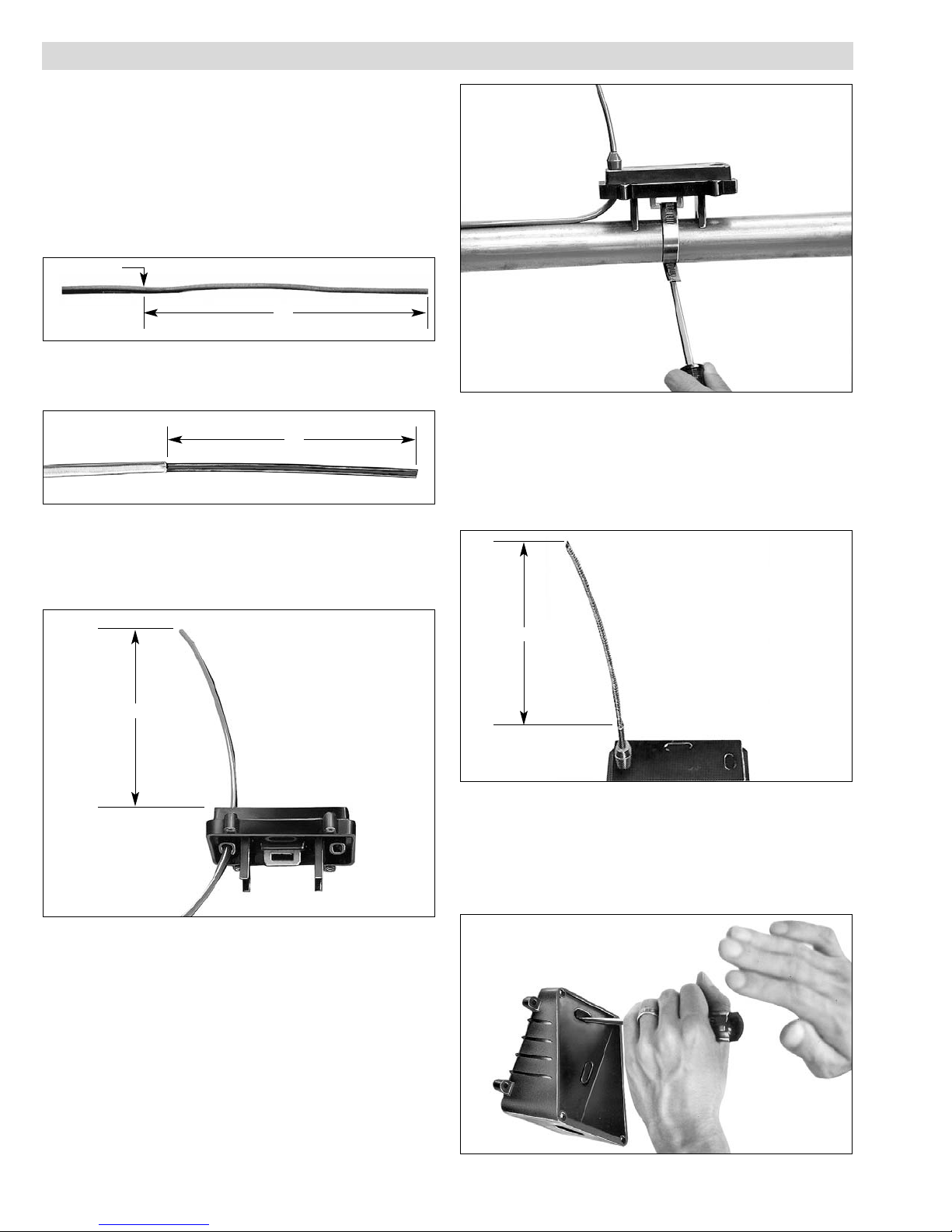

1. FOR CONSTANT WATTAGE CABLES:

Cut the cable 12 inches past the last module point (indentation

in cable). NOTE: Cutting the cable between module points

creates a non-heating cold lead. See Figure 1.

Module Point

12”

Figure 1

2. FOR CABLE WITH EXPOSED METAL BRAID (-C):

Push the braid back 12 inches on the cable. See Figure 2.

12”

Figure 2

Figure 4

5. FOR OVERCOATED CABLES (-CR or -CT):

Score the outer insulation seven (7) inches from the end of

cable. Remove the jacket to expose the metal braid. See Figure 5.

CAUTION: When removing the outer jacket, be

careful not to damage the braid or the base

cable insulation.

3. FOR ALL CABLES:

Feed the ends of the cables through the appropriate hole in

the base. Allow eight (8) inches of cable to extend above the

top of the base. See Figure 3.

8”

Figure 3

4. FOR ALL CABLES:

Slide cable grommet over the end of the cable and insert it

into the opening in the base. Secure the base to the pipe by

threading the appropriate sized pipestrap through the slot in

the mounting plate. Tighten the pipestrap until the base is

securely attached to the pipe. See Figure 4.

7”

Figure 5

6. FOR ALL CABLES:

Punch out the knockouts on the bottom of the box which correspond to the openings in the base through which the heating

cable passes. Be careful to punch out only those knockouts to

be used. If one is mistakenly punched, blank grommets can be

ordered to re-establish the water tight seal. See Figure 6.

Figure 6

Page 3

INSTALLATION

7. FOR ALL CABLES:

Feed the cables through the corresponding holes in the box.

Secure box to base using all four (8-32) screws. See Figure 7.

#8/32 Screw

Figure 7

8. FOR OVERCOATED CABLES:

Starting from the end of the cable, unravel 2-1/2 inches of the

braid. Twist the strands together to form a pigtail. See Figure 8.

2-1/2”

described above. Separate the buss wires and strip off the last

3/8 inch of insulation from both buss wires. See Figure 10.

3/4”

3/8”

Figure 10

11. FOR ALL CABLES:

Insert the bared ends of the conductors into the openings in

the terminal block. Tighten screws firmly to hold conductors

in place. See Figure 11.

Figure 8

9. FOR SELF-REGULATING CABLES:

Using standard electrical cutters, cut a 3/4 inch long notch out

of the cable between the conductor wires. Bare a 3/8 inch

length of each conductor by stripping off the outside insulation and the inner black core material. See Figure 9.

3/8”

3/4”

Figure 11

12. FOR OVERCOATED CABLES (-CR or -CT):

Insert the end of the braid pigtail into the remaining opening

in the terminal block. Tighten screw firmly to hold the braid in

place. See Figure 12.

Figure 12

13. FOR ALL CABLES:

Connect conduit hub (Chromalox CCH or equal) to the box.

Attach conduit to hub and bring power leads into box. See

Figure 13.

Figure 9

10. FOR CONSTANT WATTAGE CABLES:

Score the outer jacket 3/4 inch from the end of the cable and

remove the jacket. Cut off the exposed nichrome wire, pushing any remainder back under the jacket. These cables have an

inner layer of insulation which is also to be removed as

Figure 13

Page 4

INSTALLATION

14. FOR ALL CABLES:

Strip 3/8 inch length of each conductor of the power cord.

Insert the bared ends of the conductors into the corresponding

openings on the unused side of the terminal block. Remember,

the green (ground) wire must be opposite of the opening of the

terminal block which is either empty or contains the metal

braid. See Figure 14.

Figure 16

17. FOR CABLE WITH EXPOSED METAL BRAID (-C):

Unravel four (4) inches of braid from the cable and twist into

a pigtail.

Figure 14

15. FOR ALL CABLES:

Mount terminal block to bottom of the box by driving the 6/32

self-tapping screw into the mounting hole as shown. See

Figure 15.

#6/32 Screw

Figure 15

16. FOR ALL CABLES:

Carefully push the wires into the box. Secure the lid to box.

See Figure 16.

ELECTRIC SHOCK HAZARD. The twisted braid

must be effectively grounded in accordance with

the National Electrical Code to eliminate electric

shock hazard.

SRL-C

or

CWM-C

Figure 17

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Limited Warranty:

1347 HEIL QUAKER BLVD., LAVERGNE, TN 37086

Phone: (615) 793-3900 www.chromalox.com

Loading...

Loading...