Page 1

Process Air and Radiant

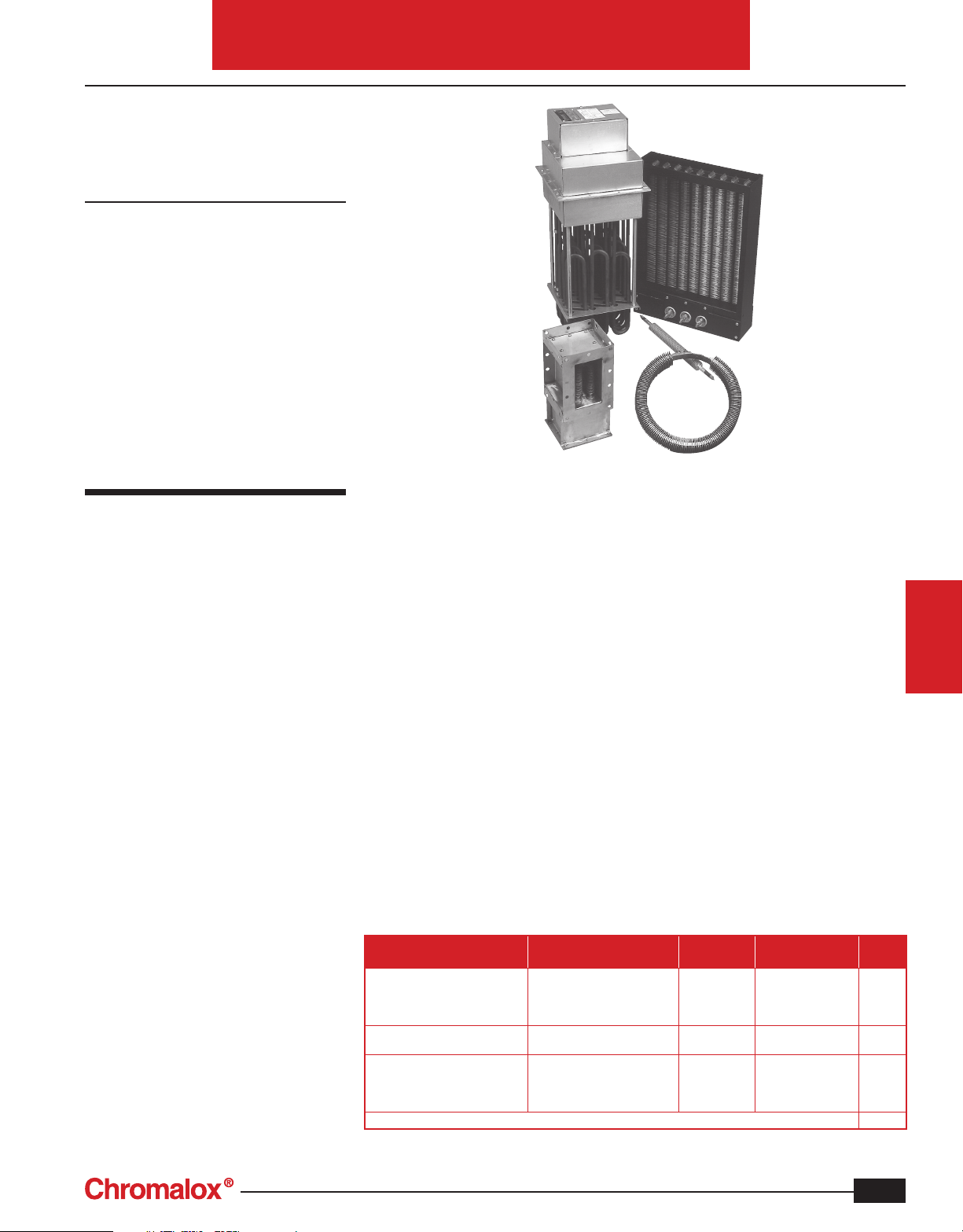

Process Air Heaters

Overview

• Fintube®Heaters

• Finstrip®Heaters

• CircularFinstrip®Heaters

• HighTemperature

DuctHeaters

• MediumTemperature

DuctHeaters

• LowTemperature

DuctHeaters

Fintube

sign provides the same benefits as the finned

Heat processing applications vary widely

from industry to industry. Curing, drying,

heat treating, comfort heating, sterilizing and

bonding represent just a few of the many uses

for electrically heated air. Applications vary in

temperature from super cool cryogenic to high

temperatures up to 1200°F. Chromalox electric

heaters can also be designed to heat special

atmospheres such as argon or nitrogen.

Special materials and custom designs are

available for marine applications, power plants

or hazardous applications.

Chromalox can supply individual finned elements for use in OEM equipment or entire duct

heater assemblies where we have complete

control over the product including the elements, frames and controls. Chromalox has

earned an outstanding reputation for exceptional quality, reliability and long life.

Finned Heating Elements

Finstrip® Elements — Superior to open

coil elements, the heating coil is completely

encased in a metal sheath, minimizing a shock

hazard due to accidental contact with the

heater. The rigid metal sheath minimizes hot

spots and electrical shorting, likely with open

coil elements. Application temperatures to

565°F are typical using finned strip units.

strip heater and additional features, allowing

for special bending configurations to provide

higher concentrations of installed kW for a

given area. The elements can be supplied with

bulkhead threaded fittings, and may include

optional hermetically sealed terminals, or extra

heavy wall thickness for use in atmospheres

containing hazardous fumes or gasses. Element diameters of 0.315" and 0.475" are standard, with high temperature aluminum painted

steel sheath and furnace brazed fins being the

most common materials. Stainless Steel or

MONEL

corrosive environments.

Duct Heater Assemblies

High Temperature — Type ADHT is designed

to provide outlet air temperatures up to

1200°F using conservatively rated, low watt

density, INCOLOY

heater includes three inches of high temperature rated insulation below the mounting

flange to reduce heat transfer to the wiring

enclosure. The elements are prewired and

Process Air Heaters — Selection Guidelines

Fintube

Finstrip

Air Duct Medium Temperature 5 - 270 ADH E-14

Custom Air Heating Solutions E-20

®

Elements — The finned tubular de-

®

sheath and fins are also available for

®

tubular elements. The

Type Feature kW Rating Model Page

®

®

0.475" Fintube

0.315" Fintube

0.475" Single End 0.5 - 4.3 SFTS & SFTI E-5

0.315" Single End 0.3 - 2.4 SFTS & SFTI E-7

®

Finstrip

Circular Strip 1.9 - 5.0 KSEF E-11

High Temperature 5 - 300 ADHT E-15

Low Temperature 6 - 100 CAB & CABB E-17

Round Duct 2.5 - 5 DAB E-19

subdivided into 48 Amp maximum circuits in

compliance with the National Electrical Code.

The heater is provided with a Type “K” thermocouple attached to the sheath of one element

to be used with a Chromalox high limit control.

Medium Temperature — Application temperatures to 750°F are common for ADH type

duct heaters which feature INCOLOY

tubular heating elements. These versatile units

are fully assembled and prewired with the

elements subdivided into 48 Amp maximum

circuits in compliance with the National Electrical Code.

Low Temperature — Outlet air temperatures

to 440°F are typical for types CAB, CABB and

DAB which use finned strip heater elements

in an assembly which is then inserted in and

bolted to existing ductwork.

®

®

0.47 - 10 FTS & FTI E-3

0.5 - 6.2 FTS & FTI E-4

0.2 - 4.1 OTF E-9

®

sheath

process Air

And rAdiAnt

E-1

Loading...

Loading...