Page 1

(Supersedes PQ431)

PQ431

CHTV

161-058058-001

JULY, 1983

4

and

Installation, Operation

RENEWAL PARTS IDENTIFICATION

Type CHTV Horizontal Vaporizers for Dowtherm®,

Therminol®and Other Organic Fluids

(Temperatures to 750°F at 150 psi, 15 kW thru 300 kW)

© 2010 Chromalox, Inc.

Specifications & Dimensions

System Model Number and Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . System Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer’s Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Customer’s Order Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

National Board Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ampere* Model Number Dimensions Weight

Oil & Weather- Explosion-

(In.) (Lbs.)

Standard Dust Tight resistant resistant Operating w/o

kW BTUH 240V 480V NEMA I NEMA XII NEMA IV Class1, Group D Volume L W H Controls

15 51,180 36.0 18.0 CHTV-316-15 CHTVO-316-15 CHTVW-316-15 CHTVX-316-15 15.7 80 36 50 600

20 68,240 48.1 24.0 CHTV-316-20 CHTVO-316-20 CHTVW-316-20 CHTVX-316-20 19.4 94 36 50 700

25 78,500 60.1 30.1 CHTV-316-25 CHTVO-316-25 CHTVW-316-25 CHTVX-316-25 23.6 110 36 50 825

30 102,360 72.2 36.1 CHTV-316-30 CHTVO-316-30 CHTVW-316-30 CHTVX-316-30 27.2 124 36 50 925

40 136,480 96.2 48.1 CHTV-316-40 CHTVO-316-40 CHTVW-316-40 CHTVX-316-40 35.6 156 36 50 1175

50 157,000 120.3 60.1 CHTV-316-50 CHTVO-316-50 CHTVW-316-50 CHTVX-316-50 43.5 186 36 50 1400

40 136,480 96.2 48.1 CHTV-624-40 CHTVO-624-40 CHTVW-624-40 CHTVX-624-40 75.0 95 48 60 1200

50 157,000 120.3 60.1 CHTV-624-50 CHTVO-624-50 CHTVW-624-50 CHTVX-624-50 106.0 111 48 60 1450

60 204,720 144.3 72.2 CHTV-624-60 CHTVO-624-60 CHTVW-624-60 CHTVX-624-60 137.0 125 48 60 1600

75 235,500 180.4 90.2 CHTV-624-75 CHTVO-624-75 CHTVW-624-75 CHTVX-624-75 168.0 149 48 60 1900

100 341,200 240.6 120.3 CHTV-624-100 CHTVO-624100 CHTVW-624-100 CHTVX-624-100 218.0 187 48 60 2350

100 341,200 240.6 120.3 CHTV-1230-100 CHTVO-1230-100 CHTVW-1230-100 CHTVX-1230-100 218.0 111 54 66 2400

125 392,500 – 150.4 CHTV-1230-125 CHTVO-1230-125 CHTVW-1230-125 CHTVX-1230-125 222.0 129 54 66 2700

150 511,800 – 180.4 CHTV-1230-150 CHTVO-1230-150 CHTVW-1230-150 CHTVX-1230-150 263.0 149 54 66 3100

175 549,500 – 210.5 CHTV-1230-175 CHTVO-1230-175 CHTVW-1230-175 CHTVX-1230-175 300.0 167 54 66 3500

200 682,400 – 240.6 CHTV-1230-200 CHTVO-1230-200 CHTVW-1230-200 CHTVX-1230-200 340.0 187 54 66 3950

225 767,700 – 271.0 CHTV-1836-225 CHTVO-1836-225 CHTVW-1836-225 CHTVX-1836-225 379.0 149 60 72 4600

250 853,000 – 301.0 CHTV-1836-250 CHTVO-1836-250 CHTVW-1836-250 CHTVX-1836-250 417.0 162 60 72 5200

275 938,300 – 331.0 CHTV-1836-275 CHTVO-1836-275 CHTVW-1836-275 CHTVX-1836-275 455.0 175 60 72 5600

300 1,023,600 – 361.0 CHTV-1836-300 CHTVO-1836-300 CHTVW-1836-300 CHTVX-1836-300 490.0 187 60 72 6000

Manufacturing

Data –

*All amperes based on 3ph 60 cycle power.

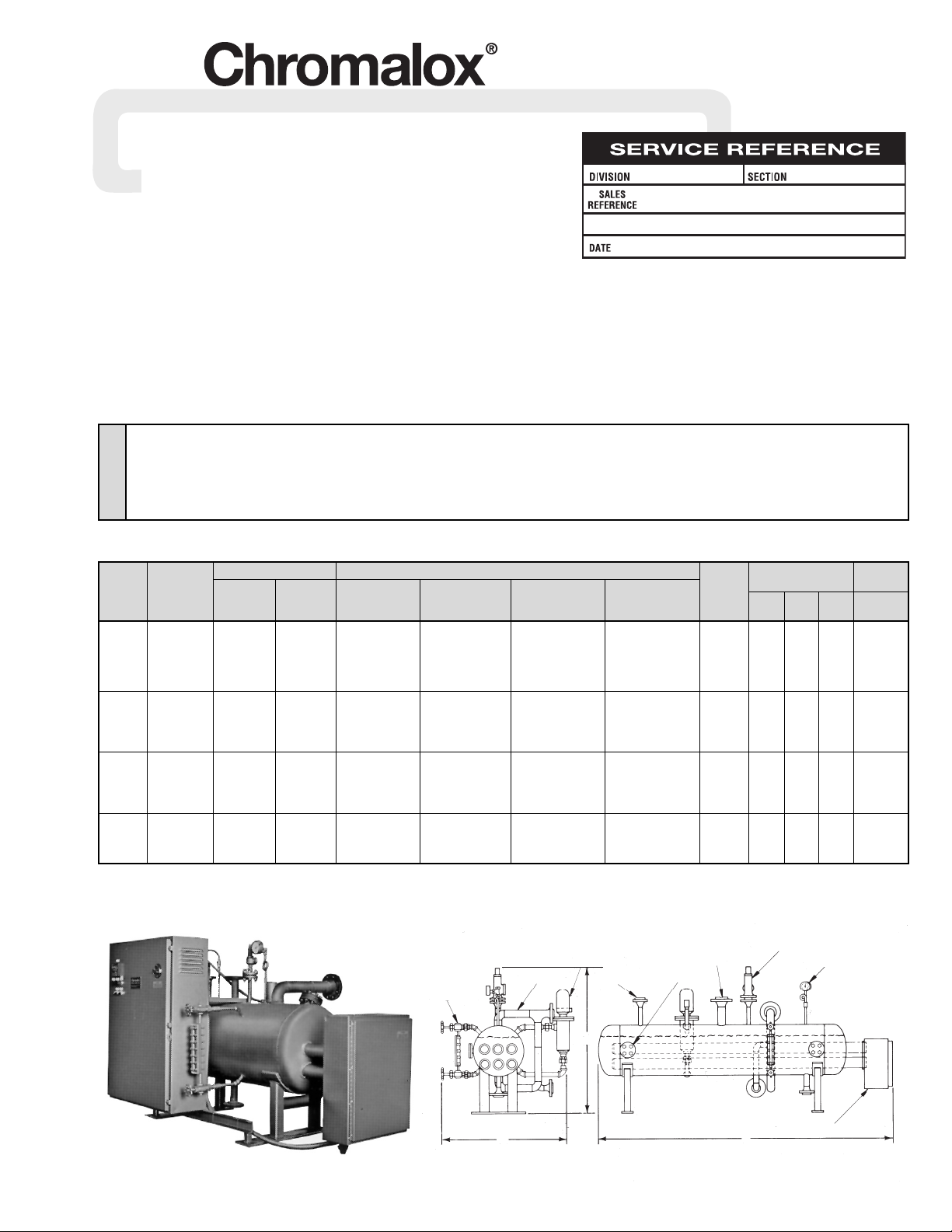

Sight Glass

Hartford Loop

Level Switch

Vent

W

L

H

Inspection Ports (2)

Spare or Fill

ASME Relief Valve

Pressure Gage

Heater Terminal Cover

Page 2

CAUTION: This vaporizer is not for use with water or ethylene

glycol and water mixtures as the heat transfer media. Check with

your local Chromalox Sales and Application Engineer to be sure

that you are using an accepted heat transfer media in this vaporizer or consult PQ301.

Note: When installing the vaporizer, allow a minimum of 3 feet for

removing heating element if, and when, necessary.

HYDRAULIC OR MECHANICAL:

Note: The CHTVW vaporizer should be mounted so that the control box does not fall in direct sunlight.

The bed plate should be mounted on solid foundation, prefer-

ably level.

The pipe lines from the Chromalox vaporizer to the process

should be the same size as the vaporizer’s piping connections. All

piping should be arranged so that the vaporizer is not subject to

extreme nozzle loading due to thermal expansion and contraction of

pipe lines. If these instructions are not followed, cracks could develop in the vaporizer where the inlet and outlet nozzles are attached.

1. The piping of the entire system should be arranged to minimize

pockets where air may be trapped. Manual air vents or bleeder

valves should be provided at all high points in the system and

every time the flow of the condensate has to drop.

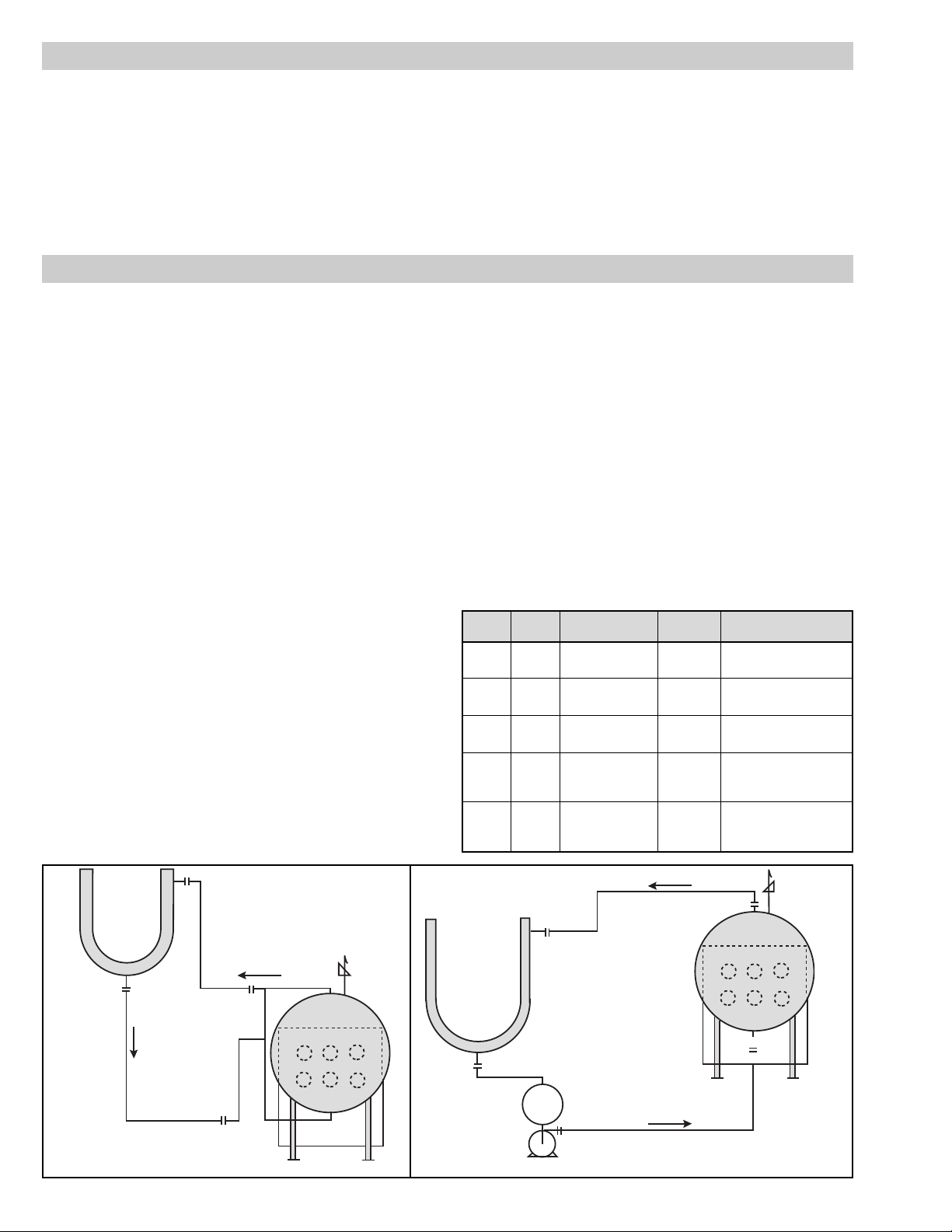

2. Condensate return systems:

A. Gravity return type: The simplest and most easily operat-

ed type of vaporizer is one in which the condensate from the

heating equipment is returned to the vaporizer by gravity,

thus providing a system without moving parts. Such a system is possible if there is sufficient difference in elevation

between the process and the vaporizer so the static liquid

head will counter-balance all frictional losses in the vaporizer, vapor piping process and condensate return piping

without flooding the heated equipment. See Figure 1 for a

typical schematic piping diagram.

B. Pumped return type: Where there is insufficient differ-

ence in elevation between the vaporizer and the process, the

condensate must be returned to the vaporizer by a pump.

Normally, these pumps are of the centrifugal type; however, positive displacement pump may also be used. See

Figure 2 for a typical schematic piping diagram.

3. Hartford Loop – In gravity return systems a Hartford Loop

should be incorporated where the condensate is returned to any

point below the desired liquid level of the vaporizer.

A Hartford Loop consists of a line without valves outside of

the vaporizer connecting the vapor outlet and the condensate

inlet. The condensate return line is connected to the vapor-condensate line or loop at the same elevation as the lowest permissible level in the vaporizer. Thus, a vacuum in the heated equipment can then pull liquid from the vaporizer (or a closed valve

in the vapor line can force liquid from the vaporizer) only until

the level in the vaporizer falls to the level of this connection.

Also, the resultant liquid hammering will give warning that the

liquid level in the vaporizer is too low. (See Figure 1 below.)

4. Note: All flange connections should be checked and tightened

if necessary. These sometimes loosen during transit.

ELECTRIC:

GENERAL

The Chromalox Horizontal Electric Vaporizer is a thoroughly

engineered pre-tested package, designed to give years of service,

virtually maintenance free if properly installed. The CHTV series

is ASME certified for 150 PSI at 750°F and is available in four

models, each with basic features that comply with the National

Electrical Code. Model CHTV has general-purpose NEMA I construction and can be used where no hazards exist. Model CHTVO

is oil and dust tight as specified by NEMA XII standards. Model

CHTVW can be used where weather-resistant construction is

required and is constructed according to NEMA IV specifications.

Model CHTVX, Class 1, Group D, Division 1 is explosion-resistant and is constructed to operate in hazardous or explosive areas.

WARNING: Vessel and pipe surfaces could achieve temperatures

higher than allowed for Class 1, Group D, Division 1 hazardous

areas. Common to all four models: OCE (open coil element) type

heating elements installed in 3”, schedule 40 seamless carbon steel

pipes; watt density on the outside of the pipe surface is 10 watts

per square inch; elements are removable without draining the fluid

in the vaporizer; requirements 208, 240, 480 and 550 volt, 3 phase,

60 cycle, 15 to 300kW.

INSTALLATION

Heater Terminal

Enclosure

Heater Terminal

Enclosure

Safety

Valve

Jacketed

Vessel

Vapor

Outlet

Hartford

Loop

Jacketed

Vessel

Liquid

Liquid Return

Liquid

Return

Pump

Condensate

Return

Tank

Vapor Outlet

Figure 1

Figure 2

Control Box Size No. Control

kW Volts H L D Circuits Accomplished By

15 240 1 Pressure

Thru or 30 x 24 x 8 1 Control with

30 480 1 Switch

40 240 1 Pressure

Thru or 30 x 30 x 8 2 Control with

60 480 2 Switches

75 240 1 Pressure

Thru or 42 x 30 x 8 3 Control with

100 480 3 Switches

1 Proportional

125 Pressure Control

Thru 480 48 x 36 x 8 4 with 4-step

150 electronic stepper

1 Proportional

175 Pressure Control

Thru 480 60 x 36 x 8 6 with 6-step

300 electronic stepper

Page 3

CAUTION: Hazard of Electric Shock. The vaporizer

must be grounded using the grounding means provided in the heater terminal box and in the control

box, and employ wiring in accordance with the

National Electrical Code.

1. The vaporizer is normally supplied one of three different ways:

A. Without controls as they are going to be provided by the

customer. The customer will have to wire from his supplied

controls to the level or float switch on the vessel, and to the

heater terminal blocks and the ground lug in the heater terminal enclosure.

B. With controls supplied, but mounted remotely by the user.

The customer will have to wire from remote controls to the

level or float switch on the vessel, and to the heater terminal

blocks and the ground lug in the heater terminal enclosure.

C. With all controls mounted on the same skid with the

hydraulic or mechanical part of the vaporizer. The unit is

completely wired. The only wiring necessary is to terminals

L1, L2 and L3 on the main circuit breaker and the grounding lug in the control panel.

2. Note: All electrical connections should be checked and tightened if necessary. These sometimes loosen in transit.

CAUTION: Hazard of Electric Shock. Disconnect all

power before servicing the vaporizer.

INSTALLATION

WIRING DIAGRAMS

OPERATION

CAUTION: To avoid possible damage to the heaters, do not energize the heaters until the vaporizer is filled with fluid.

1. The filling of the Chromalox CHTV type horizontal vaporizer

is accomplished in one of two ways:

A. On vaporizers with gravity return type condensate return

systems, the filling is done simply by pouring the heat

transfer or other organic media into the vaporizer shell

using the spare or fill nozzle and, while the filling is taking

place, bleeding the displaced air from the vent.

B. On vaporizers that use pump condensate return systems or

on systems where the condensate is not returned, the filling

would be done by first filling the condensate return tank or

supply or reservoir tank and then energizing the condensate

return or supply pump. While the vaporizer vessel is being

filled, the vent nozzle should be opening for bleeding out

the air.

2. Set the thermostat at 220°F and/or the controlling pressure

switch at its equivalent.

3. To energize the heaters, turn the “on-off” selector switch to the

“on” position. The heaters are interlocked with the level or

float switch located on the vessel, so that the heating element

will shut off automatically in case of a low liquid level.

4. Operate the vaporizer until 220°F is reached. Periodically open

the bleed valves to remove air from the system. At 220°F any

moisture that has been trapped in the system will flash into

steam and can be bled off through the bleeder valves.

WARNING: Avoid having the heat transfer fluid or the fluid to be

vaporized spilled or leaked into the pipeline or vessel insulation as

it has been found that spontaneous ignition of some of these fluids

may result at elevated temperatures.

5. After the vaporizer has been completely charged and free of

steam pockets, set the controlling pressure switch or thermostat to

the pressure or temperature point where the fluid will vaporize.

6. Operate the vaporizer until this set point is reached.

Periodically open the bleeder valves to remove air from the

system.

7. After the system is completely free of air, set the controlling

pressure switch or thermostat to the desired operating point.

Circuit

Breaker

Circuit

Breaker

L1

L2

L3

C1

C2

F1

F2

F3

F4

F5

F6

H4 H2 H3 H1 H4 H2 H3 H1

F8F7

H4

H2 H3

H1

X1 120-Volt X2

240V 480V

Transformer Primary

Pilot Light

Feed or Condensate

Return Pump (Optional)

Pilot Light

High Limit Circuit

Pilot Light

Heat #1

Pilot Light

Heat #2

Off On

Off On

Off On

3

5

7

10

4

6

8

11912

M

CR

C1

C2

1CR

1CR

R

G

A

A

F9

OPC

FS2

FS-1

PSI-1

PSI-2

H4 H2 H3 H1 H4 H2 H3 H1

240V 480V

Transformer Primary

Off On

C1

C2

C3

C4

L1

L2

L3

F1

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

F12

F13

F14

H4

H3

H2

H1

F15

34

5

6

X1

X2

FS2

FS1

OPC

4-20MA

Input

135 ohm

Input

Stepper

X1

X2

A+

B-

C

D

E

1

2

3

4

1CR

1CR

Off On

Off On

Off On

Off On

7

8

9

10

11

12

13

14

15

M

R

G

A

C1

C2

C3

C4

A

A

A

Pilot LIght

Feed or Condensate

Return Pump (Optional)

Pilot Light

Low Level and

High Limit Circuit

Pilot Light

Heat #1

Pilot LIght

Heat #2

Pilot LIght

Heat #3

Pilot LIght

Heat #4

Typical Wiring Diagram

15 to 100 kW (All Voltages)

Typical Wiring Diagram

125 to 300 kW 440/480 and 550/575V

Page 4

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

MAINTENANCE

RENEWAL PARTS IDENTIFICATION

CAUTION: Hazard of Severe Shock. Disconnect all

power to heater before servicing or replacing

heaters.

1. Heaters should be checked periodically for coatings and corrosion and cleaned if necessary.

2. The tank should be checked regularly for sediment around the

heater as sediment can act as an insulator and shorten heater life.

3. Remove any accumulated sludge deposits form heater and

from tank.

4. Check for loose terminal connections and tighten if necessary.

Vaporizer Heating Element Part Number

Model No.

CHTV, CHTVO, CHTVW

or CHTVX 240V 480V

316-15 063-122121-001 063-122121-002

316-20 063-122121-003 063-122121-004

316-25 063-122121-005 063-122121-006

316-30 063-122121-007 063-122121-008

316-40 063-122121-013 063-122121-014

316-50 063-122121-017 063-122121-018

624-40 063-122121-003 063-122121-004

624-50 063-122121-005 063-122121-006

624-60 063-122121-007 063-122121-008

624-75 063-122121-011 063-122121-012

624-100 063-122121-017 063-122121-018

1230-100 063-122121-005 063-122121-006

1230-125 063-122121-009 063-122121-010

1230-150 063-122121-011 063-122121-012

1230-175 063-122121-015 063-122121-016

1230-200 063-122121-017 063-122121-018

1836-225 063-122121-011 063-122121-012

1836-250 063-122121-019

1836-250 063-122121-020

1836-300 063-122121-017 063-122121-018

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...