Page 1

PQ402-6

161-049460-001

FEBRUARY, 1999

4 CES

SERVICE MANUAL

(Supersedes PQ402-5)

Chromalox Electric

Steam Boilers

© 2010 Chromalox, Inc.

Boiler does not heat:

1. Check power fusing.

2. Examine control circuit fuse.

3. Reset button on the Low Water Control must be depressed (for

states requiring a reset button).

4. Float valve in the Low Water Control is not functioning properly.

5. Elements and/or contactors faulty.

6. Mercury tube in Low Water Control has cracked and mercury

has escaped.

Boiler takes too long to reach operating pressure or

does not maintain desired pressure:

1. Check amperage on each supply leg of power harness. Reading

should correspond to a rating of not less than 10% of rated boiler amperage.

If considerable difference exists:

A. Available voltage is insufficient for boiler needs.

B. Heating element failure has occurred.

C. Fibre carrier in contactor requires replacement. On multi

contactor units, check contactors and coils to determine if

one is defective.

2. Check to determine whether boiler selected is underrated for

the application.

3. Additional Equipment added after initial installation, thus

undersizing boiler.

4. Steam piping not insulated.

Boiler continuously blows power fuses:

1. External fusing is not sized properly. Correct sizing is next size

larger than boiler rating.

2. Check lines between element and contactors with an ammeter

for uniform readings.

3. Check for evidence of charring which indicates loose connections.

4. A short circuit exists in the boiler.

Boiler does not fill with water automatically or does not

maintain constant pressure:

1. Check water supply line for closed valves.

2. Check power fusing.

3. For boiler without motor and pump assembly: check pressure

of water supply to insure that it is consistently a minimum of

10 psi greater than the desired boiler operating pressure.

4. Check water inlet check valve.

5. For boiler with motor and pump assembly: check mercury

tubes in the Low Water Control.

6. A. Check motor and pump for binding and over

heating. If caught in time, this can be observed

by a humming sound. Replace if defective.

B. Check for defective solenoid valve.

C. Make sure pump is running with correct rotation.

D. Check impeller adjustment on turbine type pumps.

Boiler appears to be leaking from beneath the jacket:

1. Check boiler fittings for looseness; tighten as required.

2. Check boiler fittings for cracks; replace as necessary.

3. Examine heating elements around boiler flange.

IMPORTANT: Leaking is a hazard, correct to prevent further

damage to other components.

Boiler overflows:

1. Float valve on the Low Water Control is stuck in the down

position.

2. Solenoid valve is not operating.

3. Check for defective mercury tube on the Low Water Control if

boiler has a motor and pump assembly.

Pressure increases beyond the preset limits causing

safety valve to blow:

1. Check bellows in the pressure control.

2. Check for clogged syphon tube.

3. Contactor points have fused.

4. Check pressure control setting against safety valve rating.

Manual reset button needs constant resetting (for

states requiring reset buttons only):

1. Boiler is not level; relocate if necessary.

The troubleshooting of Chromalox electric boilers can best be

placed into five major areas. These areas are: (1) fusing (2) contacts, elements and voltages (3) pressure control (4) low water cutoff (5) water feed mechanism.

WARNING: Hazard of Electric Shock and Thermal

Burns. These troubleshooting checks should only

be performed by qualified personnel after review

of the Installation and Operating Instructions for

your specific Chromalox Electric Steam Boiler.

For convenience, we have outlined a brief description of typical

malfunctions and the area that should be explored in order to make

the proper correction. This is followed by a detailed analysis of the

five areas listed above.

TYPICAL MALFUNCTIONS & PROPER CORRECTION

Page 2

Boiler syphons water:

1. Follow blowdown instructions.

Boiler with condensate system floods overnight:

1. Vacuum breaker is not operating.

Elements fail:

1. Low Water Cut-Off system has failed.

2. Lower equalizer tube on Low Water Cut-Off is clogged due to

lack of blowdown.

3. Contactor points have fused.

4. Lack of blowdown has allowed accumulation of foreign mate-

rial, which has smothered the heating elements.

5. Water softener is being used without an aeration device.

Motor runs too frequently and/or the boiler does not

maintain pressure:

1. Test check valve.

Motor runs continuously, but does not pump (CMB-10L

to CES-30):

1. Test flexible coupling on motor and pump.

2. Check water supply.

3. Blowdown valve partially open.

FUSING — The power fuses should be the first component of

equipment checked in any power failure. The fuses will be located in a panel near the boiler (or within the boiler on 72kW and

larger models).

Test each fuse with a test light or an ohmmeter. If the test

light glows or the ohmmeter reads infinite resistance, then the

fuse is defective and must be replaced. Fuses can be intermittent.

If all other boiler components appear to be in proper order,

replace all fuses with known good ones.

If a circuit breaker is used instead of fuses, check to see if all

breakers are in the “on” position. Reset if necessary.

If the fuses continue to blow or the circuit breakers continue

to trip off, then the internal circuits should be investigated for a

short circuit or ground.

CONTACTORS, ELEMENTS AND VOLTAGES

— The power supply voltage must be within ten percent of the

boiler voltage rating. The standard voltages are 120, 208, 240

and 480 volts; optional voltages are 190, 275, 380, 415 and 550

volts. All boilers rated at 275 volts and higher are supplied with a

separate control circuit of either 120, 208 or 240 volts.

To insure good current flow, it is important that all contacts

are mating properly. Contacts that appear burnt or charred must

be replaced.

DETAILED ANALYSIS

Page 3

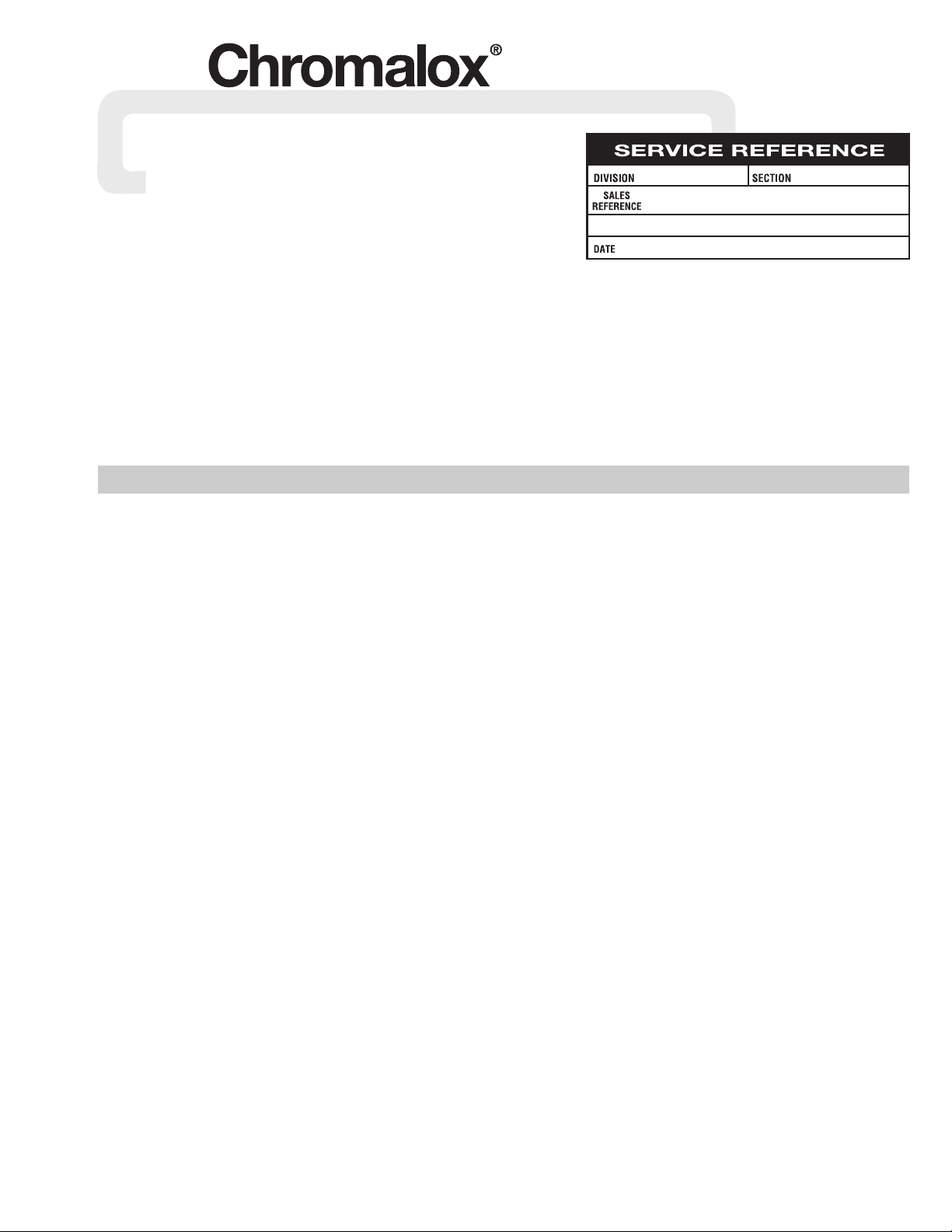

If the contactor fails to energize, check for blown fuses in

the control circuit. If the fuses are not blown, check the contactor holding coil. The holding coil can be checked by jumpering

Terminal L1 of the line and Terminal No. 4 (coil lead) on the

contactor. See Figure 1.

A. If the contactor fails to energize, then the coil is defective.

B. If the contactor energizes, it is an indication of failure in

either the Pressure Control or in the McDonnell-Miller three

wire mercury switch.

Pressure

Control

Setting

Differential

Control

Setting

Bellows

Syphon

Tube

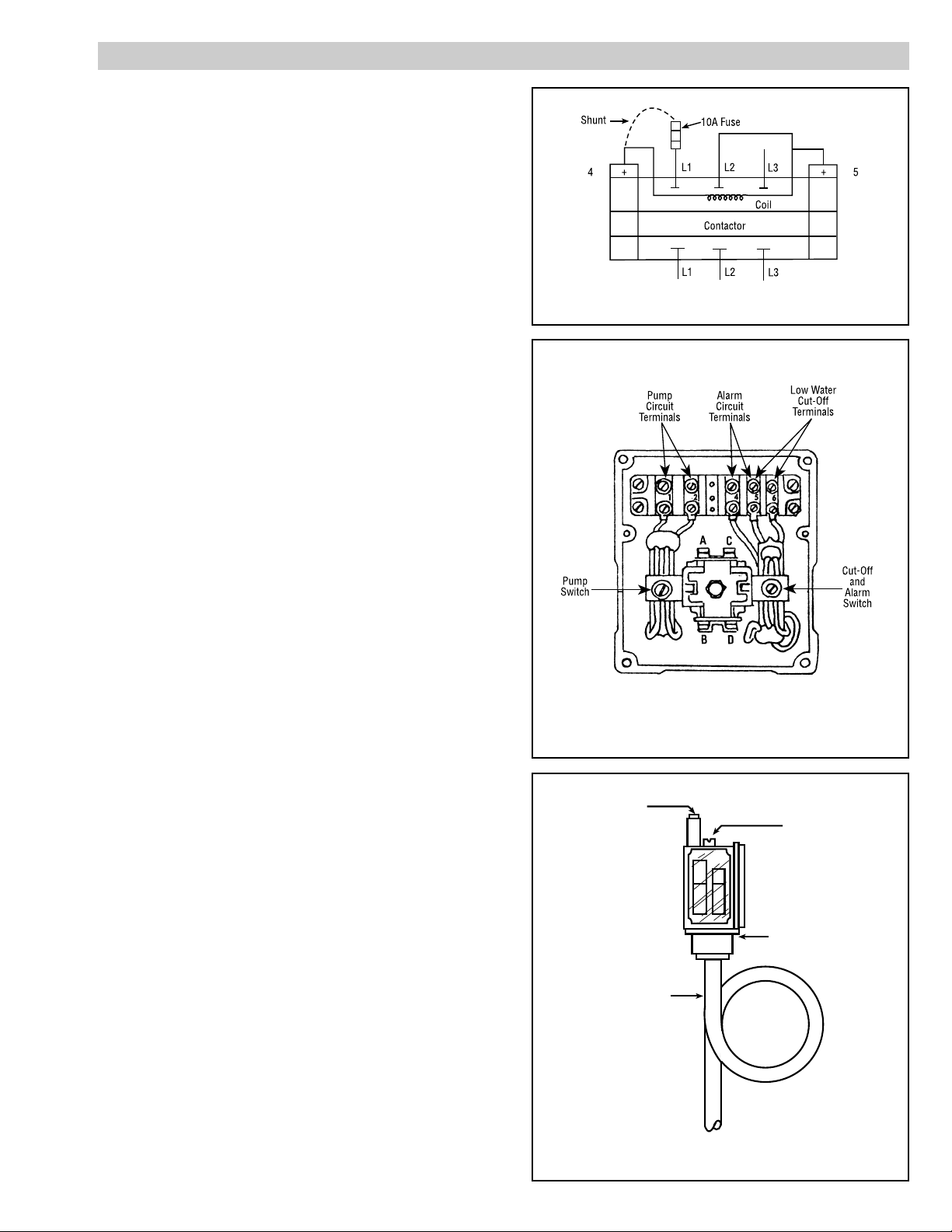

Since the Pressure Control and the three wire mercury switch

are wired in series, they can be checked one at a time by placing

a jumper across each control. If the mercury switch or Pressure

Control fail to energize, check the McDonnell-Miller controls by

jumpering Terminals 5 and 6. See Figure 2.

At this point, the contactor should energize unless there is an

open wire in the control circuit.

PRESSURE CONTROL — Malfunctions in the pressure control

can be mechanical or electrical.

The bellows should be removed and the small orifice at the

bottom cleaned out. The bellows must be replaced if it is punctured. The syphon tubing should also be cleaned by steam while

the control is removed; it will be necessary to join the two loose

leads in order to activate the boiler. See Figure 3.

The electrical controls should be checked by referring to the

Contactors, Elements and Voltages section.

NOTE: If control is purchased locally, remove #8-32 orifice

screw.

Figure 3 — Pressure Control

Figure 2 — Low Water Cut-Off Junction Box

Figure 1

CONTACTOR FAILS TO ENERGIZE

Page 4

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

LOW WATER CUT-OFF — Like the pressure control, difficulties can be broken down into the mechanical and electrical

groups.

The mechanical difficulties can be corrected on the high pres-

sure 100 psig motor and pump units in the following manner:

1. Remove the cover and test the free movement of the float

valve. If the float valve is in the off or down position, then the

float is either punctured or dirt and sediment is encrusted in the

float chamber. Both of these problems will involve disassembly of the float chamber.

2. Check the electrical contacts to determine if they are defective.

Defective mercury tube contacts will cause the boiler to fill higher than normal. This occurrence will require replacement of the

mercury tube.

On low pressure feed units, the mechanical test is best made

by cleaning the valve seat beneath the float valve linkage to

assure that it is properly seated. If the valve seat is scarred or

defective, the entire valve seat must be replaced. Also, if the float

valve is in the down or “off” position, it may be punctured or

encrusted with dirt and the unit must be disassembled.

On all McDonnell-Miller cut-offs, restrictions in the equalizer

column can cause burnt out elements. The cause will appear to be

a low water condition. Regular blowdown procedures on the

equalizer column as well as the boiler will prevent this occurrence. Correction of the problem can be made by both removing

the plug from the side of the column and opening the Low Water

Cut-Off blowdown valves. A snake should be used to clean the

vertical and horizontal columns.

The electrical trouble shooting should be checked by referring

to the Contactors, Elements and Voltages section.

WATER FEED MECHANISMS — A common problem in this

area is boiler flooding, which may be caused by a defective float

or solenoid.

The Low Water Cut-Off must be disassembled to check the

float valve. The solenoid can be isolated by disconnecting the

union after the solenoid and energizing and de-energizing the

solenoid. If water comes out continuously or does not come out

at all, then the solenoid is defective.

A defective check valve can cause the pump motor to run

continuously or cause loss of water pressure. If the pipe between

the check valve and the water supply is hot, boiler water is backing up through the check valve and the check valve must be

replaced. A defective check valve can also prevent water from

entering the boiler.

The coupling between the motor and pump may be loose; the

entire pump must be replaced if the coupling is excessively worn.

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...