Page 1

Chromalox

®

DIVISION 4 SECTION

GEN

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation Instructions

POO400-7

161-048339-001

DECEMBER, 2006

(Supersedes POO400-6)

© 2010 Chromalox, Inc.

GENERAL

INSTALLATION

CHROMALOX ELECTRIC HEATING ELEMENTS FOR CLAMP-ON

Users should install adequate controls and safety

devices with their electric heating equipment.

Where the consequences of failure may be severe,

back-up controls are essential, including GFCI

(Ground Fault Circuit Interrupters). Although the

safety of the installation is the responsibility of the

user, Chromalox will assist in identifying equipment

options.

FIRE HAZARD. Since heaters are capable of developing high temperatures, extreme care should be

taken to:

A. Avoid mounting heaters in an atmosphere containing com-

bustible gases and vapors.

B. Avoid contact between heaters and combustible materials.

C. Keep combustible materials far enough away to be free of the

effects of high temperatures.

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed by a qualified person

in accordance with the National Electrical Code,

NFPA 70.

High heating efficiency, low sheath temperatures and long

heater life result when electric heaters are properly installed.

INSTALLATION – CLAMP-ON

1. Clamp strip heaters securely, along their entire length, to

smooth metal surface. Use utility clamps spaced 5” apart and

5/16” stainless steel studs or oversized steel studs for clamping.

Retighten following initial heat-up. Allow for expansion. When

more that one clamp is used, tighten clamps to avoid bowing of

heater, poor heat transfer and possible premature failure. Leave

1/2” space between heater ends clamped in line for expansion.

Do not use mounting tabs for clamping to surface.

2. When strips are clamped to tank bottom for melting paraffin,

waxes, asphalt, greases, etc., one or two strips should be

clamped vertically to the tank side extending above the liquid

level. This is necessary to open a passage to the tank surface for

the initially melted material, and prevent build-up of pressure.

3. Clamp ring heaters to smooth metal surface. Use cast iron utility

clamps with 1/4” MONEL

®

or stainless steel studs. Retighten

following initial heat-up.

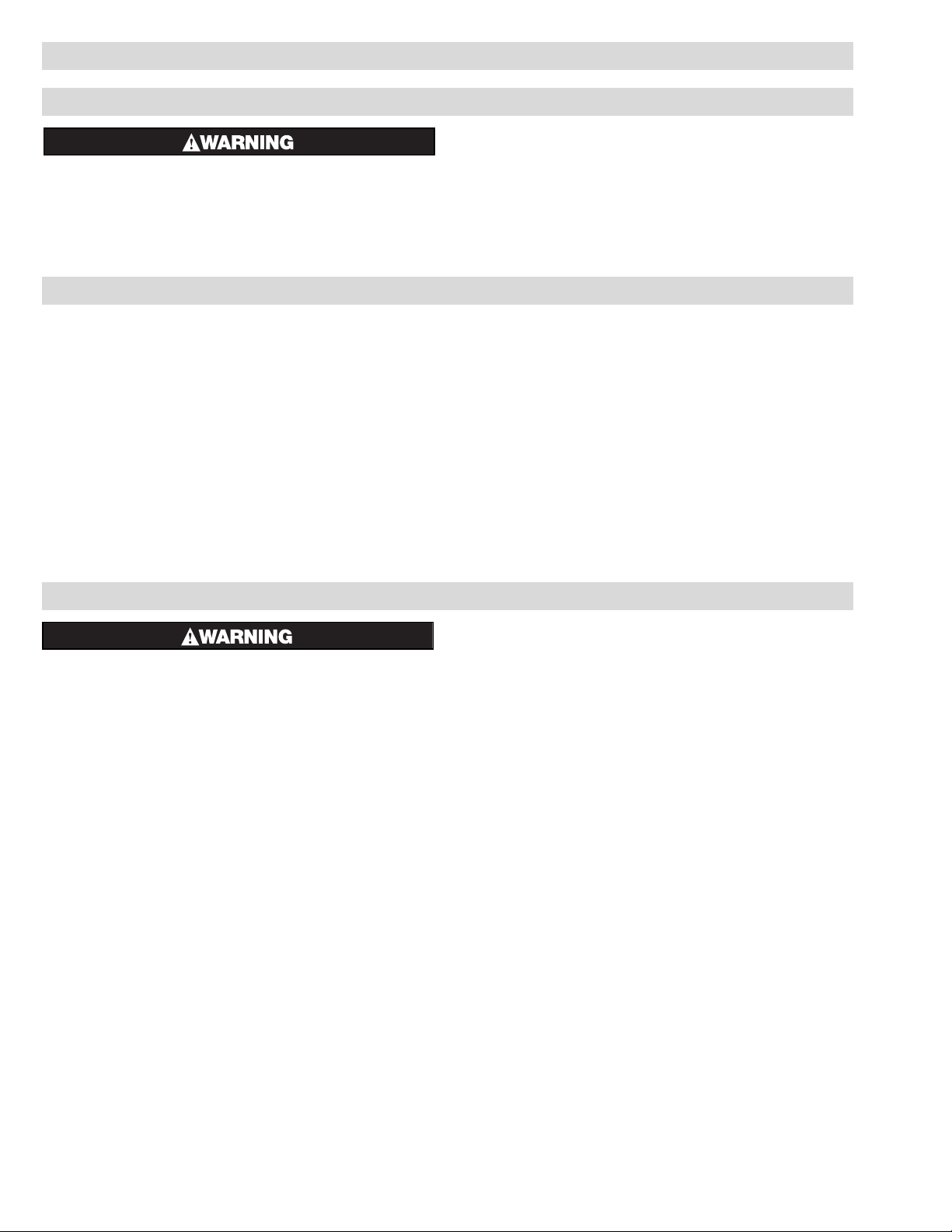

4. Tubular heaters are clamped the same as strips against the metal

surface.

5. Allow a minimum of 1” air space between heaters and insula-

tion.

General Recommendations on the Use of Chromalox

®

Electric Heating Elements for Clamp-On,

Oven and Air Duct Heating

The electric heating element(s) supplied herein are ruggedly

constructed and if properly installed, operated and maintained, are

designed for long life and dependable, trouble-free service.

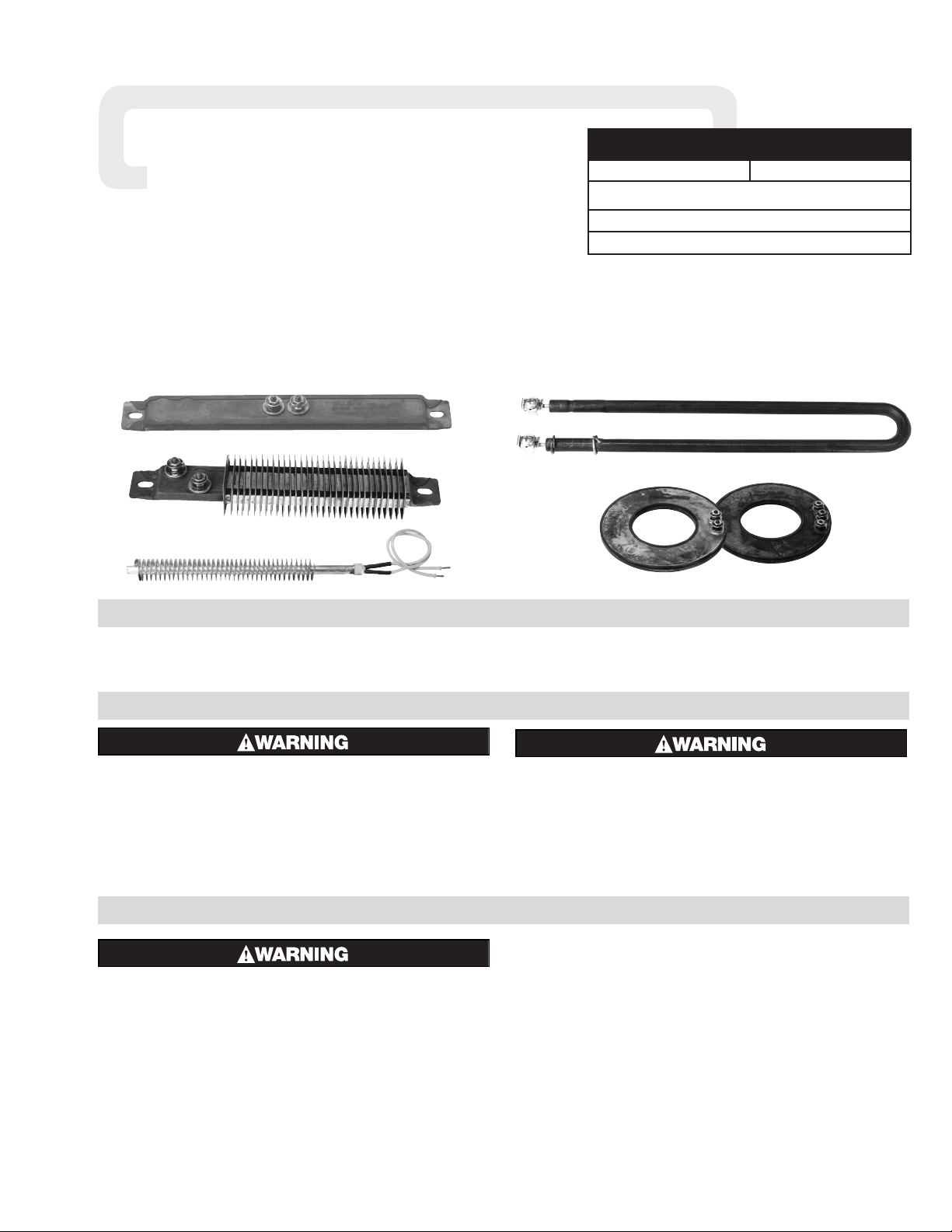

The following units are generally used in these applications:

Tubular, Strip, Ring, Fin-Tubular and Fin-Strip

Page 2

WIRING

GENERAL INFORMATION

MAINTENANCE

ELECTRIC SHOCK HAZARD. Any installation

involving electric heaters must be performed by a

qualified person and must be effectively grounded

in accordance with the National Electrical Code to

eliminate shock hazard.

1. Electric wiring to heating elements must be installed in accor-

dance with National Electrical Code or local electrical codes by

a qualified person.

2. Temperatures at heater terminals may require use of

high-temperature wire. Check factory for recommendations.

3. Maximum torque on strip heater terminals is 25 in-lbs.

4. Maximum tourque on secondary insulation bushings

used in strip heater mounting is 40 in-lbs; (Part # 00036-001)

PCN 255716

1. Strip heaters of equal wattage and voltage may be series con-

nected for use on a power supply up to 480 volts. Where the

power supply is greater than 480 volts (600 volt max.) series

connections may be used but secondary insulation bushings

must be provided.

2. Ring heaters of equal wattage and voltage with a surface tem-

perature of less than 1000˚F may be series connected for use on

a power supply up to 240 volts maximum.

3. Tubular heaters of equal wattage and voltage can be series con-

nected for use on a maximum power supply of 480 volts.

Heaters for use above 480 volts must be equipped at the factory

with special high voltage terminal insulation.

4. Use iron or steel sheathed heaters for temperatures up to 750˚F

maximum sheath temperature. Use chrome steel sheathed rings

or strips for temperatures up to 1200˚F maximum sheath temperature. Use alloy or Inconel® sheathed tubular heaters for

temperatures up to 1500˚F maximum sheath temperature. The

sheath temperature is the highest temperature on the surface of

the heater when operating.

5. Do not bend or form strip heaters. Do not bend tubular heaters

on inside radii of less that 4”. When it is required to bend or

curve strips or dish rings, or bend tubulars on small radii, consult our factory.

6. Use seamless strips where condensation, spray, oil or fumes are

present.

7. Protect terminals from drippings, spray, condensation or

spillover. Provide adequate electrical clearance.

8. Use manganese nickel wire or alloy bus bar for making electri-

cal connections within the heater itself, and for bringing leads

out through the insulating jacket to a cooler region where insulated copper wire may be attached.

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed by a qualified person

in accordance with the National Electrical Code,

NFPA 70.

1. Periodically clean terminals of dust and corrosion to maintain

good electrical connections and to permit rapid heat dissipation.

Use airblast and be careful to avoid damage to mica insulation.

2. Check for loose terminal connections.

CHROMALOX ELECTRIC HEATING ELEMENTS FOR CLAMP-ON (cont’d)

2

Page 3

CHROMALOX ELECTRIC HEATING ELEMENTS FOR OVEN HEATING – AIR DUCTS

The electric heating element(s) supplied herein are ruggedly constructed and if properly installed, operated and maintained, are

designed for long life and dependable, trouble-free service.

GENERAL

INSTALLATION

Temperature regulating and temperature limiting controls are

recommended to be used with electric heaters to control the heating

process and safeguard the electric heaters from excessive temperatures that can damage heaters.

FIRE HAZARD. Since heaters are capable of developing high temperatures, extreme care should be

taken to:

A. Avoid mounting heaters in an atmosphere containing com-

bustible gases and vapors.

B. Avoid contact between heaters and combustible materials.

C. Keep combustible materials far enough away to be free of the

effects of high temperatures.

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed by a qualified person

in accordance with the National Electrical Code,

NFPA 70.

High heating efficiency, low sheath temperatures and long

heater life result when electric heaters are properly installed.

INSTALLATION – OVEN HEATING

1. When mounting the strip heaters vertically, locate the terminals

at the bottom or cooler parts of the oven. Allow for expansion

and contraction by loosely bolting the top mounting tab. Secure

the bottom tab firmly.

2. In a forced air system, the width of the strip should be parallel to

the direction of air flow.

3. For horizontal installation of strips, the tab on the terminal end

should be firmly connected and the opposite end loosely con-

nected to allow for expansion and contraction.

4. Mount strips on edge in horizontal installation across the bottom

and along the sides on the oven, allowing 3” minimum air space

between the heaters and the bottom of the oven and 1” from the

oven wall to allow for proper circulation of heated air. For large

ovens, allow a 6” minimum clearance.

5. In horizontal mounting, install a protective screen or grill above

the strips at the bottom of the oven.

6. Support long iron sheathed strips on 36” centers and chrome

steel sheathed strips on 24” centers to prevent sagging.

INSTALLATION – AIR DUCTS

1. Locate protective thermostat on downstream side of heaters near

the top of the duct and close to the heated portion of the heaters.

2. Mount heaters with terminals at the duct bottom to prevent over-

heating.

3. Where condensation, spray, oil or fumes are present use seam-

less finstrips, type SSEF, with the terminals placed outside of

the air duct.

4. As a safety feature in advent of abnormal temperatures, it is sug-

gested to use a thermal cutout in conjunction with thermostatic

control.

WIRING

ELECTRIC SHOCK HAZARD. Any installation involving electric heaters must be performed by a qualified person and must be effectively grounded in

accordance with the National Electrical Code to

eliminate shock hazard.

1. Electric wiring to heating elements must be installed in accor-

dance with National Electrical Code or local electrical codes by

a qualified person.

2. Temperatures at heater terminals may require use of high-tem-

perature wire. Check factory for recommendations.

3

Page 4

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

GENERAL INFORMATION

1. Strips of equal wattage and voltage can be series connected for

a maximum of 480 volts. If a higher voltage (600 volt max.) is

necessary use the same series connections and use secondary

insulation bushings.

2. Use iron or steel sheathed heaters for temperatures up to 750˚F

maximum sheath temperature. Use chrome steel sheathed strips

for temperatures up to 1200˚F maximum sheath temperature.

Use alloy or Inconel® sheathed tubular heaters for temperatures

up to 1500˚F maximum sheath temperature. The sheath temperature is the highest temperature on the surface of the heater

when operating.

3. Do not bend or form strips.

4. Use manganese nickel wire or alloy bus bar for making electri-

cal connections where temperatures are above 350˚F. Insulated

copper wire may be used in the cooler region.

5. Terminals should always be in the coolest part of the oven. If

oven temperature is over 800˚F the terminals should be placed

outside the oven if possible. If not possible, weld electrical connections to heater terminals. Protect terminals from welding

flux.

6. Tubulars are to be mounted the same as strips and supported on

24” centers.

MAINTENANCE

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed by a qualified person in accordance with the National Electrical

Code, NFPA 70.

1. Periodically clean terminals of dust and corrosion to maintain

good electrical connections and to permit rapid heat dissipation.

Use airblast and be careful to avoid damage to mica insulation.

2. Check for loose terminal connections.

CHROMALOX ELECTRIC HEATING ELEMENTS FOR OVEN HEATING – AIR DUCTS (cont’d)

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...