Page 1

LTFX

Electric Tank

Immersion Heaters

Installation Instructions

PN403-3

161-049178-101

1

April 2013

Page 2

LTFX

Electric Tank Immersion Heater Installation Instructions

General

The Chromalox Electric Tank Immersion Heater, Model

LTFX, is an engineered, pretested package designed to

give years of virtually maintenance free service and it is

shipped ready for installation into a storage tank. LTFX

provides low watt-density heating over a large heating surface with precise temperature control for such

materials as asphalt, fuel oil, pitch and tar, liquid sugar,

lube oils, linseed oil, biodiesel, glycerin, ethanol and

many other heat sensitive compounds.

The open coil heating elements (OCE) are housed in

either 2” or 3” Schedule 40 carbon or stainless steel

pipes, which are welded into the 150# ANSI flange.

Once the Unitary Immersion Heater is mated to your

tank, the heating elements may be removed and replaced without draining the tank.

Installation

Since excessive temperatures may permanently damage the heater and cause premature failure, the use of

temperature controls, limiting controls, and liquid level

sensors are required.

The system designer is responsible for the

safety of this equipment and should install adequate back-up controls and safety devices

with their electric heating equipment. Where

the consequences of failure could result in personal injury or property damage, back-up controls are essential.

FIRE OR EXPLOSION HAZARD: The tank must

be purged of all flammable vapors prior to cutting or welding.

High heating efficiency, low element temperatures, and

longer heater life are achieved when the unit is properly

installed.

1. To avoid chipping or cracking, precaution should be

taken while unpacking, handling, and installing the

ceramic insulators. Heaters with damaged insulators should be returned to the factory for repair or

replacement. Contact your local sales office for return authorization.

2. The LTFX unit must not be mounted in the vertical

position as the resistance wire on the OCE element

can sag, thus causing uneven heating or short circuit. Unit should be installed in a horizontal position

with the thermowell on top only.

FIRE OR EXPLOSION HAZARD: Mount the heater in a level, horizontal orientation only. All

other orientations may result in property damage or personal injury.

3.

IMPORTANT: Mount heater in the tank so the liquid

level will always be above the effective heated portion

of the heater. Provide expansion tank if necessary.

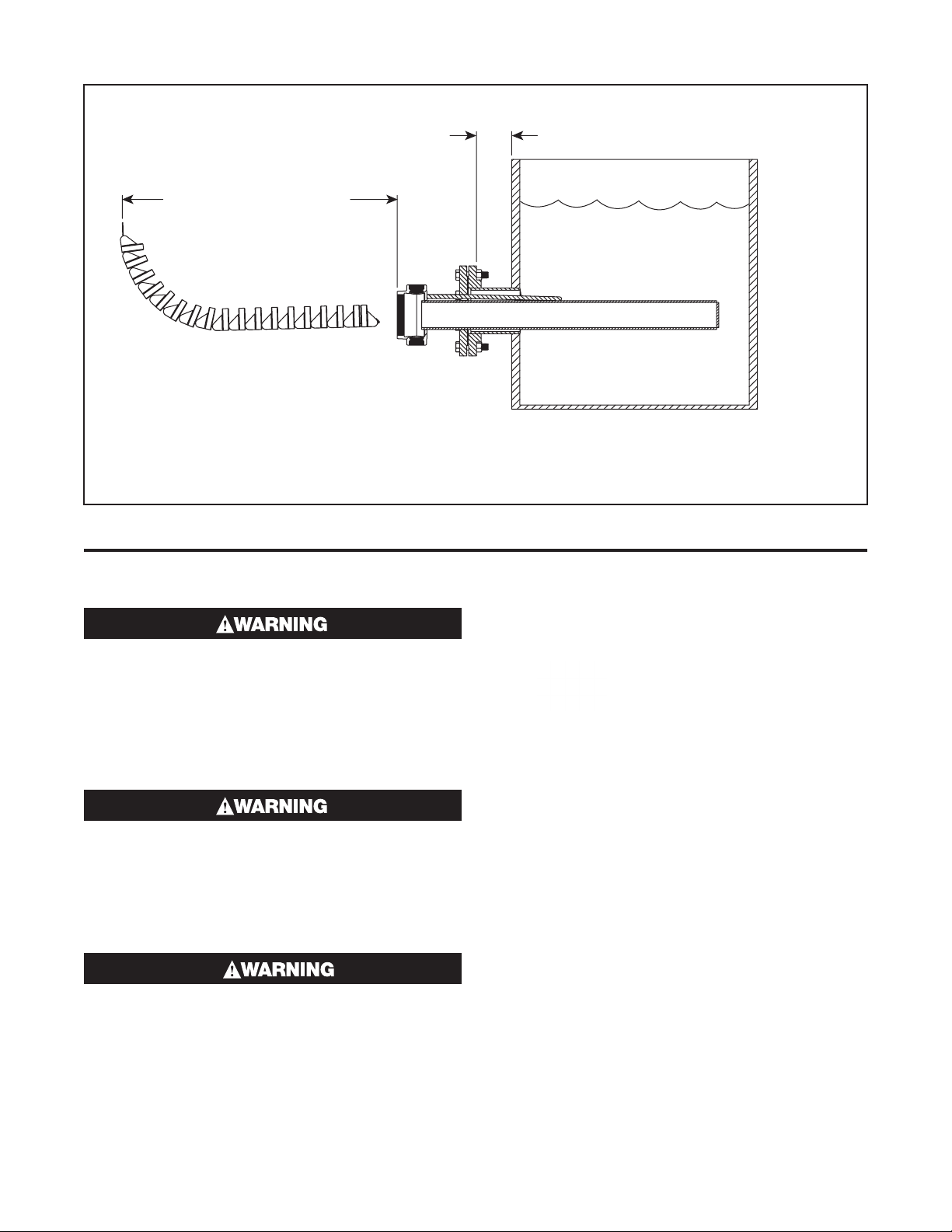

4. Select a location for this installation according to

the following guidelines: (refer to Figure 1)

A. Heating elements are removable through the ter-

minal enclosure however adequate room must

be provided for this purpose. The removal length

of the OCE heating element is 3 feet since the

center section may be bent on a 12” radius. OCE

elements should only be bent in a vertical plane

with ground strap on the bottom.

B. The neck on the tank’s mating flange should be

of adequate length to accommodate tank insulation and flange bolting.

5. Tube supports (internal to the tank) should be

placed approximately three feet from the ‘wet-side’

of the LTFX flange to ensure gasket sealing integrity.

Additional tube supports can then be spaced on 10

foot centers. Do not anchor the heater tubes to the

supports, as the tubes must be allowed to expand.

6. To ensure proper sealing, a material appropriate

gasket needs to be installed between the mating

flanges. The mating flanges should then be secured

by tightening the bolting according to TEMA Standards.

7. A tank suction pipe should be mounted at least 2”

above the level of the heaters. A separate line can

be provided to drain tank after heaters have been

de-energized.

2

Page 3

Allow for Tank

Insulation and Bolting

36” Min. Element

Removal Distance

Open-Coil Elements

Figure 1

Wiring

ELECTRIC SHOCK HAZARD. Disconnect all

power before installing or servicing heater.

Failure to do so could result in personal injury

or property damage. Heater must be installed

or serviced by a qualified person in accordance

with applicable National Electric Codes, NFPA

70 and/or International Electric codes.

Fluid

Level

Model LTFX

1. Electrical wiring to heating elements must be sized

and installed in accordance with applicable National

Electric Codes, International Electric Codes and/or

and applicable local codes by a qualified person as

defined by the code.

2. Temperatures at the heater terminals will require the

use of manganese nickel or equivalent temperature

lead wire. (Type TGS, TGT, or TGGT are recommended.)

ELECTRIC SHOCK HAZARD. Any installation

involving electric heaters must be performed

by a qualified person and must be effectively

grounded in accordance with applicable National Electric Codes and/or International Electric Codes to eliminate shock hazard.

The system designer is responsible for the

safety of this equipment and should install adequate back-up controls and safety devices

with their electric heating equipment. Where

the consequences of failure could result in personal injury or property damage, back-up controls are essential.

Wiring Entrance Locations - Moisture

Resistant Housing Only (E4 Option)

The Moisture Resistant (E4) Housing offers several

convenient options for conduit wiring & location. The

housing is equipped with two removable service entrance plates for installation of wiring. Any or all of the

six sides can be used for wiring locations. Refer to exploded view drawing. The housing can also be rotated

(by removal from flange) to allow for more position

possibilities. To install service entrance holes, simply

remove the side Allen screws and use the centering

depression to drill the appropriate size hole. Reinstall

the gasket(s), if applicable, and service entrance plates

by tightening the Allen head screws to 4-5 in/lbs. The

‘Octobox’ style of housing can be removed for ease of

access to element bussing or to better locate the power conduit(s) entry point. To accomplish, simply remove

the Allen-head screws on the outside of the housing.

3

Page 4

When reinstalling, be sure to properly align gasket, if

applicable, and tighten to 40-50 in/lbs.

Tip for Reinstalling Gaskets:

Place allen head screws through metal covers and

gentle push gasket hole over the threaded screw. This

will allow the gasket to stay in place while tightening

the cover.

Table A – E4 Wiring Information

Heater kW Volts Phase

LTFX-125-004E4 4 480 3 4.8 1

LTFX-128-008E4 8 480 3 9.6 1

LTFX-1212-012E4 12 480 3 14.5 1

LTFX-2212-024E4 24 480 3 28.9 1

LTFX-3212-036E4 36 480 3 43.4 1

LTFX-2325-060E4 60 480 3 72.3 1

LTFX-3325-090E4 90 480 3 108.4 3

LTFX-4325-120E4 120 480 3 144.5 2

LTFX-6325-180E4 180 480 3 216.8 3

LTFX-8325-240E4 240 480 3 289.0 4

Total

Amps Circuits

Wiring Entrance Locations - Explosion

Resistant Housing Only (E2 Option)

The Explosion Resistant (E2) Housing features dedicated conduit connection sizes and locations for either

NPT installation of conduit or Metric cable glands. Incoming wiring must be suitable for a maximum terminal enclosure temperature of 158˚F (70˚C). Wiring installation must be in accordance with Hazardous Area

requirements. The use of EYS seals or rigid conduit

may be required. Please consult with the local inspection authority.

Maximum Temperatures

Safe operation in a hazardous location requires the

maximum operating temperatures of all exposed surfaces of the heater including temperatures on the outside of the vessel, piping, flanges, screw plugs, enclosures and other heat conducting parts be limited. The

flammable liquids, vapors or gases present determine

the maximum surface temperature permitted in any

hazardous location. The end user or purchaser of the

electric heating equipment is responsible for determining the proper classification of an area and for providing Chromalox with hazardous area specifications and

requirements for proper equipment design. (NEC and

IEC provide guidelines for evaluating and classifying

hazardous locations.)

An approved liquid level control or overtemperature control must be installed to deenergize

the heater if the liquid level drops below the

top of the heater.

Maximum fluid temperature per following table:

Temperature Class Maximum Fluid Temperature

T1 (450˚C) 440˚C

T2 (300˚C) 290˚C

T3 (200˚C) 195˚C

T4 (135˚C) 130˚C

T5 (100˚C) 95˚C

T6 (85˚C) 80˚C

The external surfaces of the heater must not exceed

the marked fluid temperature. An over-temperature

control should be used if there is a possibility of the

heater’s external surface temperature exceeding the

fluid temperature.

Table B – E2 Wiring Information

Heater kW Volts Phase

LTFX-125-004E2 4 480 3 4.8 1

LTFX-128-008E2 8 480 3 9.6 1

LTFX-1212-012E2 12 480 3 14.5 1

LTFX-3210-024E2 24 480 3 28.9 1

LTFX-3215-036E2 36 480 3 43.4 1

LTFX-3225-060E2 60 480 3 72.3 1

LTFX-4225-090E2 90 480 3 108.4 2

LTFX-8215-120E2 120 480 3 144.5 2

LTFX-9220-180E2 180 480 3 216.8 3

LTFX-12225-240E2 240 480 3 289.0 4

Total

Amps Circuits

4

Page 5

Third Party Certifications

E4 Moisture Resistant Enclosure Certifications

North

American

Designations(s)

Rating NEMA 4 NEMA 4 IP66 IP66

Agency(s)

E2 Moisture Resistant Enclosure Certifications

Canadian

Designation(s)

European

Designation(s)

Manufacturers

Declaration

International

Designation(s)

Manufacturers

Declaration

North American

Designations(s)

Rating Explosion

Resistant

Agency(s) CSAus CSA ATEX IECEx

Ratings Class I, Div. 1

Groups B, C & D

Class II, Div. 1

Groups E, F & G

Class I Zone 1

AEx d

IIB + H2 Gb

T1 to T6

*Note: Temps over T3 (200˚C) require stand-offs for third-party listing. Refer to IECex and

ATEX certificates for stand-off dimensions.

Operation

Canadian

Designation(s)

Explosion

Resistant

Class I, Div. 1

Groups B, C & D

Class II, Div. 1

Groups E, F & G

Class I Zone 1

Ex d

IIB + H2 Gb

T1 to T6

-50˚C < Ta < +60˚C

European

Designation(s)

Explosion

Resistant

0359

II 2 G

Ex d IIB+H2 Gb

T1 to T6

IP66 IP66

International

Designation(s)

Explosion

Resistant

Ex d IIB+H2 Gb

T1 to T6

contaminants can create leakage (shock) hazards,

permanent heater damage, or cause heater failure

and therefore should be avoided.

FIRE OR EXPLOSION HAZARD. To avoid possible damage to the heater, do not energize until

the tank is filled with fluid. Recommended fluid

level is 2” above the heater tube or pipe.

For initial operation and tuning the control scheme:

1. Turn the master circuit breaker off and open the

control box door.

2. Set the indicating temperature control at the de-

sired temperature and the over-temperature cutout

FIRE or EXPLOSION HAZARD. Do not open enclosure when energized. Do not open enclosure

when an explosive gas atmosphere is present.

1. Do not operate heaters at voltages in excess of that

stamped on the heater, since excess voltage will

shorten heater life.

at 50°F above this temperature.

3. Interlock the liquid level control with the cutout device.

4. Close the control box door and turn the circuit

breaker on. To energize the heater circuits, turn the

on-off selector switch to the “on” position.

2. Heaters should not be operated in environments

with factors that can destroy the electrical insulating

characteristics of the ceramic insulators. Foreign

5

Page 6

Maintenance

FIRE or EXPLOSION HAZARD. Do not open enclosure when energized. Do not open enclosure

when an explosive gas atmosphere is present.

ELECTRIC SHOCK HAZARD. Disconnect all

power before installing or servicing heater.

Failure to do so could result in personal injury

or property damage. Heater must be installed

or serviced by a qualified person in accordance

with applicable National Electric Codes, NFPA

70, and/or International Electric Codes.

1. Make certain both the terminals and the ceramic

insulators are free from contact with oil, liquid, or

other foreign matter. NOTE: Chromalox cannot be

responsible for failures or damage caused by contamination on the ceramic insulators. Make certain

the heaters are not exposed to contaminants.

2. Check electrical connections at heater terminals

and tighten if necessary. This will help avoid hot terminals which may destroy wire insulation or heater

terminals

3. Check overheat operation to assure heater protection.

Element Replacement - Moisture Resistant Housing Only (E4 Option)

1. To remove the OCE heating elements, first turn the

circuit breaker to the off position.

2. Next remove the housing lid, element wiring and

the element mounting screw. Now pull the element

straight out of the heating tube. NOTE: OCE elements should only be bent in a vertical plane with

ground strap on the bottom.

3.

When removing the heating elements, make certain that

the terminals and the ceramic insulators do not contact

oil or any other liquid foreign matter. Note: Chromalox

cannot be responsible for failures or damage caused

by contamination on the ceramic insulators.

4. Installation is the reverse of the above.

Element Replacement - Hazardous Locations,

Explosion Resistant Housing Only (E2 option)

1. To remove the OCE heating assembly, first turn the

circuit breaker to the off position.

Next remove the housing lid, element wiring, and

2.

8mm bolting around the element flamepath module.

If bolts must be replaced, use a minimum of grade

10.9. If needed, (2) 1/4-20x2” bolts may be used to

break loose the module from the flange. Turn bolts

evenly until module is free. The flamepath module will

be re-used, so disconnect the heating element from

the module pins. Now pull the element assembly out

of the heating tube. NOTE: OCE elements should

only be bent in a vertical plane with ground strap on

the bottom.

3.

When removing the heating elements, make certain that

the terminals and the ceramic insulators do not contact

oil or any other liquid foreign matter. Note: Chromalox

cannot be responsible for failures or damage caused

by contamination on the ceramic insulators.

4. Inspect the element assembly flange and mating surface for any debris, oils, or contamination.

NOTE: Surfaces must be in suitable condition to ensure proper hazardous rating.

5. Wire connection to OCE heating element should

be made using ring connectors. Wire connection to

flamepath module must be made with crimp-style

barrel connectors. If wires between flamepath module and OCE element need to be replaced, the wires

should be rated for a minimum of 250˚C. It is also

required to cover the barrel connector, wire and ring

connector with electrical sleeving to prevent unwanted grounding. Connect the new element to the

flame path module by wiring connection(s) to the

OCE element and slide the OCE element into tube.

6. Connect the new element to the flamepath module

and slide into tube. Flamepath module bolting must

be tightened to 26 ft/lbs. of torque.

7. Reattach element wiring. When reinstalling housing lid, be sure to properly align gasket, and tighten

housing bolts to 26 ft/lbs.

6

Page 7

Renewal Parts Identification

Table C – E4 Housing Renewal Parts Identification

Immersion

Heater Model kW Volts Phase

LTFX-125-004E4 4 480 3 60 (1,524)

LTFX-128-008E4 8 480 3 96 (2,438)

LTFX-1212-012E4 12 480 3 144 (3,658)

LTFX-2212-024E4 24 480 3 144 (3,658)

LTFX-3212-036E4 36 480 3 144 (3,658)

LTFX-2325-060E4 60 480 3 300 (7,620)

LTFX-3325-090E4 90 480 3 300 (7,620)

LTFX-4325-120E4 120 480 3 300 (7,620)

LTFX-6325-180E4 180 480 3 300 (7,620)

LTFX-8325-240E4 240 480 3 300 (7,620)

Length In.

(mm)

Table D – E2 Housing Renewal Parts Identification

Immersion

Heater Model kW Volts Phase

LTFX-125-004E2 4 480 3 66 (1,676)

LTFX-128-008E2 8 480 3 96 (2,438)

LTFX-1212-012E2 12 480 3 144 (3,658)

LTFX-3210-024E2 24 480 3 120 (3,048)

LTFX-3215-036E2 36 480 3 180 (4,572)

LTFX-3225-060E2 60 480 3 300 (7,620)

LTFX-4225-090E2 90 480 3 300 (7,620)

LTFX-8215-120E2 120 480 3 180 (4,572)

LTFX-9220-180E2 180 480 3 240 (6,096)

LTFX-12225-240E2 240 480 3 300 (7,620)

Length In.

(mm)

ANSI

Flange Size

Number

of Tubes

Nominal

Tube Dia.

(In)

4" - 150# 1 2”

4" - 150# 1 2”

4" - 150# 1 2”

6" - 150# 2 2”

6" - 150# 3 2”

8" - 150# 2 3”

10" - 150# 3 3”

10" - 150# 4 3”

12" - 150# 6 3”

14" - 150# 8 3”

ANSI

Flange Size

Number

of Tubes

Nominal

Tube Dia.

(In)

4" - 150# 1 2”

4" - 150# 1 2”

4" - 150# 1 2”

8" - 150# 3 2”

8" - 150# 3 2”

8" - 150# 3 2”

10" - 150# 4 2”

12" - 150# 8 2”

14" - 150# 9 2”

14" - 150# 12 2”

Replacement OCE

Model No.

OCE-05040-2-483

OCE-06080-2-483

OCE-12120-2-483

OCE-12120-2-483

OCE-12120-2-483

OCE-25300-3-483

OCE-25300-3-483

OCE-25300-3-483

OCE-25300-3-483

OCE-25300-3-483

Replacement OCE

Model No.

OCE-06040-2-483

OCE-06080-2-483

OCE-06080-2-483

OCE-06080-2-483

OCE-06080-2-483

OCE-25200-2-4803

OCE-25225-2-4803

OCE-15150-2-4803

OCE-25200-2-4803

OCE-25200-2-4803

7

Page 8

© 2013 Chromalox, Inc.

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

8

Loading...

Loading...