Page 1

(Supersedes PK413-3)

PK413-4

AR

161-562791-001

SEPTEMBER, 1995

4

and

Installation, Operation

RENEWAL PARTS IDENTIFICATION

Type AR-EP Industrial Explosion-Resistant

Thermostat

© 2010 Chromalox, Inc.

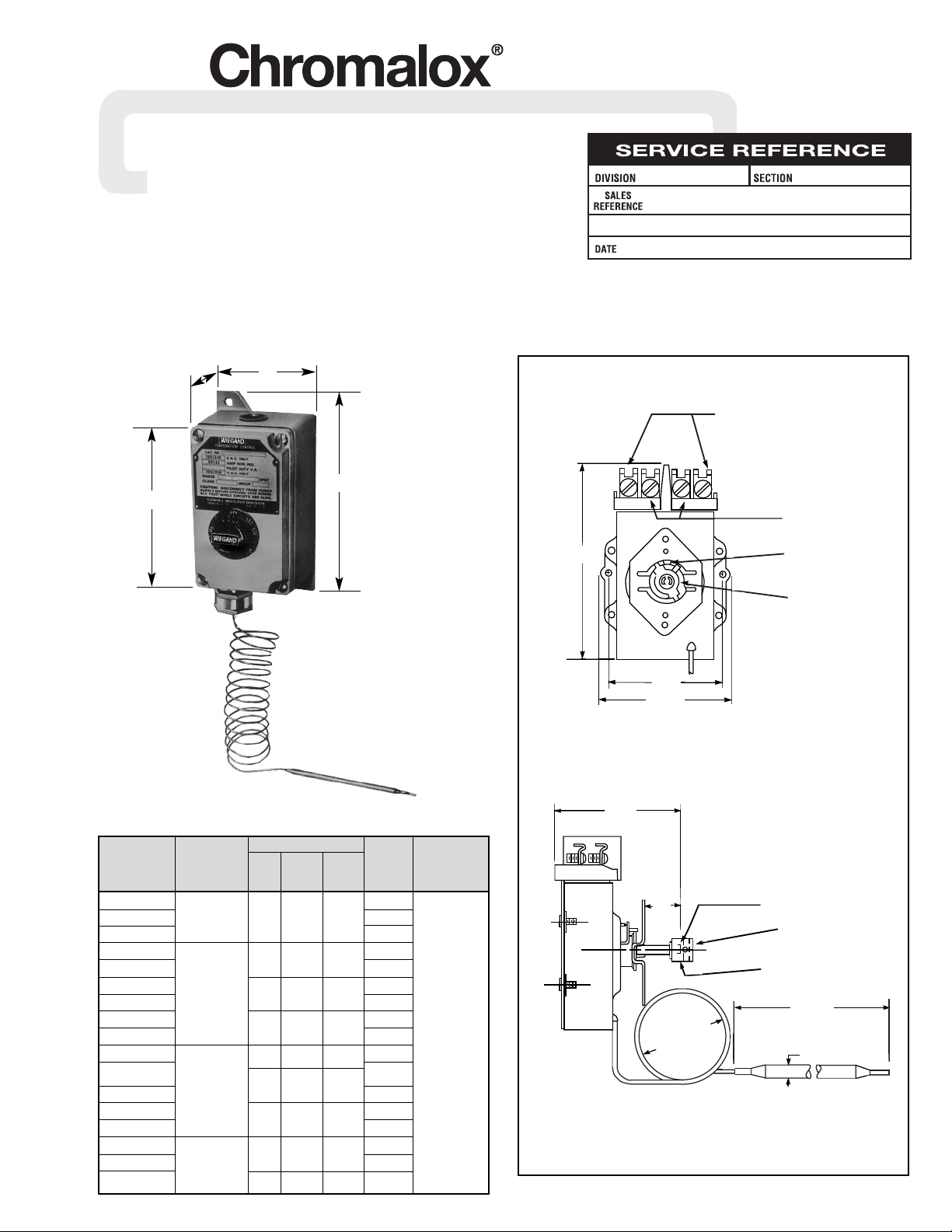

Specifications – Table A

2 / "

17

32

Length

(Refer to Specifications —

Table A)

2" O.D. Typ.

Capillary

2 / "

21

32

4 / "

3

32

2 / "

9

32

Dial

Stop

Post

Connect Load

Here

Shaft Shown

In "Off" Position

(Without Calibrated Cap)

Connect Power

Supply Here

/ "

11

16

Calibration Cap

White Nylon

Universal Coupler

Set Screw Lock

Figure 1

Sensing Bulb

Temperature Approx. Capillary Max.

Range Dia. Length Length A.C. Rating

Model (°F) Style (In.) (In.) (Ft.) (Amps)

AR-115EP 7

AR-115AEP 0 – 100 5 0.375 4

3

/8 2

AR-115CEP 12

AR-214EP 7

30 Amp

AR-214DEP

4 0.250 55/32

15 120-277 VAC

AR-215EP

60 – 250

7

AR-215AEP

5 0.375 4

2

AR-219EP 7

AR219DEP

9 0.188 10

3

/4

15 250 VA

AR-514EP 4 0.250 5

5

/8 7

120-277 VAC

AR-515EP 7

(Pilot Duty)

AR-515AEP

200 – 550 5 0.375 3

5

/8

2

AR-519EP

9 0.188 9

7

AR-519DEP 15

AR-715EP 5 0.375

3

11

/16

7

AR-715DEP 300 – 700 5 0.375 15

AR-719EP 9 0.188 12 7

61/2”

81/4”

4

1

/4”

4”

Page 2

GENERAL

NOTICE: Type AR-EP controls are designed for temperature control service only. Because they do not fail safe, they should not be

used for temperature limiting duty.

WARNING: Users should install adequate back-up

controls and safety devices with their electric

heating equipment. Where the consequences of

failure may be severe, back-up controls are essential. Although the safety of the installation is the

responsibility of the user, Chromalox will be glad to

make equipment recommendations.

Principle of Operation — Control action of these thermostats is

provided through the principle of liquid volume change. With a

variation in temperature, the liquid in the sensing bulb expands or

contracts, causing a bellows to actuate the switching mechanism.

Housing — The control housing and cover assembly is of heavyduty cast aluminum.

Control Range — The following temperature ranges are available:

Fahrenheit

0° to 100° 200° to 550°

60° to 250° 300° to 700°

Process Temperature Differential — is variation in controlled

process temperature between maximum, when thermostat turns

OFF and minimum, when thermostat turns ON. This spread in

temperature may be minimized by —

1. Making sure control is mounted to vertical surface. (See Step

1, MOUNTING section.)

2. Avoiding excess heating capacity (oversized heaters).

3. Locating control sensing bulb in optimum position between

heat source and work.

In general, it is difficult to predict the actual operating differential of a given process. Temperature differential may be as

low as 4°F for low range controls to as high as 17°F for higher range controls since the differential is a percentage function

of the dial range.

Packing Glands — If a sealed or leak-proof connection is required

at the point where the capillary enters the oven, tank, pipe or similar equipment, an appropriate packing gland is available as an

optional part. (Model CCF-25A, CCF-25D or CCF-25E)

WIRING

MOUNTING

WARNING: Hazard of Electric Shock. Disconnect all

power before wiring or servicing this control.

Failure to comply can result in electrical shock or

electrocution.

1. Electric wiring to heater must be installed in accordance with

National Electrical Codes and local codes. WARNING: Use

copper conductors only.

2. Entrance for wiring is provided by one

3

/4” NPT hole in the top

of the housing. Wiring to control housing must be in rigid conduit also in accordance with National Electrical Codes (NEC)

for hazardous locations.

3. Set thermostat knob to OFF position and remove cover plate by

loosening and removing four (4) fastening screws (see Figure 5).

Note: Do not mount thermostat where it will be subject to vibration, shock, grease, dust, lint or corrosive vapors. Do not mount

adjacent to a large magnetic contactor, as vibration and shock will

cause thermostat to interact erratically — resulting in chattering of

the contactor.

The air temperature in and around the thermostat enclosure

should be kept as near to normal room temperature as possible...

never above 150°F.

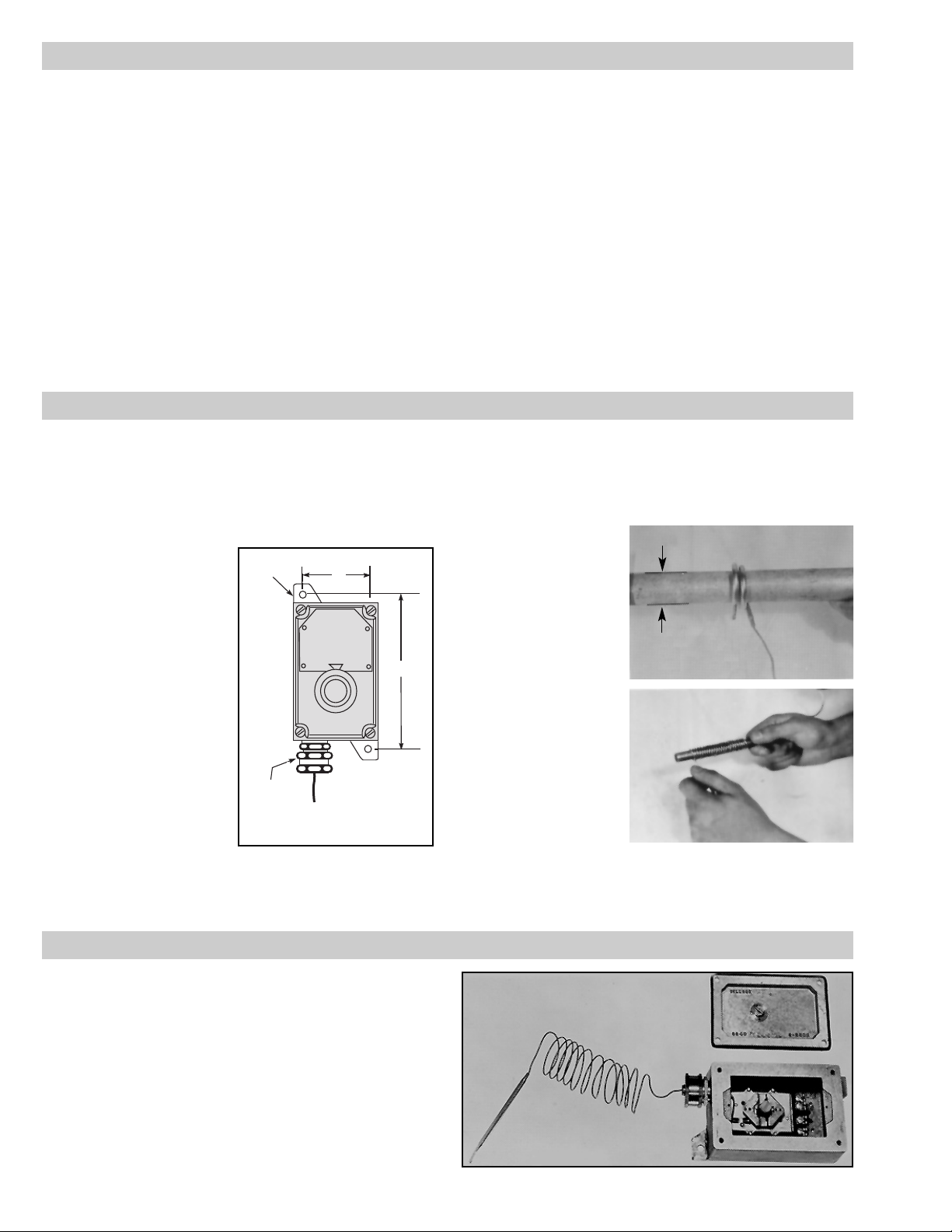

1. Thermostat must be mount-

ed in a vertical position only.

2. Use sheet metal or wood

screws through the two

5

/16”

diameter mounting holes in

mounting lugs to mount

control (see Figure 2).

3. For controlling platen or die

temperatures, insert entire

sensing bulb into drilled holes

selected for snug slip fit.

The longer, more sensitive Style 9 bulbs should be

used for controlling air temperatures or pipe line heating.

4. NOTICE:

A. Bending or deforming

sensing bulb will alter

control calibration —

requiring recalibration after installation. See CALIBRATION section, page 3. If necessary, Style 9 bulbs can be

coiled to 1” I.D. (see Figure 3).

B. Do not kink capillary tube. The resulting constrictions in

fluid flow can destroy control function or broaden temperature differential. Minimum capillary tube bending diameter is

1

/2” I.D. (see Figure 4).

C. Any deformations of bulb or capillary that result in leakage

of fluid from control renders control inoperative.

D. Avoid passing control capillary tube through zones whose

temperature is in excess of controlled process temperature.

Erratic control or destruction of control function may result.

Lugs

Capillary

Seal

Fitting

3"

7 / "

3

8

Figure 2

Figure 3

(Sensing Bulb)

Figure 4

(Capillary Tube)

Figure 5

Do Not

Bend or Kink

Crimped End

1

/2”

Rod

1”

-2-

Page 3

1

2

3

4

1

2

3

4

Pilot

Light

Load

Line

Single Phase

Pilot Light

Load

Line

Single Phase

1

2

3

4

Pilot Light

Line

Load

Load

Two Circuit

4. Remove white shaft coupler for safe-keeping while making

wiring connections (see Figure 6).

5. Connect wires according to wiring diagrams (Figures 7 thru 11).

Note: Electrical connections should be made with generous

loops of wire — approximately 6” per lead.

6. Replace white shaft coupler.

7. WARNING: It is possible to replace enclosure

cover with adjustment knob 180 rotational

degrees out of alignment resulting in large calibration errors. To avoid this, carefully follow

these procedures.

A. Be sure that thermostat shaft is fully counter-clockwise (see

Figure 12). With thermostat knob held in the indicated OFF

position, carefully replace enclosure cover while feeling for

proper engagement of

shaft coupling.

B. With cover screws replaced

and moderately fastened,

check for full rotation of

dial knob. Note: Mild shaft

resistance should be

encountered. If satisfied,

that proper engagement of

shaft coupler is accomplished; finish tightening

cover screws.

8. Note: If load amperage or

voltage rating exceeds switch

rating, a contactor must be

used. Contactor and wiring to

be supplied by customer (see

-3-

WIRING

CALIBRATION

WARNING: Hazard of Electric Shock. Extreme care

should be exercised during calibration adjustments

because of shock hazard due to exposed electrical

terminals. Failure to comply can result in electrical

shock or electrocution.

These controls are factory calibrated to the range indicated on

the control adjustment knob.

If calibration is required, either one of two methods may be

followed.

1. If accurate measurement standards are not available, the thermostat can readily be adjusted to a known temperature standard

such as boiling water (212°). See Figure 13.

2. With the aid of an accurate thermometer or other temperature

measuring device, recalibration may be performed within the

process as in Figure 14.

For either method, the following general calibration procedures

should be followed.

Dial

Stop

Post

Stop

Tab

Figure 12

Figure 6

1

2

3

4

1

2

3

4

Pilot

Light

Line

Three Phase

when Load

Does Not

Exceed

Rating of

Thermostat

}

Three Phase

and Single

Phase when

Load Exceeds

Rating of

Thermostat

Control

Voltage

Line

Pilot

Light

Contactor

Figure 13

Figure 7

Figure 8 Figure 9

Figure 10 Figure 11

Page 4

CALIBRATION

THERMOSTAT SUB ASSEMBLY REPLACEMENT

DANGER: Calibration will involve exposure of inter-

nal control terminals to ambient conditions during

some part of the recalibration procedure.

Combustible materials which cause hazardous

conditions must not be present during recalibration process — otherwise explosion may result.

1. Heat water bath or the equipment in which the control is

installed (tank, die, platen or machine) to the selected calibration temperature. The entire sensing bulb and at least one foot

of its capillary tube are to be exposed to calibrating temperature. With thermostat energized, allow process or bath to reach

setpoint. This is accomplished when thermostat begins cycling

action.

2. Compare adjustment knob cut off temperature indication

against actual temperature to which sensing bulb is exposed.

Figure 15 shows example of a control knob showing a control

indication of 250°F when true process temperature measured

230°F. In this example, the control knob must be rotated 20°

counterclockwise to bring the 230°F knob marking under the

index mark in order to recalibrate the control.

3. Without disturbing the shaft setting, loosen the thermostat

knob set-screw and re-align dial setting accordingly. Retighten

knob set-screw.

4. Recheck for thermostat operation as per steps 2 and 3 and make

further calibration adjustment if indicated.

5. Recheck of thermostat operation following final adjustment

completes the calibration procedure.

IMPORTANT: Under no circumstances must the temperature

range, and in particular, the maximum temperature setting of control be increased above maximum temperature indicated on control

nameplate. Such changes voids U.L. listing of the control.

1. Before removing enclosure cover, turn thermostat knob to the

OFF position (counterclockwise). Place a piece of masking

tape over the knob to keep it in the OFF position.

2. Remove the enclosure cover by removing four fastening

screws (Figure 5).

3. Remove the white shaft coupler for safe-keeping.

4. Remove the thermostat mounting screws (2).

5. Loosen the capillary-seal retaining cap set screws and then

remove the retaining cap.

Note: Do not remove the entire capillary seal fitting from the

enclosure.

6. Remove the capillary seals and thermostat from the enclosure.

7. Remove the calibration cap (Figure 1) and insert pin from the

old thermostat. Rotate the position of the calibration cap, for

use in the next step.

8. With replacement thermostat in the OFF position (shaft complete-

ly counterclockwise), install insert pin and calibration cap. Install

calibration cap with same orientation as noted in step 7 above.

9. If excess capillary, on old thermostat, had been coiled in enclo-

sure, it may be necessary to coil an equal amount on replacement thermostat per step 4D mounting instructions.

10. After proper capillary length is obtained on replacement ther-

mostat, insert capillary in the enclosure and thru the capillary

seal fitting.

11. Recheck for proper capillary length (external to enclosure) and

adjust if necessary.

12. Align spacer plate and replacement thermostat to mounting

holes in the bottom of enclosure using mounting screws (2 –

#10-32 x

3

/8 Lg.) to secure thermostat to enclosure.

13. Slide the capillary seals into the capillary fitting making sure

the capillary is positioned in the center groove of the seals.

WARNING: If capillary is not located in the center groove properly, damage to the capillary will

result, rendering the thermostat inoperable or

unreliable.

14. Replace capillary seal retaining cap and tighten set screws to

lock in position.

Note: Per the NEC, all threaded connections in a hazardous

environment must be tightened sufficiently to engage five full

threads.

15. Rewire replacement thermostat per appropriate wiring dia-

grams (Figures 7 thru 11).

16. Replace the white nylon coupling on the calibration cap and

enclosure cover per step 7 of the wiring section.

17. Replacement thermostat control should be monitored to insure

proper operation. If calibration is required, see the calibration

section for instructions.

Thermometer

Load (Tank, vat, die or platen)

True Temp

250

200

A

Figure 14

Figure 15

-4-

Page 5

-5-

RENEWAL PARTS IDENTIFICATION

Thermostat

Model Sub Assembly Control Knob

AR-115EP 300-027566-001 169-019605-002

AR-115AEP 300-027566-014 169-019605-002

AR-115CEP 300-027566-012 169-019605-002

AR-214EP 300-027566-004 169-019604-001

AR-214DEP 300-027566-015 169-019604-001

AR-215EP 300-027566-009 169-019604-001

AR-215AEP 300-027566-007 169-019604-001

AR-219EP 300-027566-002 169-019604-001

AR-219DEP 300-027566-016 169-019604-001

AR-514EP 300-027566-005 169-019604-002

AR-515EP 300-027566-008 169-019604-002

AR-515AEP 300-027566-006 169-019604-002

AR-519EP 300-027566-003 169-019604-002

AR-519DEP 300-027566-018 169-019604-002

AR-715EP 300-027566-010 169-019605-001

AR-715DEP 300-027566-011 169-019605-001

AR-719EP 300-027566-013 169-019605-001

Parts Common to All

Part Part Number

Capillary Seal Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119-053954-001

White Nylon Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .079-512424-001

Page 6

1347 HEIL QUAKER BLVD., LAVERGNE, TN 37086

Phone: (615) 793-3900 www.chromalox.com

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...