Page 1

PK410-1

161-048634-001

JUNE, 1989

4WR

Installation Instructions

(Supersedes PK410)

Type WR Room Thermostat

© 2010 Chromalox, Inc.

Specifications – Table A

GENERAL

Positive accuracy, long and reliable service, 3° differential.

Heavy-duty, single stage, SPST line voltage snap-acting switch.

Patented hydraulic element. WR-80 has internal sensing element

and thermometer on cover; WR-90 has external, coiled sensing

element but no thermometer. Both have a low position which

drops control point to keep heater off. WR-80 and WR-90 finished in tough metallic gray with chrome trim; mounting plate

fits outlet or conduit box.

Uses – Automatically controls room temperature by turning electric air heaters on and off. Can be used to control the air heaters

directly, within thermostat rating. For higher ratings use thermostat with magnetic contactor. Place thermostat on inside wall,

away from undue heating or cooling influences, about 4 feet

above the floor. WR-90 is especially useful in holding lower temperatures, for example, in garages, warehouses, factories, etc.

NOTICE: Type WR thermostats are designed for temperature

control service only. Because they do not fail safe, they should

not be used for temperature limiting duty.

CAUTION: Users should install adequate back-up controls and

safety devices with their electric heating equipment. Where the

consequences of failure may be severe, back-up controls are

essential. Although the safety of the installation is the responsibility of the user, Chromalox will be glad to make equipment recommendations.

Principle of Operation – Control action of these thermostats is

provided through the principle of liquid volume change. With a

variation in temperature, the liquid in the sensing element

expands or contracts, causing a bellows to actuate the switching

mechanism.

CAUTION: Not for use in hazardous environments

as described in National Electrical Code. Failure to

comply can result in explosion or fire.

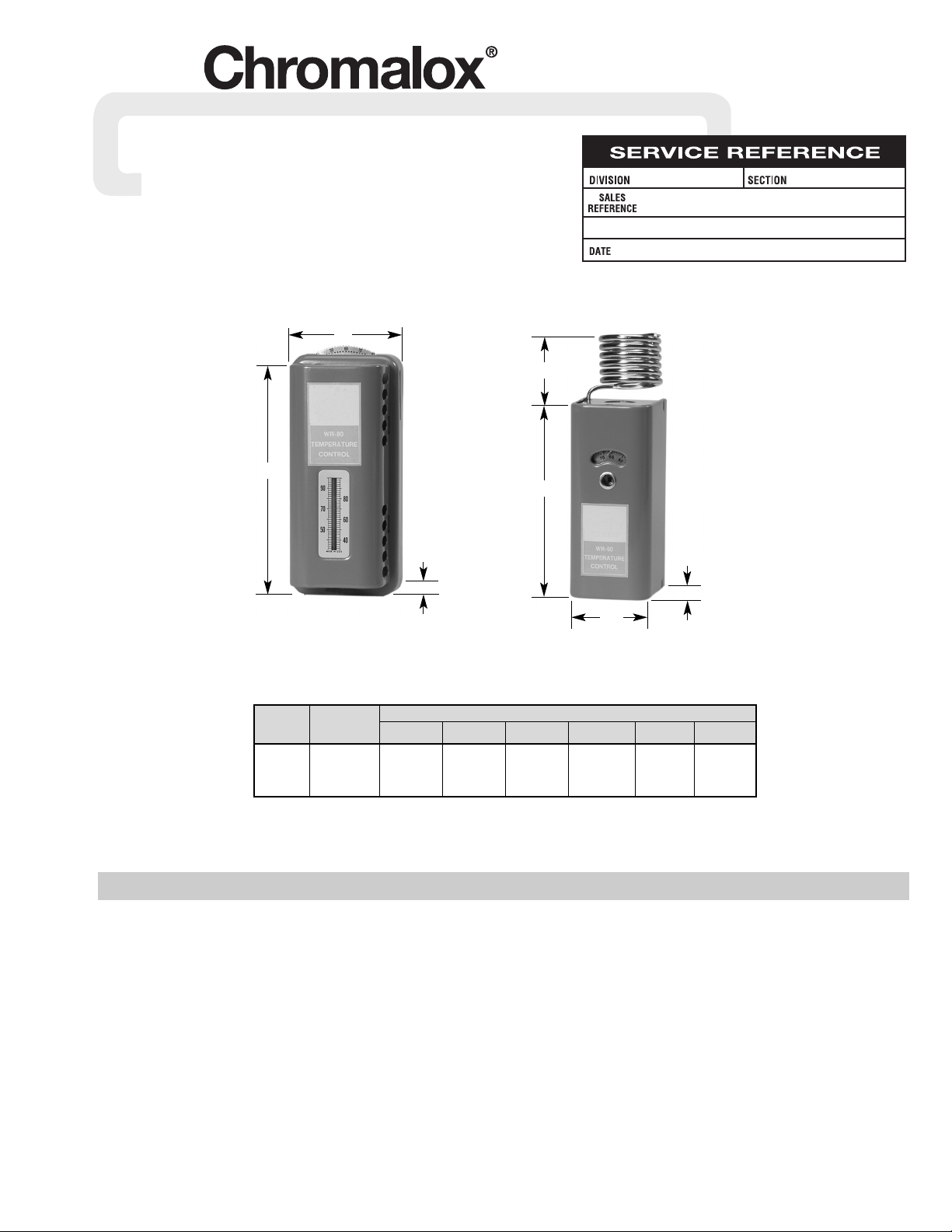

WR-80

40 to 80°F

UL Listed

Maximum Rating

Range

Model (°F) 120Vac † 115Vac 240Vac † 230Vac 277Vac 480Vac

WR-80 40-80 125va pilot 125va pilot 125va pilot

25 amps duty (use 22 amps duty (use 18 amps duty (use

WR-90 20-90 or 3000 with d-c or 5280 with d-c or 5000 with a-c

total watts contactor) total watts contactor) total watts contactor)

WR-90

20 to 90°F

UL Listed

† d-c ratings not UL listed

53/8”

21/2”

21/4”

2

9

/16”

6”

23/4”

2

1

/2”

Note —

WR-80 is

not a

Fail-Safe

Device.

Page 2

MOUNTING

Note: Do not mount control where it will be subject to vibration,

shock, grease, dust, lint or corrosive vapors. Do not mount adjacent to a large magnetic contactor, as vibration and shock will

cause thermostat to interact erratically – resulting in chattering of

the contactor.

CAUTION: Do not twist or uncoil the coiled element on top of the

case of the WR-90.

The proper location of a heavy duty room thermostat is important

to assure good performance.

1. Locate where air circulates freely.

2. Never install on or near outside wall.

3. Keep away from windows or doors.

4. Do not locate too close to strong light or other false source of

heat, such as sunlight, steam lines, etc.

5. If electrical conduit leads into cooler or warmer room, plug up

space around wires in the conduit with rock wool.

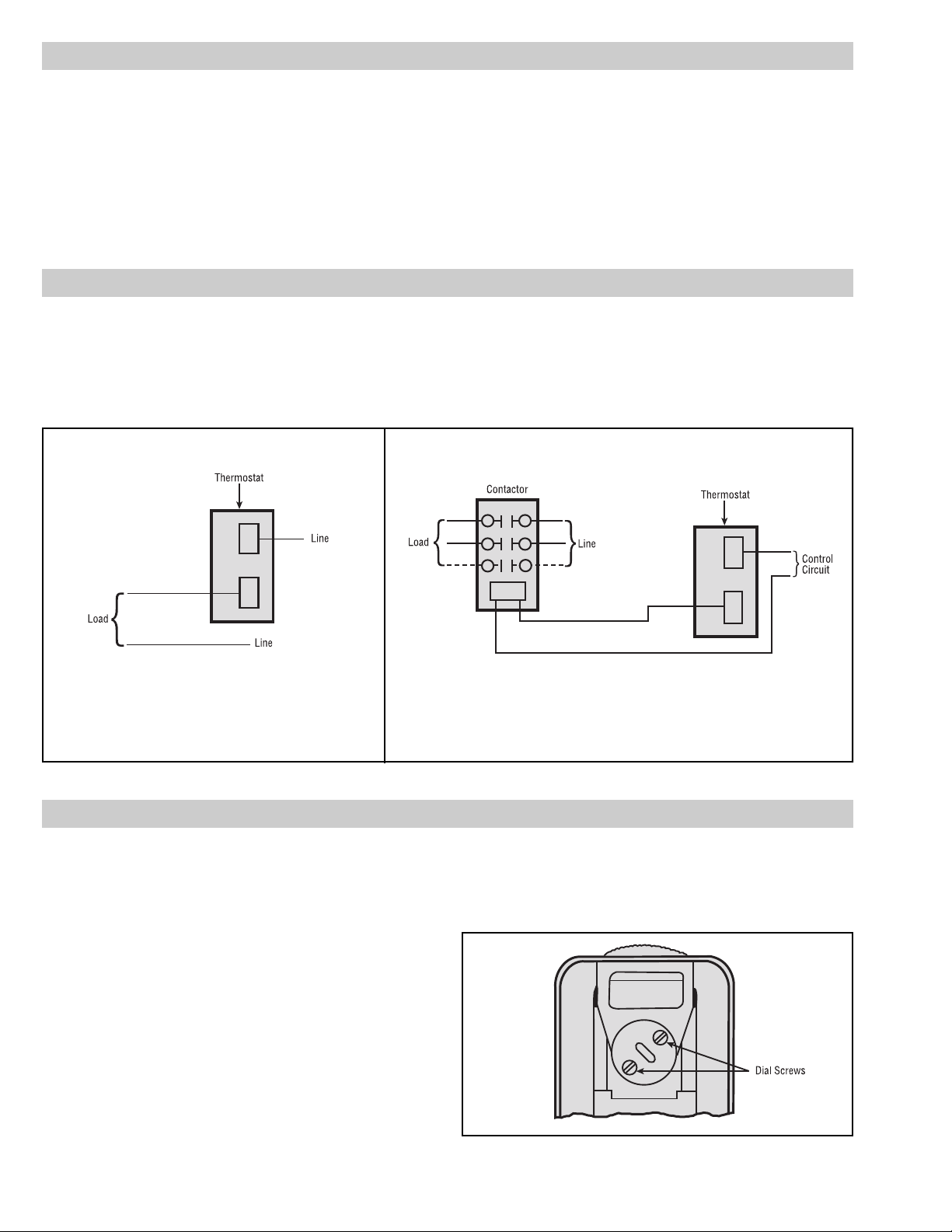

WIRING

CALIBRATION

CAUTION: Hazard of Electric Shock. Disconnect all

power before wiring or servicing this control.

1. Electric wiring to heater must be installed in accordance with

National Electrical Code and with local codes. WARNING:

Use copper conductors only.

Connect wires according to wiring diagrams (Figures 1 and 2).

Note: Electrical connections should be made with generous

loops of wire – approximately 6” per lead.

Note: If load amperage or voltage rating exceeds switch rating,

a contactor must be used. Contactor and wiring to be supplied

by customer. (See Figure 2)

CAUTION: Hazard of Electric Shock. Extreme care

should be exercised during calibration adjustments

because of shock hazard due to exposed electrical

terminals.

WR-80 thermostats are accurately calibrated at the factory so

the dial setting correctly indicates the temperature at which the

contacts open on temperature rise. If, as a result of damage in transit or for other reasons the room temperature differs appreciably

from the dial setting, the calibration may be adjusted as follows:

1. Note temperature on thermometer.

2. Set dial at highest temperature.

3. Turn dial slowly to lower temperature and stop when thermo-

stat contacts open.

4. Loosen screw at bottom of thermostat and remove thermostat

from mounting plate.

5. On back of thermostat, loosen two dial screws (Figure 3).

Carefully turn the dial only to correct temperature setting as

indicated by thermometer. Be sure the thermostat shaft is not

moved during this operation.

6. Tighten the dial screws and replace thermostat.

Figure 3

Figure 1 — Single phase loads when load does not exceed

rating of thermostat.

Figure 2 — Single phase loads when load exceeds rating of thermostat and

three phase loads.

Page 3

SETTING

WR-90 controls have an adjustable differential. The movable

indicator points to the temperature at which the contacts open. The

fixed indicator points to the temperature at which the contacts close.

The difference between these two indicators is the differential.

To set the control, proceed as follows:

1. Use screwdriver in slot and turn the dial so the fixed indicator

“B” points to the temperature at which heating is to start.

2. Turn the differential adjusting screw “C” until the movable

indicator “D” points to the temperature at which the heating is

to stop.

UNITING LIQUID IN THERMOMETER

Sometimes the red liquid inside the thermometer on the WR80 becomes separated during shipment. The thermometer will not

read correctly when this red liquid is separated at any point. If the

red liquid in the thermometer of this thermostat has become separated it may be reunited as follows:

1. Remove the thermostat from the wall, and straighten out the

four prongs so the cover can be removed to expose the ball of

the thermometer.

2. Hold the lighted end of a cigarette or a match at such a distance

from the SIDE of the ball of the thermometer so the red liquid

rises SLOWLY in the stem of the thermometer.

3. When the lowest separation goes into the reservoir, immedi-

ately remove the heat and blow on the thermometer.

CAUTION: If there is more red liquid in the stem of the thermometer above the lowest separation than there is below it, it is

best to replace the thermometer.

CALIBRATION

Figure 4

Figure 5

Page 4

1347 HEIL QUAKER BLVD., LAVERGNE, TN 37086

Phone: (615) 793-3900 www.chromalox.com

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...