Page 1

DIVISION 4 SECTION

U-RAD

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation, Operation

and

RENEWAL PARTS IDENTIFICATION

161-048457-001

APRIL, 2005

PG405-5

(Supersedes PG405-4)

Chromalox

®

© 2010 Chromalox, Inc.

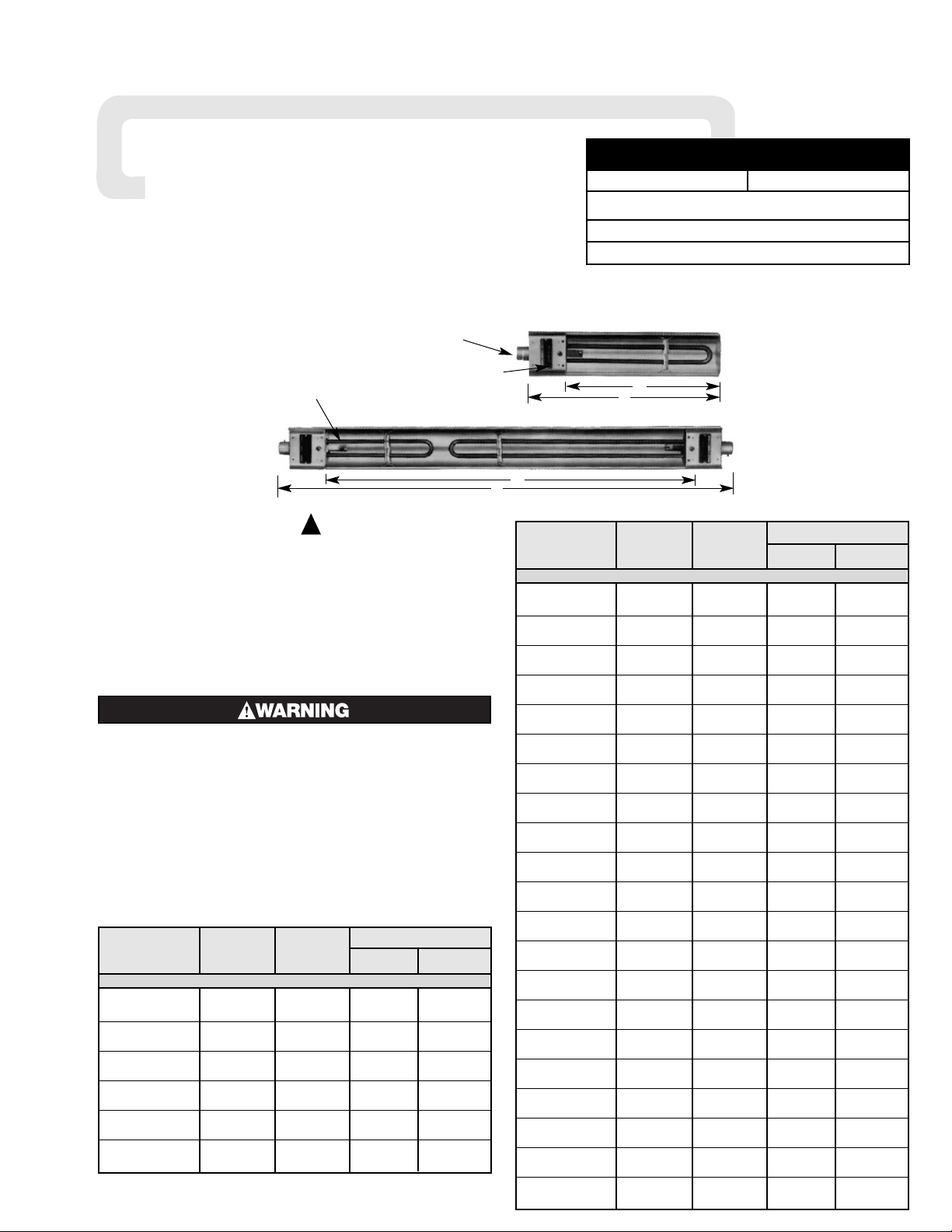

Model Volts kW

Overall Heated

U-RAD-2 120 or 240

800 12-3/4 8-5/16

U-RAD-2V 208 or 275

U-RAD-3 120 or 240

1100 15-7/8 11-7/16

U-RAD-3V 208 or 275

U-RAD-4V 208 or 275

1800 23-13/16 19-3/8

U-RAD-4 240 or 480

U-RAD-5V 208 or 275

2500 31-1/4 26-13/16

U-RAD-5 240 or 480

U-RAD-6V 208 or 275

3000 37-1/4 32-13/16

U-RAD-6 240 or 480

U-RAD-7V 208 or 275

3600 43-3/8 38-15/16

U-RAD-7 240 or 480

Type U-RAD Electric Radiant Heaters

The Safety Alert Symbol is used to indicate a

risk of personal injury.

Please familiarize yourself with these instructions before

attempting to install or operate this Radiant Heater.

Before Installing

1. Open carton and remove heater at the place of installation.

Mounting clamps are in parts bag in carton.

2. Check nameplate volt and watt rating against your power supply

voltage and heating requirements of your installation. This

nameplate is located on one end of the heater.

The system designer is responsible for the safety of

this equipment and should install adequate back-up

controls and safety devices with their electric heating equipment. Where the consequences of failure

could result in personal injury or property damage,

back-up controls are essential.

Specifications Table –

Single U-Shaped Element

Model Volts kW

Overall Heated

U-RAD-22 120 or 240

1600 25-1/2 16-5/8

U-RAD-22V 208 or 275

U-RAD-32 120 or 240

1900 28-5/8 19-3/4

U-RAD-32V 208 or 275

U-RAD-33 120 or 240

2200 31-3/4 22-7/8

U-RAD-33V 208 or 275

U-RAD-42V 208 or 275

2600 36-9/16 27-11/16

U-RAD-42 240

U-RAD-43V 208 or 275

2900 39-11/16 30-13/16

U-RAD-43 240

U-RAD-44V 208 or 275

3600 47-9/16 38-11/16

U-RAD-44 240

U-RAD-52V 208 or 275

3300 44 35-1/8

U-RAD-52 240

U-RAD-53V 208 or 275

3600 47-1/8 38-1/4

U-RAD-53 240

U-RAD-54V 208 or 275

4300 55-1/16 46-3/16

U-RAD-54 240 or 480

U-RAD-55V 208 or 275

5000 62-7/16 53-9/16

U-RAD-55 240 or 480

U-RAD-62V 208 or 275

3800 50 41-1/8

U-RAD-62 240

U-RAD-63V 208 or 275

4100 53-1/8 44-1/4

U-RAD-63 240

U-RAD-64V 208 or 275

4800 61-1/16 52-3/16

U-RAD-64 240 or 480

U-RAD-65V 208 or 275

5500 68-1/2 59-5/8

U-RAD-65 240 or 480

U-RAD-66V 208 or 275

6000 74-1/2 65-5/8

U-RAD-66 240 or 480

U-RAD-72V 208 or 275

4400 56-1/8 47-1/4

U-RAD-72 240

U-RAD-73V 208 or 275

4700 59-1/4 50-3/8

U-RAD-73 240

U-RAD-74V 208 or 275

5400 67-1/8 58-1/4

U-RAD-74 240 or 480

U-RAD-75V 208 or 275

6100 74-1/2 65-5/8

U-RAD-75 240 or 480

U-RAD-76V 208 or 275

6600 80-5/8 71-3/4

U-RAD-76 240 or 480

U-RAD-77V 208 or 275

7200 86-3/4 77-7/8

U-RAD-77 240 or 480

Two U-Shaped Elements

A

B

A

B

Conduit

Connector

Single-Element U-RAD

Double-Element U-RAD

Length (In.)

Length (In.)

!

Page 2

INSTALLATION

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed or serviced by a qualified person in accordance with the National

Electrical Code, NFPA 70.

Mounting

1. These radiant heaters are designed for indoor installation only.

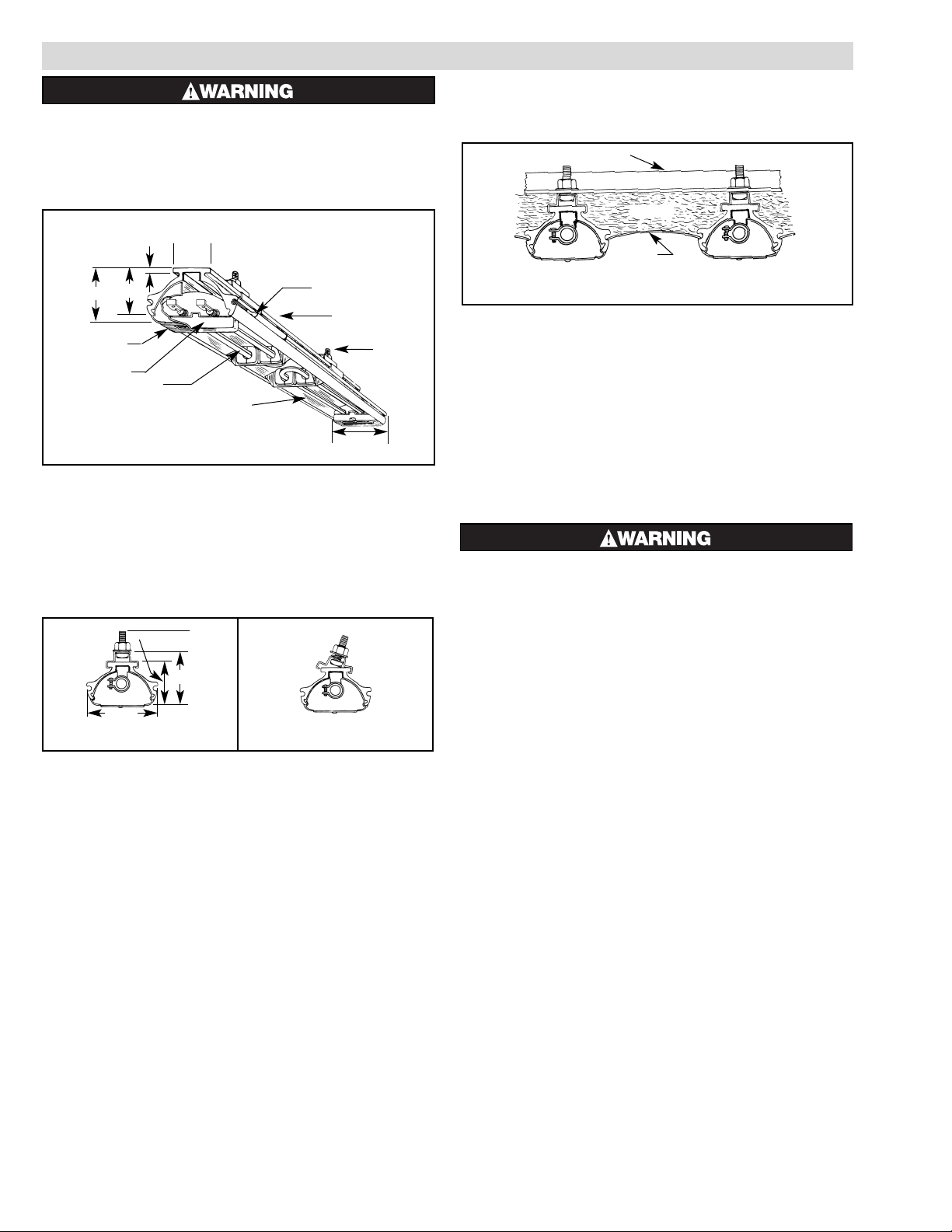

2. Clamps — Heaters are mounted by means of the mounting

clamp and 3/8” bolt assembly which is used as shown in Fig. 2.

Clamp assembly may be attached to heater by sliding over end

or by snapping over top of extruded frame section at any point

along its length (see Fig. 3). For proper heater support, the maximum distance between clamps must not exceed 48”. On extralong heaters, more than two clamps are furnished.

3. Mounting Holes — When heaters are mounted adjacent to

each other in the same plane, note that distance between mounting

holes on framing to support heaters will be 3-11/16”minimum.

When heaters are not in the same plane, i.e. set at an angle to one

another, distance between mounting holes in framing will be either

greater or less than 3-11/16”.

4. Framing — Where an extensive installation is being made,

the use of continuous slot metal framing manufactured by several concerns will be of assistance in saving time and money.

The frame is reusable.

5. Reflector Spacer Sheets — Where heaters are not mounted

side by side (see Fig. 4), reflector spacer sheets can be used

between heaters. These reflector spacer sheets and companion

reflectors consisting of an extruded aluminum housing with

reflector sheet and mounting clamps are available. Check with

local sales representative.

6. Insulation — Where unusually high work temperatures are

encountered, it may be desirable to insulate backs of heaters

with high-temperature fibrous insulation. A suggested method

of accomplishing this is indicated in Fig. 4.

7. Ventilation — Where solvents, water, etc. are being evaporat-

ed from work in process, it is necessary to provide substantial

quantities of ventilation air to carry away the resulting vapors.

FIRE HAZARD. Since Radiant heaters are capable

of developing high temperatures, extreme care

should be taken to:

A. Keep combustible materials at least 6” away

form sides and back of heater housing and its supporting brackets and spaced far enough in front of

heater (heating element side) so thermal radiation

from the elements will not ignite combustible

materials.

B. If combustible materials are being processed,

stoppage of process should initiate immediate

heater shutdown and interception of residual heat

from radiant heaters (use radiation baffles or move

heaters away from work).

C. In the case of solvents of an explosive nature,

ventilation air must be in sufficient volume to

dilute the solvent vapor so that explosive mixtures

cannot occur, refer to NFPA 86, Standard for Ovens

and Furnaces.

Figure 4

Insulation

Reflector

Spacer Sheet

Mounting Frame

Figure 1 — Heater Parts and Dimensions

Terminal Cover

Terminal Block

Element

Polished Aluminum Reflector

Interlocking Connector

Housing

Mounting

Clamp

Assembly

2-3/8”

3-11/16”

1/4”

1-7/8”

Figure 3

2-3/8”

2-15/16”

3-

Figure 2

Page 3

WIRING

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed or serviced by a

qualified person in accordance with the National

Electrical Code, NFPA 70.

ELECTRIC SHOCK HAZARD. Any installation

involving electric heaters must be performed by a

qualified person and must be effectively grounded

in accordance with the National Electrical Code to

eliminate shock hazard.

1. Electrical connection to the type U-RAD Radiant Heater is

made through the 7/8” dia. opening in the end of the terminal cover of

the element assembly. A 1/2” flexible conduit connector is provided

with each element assembly for this purpose.

2. Wiring should be run in flexible or rigid metal conduit and must

be installed in accordance with the requirements of the National

Electrical Code and such other local requirements by a qualified person as defined in the NEC.

3. Access to the element terminals is obtained by removing

the mounting bolt and nut (see Figure 8, item and ) and sliding the terminal end of the element assembly out of the housing.

4. Wires supplying power to heating element terminals shall have

insulation rated for 150°C minimum.

High temperatures will oxidize copper. Use only

nickel-plated copper wire for supplying power to

heater. Do not use aluminum conductors.

5. A sufficient length of this wire (not less than 12”) should be

used to extend from each heater terminal into a connection box

location where the temperature does not exceed 300˚F.

6. Assemble terminal, screw and wire as shown in Fig. 5.

7. Hold terminal with pliers and tighten the terminal screw

securely with a screwdriver.

Note: Where circuit wiring is installed in locations of high

ambient temperature, conductors should be insulated in accordance with requirements for temperature and voltage.

8. SERIES CONNECTION of Radiant Heaters of equal volt

and watt rating is permitted in all line voltages up to 600 volts.

In making such series connections it is necessary to observe the

“right” (series-parallel) connection rather than the “wrong”

(parallel-series) connection both shown in Figure 6. If heaters

are connected according to the “wrong” illustration, failure of

any one heater will cause progressive failure of other heaters

still operating.

9. DELTA CONNECTIONS — When heaters occur in multi-

ples of three, they may be connected to, and balanced across,

three-phase lines. The most commonly used connection is the

delta connection illustrated in Figure 7.

Three phase Delta connections to minimize inductive effect in

conduits are made per this diagram. The rule: run all 3 threephase conductors in the same conduit as far as possible. For single-phase, run only two conductors and follow the same rule.

L1

L2

L1

L2

Wrong

Right

Radiant

Heaters

L1

L2

L3

Radiant

Heaters

3 Conductors

in 1 Conduit

3 Conductors

in 1 Conduit

FEDCBA

Figure 6

Figure 7

Figure 5

18

16

Page 4

MAINTENANCE

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed or serviced by a qualified person in accordance with the National

Electrical Code, NFPA 70.

A. To Remove Heating Element —

1. Remove element assembly mounting nut and bolt and and

element support clips (see Figure 8) and slide element assembly out

of housing.

2. Disconnect heating element from electrical leads at both ends.

3. Remove screws from porcelain terminal blocks.

4. Remove element support clips and secondary insulating

bushings.

5. Lift element out of heater.

B. To Install Element —

Observe instructions for removing element and proceed in

reverse fashion. Be sure to replace secondary insulating bushings.

C. Care of Reflectors —

Reflectors should be cleaned periodically. A mild soap and

water solution or fine cleaning powder is best although more

drastic means may be required if reflectors are badly soiled by

chemical or other deposits. The reflector is aluminum. DO NOT

use alkali cleaners since alkalies will dull reflector. Mild nonalkaline cleaners, such as used for scouring kitchen sinks, may

be used. Reflectors are replaceable and may be purchased from

Chromalox.

18 16

OPERATION

FIRE/EXPOSION HAZARD. This heater is not

intended for use in hazardous atmospheres where

flammable vapors, gases, liquids or other combustible atmospheres are present as defined in the

National Electrical Code. Failure to comply can

result in personal injury or property damage.

Before energizing this heater:

1. Be sure all electrical connections are tightly made. Hold ter-

minal with pliers when tightening screw.

2. Be sure that all conductors are properly insulated.

3. Be sure that all element assemblies have been properly

replaced, and that secondary insulation bushings have not been

omitted.

A. Controlling Radiant Intensity —

Standard Radiant Heaters are built to operate at approximately

40 watts per sq. inch on the element sheath. When it is desired

to reduce radiant intensity, one or more of the following methods may be used.

1. INPUT CONTROLLERS. These motor-driven cycling

devices can be used to vary heater output capacity from 4 to

100%. They are usually connected in holding coil circuit of

magnetic contactors. See Chromalox Radiant Heater Manual

for further information regarding Input Controllers and

Contactors.

2. SOLID STATE THYRISTOR POWER CONTROLLERS.

For best non-contact control of radiant heat, a Series #6

Chromalox Thyristor Power Controller with manual potentiometer setting is recommended. Truly proportional output

of from 0-100% can be easily dialed-in to suit the particular

product or process requirements. The Series #6 panels are

pre-engineered, pre-packaged assemblies in an enclosure

with circuit disconnect provided and ready for installation.

B. Maximum Ambient Temperatures —

CHROMALOX Radiant Heaters are not recommended for

applications in ambient temperature exceeding 450˚F. Higher

ambient temperatures mean shorter heater life.

Maximum work temperature in a given time depends on several factors: Reflectivity of work, specific heat of work, mass of

work, kW input and losses from oven, and time of exposure. As

work temperature increases, the work loses heat by radiation and

by convection to the surrounding ambient. Although it is a general principle of Radiant Heater application that work temperature conventionally exceeds ambient temperature, in cases

where extremely high work temperatures are desired, it is necessary to enclose the heaters in order to increase the ambient. If

evaporation of a liquid is desired as a result of increasing work

temperature, it is necessary to provide ventilation air in order to

carry away the evaporated liquid. Under carefully engineered

circumstances, a maximum work temperature of 600˚F may be

attained.

Page 5

RENEWAL PARTS IDENTIFICATION

STANDARD PARTS USED ON ALL HEATERS

Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .303-014316-001

Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .303-014317-001

Terminal Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .080-016868-001

Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .027-016372-001

Spacer Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .032-075525-012

1/2” Flexible Conduit Connector and Locknut . . . . . . . . . . . . . . . .119-075454-005

200-075482-002

Terminal Screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .248-046044-002

Element Support Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .059-014304-002

Insulating Bushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .032-013454-001

Bushing Retaining Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .059-017175-001

Mounting Clamp Parts Bag — For mounting heaters with overall length less than

74-1/2”, use Parts Bag 168-013071-001. For heaters with 74-1/2” or larger overall length, use Parts Bag 168-013071-002.

MISCELLANEOUS HARDWARE

#8-32 Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200-075520-064

#8-32 x 1-3/4” Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .248-075512-194

#8-32 x 1” Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .248-075512-185

#8 Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .328-075528-036

9

5

6

7

8

Volts kW Element Reflector

Aluminum

Model

Housing

208

UTU-4-208V 234-016383-003

UTU-3-208V 234-016383-002

U-RAD-43 240 2900

UTU-4-240V 234-016383-003

152-016376-005

UTU-3-240V 234-016383-002

275

UTU-4-275V 234-016383-003

UTU-3-275V 234-016383-002

208 UTU-4(2)-208V

U-RAD-44 240 3600 UTU-4(2)-240V 234-016383-003 (2) 152-016376-006

275 UTU-4(2)-275V

208

UTU-5-208V 234-016383-004

UTU-2-208V 234-016383-001

U-RAD-52 240 3300

UTU-5-240V 234-016383-004

152-016376-007

UTU-2-240V 234-016383-001

275

UTU-5-275V 234-016383-004

UTU-2-275V 234-016383-001

208

UTU-5-208V 234-016383-004

UTU-3-208V 234-016383-002

U-RAD-53 240 3600

UTU-5-240V 234-016383-004

152-016376-008

UTU-3-240V 234-016383-002

275

UTU-5-275V 234-016383-004

UTU-3-275V 234-016383-002

208

UTU-5-208V 234-016383-004

UTU-4-208V 234-016383-003

U-RAD-54

240

4300

UTU-5-240V 234-016383-004

UTU-4-240V 234-016383-003

152-016376-009

275

UTU-5-275V 234-016383-004

UTU-4-275V 234-016383-003

480

UTU-5-480V 234-016383-004

UTU-4-480V 234-016383-003

U-RAD-55

208

5000

UTU-5(2)-208V 234-016383-004 (2)

152-016376-010

240 UTU-5(2)-240V 234-016383-004 (2)

275 UTU-5(2)-275V 234-016383-004 (2)

480 UTU-5(2)-480V 234-016383-004 (2)

208

UTU-6-208V 234-016383-005

UTU-2-208V 234-016383-001

U-RAD-62 240 3800

UTU-6-240V 234-016383-005

152-016376-011

UTU-2-240V 234-016383-001

275

UTU-6-275V 234-016383-005

UTU-2-275V 234-016383-001

208

UTU-6-208V 234-016383-005

UTU-3-208V 234-016383-002

U-RAD-63 240 4100

UTU-6-240V 234-016383-005

152-016376-012

UTU-3-240V 234-016383-002

275

UTU-6-275V 234-016383-005

UTU-3-275V 234-016383-002

208

UTU-6-208V 234-016383-005

UTU-4-208V 234-016383-003

U-RAD-64

240

4800

UTU-6-240V 234-016383-005

UTU-4-240V 234-016383-003

152-016376-013

275

UTU-6-275V 234-016383-005

UTU-4-275V 234-016383-003

480

UTU-6-480V 234-016383-005

UTU-4-480V 234-016383-003

2 3 4

Volts kW Element Reflector

Aluminum

Model

Housing

208

UTU-6-208V 234-016383-005

UTU-5-208V 234-016383-004

U-RAD-65

240

5500

UTU-6-240V 234-016383-005

UTU-5-240V 234-016383-004

152-016376-014

275

UTU-6-275V 234-016383-005

UTU-5-275V 234-016383-004

480

UTU-6-480V 234-016383-005

UTU-5-480V 234-016383-004

U-RAD-66

208

6000

UTU-6(2)-208V 234-016383-005 (2)

152-016376-015

240 UTU-6(2)-240V 234-016383-005 (2)

275 UTU-6(2)-275V 234-016383-005 (2)

480 UTU-6(2)-480V 234-016383-005 (2)

208

UTU-7-208V 234-016383-006

UTU-2-208V 234-016383-001

U-RAD-72 240 4400

UTU-7-240V 234-016383-006

152-016376-016

UTU-2-240V 234-016383-001

275

UTU-7-275V 234-016383-006

UTU-2-275V 234-016383-001

208

UTU-7-208V 234-016383-006

UTU-3-208V 234-016383-002

U-RAD-73 240 4700

UTU-7-240V 234-016383-006

152-016376-017

UTU-3-240V 234-016383-002

275

UTU-7-275V 234-016383-006

UTU-3-275V 234-016383-002

208

UTU-7-208V 234-016383-006

UTU-4-208V 234-016383-003

U-RAD-74

240

5400

UTU-7-240V 234-016383-006

UTU-4-240V 234-016383-003

152-016376-018

275

UTU-7-275V 234-016383-006

UTU-4-275V 234-016383-003

480

UTU-7-480V 234-016383-006

UTU-4-480V 234-016383-003

208

UTU-7-208V 234-016383-006

UTU-5-208V 234-016383-004

U-RAD-75

240

6100

UTU-7-240V 234-016383-006

UTU-5-240V 234-016383-004

152-016376-015

275

UTU-7-275V 234-016383-006

UTU-5-275V 234-016383-004

480

UTU-7-480V 234-016383-006

UTU-5-480V 234-016383-004

208

UTU-7-208V 234-016383-006

UTU-6-208V 234-016383-005

U-RAD-76

240

6600

UTU-7-240V 234-016383-006

UTU-6-240V 234-016383-005

152-016376-019

275

UTU-7-275V 234-016383-006

UTU-6-275V 234-016383-005

480

UTU-7-480V 234-016383-006

UTU-6-480V 234-016383-005

U-RAD-77

208

7200

UTU-7(2)-208V 234-016383-006 (2)

152-016376-020

240 UTU-7(2)-240V 234-016383-006 (2)

275 UTU-7(2)-275V 234-016383-006 (2)

480 UTU-7(2)-480V 234-016383-006 (2)

2 3 4

10

11

12

13

14

15

16

17

18

19

Note: Part Numbers suffixed by a number in ( ) indicates the number of parts of the same part number used or supplied if more than one.

Page 6

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

RENEWAL PARTS IDENTIFICATION

Volts kW Element Reflector

Aluminum

Model

Housing

U-RAD-3

120

1100

UTU-3-120V

234-016383-002 152-016384-002

208 UTU-3-208V

240 UTU-3-240V

275 UTU-3-275V

U-RAD-4

208

1800

UTU-4-208V

234-016383-003 152-016384-003

240 UTU-4-240V

275 UTU-4-275V

480 UTU-4-480V

U-RAD-5

208

2500

UTU-5-208V

234-016383-004 152-016384-004

240 UTU-5-240V

275 UTU-5-275V

480 UTU-5-480V

U-RAD-6

208

3000

UTU-6-208V

234-016383-005 152-016384-005

240 UTU-6-240V

275 UTU-6-275V

480 UTU-6-480V

U-RAD-7

208

3600

UTU-7-208V

234-016383-006 152-016384-006

240 UTU-7-240V

275 UTU-7-275V

480 UTU-7-480V

U-RAD-22

120

1600

UTU-2(2)-120V

234-016383-001 (2) 152-016376-001

208 UTU-2(2)-208V

240 UTU-2(2)-240V

275 UTU-2(2)-275V

120

UTU-3-120V 234-016383-002

UTU-2-120V 234-016383-001

U-RAD-32

208

1900

UTU-3-208V 234-016383-002

UTU-2-208V 234-016383-001

152-016376-002

240

UTU-3-240V 234-016383-002

UTU-2-240V 234-016383-001

275

UTU-3-275V 234-016383-002

UTU-2-275V 234-016383-001

U-RAD-33

120

2200

UTU-3(2)-120V

234-016383-002 (2) 152-016376-003

208 UTU-3(2)-208V

240 UTU-3(2)-240V

275 UTU-3(2)-275V

208

UTU-4-208V 234-016383-003

UTU-2-208V 234-016383-001

U-RAD-42 240 2600

UTU-4-240V 234-016383-003

152-016376-004

UTU-2-240V 234-016383-001

275

UTU-4-275V 234-016383-003

UTU-2-275V 234-016383-001

Element assembly includes all parts shown except items and

For element assembly part number, add prefix “R” to Element part

number Ex: R UTU-6-208V.

Volts kW Element Reflector

Aluminum

Model

Housing

U-RAD-2

120

800

UTU-2-120V

234-016383-001 152-016384-001

208 UTU-2-208V

240 UTU-2-240V

275 UTU-2-275V

2

3

4

2 3 4

1

2

4

17

10

7

19

5

6

11

8

16

2

4

3

9

16

18

14

13

12

Element

Support

Clip

Assembly

3

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...