Page 1

DATE

SALES

REFERENCE

DIVISION SECTION

Chromalox

®

(Supersedes PF455-2)

PF455-3

DH

161-562766-001

FEBRUARY, 2001

4

Chromalox Electric Airduct Heaters

with Fintube Heating Elements

© 2010 Chromalox, Inc.

GENERAL

These heaters are designed to be installed in either a horizontal

or vertical duct in one of the six positions shown in figure 16. The

heater is constructed with individual metal sheath fintube elements

mounted to a heavy gauge metal terminal box.

Due to the various options and materials available, check the

nameplate attached to the heater terminal box with the catalog

number designation system on page 7 before installing to insure

the heater you received conforms to your specification.

Please read these directions carefully to insure all limitations

are properly observed and all wiring and controls are properly

installed and connected.

IMPORTANT — Observe at least one complete heating cycle

operation before leaving the installation.

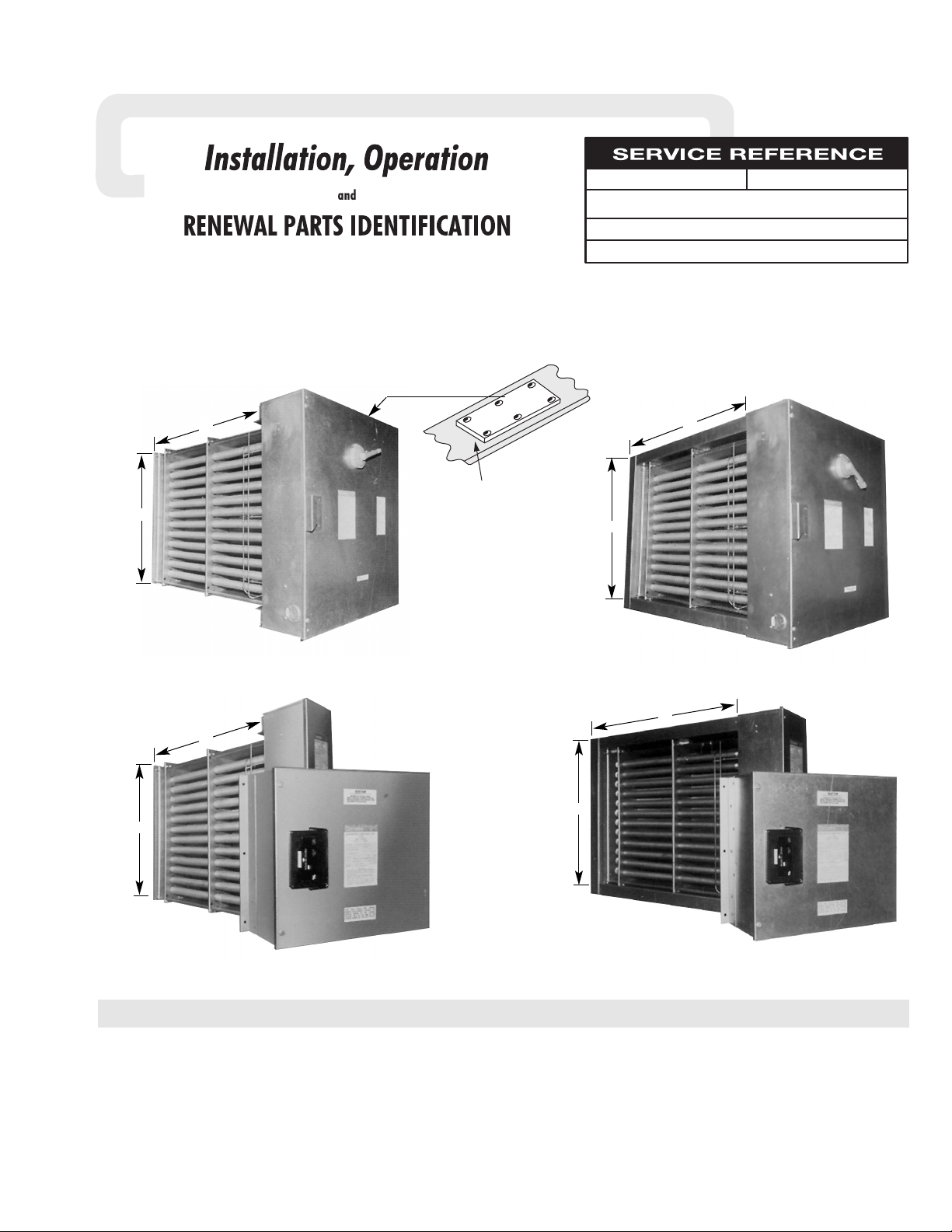

DHII

Integral Controls

Insert Type

Figure 1

DHIF

Integral Controls

Flanged Type

Figure 3

DHRF

Remote Controls

Flanged Type

Figure 4

DHRI

Remote Controls

Insert Type

Figure 2

Conduit

Entrance Plate

W

H

W

H

W

H

W

H

Page 2

GENERAL

Limitations: Ductwork must be in accordance with one of the following: Standards of the National Fire Protection Association for

the installation of Air Conditioning and Ventilating Systems of

other than Resident Type (Pamphlet 90A) or Residential Type

Warm Air Heating and Air Conditioning Systems (Pamphlet 90B).

Location: Chromalox Duct Heaters may be located anywhere in

the duct system.

NOTE: The minimum distances shown are limitations. Wherever

possible, locate as far away from these limits as practical. In any

case, this distance with any required airflow correction must be

sufficient to accomplish even air flow at a velocity equal to, at

least, the minimum stated on the heater nameplate.

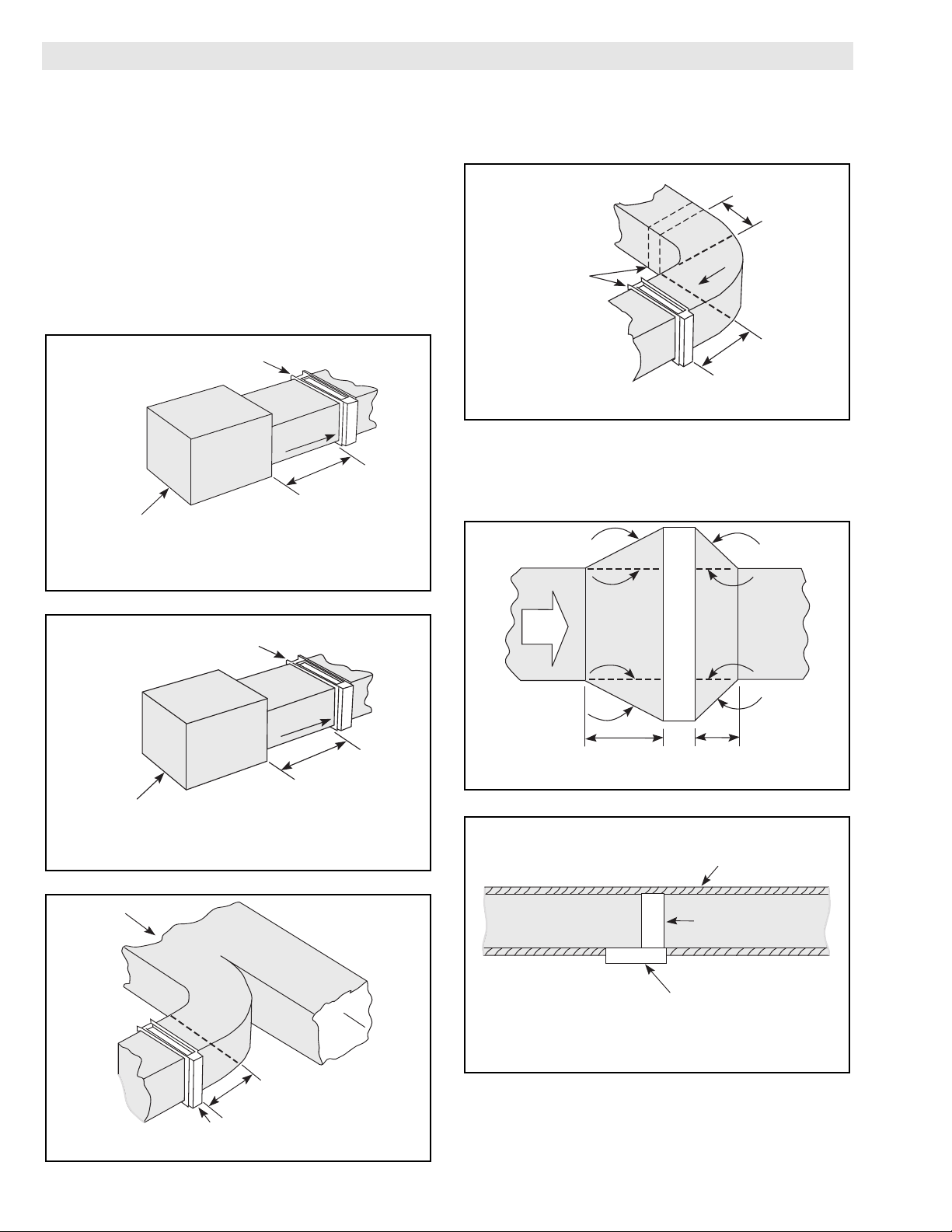

1. Installation near heat pump, central air conditioner, filters or

humidifier. (Refer to Figure 5).

2. Installation near air handler discharge. (Refer to Figure 6).

3. Installation in branch duct take-off. (Refer to Figure 7).

4. Installation near turns. (Refer to Figure 8). If heater must be

installed closer than 4 feet from the downstream side of a turn,

turning vanes must be installed in the turn. The turning vanes

will straighten out the air flow so it will be uniform over the

face of the heater.

5. Installation with duct transitions in some air distribution systems, the duct heater may be considerably larger than the ductwork and the duct area must be increased by a sheet metal transition. The slope of the transformation piece on the upstream

side of the equipment is limited to 30° as indicated in Figure 9.

On the leaving side, the slope should not be more than 45°.

6. Do not insulate control or terminal box. (Refer to Figure 10).

Leave Control

Box Uninsulated

External

Insulation

Top of Duct

Duct Heater

Air

Flow

30"

Max.

45°

45°

30°

4 Ft. Min.

4 Ft. Min.

Max.

Duct Heater

4 Ft.

Min.

Duct Heater

Here or Here

2 Ft.

Min.

Air Flow

Duct Heater

4 Ft. Min. Straight Section

Air Flow

Duct Heater

4 Ft.

Min.

Air Handler

Air

Flow

Duct Heater

4 Ft.

Min.

Heat Pump,

Central Air Conditioner,

Filters or Humidifier

Air

Flow

-2-

Figure 5

Figure 8

Figure 9

Figure 6

Figure 10

Figure 7

Page 3

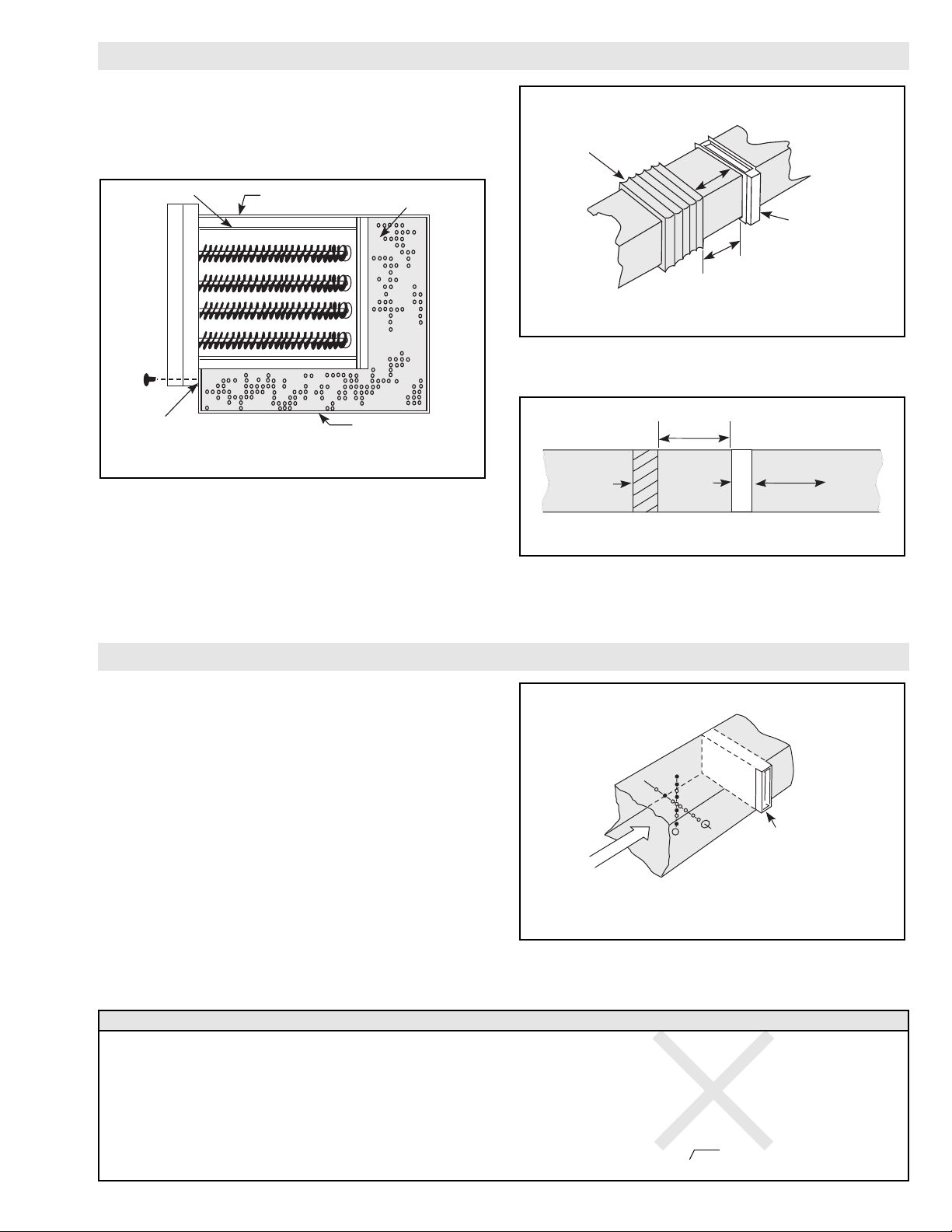

7. Installation in duct larger than heater. For installation where the

duct dimensions exceed the insert type heater dimensions, the

area beyond the heater dimensions must be filled with wire

mesh, expanded or perforated sheet metal of 50% open area as

shown in Figure 11. This will maintain a uniform air velocity

across the face of the duct.

8. Installation with flexible duct. Where a duct heater must be

installed near a flexible duct connection, be certain that a 4’

minimum distance between the duct heater and the flexible

connector exists and that the connector is suitable for 195°F

temperature. (Refer to Figure 12).

9. Do not install duct heater outdoors. Duct heaters cannot be

installed with rooftop equipment where they are exposed to the

weather.

10. Installation with dampers or filters. Maintain at least 4’ distance between duct heater and damper, filter frames, or other

similar obstructions. (Refer to Figure 13).

Clearance: Zero clearance between duct heater and combustible

materials such as wood is permissible. However, adequate clearance must be provided around terminal box for proper ventilation

and future service accessibility.

4 Ft.

Min.

Damper

Air Flow

Top of Duct

Duct

Heater

4 Ft.

Min.

Air

Flow

Duct Heater

Flexible Duct

(Must be suitable

for 195°F)

Inner Baffle

Insert Type

Duct Heater

Remove Bracket and

Use Sheetmetal Screws

Thru Same Holes into Duct.

Oversized Duct

Perforated Metal

(50% Open Area)

-3-

GENERAL

Flow through duct heater must never drop below the minimum

air velocity shown on duct heater nameplate. If the air handling

system includes filters, they must be cleaned whenever necessary

in order to maintain air flow above the minimum, otherwise poor

temperature control and discomfort will result.

If air flow is poorly distributed within the duct, deflector vanes

must be added to provide correction.

The minimum air velocities shown on the nameplate are not to

be considered average readings. Do not add various velocities

taken across the face of the duct, find an average value, and compare it to the minimum velocity shown on the heater nameplate.

The minimum air velocity refers to any point along the face of

the duct heater when checking duct velocities, no velocity can be

below that sown on the heater nameplate (remembering inlet air

temperature). Velocities are best checked with an anemometer, taking numerous readings along the horizontal and vertical centerline

of the duct heater at the location prior to installation or slightly up

stream from the heater after installation. (Refer to Figure 14).

Large ducts will require additional readings taken at locations in

addition to the centerline.

Incoming Air Temperature: Incoming air temperature entering

the duct heater must not exceed 100°F.

Duct Heater

Velocity

Profile

Air Flow

AIR FLOW

Example: 500 FT./MIN. Minimum Air Velocity on Heater Nameplate.

600 200x

500 400x

700 800

Velocity 600 Velocity 900

Profile 900 Profile 600

FT./MIN. 700 FT./MIN. 700

600 200x

500 300x

400x

RIGHT: 500 FT./MIN. MINIMUM WRONG: 9 4500 = 500 FT./MIN. AVERAGE

X – below 500 FT./MIN.

Figure 11

Figure 12

Figure 13

Figure 14

Page 4

MOUNTING

Multiple Duct Heaters: Up to six duct heaters may be combined

into a heating bank as shown in Figure 15. When called for on

order, brackets will be furnished for fastening flange type duct

heaters together to form a bank. Heater will be coded for proper

assembly in the field.

Two to six duct heaters (with flange) may be installed in a hor-

izontal or vertical duct.

Heaters must be mounted in the position designated by arrows

on the heater frame. (Refer to Figure 16).

The heater terminal box on vertical duct installations can be

located on any side of the duct but for horizontal duct installation

the terminal box must be on the side of the duct.

This heater is not intended for use in hazardous

atmospheres where flammable vapors, gases, liquids, or other combustible atmospheres are present as defined in the National Electric Code.

Failure to comply can result in explosion or fire.

HORIZONTAL DUCT — Side terminal

box entry for style DHII & DHIF heaters.

Air flow as shown.

Install with this arrow up.

Mounting Position 4

VERTICAL DUCT — side terminal box

entry for style DHRI & DHRF heaters. Air

flow as shown. Install with this arrow up.

Mounting Position 3

VERTICAL DUCT — Side terminal box

entry for style DHII & DHIF heaters. Air

flow as shown.

Install with this arrow up.

Mounting Position 6

HORIZONTAL DUCT — side terminal

box entry for style DHRI & DHRF

heaters. Air flow as shown. Install with

this arrow up.

Mounting position 2

HORIZONTAL DUCT — Side terminal

box entry for style DHII & DHIF heaters.

Air flow as shown.

Install with this arrow up.

Mounting Position 5

HORIZONTAL DUCT — side terminal box

entry for style DHRI & DHRF heaters. Air

flow as shown. Install with this arrow up.

Mounting Position 1

Figure 16

Figure 15

-4-

Page 5

Mounting Procedure — DHIF

(Flanged heaters with control box)

1. At heater location, cut out a section of duct, or a new construction lay out duct work to accommodate dimensions of

heater.

2. Form mounting flanges on cut edges of duct as shown in

Figure 17. Omit flange in side when terminal box overhangs.

3. Position heater in duct and attach duct lip to heater flanges with

sheet metal screws.

4. Attach control box to duct with sheet metal screws through the

mounting holes provided inside the control box.

NOTE: Where necessary, make provision to support weight of

heater. Any part of heater flange may be drilled for attaching hanger straps or duct.

5. Where necessary, joint between duct and heater flange may be

sealed with silicone gaskets or silicone sealant.

Mounting Procedure DHII

(Insert heaters with control box)

1. Measure dimension “H” of duct heater (Figure 1) and mark the

duct with an outline for a rectangular hole with dimensions of

D-1

1

/2”. The D-11/2” dimension is to be parallel to the direction

of air flow.

2. Increase D-1

1

/2” slot to D by forming a 3/4” double lip on both

sides of the duct opening. (See Figure 18).

3. Slide heater into duct.

4. Attach control box to duct with sheet metal screws through the

mounting holes provided inside the control box and through

the brackets on the top and bottom of heater.

5. Where necessary, make provision to support weight of heater

and terminal box.

Mounting Procedure — DHRF

(Flanged heaters with compact terminal box)

1. At heater location, cut out a section of duct, or on new con-

struction lay out duct work to accommodate dimensions of

heater.

2. Form mounting flanges on cut edges of duct as shown in

Figure 19.

3. Position heater in duct and attach duct lip to heater flanges with

sheet metal screws.

NOTE: Where necessary, make provision to support weight of

heater. Any part of heater flange may be drilled for attaching hanger straps or duct.

4. Attach control box to duct with sheet metal screws through the

mounting holes provided inside the control box.

5. Where necessary, joint between duct and heater flange may be

sealed with silicone gasket or sealant.

Mounting Procedure — DHRI

(Insert heaters with compact terminal box)

1. Measure dimension “H” of duct heater (Figure 2) and mark the

duct with an outline for a rectangular hole with dimensions of

D-1

1

/2” x “H”. The D-11/2” dimension is to be parallel to the

direction of air flow.

2. Increase D-1

1

/2” slot to “D” by forming a 3/4” double lip on each

side of the duct. (See Figure 19).

3. Slide heater into duct.

4. Attach control box to duct with sheet metal screws through the

mounting holes provided inside the control box and through

the brackets on the top and bottom of heater.

5. Where necessary, make provision to support weight of heater.

-5-

MOUNTING

Self-Adhesive Gasket

Supplied with Heater and

Installed by Customer

Double

Lip

3/4"

3/4"

Duct

Sheet Metal

Screws

Control

Box

Sheet Metal

Screws

Mounting

Holes

W

W

H

H

D

Self-Adhesive Gasket

Supplied with Heater and

Installed by Customer

Double

Lip

Duct

H

W

3/4"

D

Self-Adhesive Gasket

Supplied with Heater and

Installed by Customer

Double

Lip

3/4"

Duct

Control

Box

Sheet Metal

Screws

Mounting

Holes

W

H

H

W

D

Self-Adhesive Gasket

Supplied with Heater and

Installed by Customer

Double

Lip

3/4"

Duct

D

3/4"

H

W

Figure 17

Figure 18

Figure 19

Figure 20

Page 6

WIRING

WIRING DIAGRAM

RENEWAL PARTS IDENTIFICATION

1. Connect heater only to the voltage, frequency and phase specified on the nameplate.

2. All wiring should be done according to local and National

Electric Codes.

3. Make supply connections to marked heater terminals using

wire suitable for 75°C. (Type RH-RW or equivalent).

4. Conduit attachment to heater:

a. Run conduit(s) to conduit entrance plate. (See Figure 1).

b. Mark plate where conduit(s) will enter plate.

c. Remove screws and plate.

d. Punch conduit entrance plate with a hole(s) to accommo-

date the required conduit(s).

e. Reinstall plate and install conduit(s) to plate.

Fan Interlock. The fan circuit must be interlocked with the

control circuit of the heater. Refer to the wiring diagram in the

heater terminal box.

Hazard of electrical shock. Any installation involving electric heaters must be grounded to earth to

eliminate shock hazard.

Hazard of severe shock. Disconnect all power to

heater before servicing.

Control Ratings

Manual Limit Control Automatic Limit Control

Pilot Non-Inductive Pilot Non-Inductive

Volts Duty Rating Duty Rating

120 125 VA 3000 Watts 125 VA 3000 Watts

208 125 VA 5200 Watts 125 VA 5200 Watts

240 125 VA 6000 Watts 125 VA 6000 Watts

277 125 VA 6925 Watts 125 VA 6925 Watts

The appropriate wiring diagram

will be supplied with each heater.

Contact your local Chromalox Sales Office with Complete heater catalog number or part number.

-6-

Static equalizers

(not shown) maintain

uniform air flow

across the heater

face when individual

fintubes are omitted.

Air Flow Switch

Main Disconnect

Conduit Entrance Plate

Contactor

Fusing

Air Flow Switch Automatic and Manual Reset

(not shown)

Fintube Heating

Element

Transformer Fusing

Transformer

Typical DHIF Duct Heater

Page 7

O O O O - O O O - 0 0 H X 0 0 0 W - X 0 0 . 0 0 D - 0 0 0 V 0 0 P - 0 0 0 . 0 kW

000.0kW, (16kW/Ft.2MAX.)

Phase: 1P = Single Phase’ 3P = Three Phase

0 = Number of circuits

000V = Heater voltage (up thru 600V)

00.00 = Depth of heater frame in inches

(06.50 min. – 36.00 max.)

000W = Width of duct in inches (08 thru 120)

00H = Height of duct in inches (06 thru 40)

Terminal box construction and terminal box and frame material:

GPA = General purpose terminal box and all aluminized steel construction

GPP = General purpose terminal box and all painted steel construction

GPZ = General purpose terminal box and all plated steel construction

GPS = General purpose terminal box and all stainless steel construction

DPA = Drip proof terminal box and aluminized steel construction

DPP = Drip proof terminal box and painted steel construction

DPZ = Drip proof terminal box and plated steel construction

DPS = Drip proof terminal box and stainless steel construction

General style:

DHRI = Duct heater, remote controls, insert type

DHRF = Duct heater, remote controls, flanged type

DHII = Duct heater, integral controls, insert type

DHIF = Duct heater, integral controls, flanged type

0 M P - O O O O O - O O O 0 0 0 O O

Disconnecting Means:

ND = Nonfused disconnect switch (200A max.)

FD = Fused disconnect switch (48A max.)

TB = Terminal block (200A max.), disconnect switch by others

Control circuit voltage: 000 = 120, 208, 240, or 277V

Control circuit power supply:

T = Control circuit by integral transformer (120V Sec. Only)

R = Remote control circuit by customer (120, 208, 240, or 277V)

Fan interlock method:

AS = Air flow switch

FI = Fan interlock relay

FD = Fan interlock relay with fan delay

Heating element termination:

M = Threaded terminals with mica insulation

R = Threaded terminals with ceramic insulation (480V max.)

H = Hermetic seals (480V max.)

Method of attaching heating element to heater frame:

WA = Painted steel fin and sheath

GW = Mounting washer staked to element sheath with gasket

BF = Brass fitting with gasket

SS = Stainless steel fin and sheath

Sheath, fin, and finish of heating element:

PS = Painted steel fin and sheath

MO = Monel fin and sheath

SS = Stainless steel fin and sheath

Mounting position of heater:

1MP = See Figure 16 on page 4, mounting position 1

2MP = See Figure 16 on page 4, mounting position 2

3MP = See Figure 16 on page 4, mounting position 3

4MP = See Figure 16 on page 4, mounting position 4

5MP = See Figure 16 on page 4, mounting position 5

6MP = See Figure 16 on page 4, mounting position 6

-7-

CATALOG NUMBER DESIGNATION SYSTEM

Page 8

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...