Page 1

Chromalox

®

Installation, Operation

and

RENEWAL PARTS IDENTIFICATION

DIV. SEC.

GCHMT

NUMBER 3001

SALES

REFERENCE

DATE

SERVICE REFERENCE

PE436

161-303183-001

AUGUST, 1994

(Supersedes PF465)

GENERAL

INSTALLATION

© 2010 Chromalox, Inc.

Chromalox Type GCHMT Circulation Heater For

Steam, Gas and Air Heating

DANGER:

This heater is not intended for use in hazardous

atmospheres where flammable vapors, gases, liquids, or

other combustible atmospheres are present as defined in

the National Electric Code. Failure to comply can result in

explosion or fire.

Hazardous area terminal enclosures are available, consult your

local Chromalox representative for details.

The GCHMT series is a general-purpose gas or steam circula-

tion heater intended for use indoors.

The 3 incoloy-sheathed tubular elements are centered in a 3”

diameter steel heating chamber and welded to a removable screw

plug. The assembly is surrounded by 1-1/2” insulation and sheet

metal jacket.

Depending upon the specifications, the GCHMT may or may

not be factory equipped with AR or other Chromalox thermostats.

Such thermostats function to control outlet temperatures under

abnormal flow condition. These controls do not fail-safe.

WARNING:

Users should install adequate back-up controls

and safety devices with their electric heating equipment.

Where the consequences of failure may be severe, back-up

controls are essential. Although the safety of the installation

is the responsibility of the user, Chromalox will be glad to

make equipment recommendations.

WARNING:

Hazard of electric shock. Disconnect all power

before installing heater.

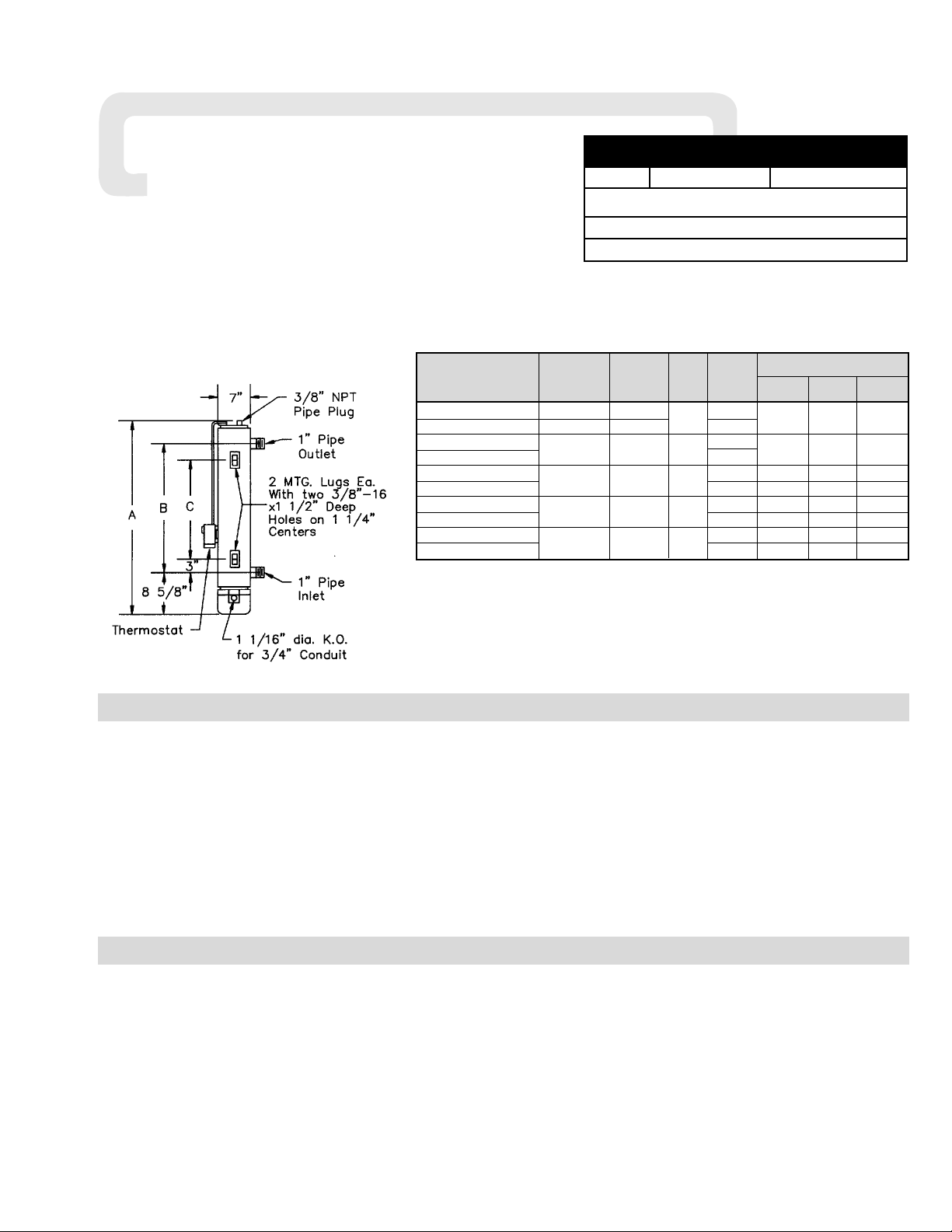

1. Vertical mounting (axis of chamber vertical as in sketch

above) is preferred. Check factory for recommendations on horizontal mounting.

2. To avoid excess temperatures at electrical wiring, mount

heater with terminal enclosure at bottom, and use lower nozzle as

inlet to the circulating steam, air, or gas.

3. The GCHMT series of circulation heaters are provided with

mounting lugs to support the heater chamber. Refer to sketch

above for location of these mounting lugs.

4. Mount heaters to permit unrestrained expansion of chamber

due to temperature. This can be accomplished by using a slotted

mounting assembly on either of the lugs.

5.

DANGER:

Hazard of fire.

Provide minimum of 6” spacing

from a chamber and related piping to nearest combustible material. Avoid operation of heater near combustible fluids or in combustible vapor or gas laden atmosphere.

6. Provide adequate space at terminal end to permit withdrawal

of the heater from chamber should servicing be required.

7. If two or more heaters are needed to provide the needed heating capacity, arrange them for series gas or vapor flow.

8.

DANGER:

Possible explosion.

A pressure relief valve

should be provided by customer at outlet of vessel. There should

be no other valving between vessel and valve.

Watts Dimensions (in.)

Catalog Per

Number Voltage Phase KW Sq.In. A B C

GCHMT-30105 120 1

1

15

20-1/2 9-3/8 —

GCHMT-3105 240 or 480 1 or 3 23

GCHMT-30305

1 or 3 3

15

30-5/8 22-1/2 16-1/2

GCHMT-3305

240 or 480

23

GCHMT-30505

1 or 3 5

15 56-3/8 45-1/4 39-1/4

GCHMT-3505

240 or 480

23 30-5/8 22-1/2 16-1/2

GCHMT-30755

1 or 3 7.5

15 67-1/8 56 50

GCHMT-3075

240 or 480

23 56-3/8 45-1/4 39-1/4

GCHMT-30905

1 or 3 9

15 78-1/8 67 61

GCHMT-3905

240 or 480

23 56-7/8 45-1/4 39-1/4

Specifications — Table A

WARNING: Safe operating conditions depend on operating pressure, mass velocity

of gas and discharge temperature of the gas. At a given discharge gas temperature

heater element sheath temperature, and pipe body temperature tend to increase as gas

flow (mass velocity) decreases. The standard GCHMT has a 750˚F limitation on the

carbon steel body and a 1500˚F limit on the incoloy sheath elements. Check factory if

any doubt exists as to temperatures that will be encountered in your specific application. A stainless steel body is required at pipebody temperatures above 750˚F.

(Std.)

(Std.)

Page 2

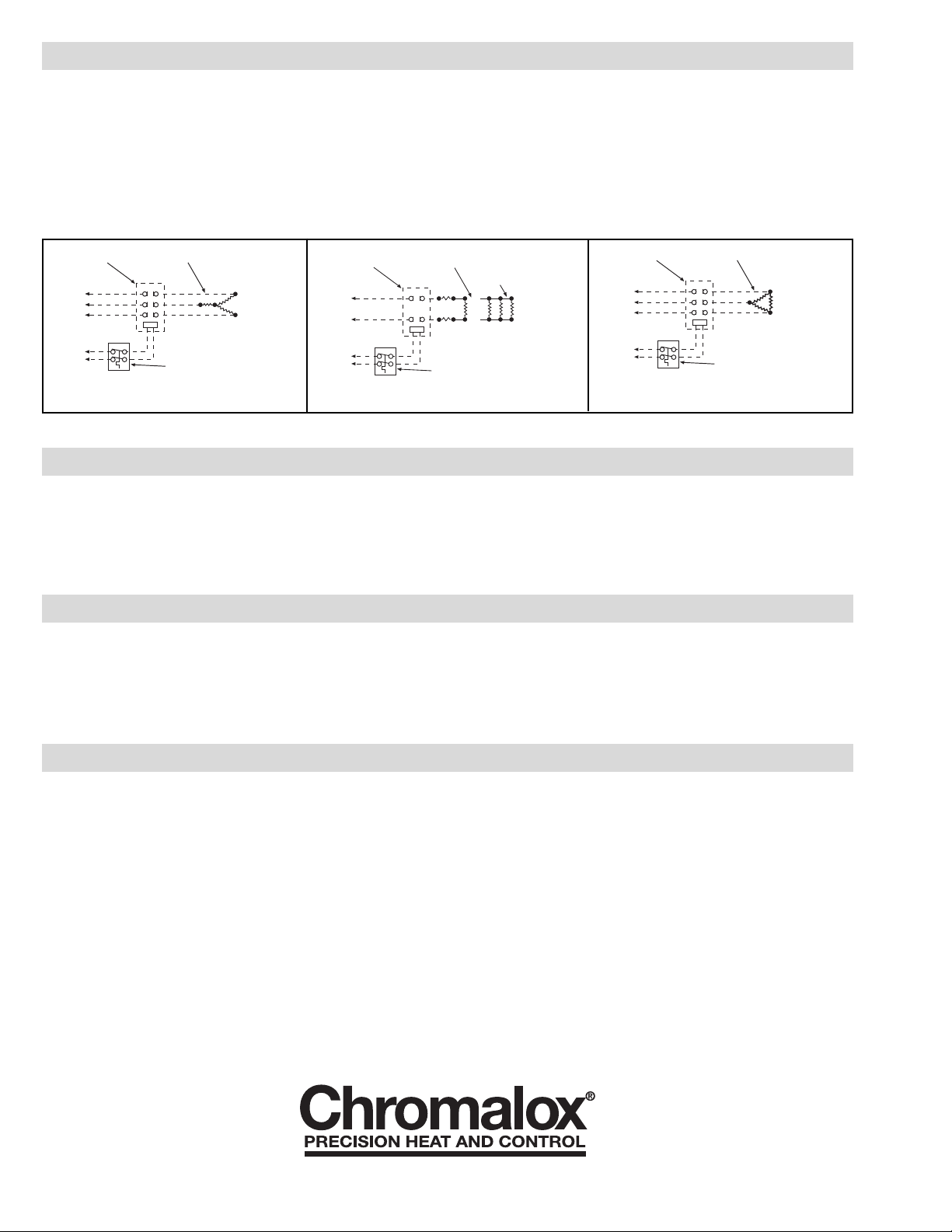

WIRING

WARNING:

Hazard of electrical shock. Any installation

involving electric heaters must be grounded to earth to eliminate shock hazard.

1. Electrical wiring to heater must be installed in accordance

with the National Electric Code and/or local electrical codes.

2. When element wattages are not equal, heaters must not be

connected in series.

3. Electrical wiring to heater should be connected in rigid con-

duit or in flexible hose to keep corrosive vapors and liquids out of

the terminal housing. If high humidity is encountered, the conduit

should slope down away from the heater.

4. If flexible cord is employed, a watertight connector should be

used for entry of the cord into the terminal box. Outdoor applications require liquid-tight conduit and connectors.

5. Bring the power line wires through the opening in the terminal

box. Connect line wire as shown in the diagram. (Figures 1 thru 3)

NOTE: Dotted lines indicate “customer furnished.”

OPERATION

1. Do not heat materials that are corrosive to the heating element

sheath or chamber. For steam heating service, condensate drain

may be provided from bottom of chamber. Check factory.

2. Terminal ends of heater must be protected from drippings condensation spray or direct spill-over of material whose presence at

the terminals may damage heater electrical insulation. Liquid-

tight terminal enclosures are available to protect heater. Check

with local sales representative.

3. If foreign material is carried by the gaseous flow, install suitable filters in the inlet pipe to the heater.

4. Do not allow heater to operate when steam, air or gas flow is

interrupted.

MAINTENANCE

WARNING:

Hazard of electric shock. Disconnect all power

before servicing heater.

1. Remove heating element assembly periodically to check

heater sheath for corrosion or excessive oxidation. Correct operating conditions to minimize sheath deterioration.

2. Periodically check temperature control and limit control operation to insure accurate and safe process operation.

3. Check all electrical connections periodically and retighten

connections which may have loosened in service. Replace wire

terminals which show signs of oxidation which would interfere

with establishment of reliable electrical connections.

RENEWAL PARTS IDENTIFICATION

THERMOSTAT 200-550˚F..........................300-048518-013

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

TA - U0 - EF

Printed in U.S.A.

3 Pole Contactors

3 Heating Elements

Line

Control

Volts

Thermostat

2 Pole Contactors

1, 2, or 3 Heating Elements

in Series

Line

Control

Volts

Thermostat

or Parrallel

3 Pole Contactors

3 Heating Elements

Line

Control

Volts

Thermostat

Figure 1

For Three Phase WYE Heaters

Figure 2

For Single Phase Heaters

Figure 3

For Three Phase Delta Heaters

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...