Page 1

Chromalox

®

DIVISION 4 SECTION

GCHIS-C

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation Instructions

and

RENEWAL PARTS IDENTIFICATION

PE433-3

161-562803-001

NOVEMBER, 1998

(Supersedes PE433-2)

GENERAL

INSTALLATION

© 2010 Chromalox, Inc.

GCHIS-C Circulation Heater

For Gas Heating

WARNING: This heater is not intended for use in haz-

ardous atmospheres where flammable vapors, gases,

liquids or other combustible atmospheres are present as defined in the National Electrical Code.

Failure to comply can result in explosion or fire.

The GCHIS-C is a gas circulation heater, designed especially for

low flow rates and/or high temperature applications.

The INCOLOY

®

sheathed cartridge style heating element is centered in a 304 stainless steel pipe body. High temperature insulation

and jacket envelope the pipe body to reduce heat loss. Its screwplug

type mounting provides easy removal when necessary.

A Type K thermocouple is located inside the heating element

sheath to provide overtemperature protection. Accurate process control

can be achieved by means of the Type J thermocouple installed in the

heater outlet. (Process and Hi-limit Controllers ordered separately.)

WARNING: Users should install adequate back-up controls and safety devices with their electric heating

equipment. When heating in closed vessels where the

consequences of failure may be severe, controls and

back-up controls must be used to prevent buildup of

temperature and/or pressure. Although the safety of the

installation is the responsibility of the user, Chromalox

will be glad to make equipment recommendations.

WARNING:

Hazard of Electric Shock. Disconnect all power

before installing heater.

1. Before installing, check your GCHIS-C circulation heater for any

damage that may have occurred during shipment.

2. Check to insure that the line voltage is the same as that stamped on

the nameplate.

3. Vertical mounting (axis of chamber vertical as in figure above)

is preferred.

4. To avoid excess temperatures at electrical wiring, mount heater

with terminal enclosure at bottom, and use lower nozzle as inlet

to the circulating steam, air or gas.

5. The GCHIS-C series of circulation heaters is provided with

mounting lugs to support the heater chamber. Refer to figure for

location of these mounting lugs.

6. Mount heaters to permit unrestrained expansion of chamber due

to temperature. This can be accomplished by using slotted mount-

ing assembly on either of the lugs.

7. Provide adequate space at terminal end to permit withdrawal of

the heater from chamber should servicing be required.

8. DANGER:

Hazard of Fire.

Provide a minimum of 6” spacing

from chamber and related piping to nearest combustible material.

Do not operate heater near combustible fluids or in combustible

vapor or gas laden atmosphere.

9. If two or more heaters are required to provide the needed heating

capacity, arrange them for series gas or vapor flow.

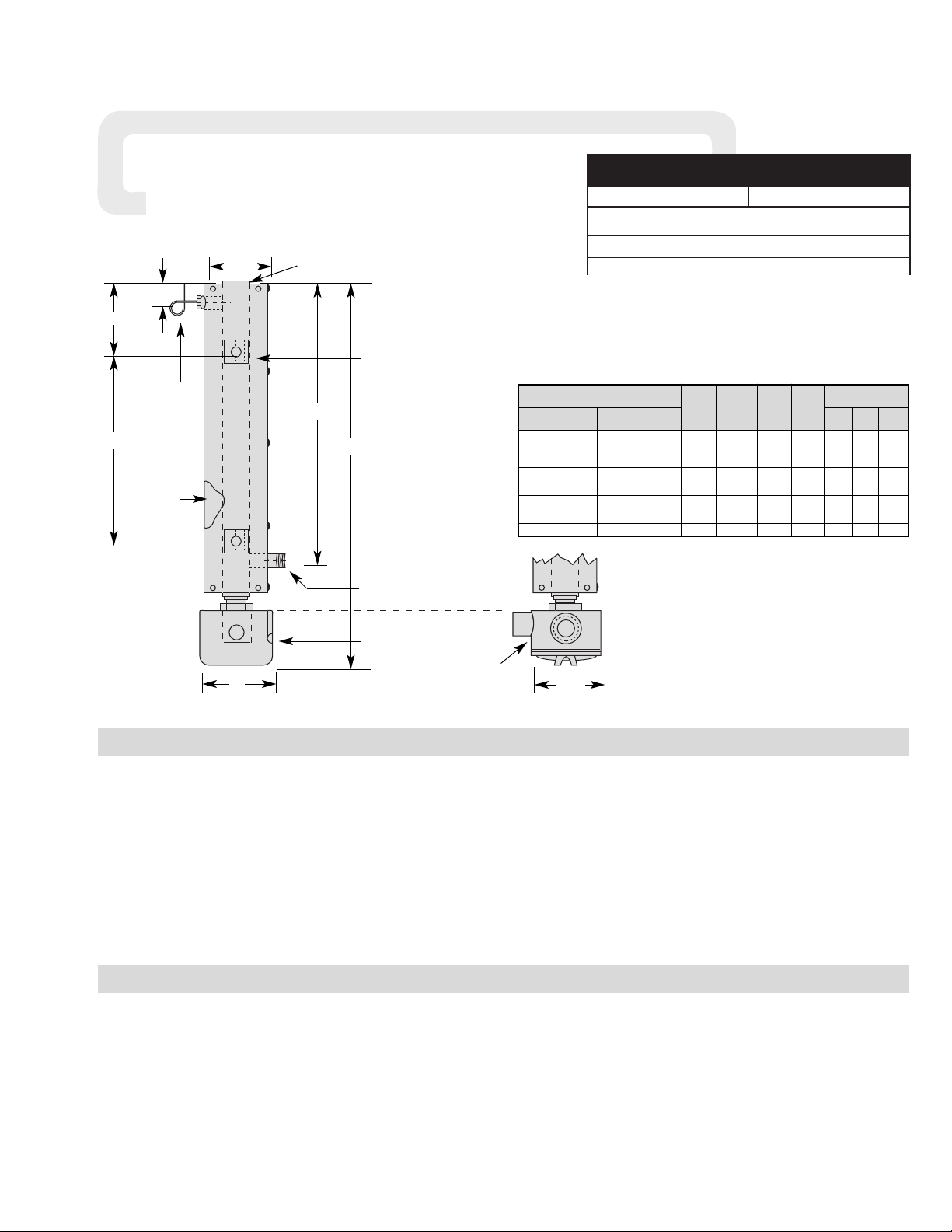

Model Dimensions (In.)

E1 E2 kW Volts CKT PH A B C

GCHIS-CO5 GCHIS-CO5E2 0.5 120 1 1 14 8 4

GCHIS-CO5 GCHIS-CO5E2 0.5 240 1 1 14 8 4

GCHIS-C10 GCHIS-C10E2 1.0 120 1 1 20 14 10

GCHIS-C10 GCHIS-C10E2 1.0 240 1 1 20 14 10

GCHIS-C20 GCHIS-C20E2 2.0 120 1 1 32 26 22

GCHIS-C20 GCHIS-C20E2 2.0 240 1 1 32 26 22

GCHIS-C30 GCHIS-C30E2 3.0 240 1 1 44 38 34

Specifications — Table A

3-1/2”4”

A

B

C

3”

1”

1” Thick

Insulation

* (2) 1” NPT

Hubs

* Power and “K” Over temperature

Thermocouple Connections (Not Shown)

* (2) 1/2” Conduit

Openings 90˚ Apart

3/4 - 14 NPT

Inlet

E1 General Purpose Enclosure E2 Moisture-Resistant/Explosion-Resistant Enclosure

(2) 3/8 - 16

Mounting Lugs

3/4 - 14 NPT Outlet

(Int. Thread)

3-1/4”

Type “J”

Thermocouple

Ungrounded

Junction

Page 2

WIRING

WARNING: Hazard of Electrical Shock. Any installa-

tion involving electric heaters must be effectively

grounded in accordance with the National Electrical

Code to eliminate shock hazard.

1. All wiring should be done in accordance with local codes and the

National Electrical Code by a qualified person.

2. Because of the high operating temperature expected, aluminum

wiring should not be used.

3. When heater element wattages are not equal, heaters must not be

connected electrically in series.

4. Electrical wiring to heater should be contained in rigid conduit or

in sealed flexible hose when corrosive vapors or liquids are present. If high humidity is encountered, the conduit should slope

down and away from the heater.

5. If flexible cord is employed, a watertight connector should be

used for entry of the cord into the terminal box. Outdoor applications require liquid-tight conduit and connectors.

6. Wire separately ordered Hi-Limit and Process Controllers to

thermocouples on heaters.

OPERATION

WARNING: Do not heat materials that are corrosive to

the heating element sheath or chamber.

It is the responsibility of the user to know the chemical composition of the corrosive solution and the characteristics of the materials

entering the solution as well as the corrosive effect of the solution

upon the heating elements and chamber. Chromalox cannot warrant

any electric circulation heater against failure by sheath corrosion.

1. Do not allow heater to operate when steam, air or gas flow is

interrupted, as dry operation of the heater can cause failure. An

air flow switch should be provided by customer and placed

upstream of the heater inlet.

2. Terminal ends of heater must be protected from drippings,

condensation, spray or direct spill-over of material whose pres-

ence at the terminals may damage heater electrical insulation.

Liquid-resistant terminal enclosures are available to protect

heater. Consult your Local Chromalox Sales office.

3. If foreign material is carried by the gaseous flow, install suitable

filters in the inlet pipe line to the heater.

4. Low Megohm Condition — The refractory material used in elec-

tric heaters may absorb moisture during transit or when subject to

a humid environment. This moisture absorption may result in a

cold insulation resistance of less than twenty megohms.

Normally, this megohm value increases after heatup and does not

affect heater efficiency or life.

A low megohm condition can easily be corrected by removing the

immersion heater from the pipe body, removing the terminal hardware and terminal enclosure and baking the heater in an oven at

350˚-700˚F for several hours, preferably overnight.

Note: The lid from an E2 enclosure may also need removed.

An alternate procedure is to energize the heaters at low voltage

until the megohm reading returns to normal. When energizing

heater without flow, the sheath temperatures should not be

allowed to exceed 750˚F for INCOLOY

®

elements.

MAINTENANCE

1. WARNING: Hazard of Electric Shock. Disconnect

all power before servicing heater.

2. Remove heating element assembly periodically to check heater

sheath for corrosion or excessive oxidation. Correct operating

conditions to minimize sheath deterioration.

3. Periodically check temperature control and pressure-temperature

safety limit control operation to insure accurate and safe process

operation.

4. Check all electrical connections periodically and retighten connec-

tions which may have loosened in service. Replace wire and wire

terminals that show signs of oxidation which would interfere with

establishment of reliable electrical connections.

5. Clean any filters in the inlet pipeline to avoid reduced flow, which

can cause element overheating and premature failure.

RENEWAL PARTS IDENTIFICATION

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

TA - U0 - EF

Litho in U.S.A.

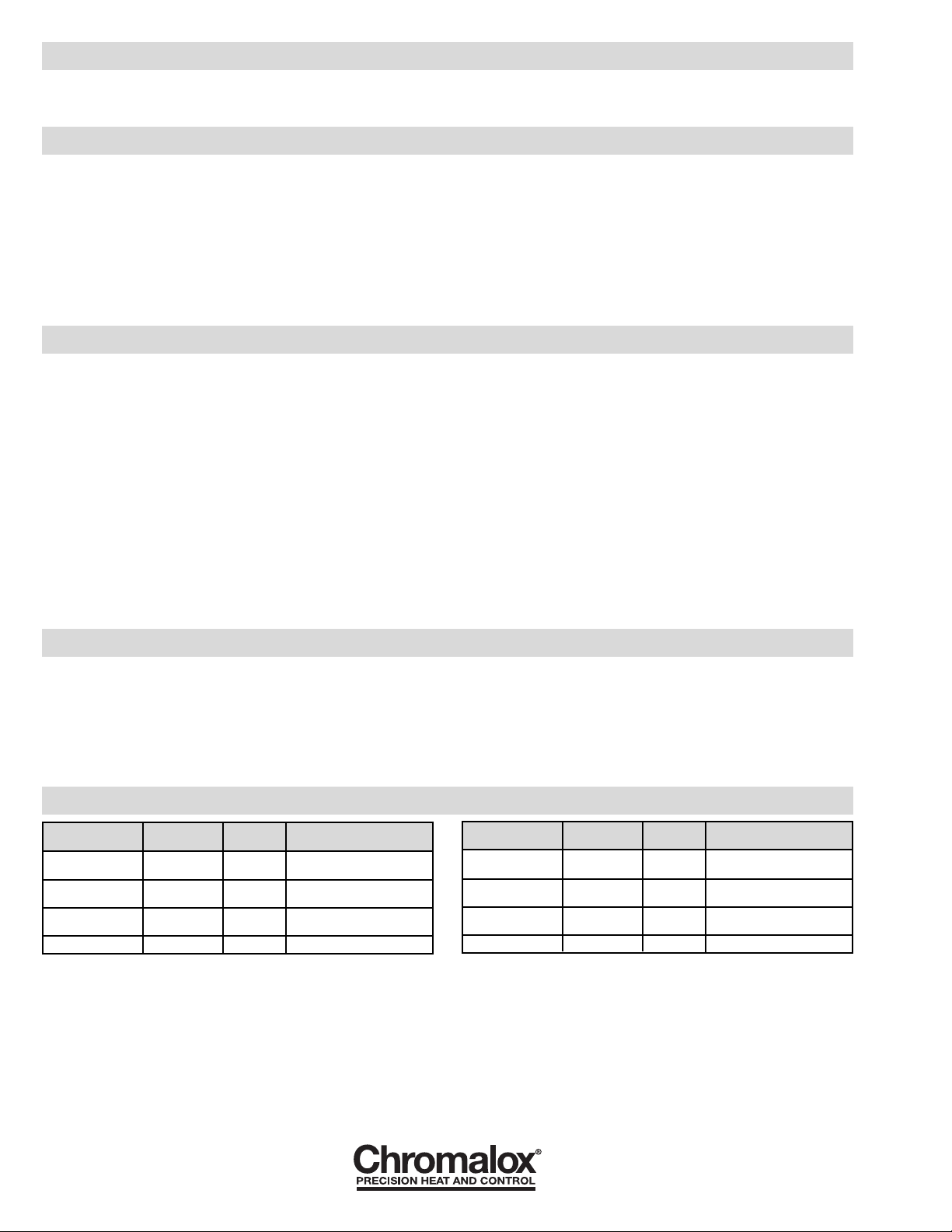

Heater Assembly

Model Volts kW

for E1 Model

GCHIS-C05 120 0.5 042-073644-012

GCHIS-C05 240 0.5 042-073644-040

GCHIS-C10 120 1.0 042-073644-017

GCHIS-C10 240 1.0 042-073644-021

GCHIS-C20 120 2.0 042-073644-028

GCHIS-C20 240 2.0 042-073644-020

GCHIS-C30 240 3.0 042-073644-016

Heater Assembly

Model Volts kW

for E2 Model

GCHIS-C05E2 120 0.5 042-073644-025

GCHIS-C05E2 240 0.5 042-073644-041

GCHIS-C10E2 120 1.0 042-073644-026

GCHIS-C10E2 240 1.0 042-073644-013

GCHIS-C20E2 120 2.0 042-073644-034

GCHIS-C20E2 240 2.0 042-073644-030

GCHIS-C30E2 240 3.0 042-073644-018

Note: When ordering parts for Model Numbers suffixed “XX” or any other letter or letters not specifically identified on this instruction sheet, order Renewal Parts on special order basis, giving name of

part, part number, model number and description.

INSTALLATION

10. DANGER: Possible Explosion. A pressure relief valve

should be provided by customer at outlet of vessel. There should

be no other valving between vessel and relief valve.

11. In a forced circulation system, use pump on the inlet side.

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...