Page 1

(Supersedes PE432-1)

PE432-2

CVCH, CVCHS

161-058123-001

APRIL, 1999

4

and

Installation, Operation

RENEWAL PARTS IDENTIFICATION

Type CVCHS Circulation Heaters

© 2010 Chromalox, Inc.

Specifications – Table A

GENERAL

WARNING: This heater is not intended for use in haz-

ardous atmospheres where flammable vapors, gases,

liquids or other combustible atmospheres are present

as defined in the National Electrical Code. Failure to

comply can result in explosion or fire.

The CVCHS is a clean solution or corrosive solution circulation

heater ideally suited for sidearm heating, in-line circulation and

engine preheaters.

The INCOLOY

®

sheathed tubular heating element is centered in

a CPVC pipe body. This material is a good thermal insulator in

reducing heat loss and eliminating the need for support jackets. Its

screwplug type mounting provides easy removal when necessary.

The CVCHS has a stainless steel flange.

An integral 60° — 180°F range thermostat is provided to control

outlet temperatures. However, this control does not fail-safe.

Therefore automatic reset (195°F) cutout is provided.

WARNING: Users should install adequate back-up

controls and safety devices with their electric heating equipment. Where the consequences of failure

may be severe, back-up controls are essential.

Although the safety of the installation is the responsibility of the user, Chromalox will be glad to make

equipment recommendations.

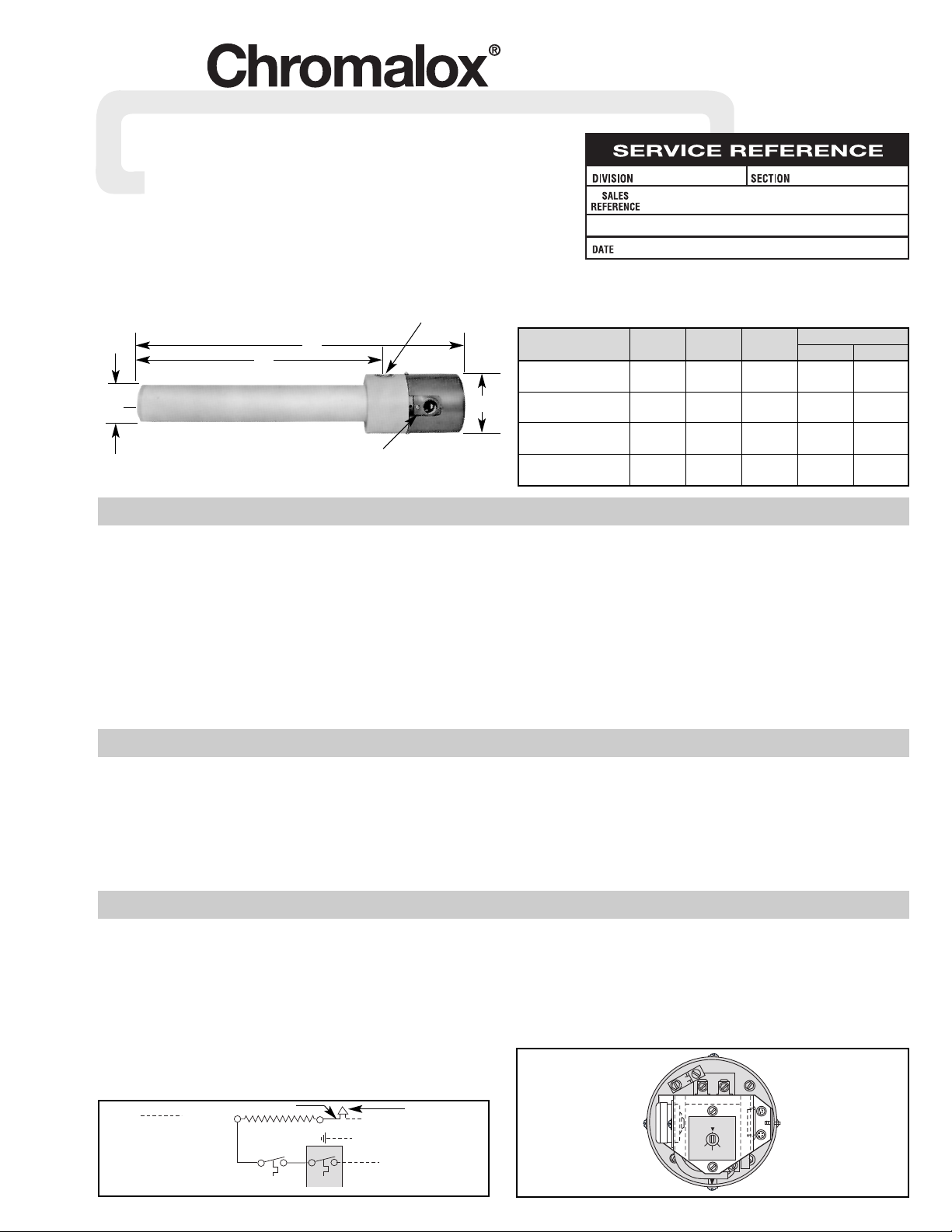

Figure 1

Dimensions (In.)

Model Volts Phase kW A B

CVCHS-151 120 1 1.5 17

5

/16 123/8

CVCHS-151 240 1 1.5 175/16 123/8

CVCHS-201 120 1 2.0 175/16 123/8

CVCHS-201 240 1 2.0 175/16 123/8

CVCHS-251 120 1 2.5 215/16 163/8

CVCHS-251 240 1 2.5 215/16 163/8

CVCHS-301 120 1 3.0 215/16 163/8

CVCHS-301 240 1 3.0 215/16 163/8

INSTALLATION

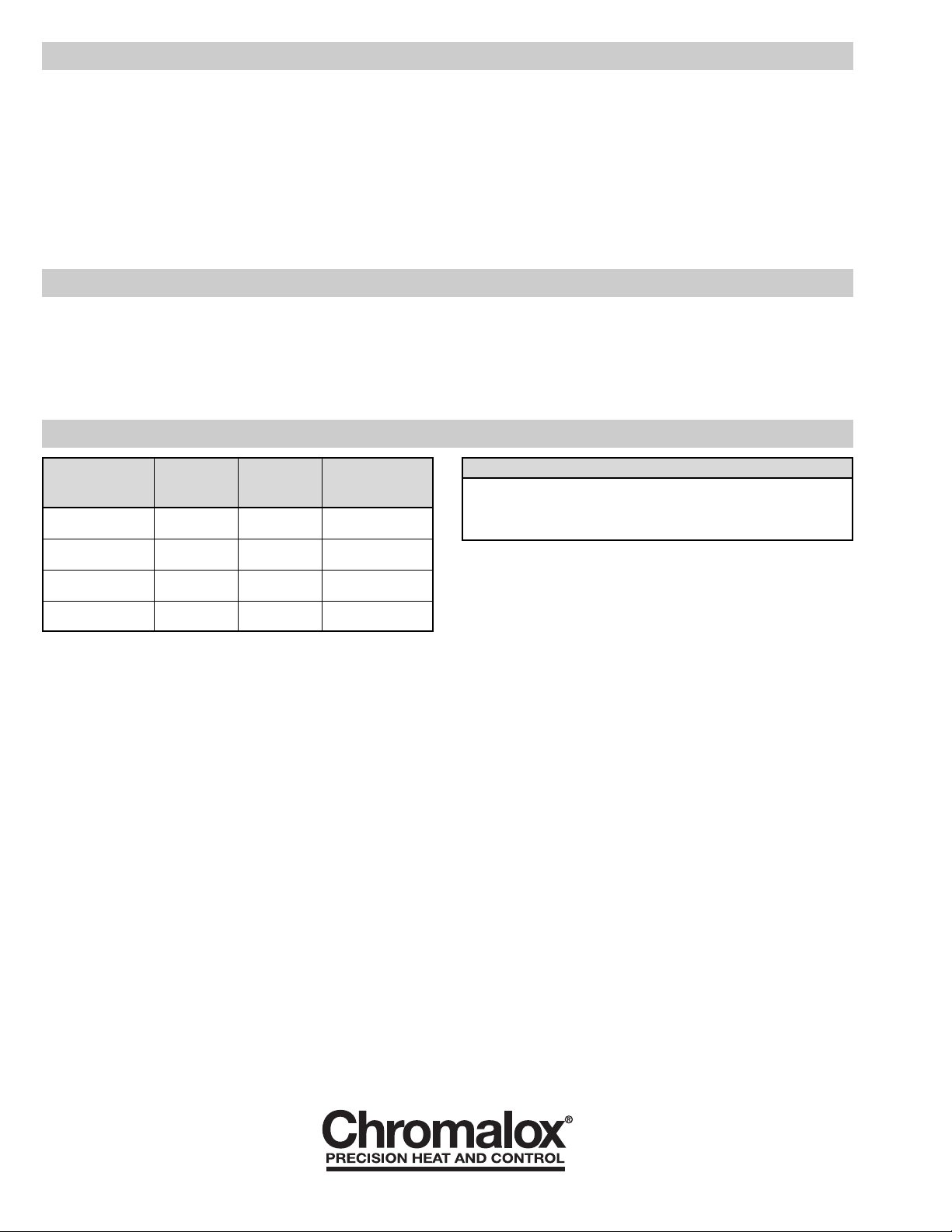

WIRING

WARNING: Hazard of Shock. Any installation involv-

ing electric heaters must be effectively grounded in

accordance with the National Electrical Code to

eliminate shock hazard.

1. Be sure line voltage matches heater voltage (on nameplate).

2. Electric wiring to heater must be installed in accordance with

local and National Electrical Codes by a qualified person as

defined in the NEC.

3. Remove terminal cover by backing out screw in center of cover

and feed wires through the conduit bracket.

4. Connect one wire to the pigtail lead and one to the unused ther-

mostat terminal. Note: Do not disturb the existing jumper wire.

5. To set thermostat, turn the slotted screw at top of thermostat

counter-clockwise until flat side is facing terminals. This is the

“OFF” position.

Next, turn the slotted screw clockwise until slot in screw points

to the desired temperature shown on scale. Note: Scale is

marked in increments of 60°F. Replace terminal cover. (See

Figure 3)

WARNING: Hazard of Shock. Disconnect all power

before installing heater.

1. When the CVCHS Circulation Heater is vertically mounted, the

terminal housing will be at the top of the heater.

2. When mounting the heater horizontally, the outlet pipe must be

up. This is to prevent any inadvertent drainage of the heater.

3. No additional support other than the connecting pipes is needed.

4. Make piping connections to either new or existing plumbing at the

1” x 11

1

/2” N.P.T. threaded inlet and outlet as shown in Figure 1.

5. DANGER: Hazard of Fire. Provide minimum of 6” spacing

from chamber and related piping to nearest combustible material. Avoid operation of heater near combustible fluids or in com-

bustible vapor or gas laden atmosphere.

6. Provide adequate space at terminal end to permit withdrawal of

the heater from chamber should servicing be required.

TURN SLOT TO

DESIRED SETTING

180

120

60

7

/8” Opening for 1/2” Conduit

1” NPT Outlet

A

B

21/2” Dia.

4”

1” NPT

Inlet

Figure 3

Figure 2

Indicates

Customer

Wiring

Pigtail Lead

Element

Ground

Thermostat

Wire Nut

By Customer

Cutout

L2

L1

Page 2

TA - U0 - EF

Litho in U.S.A.

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

OPERATION

MAINTENANCE

RENEWAL PARTS IDENTIFICATION

WARNING: Type CVCHS Circulation Heaters are

equipped with INCOLOY

®

heating elements and centered in a CVPVC pipe body. It is the responsibility of

the user to know the chemical composition of the

corrosive solution and the character of the materials

entering the solution as well as the corrosive effect

of the solution upon the heating elements and chamber. Chromalox cannot warrant any electric circulation heater against failure by sheath corrosion if

such failure is the result of operating conditions

beyond our control.

WARNING:

1. Do not permit heater to operate when liquid has been drained

from chamber. Dry operation of the heater will cause failure and

possible fire hazard.

2. Terminal ends of heater must be protected from drippings, condensation, spray or direct spill-over of material. Their presence

at the terminals may damage heater electrical insulation. Liquidtight terminal enclosures are available to protect heater. Check

Factory.

1. WARNING: Hazard of Shock. Disconnect all power

before servicing heater.

2. If automatic reset cutout fails or will not reset, do not bypass.

3. Remove heating element assembly periodically to check heater

sheath for scaling, corrosion or excessive oxidation. Correct

operating conditions to minimize sheath deterioration.

4. Periodically check temperature control operation to insure accurate and safe process operation.

5. Check all electrical connections periodically and retighten connections which may have loosened in service. Replace wire and

wire terminals which shows signs of oxidation which would interfere with establishment of reliable electrical connections.

Note: When ordering parts for Model Numbers suffixed by “XX” or any other letter or letters not specifically identified on this instruction sheet, order Renewal Parts

on special order basis, giving name of part required, as well as the part number, model number and description of the complete circulation heater.

Parts Common To All Heaters

Temperature Control Thermostat . . . . . . . . . . . . . . . . . . . .300-057474-001

Automatic Reset Cutout . . . . . . . . . . . . . . . . . . . . . . . . . . .300-026629-005

O-Ring Gasket P/N . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132-057731-001

Heater Assembly

(Heating element

Model Volts kW and flange only)

CVCHS-151 120 1.5 155-058147-007

CVCHS-151 240 1.5 155-058147-008

CVCHS-201 120 2.0 155-058147-001

CVCHS-201 240 2.0 155-058147-002

CVCHS-251 120 2.5 155-058147-003

CVCHS-251 240 2.5 155-058147-004

CVCHS-301 120 3.0 155-058147-005

CVCHS-301 240 3.0 155-058147-006

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...