Page 1

(Supersedes PE429)

PE429-1

NWHO

161-058065-001

FEBRUARY, 1986

4

and

Installation, Operation

RENEWAL PARTS IDENTIFICATION

Type NWHO-45, 72, 108

Circulation Heaters for

Regular and Fuel Oil

Heating

© 2010 Chromalox, Inc.

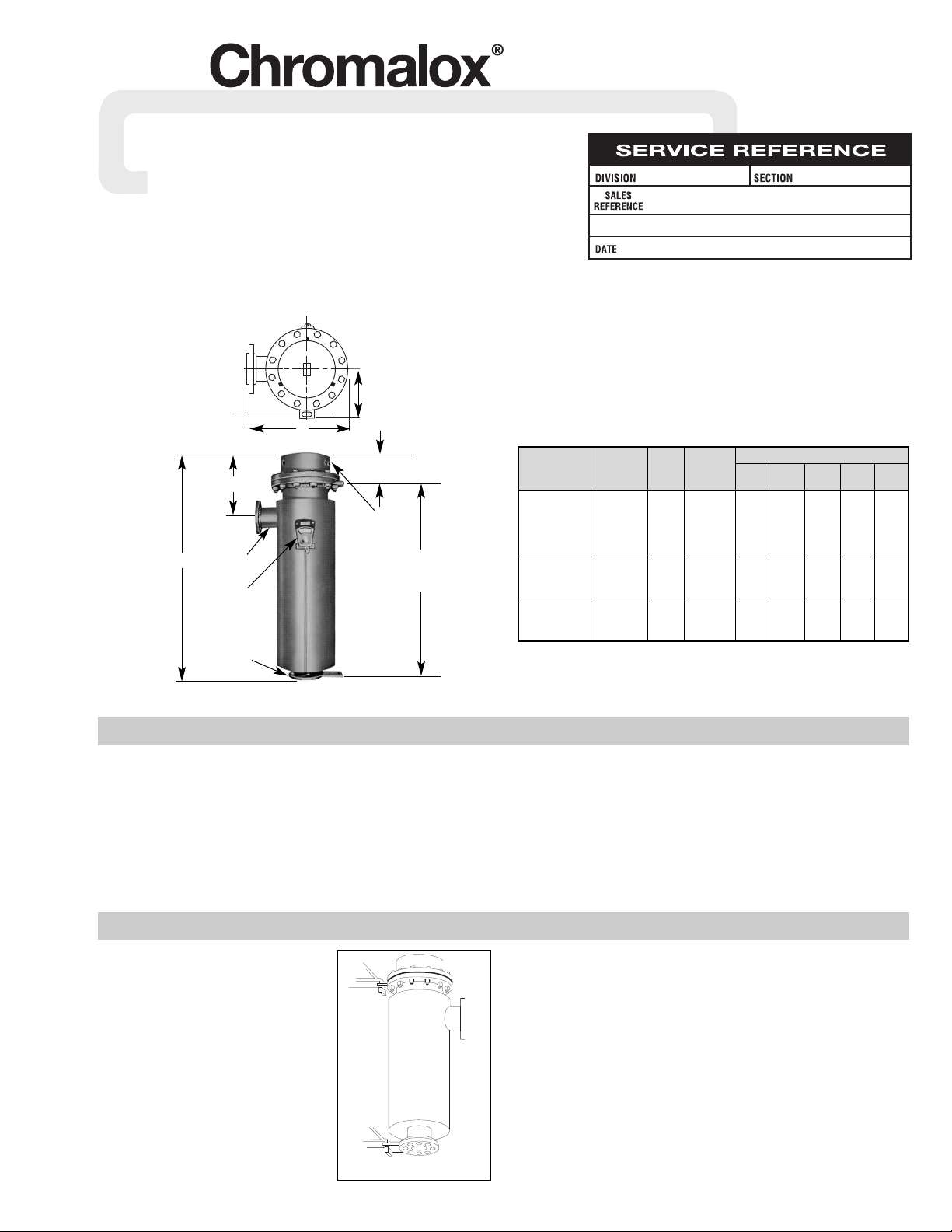

Dimensions (In.)

No. 3Ø

Model Volts 3Ø kW Circuits A B C D E

NWHO-4590 240 or 480 90 5 72

1

/2 251/2 635/8 1813/16 121/2

NWHO-45125 240 or 480 125 5 871/2 251/2 785/8 1813/16 121/2

NWHO-45150 240 or 480 150 5 1021/2 251/2 935/8 1813/16 121/2

NWHO-45175 240 or 480 175 5 1171/2 251/2 1085/8 1813/16 121/2

NWHO-45200 240 or 480 200 5 125 251/2 1161/8 1813/16 121/2

NWHO-77220 240 or 480 200 6 971/2 273/4 885/8 19 133/4

NWHO-77225 240 or 480 225 6 1051/2 273/4 965/8 19 133/4

NWHO-77250 240 or 480 250 6 1131/2 273/4 1045/8 19 133/4

NWHO-108300 240 or 480 300 6 981/2 291/2 895/16 193/8 141/2

NWHO-108325 240 or 480 325 6 1041/2 291/2 955/16 193/8 141/2

NWHO-108350 240 or 480 350 6 1101/2 291/2 1011/16 193/8 141/2

Specifications – Table A

GENERAL

The high capacity NWHO-45, 72 or 108 series are intended for

indoor use and are used primarily for oil heating.

The 45, 72 or 108 steel sheathed tubular elements are centered

in a 14”, 16” or 18” diameter steel heating chamber, respectively,

and welded to a removable steel flange. The assembly is surrounded by 2” of insulation and a sheet metal jacket.

Depending upon the order specifications, the NWHO-45, 72 or

108 may or may not be factory equipped with an MF2 or other

Chromalox thermostat. Such thermostats function to control outlet

temperatures and to limit internal temperatures under abnormal

flow conditions. These controls do not fail-safe.

CAUTION: Users should install adequate back-up

controls and safety devices with their electric

heating equipment. Where the consequences of

failure may be severe, back-up controls are essential. Although the safety of the installation is the

responsibility of the user, Chromalox will be glad to

make equipment recommendations.

INSTALLATION

1. Vertical mounting (axis of chamber

vertical) is preferred. Check factory

for constructions suitable for horizontal mounting.

2. Mount heater with terminal enclo-

sure at top, and use lower nozzle as

inlet to the circulating fluid.

3. The NWHO-45, 72 and 108 series

of circulation heaters are provided

with mounting lugs to support the

heater chamber. Refer to Figure A

for one suggested mode of support.

4. Mount heaters to permit unre-

strained expansion of chamber due

to temperature. The large flange lug

should be bolted solidly; however, the remaining lug should be

bolted loosely to allow freedom of movement with expansion.

5. DANGER: Hazard of Fire. Provide minimum of 6” spacing from chamber and related piping to nearest combustible

material. Avoid operation of heater near combustible fluids or

in combustible vapor or gas laden atmosphere. Note: Contact

factory for heaters suitable for use in hazardous locations.

6. Provide adequate space at terminal end to permit withdrawal of

the heater from chamber should servicing be required.

7. If two or more heaters are needed to provide the needed heating capacity, arrange them for series flow.

8. DANGER: Possible Explosion. A pressure relief valve

should be provided by customer at outlet of vessel. There

should be no valving between vessel and relief valve.

6” Outlet

Temperature

Control

C

Mounting

Lug Centers

8

13

/16”

D

A

6” Inlet

5 Conduit

Outlets

72° Apart

or

6 Conduit

Outlets

60° Apart

Figure A

2 x

3

/4”

Slot

1”

E

B

These Dimensions are typical. Check factory for dimensions of a particular unit.

Page 2

TA - U0 - EF

Litho in U.S.A.

1347 HEIL QUAKER BLVD., LAVERGNE, TN 37086

Phone: (615) 793-3900 www.chromalox.com

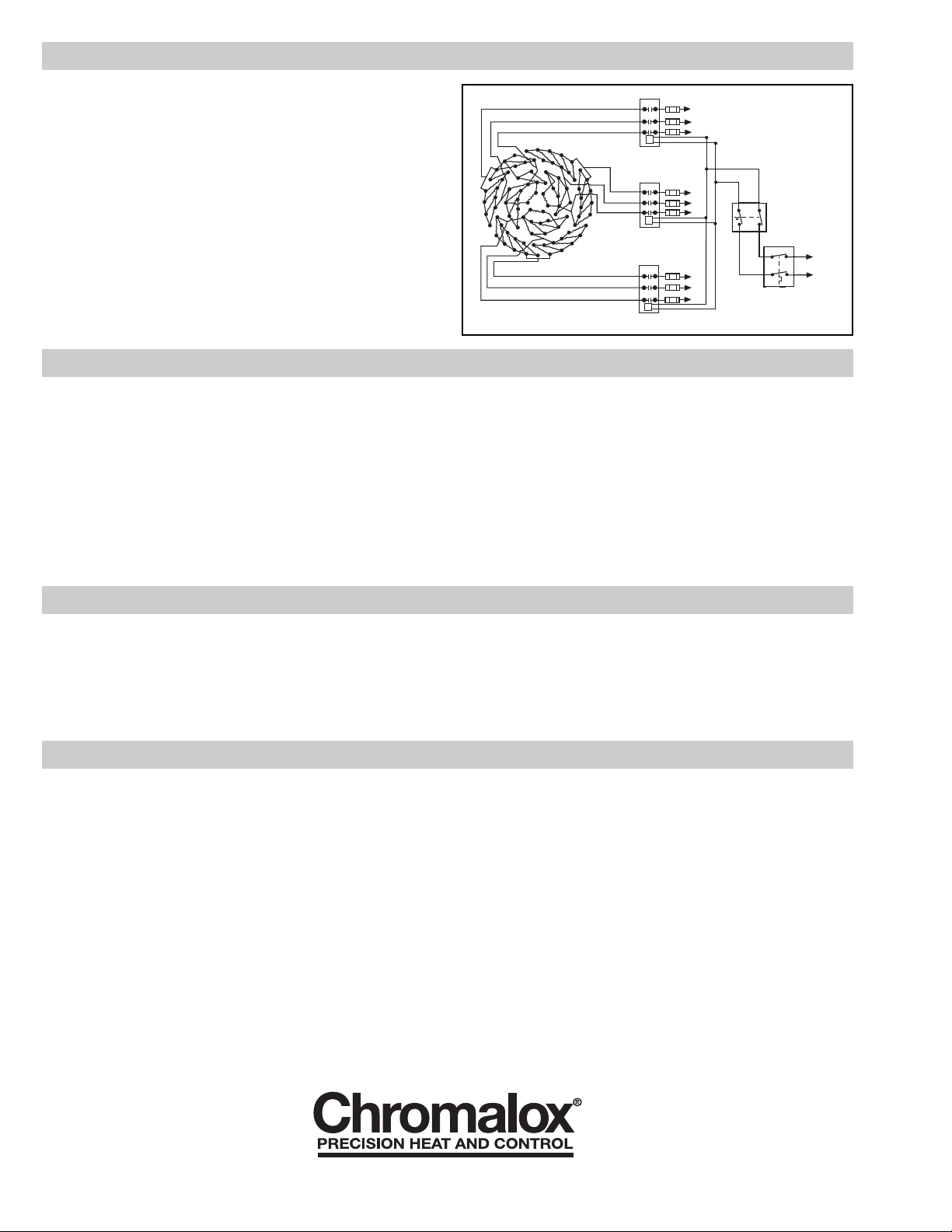

WIRING

OPERATION

MAINTENANCE

RENEWAL PARTS IDENTIFICATION

1. Do not heat materials that are corrosive to the heating element

sheath or chamber.

WARNING: Type NWHO Circulation Heaters are

equipped with steel heating elements and galvanized-steel heating chambers. It is the responsibility of the user to know the chemical composition of

the corrosive solution and the character of the

materials entering the solution as well as the corrosive effect of the solution upon the heating elements and chamber. Chromalox cannot warrant

any electric circulation heater against failure by

sheath corrosion if such failure is the result of

operating conditions beyond our control.

2. Terminal ends of heater must be protected from drippings, condensation, spray or direct spill-over of material whose presence

at the terminals may damage heater electrical insulation.

Liquid-tight terminal enclosures are available to protect heater.

Check Factory.

3. If foreign material is carried by the fluid flow, install suitable

filters in the inlet pipe line to the heater.

4. Do not allow heater to operate when oil flow is interrupted.

CAUTION: Hazard of Electric Shock. Any installation involving electric heaters must be grounded to

earth to eliminate shock hazard.

1. Electric wiring to heater must be installed in accordance with

National Electrical Code and with local codes.

2. Because of high operating temperatures expected, aluminum

wiring is not recommended.

3. Refer to Wiring Diagram Figure B for the typical wiring used

for connecting the NWHO-45 series heater.

4. Three 3 phase circuits is a typical design for these heaters.

Other circuit arrangements are often supplied depending upon

customer specifications or amperage rating.

1L1

1L2

1L3

2L1

2L2

2L3

3L1

3L2

3L3

Over-Temp

Cutout

120V

or

240V

Thermostat

Contactor

Fuses

Fuses

Fuses

Contactor

Contactor

1. CAUTION: Hazard of Electric Shock. Disconnect

all power before servicing heater.

2. Remove heating element assembly periodically to check heater

sheath for corrosion or excessive oxidation. Correct operating

conditions to minimize sheath deterioration.

3. Periodically check temperature control and pressure-tempera-

ture safety limit control operation to insure accurate and safe

process operation.

4. Check all electrical connections periodically and retighten connections which may have loosened in service. Replace wire

and wire terminals which show signs of oxidation which would

interfere with establishment of reliable electrical connections.

Order Renewal Parts on a Special Order Basis. Give the name

of the part, part number, voltage, wattage and any special features

to your local Chromalox Representative or the factory.

Figure B

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...