Page 1

Chromalox

®

DIVISION 4 SECTION

GCH-GCHIS

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation, Operation

and

RENEWAL PARTS IDENTIFICATION

PE419-5

161-027331-001

FEBRUARY, 2009

(Supersedes PE419-4)

GENERAL

© 2010 Chromalox, Inc.

GCH and GCHIS-6 Circulation Heaters

For Steam, Gas and Air Heating

Read and understand all instructions before

installing, servicing or operating product. Failure

to do so could result in personal injury or property

damage.

The GCH and GCHIS-6 series is a general-purpose gas or steam

circulation heater intended for use indoors.

The 6 INCOLOY® sheathed tubular elements are centered in a 5”

diameter heating chamber and welded to a removable flange. The

assembly is surrounded by 1-1/2” insulation and sheet metal jacket.

The GCH series has a steel flange and chamber. The GCHIS series has

stainless steel flange and chamber.

Depending upon the order specifications, the GCH-GCHIS-6 may

or may not be factory equipped with an AR or other Chromalox thermostat. Such thermostats function to control outlet temperatures and to

limit internal temperatures under abnormal flow conditions. These

controls do not fail safe.

The system designer is responsible for the safety

of this equipment and should install adequate

back-up controls and safety devices with their

electric heating equipment. Where the consequences of failure could result in personal injury or

property damage, back-up controls are essential.

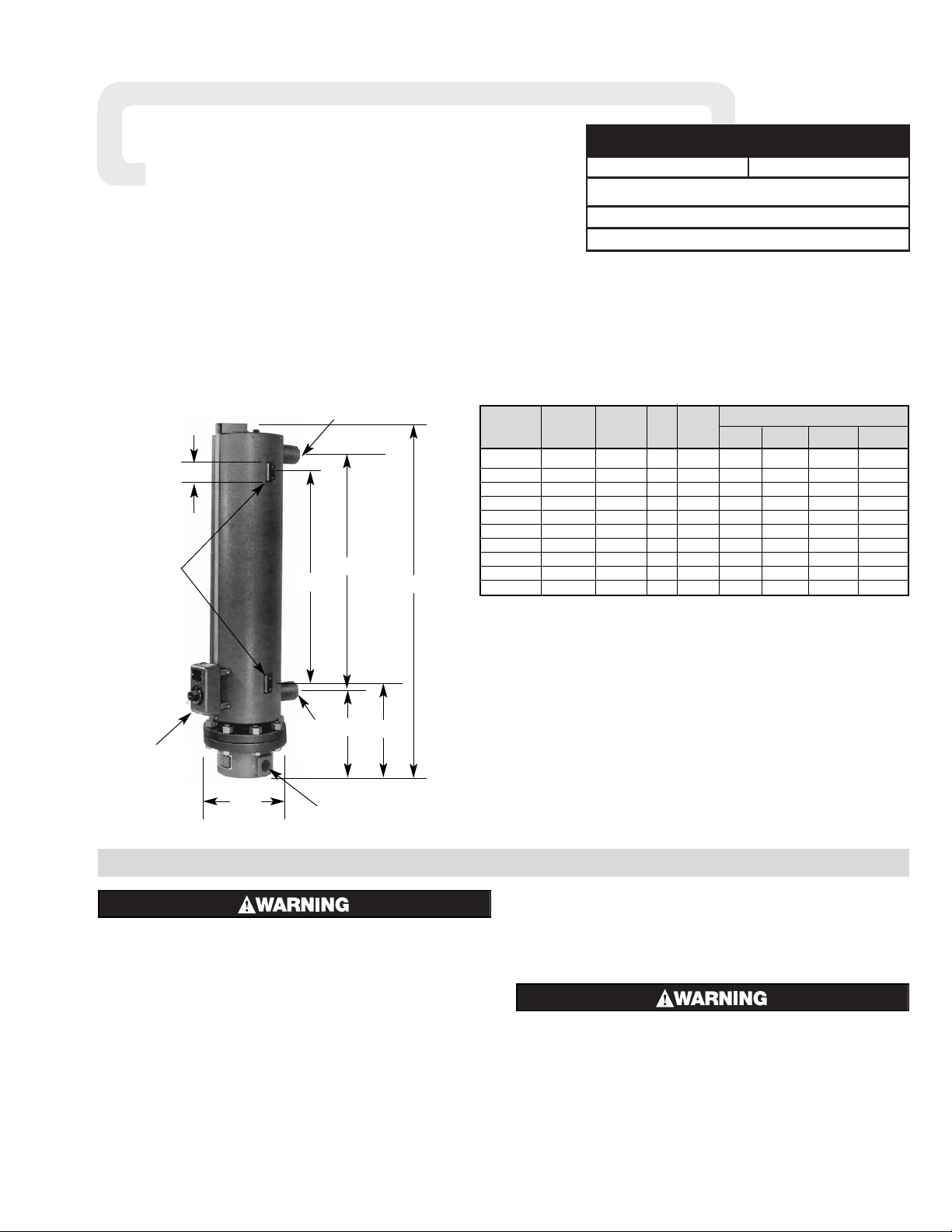

Specifications — Table A

Dimensions (In.)

Model Volts Phase kW W/In

2

AB C D

GCH-60905 240 or 480 1 or 3 LL 9 23.8 41-3/4 30 25 11-3/8

GCH-61205 240 or 480 1 or 3 LL 12 23.1 48-3/4 37 25 14-7/8

GCH-62005 240 or 480 1 or 3 LL 20 23.3 60-1/4 48-1/2 25 20-5/8

GCH-62505 240 or 480 3Y 25 22.9 73-5/8 61-7/8 25 27-5/16

GCH-63005 240 or 480 3Y 30 22.7 86-5/8 74-7/8 25 33-7/8

GCHIS-6045 240 or 480 3Y 4 15 41-3/4 30 25 11-3/8

GCHIS-6085 240 or 480 3Y 8 15 48-3/4 37 25 14-7/8

GCHIS-6125 240 or 480 3Y 12 15 60-1/4 48-1/2 25 20-5/8

GCHIS-6155 240 or 480 3Y 15 15 73-5/8 61-7/8 25 27-5/16

GCHIS-6205 240 or 480 3Y 30 15 86-5/8 74-7/8 25 33-7/8

A

B

12-1/32”

C

8-3/4”

1-1/4”

8”

Mtg. Lugs

3/8-16 Tap

1-1/2” Deep

1-3/8” K.O.

For 1” Conduit

1” Pipe

Inlet

1” Pipe

Outlet

AR

Thermostat

Page 2

ELECTRIC SHOCK HAZARD. Any installation involving electric heaters must be performed by a qualified person and must be effectively grounded in

accordance with the National Electrical Code to

eliminate shock hazard.

1. Be sure line voltage matches heater voltage (on nameplate).

2. Electric wiring to heater must be installed in accordance with local

codes and the National Electrical Codes.

3. Because of the high operating temperatures expected, 250˚C wire

should be used.

4. Power controls must be used when heaters are rated 3 phase and

when the heater amperage exceeds the rating of the thermostat.

5. Refer to Wiring Diagram Table B, to properly connect the heater.

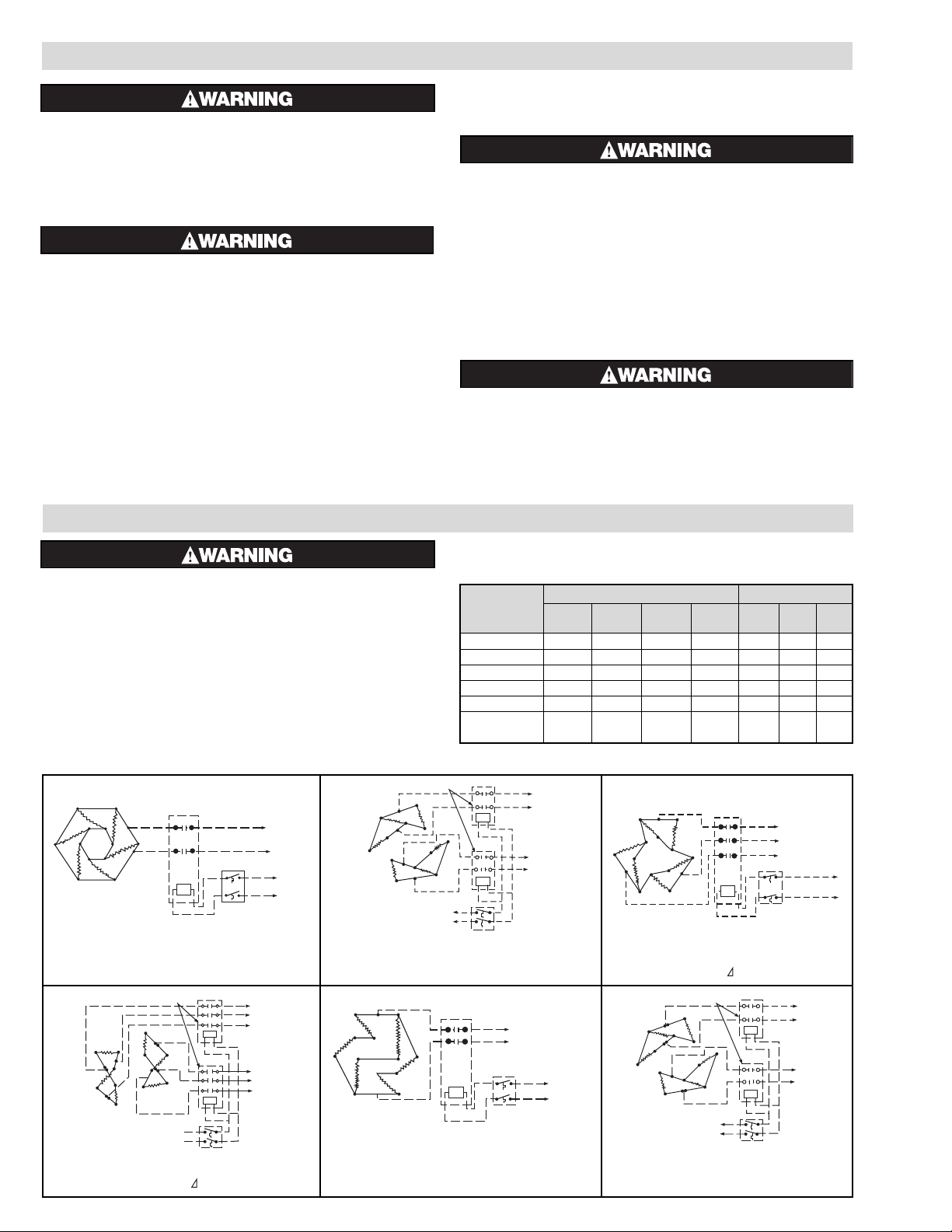

Table B — Wiring Diagrams

WIRING

240V 480V

Model 1ø 2-1ø 3ø 2-3ø 1ø 2-1ø 3ø

Fig. No. Fig. No. Fig. No. Fig. No. Fig. No. Fig. No.Fig. No.

GCH-60905 1 — 3 — 5 — 7

GCH-61205 — 2 3 — 5 — 7

GCH-62005 — 2 — 4 5 — 7

GCH-62505 — — — 4 — 6 7

GCH-63005 — — — 4 — — 7

GCHIS 4, 8

—— 8 ———9

12, 15,20 kW

INSTALLATION

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed by a qualified person

in accordance with the National Electrical Code,

NFPA 70

.

FREEZE HAZARD. This unit is equipped with a thermowell for process control or over-temperature

control. Do not allow moisture to accumulate in

thermowell. Freezing temperatures can cause

damage that may result in the heated medium

leaking into terminal enclosure.

1. Vertical mounting (axis of chamber vertical as in photo on previ-

ous page) is preferred.

2. To avoid excess temperatures at electrical wiring, mount heater

with terminal enclosure at bottom and use lower nozzle as inlet to

the circulating steam, air or gas.

3. The GCH-GCHIS-6 series of circulation heaters are provided with

mounting lugs to support the heater chamber. Refer to photo on

previous page for location of these mounting lugs.

4. Mount heaters to permit unrestrained expansion of chamber due to

temperature. This can be accomplished by using a slotted mounting assembly on either of the lugs.

FIRE HAZARD. Since heaters are capable of developing high temperatures, extreme care should be

taken to:

A. Provide minimum of 6” spacing from a chamber

and related piping to nearest combustible material.

B. Avoid operation of heater near combustible fluids

or in combustible vapor or gas laden atmosphere.

5. Provide adequate space at terminal end to permit withdrawal of the

heater from chamber should servicing be required.

6. If two or more heaters are needed to provide the needed heating

capacity, arrange them for series gas or vapor flow.

EXPLOSION HAZARD. When heating in closed vessels,

controls and back-up controls must be used to regulate build-up of temperature and/or pressure.

7. A pressure relief valve should be provided by customer at outlet

of vessel. There should be no other valving between vessel and

LINE

CONTACTOR

THERMOSTAT

120V, 240V

Figure 1 – GCH6

240V, 1ø

LINE

CONTACTORS

THERMOSTAT

120V or

240V

Figure 2 – GCH6

240V, 2-1ø

CONTACTOR

THERMOSTAT

120V, 240V

Figure 3 – GCH6

240V, 3ø

L1

L2

L3

CONTACTORS

THERMOSTAT

120V

or 240V

Figure 4 – GCH6

240V, 2-3ø

1L1

1L2

1L3

2L1

2L2

2L3

CONTACTORS

THERMOSTAT

120V or 240V

Figure 5 – GCH6

480V, 1ø

LINE

CONTACTORS

THERMOSTAT

120V or

240V

Figure 6 – GCH6

480V, 2-1ø

LINE

Page 3

OPERATION

1. Do not heat materials that are corrosive to the heating element

sheath or chamber.

2. Terminal ends of heater must be protected from drippings, con-

densation, spray or direct spill-over of material whose presence at

the terminals may damage heater electrical insulation. Liquid-tight

terminal enclosures are available to protect heater. Consult your

local Chromalox Sales office.

3. If foreign material is carried by the gaseous flow, install suitable

filters in the inlet pipe line to the heater.

4. Do not allow heater to operate when steam, air or gas flow is inter-

rupted.

FIRE/EXPLOSION HAZARD. Safe operating conditions depend on operating pressure, mass velocity

of gas and discharge temperature of the gas. At a

given discharge gas temperature, heater element

sheath temperature and pipe body temperature

tend to increase as gas flow (mass velocity)

decreases. The standard GCH-6 has a 750˚F limitation on the carbon steel body and a 1500˚F limit on

the INCOLOY sheath elements. Check factory if any

doubt exists as to temperatures that will be

encountered in your specific application. At pipe

body temperatures above 750˚F, stainless steel

pipe body is required (model GCHIS).

FIRE/EXPLOSION HAZARD. Do not exceed the

Pressure-Temperature rating of the flange as listed in ANSI B16.5.

WIRING

CONTACTOR

THERMOSTAT

120V, 240V

Figure 7 – GCH6

480V, 3ø

L1

L2

L3

CONTACTOR

THERMOSTAT

120V, 240V

Figure 8 – GCHIS

240V, 3øY

L1

L2

L3

CONTACTOR

THERMOSTAT

120V, 240V

Figure 9 – GCHIS

40V, 3øY

L1

L2

L3

166-075229-014

166-014828-024

166-075229-018

240V LINE

FIGURE A

240V, 3ø (Parallel) Connected

166-075229-014

166-014828-024

480V LINE

FIGURE B

480V, 3ø (Series) Connected

Instructions for converting

GCH6, 240V, 3ø to GCH6, 480V, 3ø

1. Remove all jumper straps and separate

according to different lengths.

2. Discard jumper straps 166-075229-018

(1-1/4” long).

3. Reassemble jumper straps 166-014828-

024 (2-1/2” long) and 166-075229-014

(1-1/2” long) as in Figure B.

4. Replace washers and nuts.

5. Check circuits.

NOTE: Broken Lines Indicate “Customer-furnished”. However, thermostat could have been furnished by chromalox if so specified on order.

MAINTENANCE

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do so

could result in personal injury or property damage.

Heater must be installed and serviced by a qualified

person in accordance with the National Electrical

Code, NFPA 70.

1. Remove heating element assembly periodically to check heater

sheath for corrosion or excessive oxidation. Correct operating conditions to minimize sheath deterioration.

2. Periodically check temperature control and limit control operation

to insure accurate and safe process operation.

3. Check all electrical connections periodically and retighten con-

nections which may have loosened in service. Replace wire and

wire terminals that show signs of oxidation which would interfere

with establishment of reliable electrical connections.

NOTE: Maintenance intervals to be determined by the user based on

their knowledge of the heated medium and operating conditions.

Page 4

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

TA - U0 - EF

Litho in U.S.A.

RENEWAL PARTS

Note: When ordering parts for Model Numbers suffixed by “XX” or any other letter or any other letters not specifically identified on this instruction sheet, order Renewal Parts on special order basis, giving

name of part, part number, model number and description. Note: Number in ( ) indicates quantity of same part number used. Model GCHIS - contact local Chromalox Representative.

Catalog Number Volts Phase kW Heating Element

240 1 9 155-115143-001

GCH-60905

240 3 LL 9 155-115143-002

480 1 9 155-115143-003

482 3 LL 9 155-115143-004

240 2-1 12 155-115143-006

GCH-61205

240 3 LL 12 155-115143-007

480 1 12 155-115143-008

480 3 LL 12 155-115143-009

240 2-1 20 155-115143-011

GCH-62005

240 3 LL 20 155-115143-012

480 1 20 155-115143-013

480 3 LL 20 155-115143-014

240 2-3 LL 25 155-115143-016

GCH-62505 480 2-1 25 155-115143-017

480 3 LL 25 155-115143-018

GCH-63005

240 2-3 LL 30 155-115143-020

480 3 LL 30 155-115143-021

PARTS COMMON TO ALL HEATERS

AR5524 Thermostat 300-013863-015

Standard Gasket 132-017222-016

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...