Page 1

Chromalox

®

(Supersedes PE414-2)

PE414-3

NWH

161-304777-001

MAY, 2007

4

RENEWAL PARTS IDENTIFICATION

Installation, Operation

and

Circulation

Heaters for Oil or Water Heating

© 2010 Chromalox, Inc.

Specifications – Table A

GENERAL

READ ALL INSTRUCTIONS BEFORE USE

FIRE/EXPLOSION HAZARD. Ordinary location

heaters (designated E1) are not intended for use in

hazardous atmospheres where flammable vapors,

gases, liquids or other combustible atmospheres are

present as defined in the National Electrical Code.

Failure to comply can result in personal injury or

property damage.

This design has the versatility of field adjustments of voltage

kW through various wiring combinations.

The NWHSRG model is a general purpose water circulation

heater intended for indoor use. E2 designs have a Moisture

Resistant/Explosion Resistant enclosure. Designs are up to 40kW

- DO NOT USE THE NWHSRG MODEL FOR OIL.

The NWHOSR model is a general-purpose regular and fuel oil

solution circulation heater intended for use indoors. E2 designs

have a Moisture Resistant/Explosion Resistant enclosure. Designs

are up to 10kW - DO NOT USE THE NWHOSR MODEL FOR

WATER. Ensure the wiring guide for oil is used for the correct

wiring diagram.

Both the NWHSRG and NWHOSR use six INCOLOY

®

sheath

elements welded to a steel 2.5” screw plug. The vessel is cast iron

and is surrounded by 1.5” insulation and a sheet metal jacket. For

water applications, the vessel has a galvanized coating. A J-type

thermocouple in a thermowell is standard. These

versaTHERM

TM

heaters

are designed for 150 psig max. at 35°F min. to 300°F max.

IMPORTANT: It is the responsibility of the purchaser of

the heater to make the ultimate choice of sheath

material based upon his knowledge of the chemical

composition of the corrosive solution, character of the

materials entering the solution, and controls which he

maintains on the process.

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed or serviced by a

qualified person in accordance with the National

Electrical Code. NFPA 70.

The system designer is responsible for the safety

of this equipment and should install adequate

back-up controls and safety devices with their

electric heating equipment. Where the consequences of failure could result in personal injury or

property damage, back-up controls are essential.

If foreign material is to be carried by the liquid flow, install

suitable filters in the inlet pipe to the heater.

Ensure the temperature/pressure is controlled below the vapor

point of the liquid at all times and is within the temperature/pressure ratings for this heater.

Heating elements must be completely immersed in liquid when

energized.

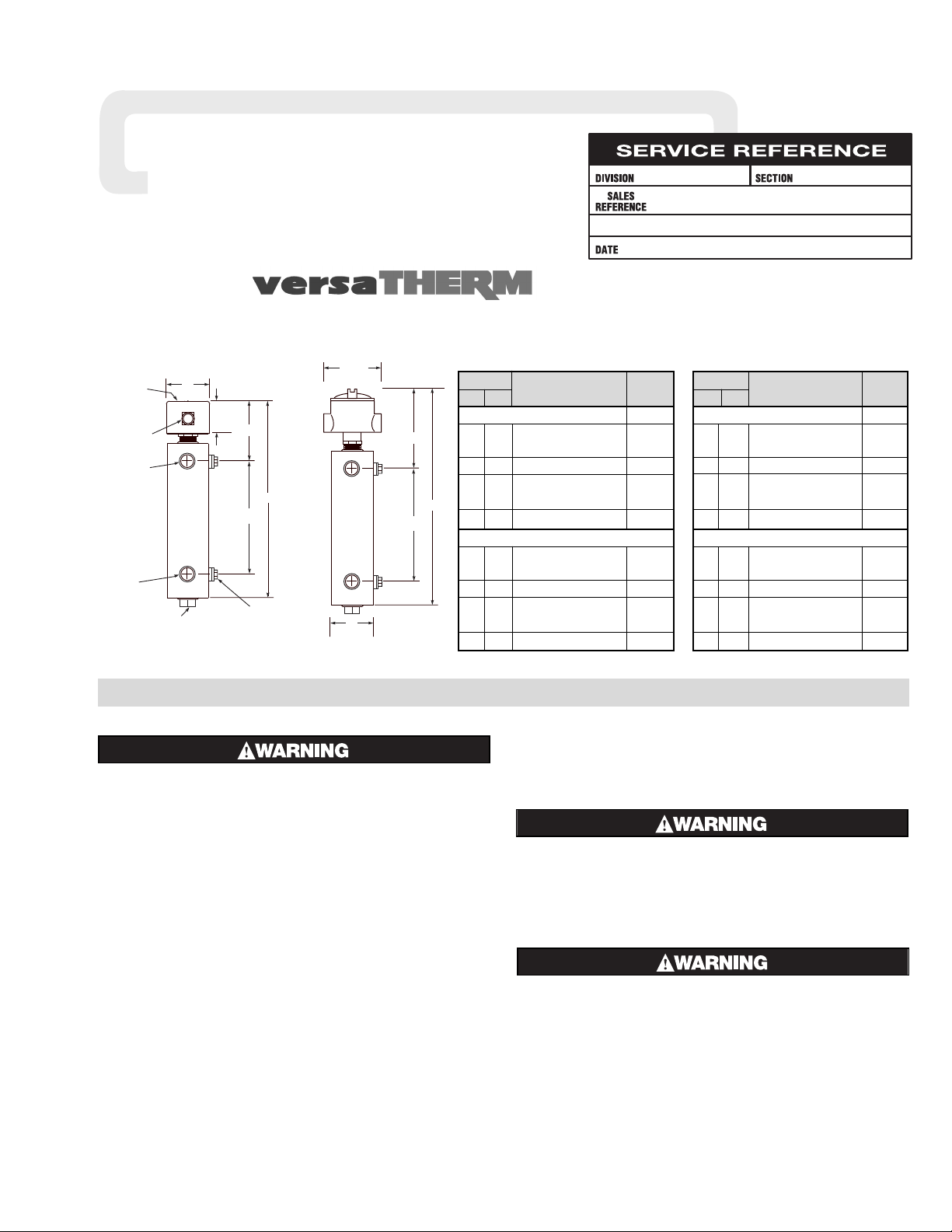

Dim. (In.)

A B Model PCN

Cast Iron Body / Oil .5 to 10 kW

29 19 NWHOSR-06-04P5-E1 100108

29 19 NWHOSR-06-04P5-E1 100116

41 30

3

/4 NWHOSR-06-005P-E1 100124

29 19 NWHOSR-06-006P-E1 100132

29 19 NWHOSR-06-006P-E1 100140

41 30

3

/4 NWHOSR-06-010P-E1 100159

Galvanized Body / Water .5 to 40 kW

29 19 NWHSRG-06-018P-E1 100010

29 19 NWHSRG-06-018P-E1 100028

41 30

3

/4 NWHSRG-06-020P-E1 100036

29 19 NWHSRG-06-024P-E1 100044

29 19 NWHSRG-06-024P-E1 100079

41 30

3

/4 NWHSRG-06-040P-E1 100095

A

B

6"

Rotatable

Terminal

Cover

1" Conduit

Opening

Outlet

1" FNPT

Inlet

1" FNPT

1" FNPT Pipe Plug

(or Inlet)

8 / "

1

2

4"

2 Mtg. Lugs

/ "-13 x / " Deep

1

1

2

2

Specifications – Table B

Dim. (In.)

A B Model PCN

Cast Iron Body / Oil .5 to 10 kW

32 19 NWHOSR-06-04P5-E2 100255

32 19 NWHOSR-06-04P5-E2 100263

44 30

3

/4 NWHOSR-06-005P-E2 100271

32 19 NWHOSR-06-006P-E2 100280

32 19 NWHOSR-06-006P-E2 100298

44 30

3

/4 NWHOSR-06-010P-E2 100300

Galvanized Body / Water .5 to 40 kW

32 19 NWHSRG-06-018P-E2 100327

32 19 NWHSRG-06-018P-E2 100343

44 30

3

/4 NWHSRG-06-020P-E2 100351

32 19 NWHSRG-06-024P-E2 100360

32 19 NWHSRG-06-024P-E2 100378

44 30

3

/4 NWHSRG-06-040P-E2 100386

Dimensions (Inches)

A

B

11"

7-7/8"

6"

E1

E2

TM

Page 2

INSTALLATION

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing heater. Failure to do so could

result in personal injury or property damage.

Heater must be installed by a qualified person in

accordance with the National Electrical Code.

NFPA 70.

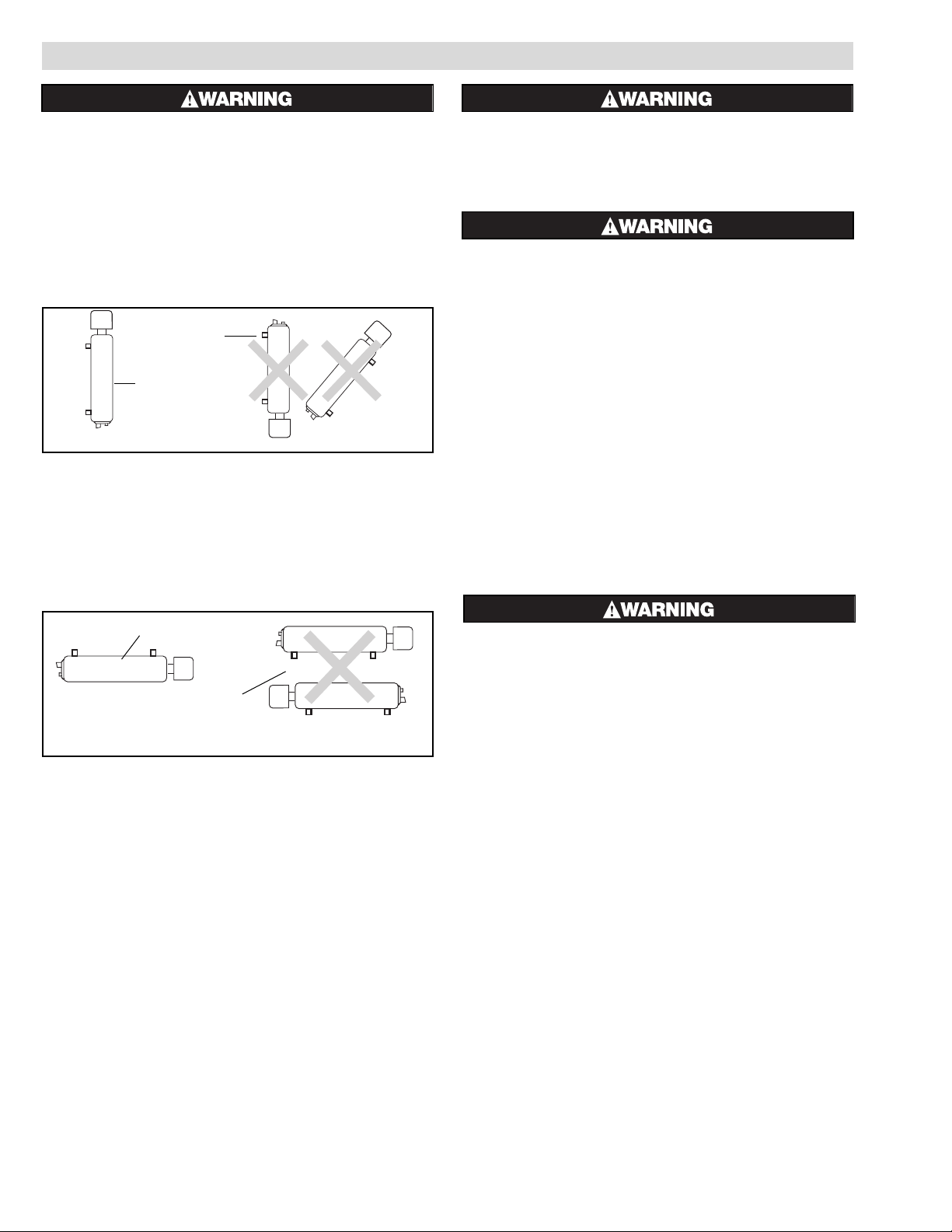

1. Vertical Mounting (Preferred) —

When the heater is vertically mounted, the electrical enclosure

will be at the top of the heater. The inlet pipe will be located on

the side near the bottom of the heater and the outlet pipe at the

top.

The axis of the chamber will be in a vertical position as in

Figure A.

2. Horizontal Mounting (Optional) —

When mounting heater horizontally, inlet and outlet pipes must

be up. In any other position, heater cannot be purged of air, and

elements may be seriously damaged. (See Figure B.)

Note: Heater cannot be completely drained in the horizontal position. When mounting the heater, allow adequate spacing for draining the heater.

3. Whether vertical or horizontal, the heater should be rigidly

mounted so that vibration is at a minimum since excessive

vibration will result in erratic thermostat operation (if thermostat is used instead of thermocouple). The NWHOSR/NWHSRG is provided with mounting lugs to support the heating

chamber. (See drawing on front page.)

FIRE HAZARD. An integral thermostat, if used, is

designed for temperature control service only.

Because the thermostat is not fail safe, it should

not be used for temperature limiting duty. Wiring to

this device is the responsibility of the user.

FIRE HAZARD. Since heaters are capable of developing high temperatures, extreme care should be

taken to:

A. Provide minimum of 6” spacing from chamber

and related piping to nearest combustible material.

B. Do not operate near combustible fluids or in

combustible vapor or gas laden atmosphere.

4. Ensure clearance is available to allow removal of the heating

assembly from the chamber. Generally this is a space extending from the electrical enclosure equal to the length of the

entire unit. Otherwise, removing the entire heater may be

required to service the heater.

5. Standard side inlet can be changed to the end connection for

ease of piping.

6. Mount heaters to permit unrestrained expansion of the chamber

due to temperature. This may be accomplished by using a slotted mounting assembly on either of the mounting lugs.

7. If two or more heaters are required to provide the heating

capacity, pipe units in series or parallel.

EXPLOSION HAZARD. When heating in closed vessels, controls and back-up controls must be used

to regulate build-up of temperature and/or pressure.

8. A pressure relief valve should be provided by customer at out-

let of vessel. There should be no other valving between vessel

and relief valve.

9. Install adequate collection/drainage below the heater to prevent

damage to other materials and property at your location.

Figure B — Horizontal Mounting

Figure A — Vertical Mounting

Correct

Correct

Incorrect

Incorrect

2

Page 3

3

WIRING

ELECTRIC SHOCK HAZARD. Any installation involving electric heaters must be performed by a qualified person and must be effectively grounded in

accordance with the National Electrical Code to

eliminate shock hazard.

Ensure the correct Wiring Guide is used for your

heated medium and model type, and ensure the

correct wiring diagram is used. Miswiring could

result in an unsafe wattage.

1. Be sure line voltage matches your intended voltage and does

not exceed the max voltage on the nameplate.

2. Electric wiring to heater must be installed in accordance with

local and National Electrical Codes by a qualified person as

defined in the NEC.

3. Power controllers must be used with this product.

4. Electrical wiring to heater should be with rigid conduit or flex-

ible conduit to keep corrosive vapors and liquids out of the

electrical enclosure. If high humidity is encountered, the conduit should slope down away from the heater.

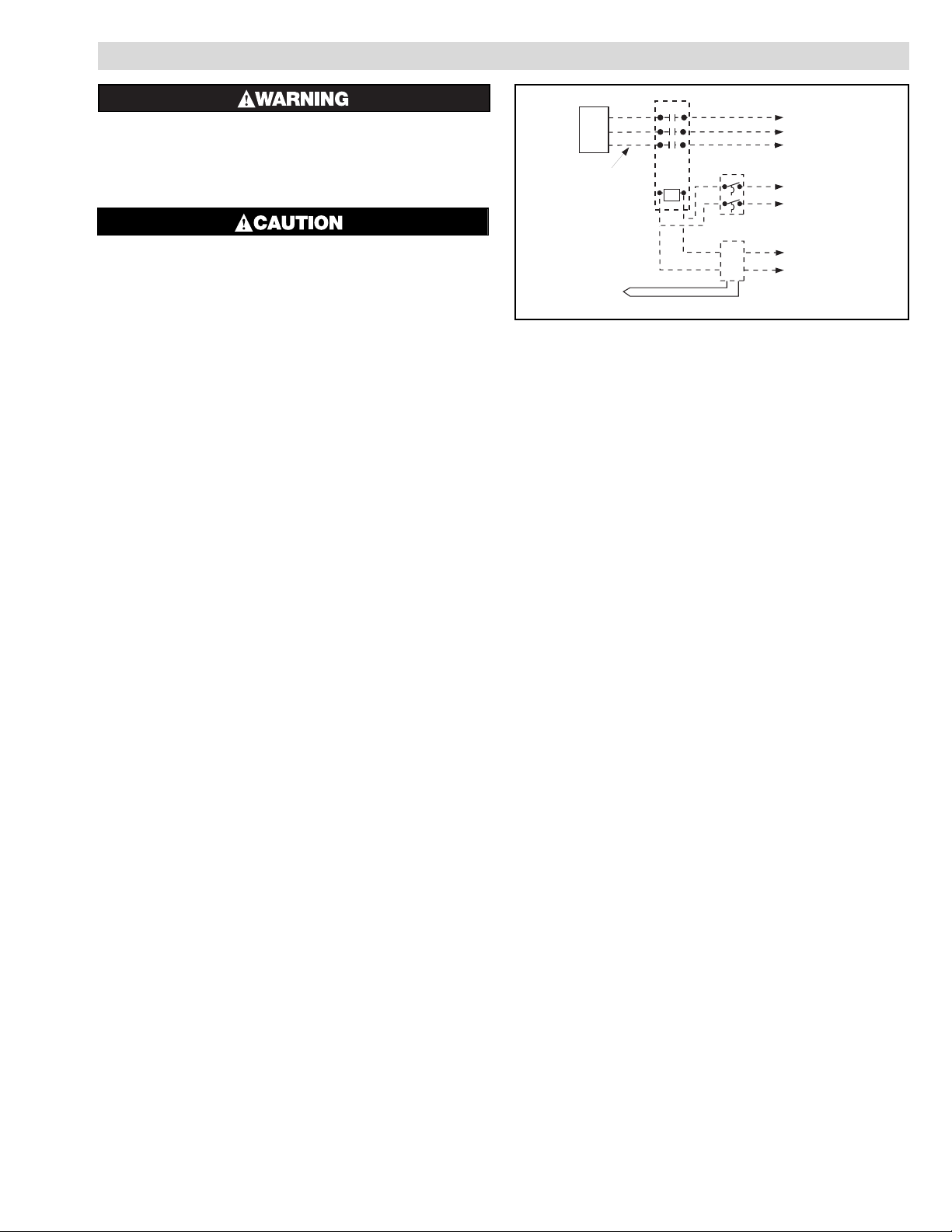

5. Refer to appropriate wiring diagram for your model heater

from the Wiring Guide (on next two pages).

The specific Wiring Guide provides easy to follow steps to

determine the appropriate wiring diagram for your heater installation. Figure 1 may be referenced as a general diagram of how

a contactor and temperature control are used in conjunction

with the specific wiring diagrams.

6. Use ground fault protection equipment where electrical insula-

tion failure can cause process problems.

7. When element wattages are not equal, heaters must not be con-

nected in series.

8. If flexible cord is employed, a watertight connector should be

used for entry of the cord into the electrical enclosure. Outdoor

applications require liquid-tight conduit and connectors.

9. If application uses a standard PCN at different voltages and

kWs from the Wiring Guide, refer to the Customer Wiring

Guide Supplement if included with these instructions, or contact Customer Service at (800) 368-2493.

Note: Dotted lines indicate “customer furnished.” Complete power/temperature

control panels or components are available. Contact Chromalox 1-800-443-2640

for more information and assistance.

Contactor

Thermostat

L1

L2

To equipment disconnect

with overcurrent protection

L1

L2

L3

Heater

1Ø or 3Ø: Refer to wiring

diagram designated from the

the Wiring Guide for specific

wiring directions to

the heater.

or

Temperature control

L1

L2

Thermocouple

}}

Type "J"

thermocouple

is standard.

Control voltage

Figure 1

Page 4

Oil Applications

Approx. Watts

Wiring

Watts-Volts Circuit-Phase (amps) /Sq. In. Diag. #

PCN 100140 (P/N 052-304749-005)

PCN 100298 (P/N 052-304749-305)

.5kW - 240V 1-3Ph (1.3 amps) 2 #6

.75kW - 120V 1-1Ph (7 amps) 5 #13*

.75kW - 208V 1-3Ph (2.1 amps) 5 #12*

1.5kW - 120V 1-1Ph (13 amps) 5 #7

1.5kW - 120V 2-1Ph (2 x 7 amps) 5 #8

1.5kW - 208V 1-3Ph (4.2 amps) 5 #4

1.5kW - 240V 1-1Ph (7 amps) 5 #10

1.5kW - 240V 1-3Ph (3.7 amps) 5 #3

2.25kW - 208V 1-1Ph (11 amps) 15 #13*

2.25kW - 208V 1-3Ph (7 amps) 15 #11*

3.0kW - 240V 1-1Ph (13 amps) 20 #13*

3.0kW - 240V 1-3Ph (8 amps) 20 #11*

4.5kW - 208V 1-1Ph (22 amps) 15 #7

4.5kW - 208V 2-1Ph (2 x 11 amps) 15 #8

4.5kW - 208V 1-3Ph (13 amps) 15 #1

4.5kW - 208V 2-3Ph (2 x 7 amps) 15 #2

6.0kW - 240V 1-1Ph (25 amps) 20 #7

6.0kW - 240V 2-1Ph (2 x 13 amps) 20 #8

6.0kW - 240V 1-3Ph (15 amps) 20 #1

6.0kW - 240V 2-3Ph (2 x 8 amps) 20 #2

6.0kW - 480V 1-1Ph (13 amps) 20 #10

6.0kW - 480V 1-3Ph (8 amps) 20 #3

PCN 100159 (P/N 052-304749-006)

PCN 100300 (P/N 052-304749-306)

2.5kW - 120V 1-1Ph (21 amps) 15 #7

2.5kW - 120V 2-1Ph (2 x 11 amps) 15 #8

2.5kW - 208V 1-3Ph (7 amps) 15 #4

2.5kW - 240V 1-1Ph (11 amps) 15 #10

2.5kW - 240V 1-3Ph (7 amps) 15 #3

10kW - 240V 1-1Ph (42 amps) 21 #7

10kW - 240V 2-1Ph (2 x 21 amps) 21 #8

10kW - 240V 1-3Ph (25 amps) 21 #1

10kW - 240V 2-3Ph (2 x 13 amps) 21 #2

10kW - 480V 1-1Ph (21 amps) 21 #10

10kW - 480V 1-3Ph (13 amps) 21 #3

WIRING GUIDE – OIL (NWHOSR)

Directions:

Step 1: Select the PCN number below which matches the PCN number on your heater.

Step 2: Choose your kW, Volts, phase, and number of circuits under your PCN number (you must know the kW and watt density

(watts/sq. in.) needs for your application).

Step 3: Note the Wiring diagram # for your selection.

Step 4: Go to Wiring Diagram sheet. Peel off the diagram that matches the # in step 3. Stick this to the inside of your electrical enclosure.*

Step 5: Peel off corresponding Volts, circuit-phase, and kW info from the Wiring Diagram sheet and stick to the designated spot on the

nameplate. (These labels will cover the maximum rating stamped on the nameplate.)**

Step 6: Wire Heater according to the sticker on the inside of your electrical enclosure (from step 4).

Oil Applications

Approx. Watts

Wiring

Watts-Volts Circuit-Phase (amps) /Sq. In. Diag. #

PCN 100108 (P/N 052-304749-001)

PCN 100255 (P/N 052-304749-301)

4.5kW - 120V 1-1Ph (38 amps) 15 #7

PCN 100116 (P/N 052-304749-002)

PCN 100263 (P/N 052-304749-302)

1.5kW - 480V 1-3Ph (2 amps) 5 #6

2.5kW - 240V 1-1Ph (11 amps) 15 #13*

2.5kW - 240V 1-3Ph (7 amps) 15 #11*

4.5kW - 240V 1-1Ph (19 amps) 15 #7

4.5kW - 240V 2-1Ph (2 x 10 amps) 15 #8

4.5kW - 240V 1-3Ph (11 amps) 15 #1

4.5kW - 240V 2-3Ph (2 x 6 amps) 15 #2

4.5kW - 480V 1-1Ph (10 amps) 15 #10

4.5kW - 480V 1-3Ph (6 amps) 15 #3

PCN 100124 (P/N 052-304749-003)

PCN 100271 (P/N 052-304749-303)

5.0kW - 120V 1-1Ph (42 amps) 11 #7

5.0kW - 208V 1-3Ph (14 amps) 11 #4

5.0kW - 240V 1-1Ph (21 amps) 11 #10

5.0kW - 240V 1-3Ph (13 amps) 11 #3

PCN 100132 (P/N 052-304749-004)

PCN 100280 (P/N 052-304749-304)

3.0kW - 120V 1-1Ph (25 amps) 20 #13*

3.0kW - 208V 1-3Ph (9 amps) 20 #12*

6.0kW - 120V 1-1Ph (50 amps) 20 #8

6.0kW - 208V 1-3Ph (17 amps) 20 #4

6.0kW - 208V 2-3Ph (2 x 9 amps) 20 #5

4

* Half of the heating elements are used

** For E2, affix to sheet metal on outside of enclosure

Page 5

5

WIRING GUIDE – WATER (NWHSRG)

Directions:

Step 1: Select the PCN number below which matches the PCN number on your heater.

Step 2: Choose your kW, Volts, phase, and number of circuits under your PCN number (you must know the kW and watt density

(watts/sq. in.) needs for your application).

Step 3: Note the Wiring diagram # for your selection.

Step 4: Go to Wiring Diagram sheet. Peel off the diagram that matches the # in step 3. Stick this to the inside of your electrical enclosure.**

Step 5: Peel off corresponding Volts, circuit-phase, and kW info from the Wiring Diagram sheet and stick to the designated spot on the

nameplate. (These labels will cover the maximum rating stamped on the nameplate.)

Step 6: Wire Heater according to the sticker on the inside of your electrical enclosure (from step 4).

Water Applications

Approx. Watts

Wiring

Watts-Volts Circuit-Phase (amps) /Sq. In. Diag. #

PCN 100010 (054-304745-001)

PCN 100327 (054-304745-301)

4.5kW - 120V 1-1Ph (38 amps) 15 #7

9.0kW - 240V 1-1Ph (38 amps) 59 #13*

9.0kW - 240V 1-3Ph (22 amps) 59 #11*

18kW - 240V 2-1Ph (2 x 38 amps) 59 #8

18kW - 240V 1-3Ph (44 amps) 59 #1

18kW - 240V 2-3Ph (2 x 22 amps) 59 #2

PCN 100028 (054-304745-002)

PCN 100343 (054-304745-302)

1.5kW - 480V 1-3Ph (4 amps) 5 #6

2.5kW - 240V 1-1Ph (11 amps) 15 #13*

2.5kW - 240V 1-3Ph (6 amps) 15 #11*

4.5kW - 240V 1-1Ph (19 amps) 15 #7

4.5kW - 240V 2-1Ph (2 x 10 amps) 15 #8

4.5kW - 240V 1-3Ph (11 amps) 15 #1

4.5kW - 240V 2-3Ph (2 x 6 amps) 15 #2

4.5kW - 480V 1-1Ph (10 amps) 15 #10

4.5kW - 480V 1-3Ph (6 amps) 15 #3

9.0kW - 480V 1-1Ph (19 amps) 59 #13*

9.0kW - 480V 1-3Ph (11 amps) 59 #11*

18kW - 480V 1-1Ph (38 amps) 59 #7

18kW - 480V 2-1Ph (2 x 19 amps) 59 #8

18kW - 480V 1-3Ph (22 amps) 59 #1

18kW - 480V 2-3Ph (2 x 11 amps) 59 #2

PCN 100036 (054-304745-003)

PCN 100351 (054-304745-303)

5.0kW - 120V 1-1Ph (42 amps) 11 #7

5.0kW - 208V 1-3Ph (14 amps) 11 #4

5.0kW - 240V 1-1Ph (21 amps) 11 #10

5.0kW - 240V 1-3Ph (13 amps) 11 #3

20kW - 240V 2-1Ph (2 x 42 amps) 80 #8

20kW - 240V 2-3Ph (2 x 25 amps) 80 #2

PCN 100044 (054-304745-004)

PCN 100360 (054-304745-404)

3.0kW - 120V 1-1Ph (25 amps) 20 #13*

3.0kW - 208V 1-3Ph (9 amps) 20 #12*

6.0kW - 120V 1-1Ph (2 x 25 amps) 20 #8

6.0kW - 208V 1-3Ph (17 amps) 20 #4

6.0kW - 208V 2-3Ph (2 x 9 amps) 20 #5

12kW - 240V 1-3Ph (29 amps) 78 #11*

24kW - 240V 3-1Ph (3 x 34 amps) 78 #9

24kW - 240V 2-3Ph (2 x 29 amps) 78 #2

* Half of the heating elements are used

** For E2, affix to sheet metal on outside of enclosure

Water Applications

Approx. Watts

Wiring

Watts-Volts Circuit-Phase (amps) /Sq. In. Diag. #

PCN 100079 (054-304745-005)

PCN 100378 (054-304745-305)

.5kW - 240V 1-3Ph (1.3 amps) 2 #6

.75kW - 120V 1-1Ph (7 amps) 5 #13*

.75kW - 208V 1-3Ph (2.1 amps) 5 #12*

1.5kW - 120V 1-1Ph (13 amps) 5 #7

1.5kW - 120V 2-1Ph (2 x 7 amps) 5 #8

1.5kW - 208V 1-3Ph (4.2 amps) 5 #4

1.5kW - 240V 1-1Ph (7 amps) 5 #10

1.5kW - 240V 1-3Ph (3.7 amps) 5 #3

2.25kW - 208V 1-1Ph (11 amps) 15 #13*

2.25kW - 208V 1-3Ph (7 amps) 15 #11*

3.0kW - 240V 1-1Ph (13 amps) 20 #13*

3.0kW - 240V 1-3Ph (8 amps) 20 #11*

4.5kW - 208V 1-1Ph (22 amps) 15 #7

4.5kW - 208V 2-1Ph (2 x 11 amps) 15 #8

4.5kW - 208V 1-3Ph (13 amps) 15 #1

4.5kW - 208V 2-3Ph (2 x 7 amps) 15 #2

6.0kW - 240V 1-1Ph (25 amps) 20 #7

6.0kW - 240V 2-1Ph (2 x 13 amps) 20 #8

6.0kW - 240V 1-3Ph (15 amps) 20 #1

6.0kW - 240V 2-3Ph (2 x 8 amps) 20 #2

6.0kW - 480V 1-1Ph (13 amps) 20 #10

6.0kW - 480V 1-3Ph (8 amps) 20 #3

12kW - 480V 1-1Ph (25 amps) 78 #13*

12kW - 480V 1-3Ph (15 amps) 78 #11*

24kW - 480V 2-1Ph (2 x 25 amps) 78 #8

24kW - 480V 1-3Ph (29 amps) 78 #1

24kW - 480V 2-3Ph (2 x 15 amps) 78 #2

PCN 100095 (054-304745-006)

PCN 100386 (054-304745-306)

2.5kW - 120V 1-1Ph (21 amps) 15 #7

2.5kW - 120V 2-1Ph (2 x 11 amps) 15 #8

2.5kW - 208V 1-3Ph (7 amps) 15 #4

2.5kW - 240V 1-1Ph (11 amps) 15 #10

2.5kW - 240V 1-3Ph (7 amps) 15 #3

10kW - 240V 1-1Ph (42 amps) 21 #7

10kW - 240V 2-1Ph (2 x 21 amps) 21 #8

10kW - 240V 1-3Ph (25 amps) 21 #1

10kW - 240V 2-3Ph (2 x 13 amps) 21 #2

10kW - 480V 1-1Ph (21 amps) 21 #10

10kW - 480V 1-3Ph (13 amps) 21 #3

20kW - 480V 1-1Ph (42 amps) 80 #13*

20kW - 480V 1-3Ph (25 amps) 80 #11*

40kW - 480V 2-1Ph (2 x 42 amps) 80 #8

40kW - 480V 2-3Ph (2 x 25 amps) 80 #2

Page 6

6

WIRING

120V

208V

240V

480V

.5kW

1.5kW

2.5kW

4.5kW

6.0kW

10.0kW

STEP 5: PEEL OFF THE APPROPRIATE VOLTS, CIRCUIT-PHASE,

AND kW, AND AFFIX TO NAMEPLATE.

STEP 4: PEEL OFF APPROPRIATE WIRING DIAGRAM AND AFFIX TO INSIDE OF ELECTRICAL ENCLOSURE.

#1

#2

#3

#4

#5

#6

#7

#8

#9

#10

#11

#12 #13

NOTES

1. ALL WIRES MARKED 1L1, 2L1, 1L2, ETC. ARE CUSTOMER SUPPLIED CONNECTIONS.

2. ALL WIRES MUST BE CAPPED.

1 CIRCUIT – 3ø (1–3PH)

2 CIRCUIT – 3ø (2–3PH)

L1 L2 L3

YELLOW

BLUE

BROWN

BLACK

ORANGE

RED

BROWN

BLACK

YELLOW

BLUE

ORANGE

RED

1L1

B

ROWN

BLUE

1L2

ORANGE

BLUE

1L3

ORANGE

BROWN

2L1

YELLOW

BLACK

2L2

YELLOW

RED

2L3

BLACK

RED

BLACK

BLUE

BROWN

YELLOW

RED

ORANGE

L1

YELLOW

ORANGE

L2

RED

BLUE

L3

BLACK

BROWN

1L1

BLUE

1L2

ORANGE

1L3

BROWN

2L3

RED

2L2

YELLOW

2L1

BLACK

RED

YELLOW

BLACK

YELLOW

BRO

W

N

ORANGE

B

LUE

BROWN

ORANG

E

NEUTRAL NEUTRAL

1

2

NEUTRAL

L3

RED

L2

BLUE

L1

BLAC

K

BLACK

BROW

N

BLUE

ORANGE

RED

YELLO

W

L3

RED

ORANG

E

L2

BROWN

YELLOW

L1

BLACK

BLUE

ORANG

E

YELLOW

BLUE

BROWN

BLACK

RED

ORANGE

BROWN

BLACK

1L2 2L1

2L2

1L1

YELLOW

BLUE

RED

YELLOW

BLUE

RED

ORANG

E

BROW

N

BLACK

ORANGE

B

ROWN

BLACK

L1 L2

YELLOW

BLUE

RED

ORANGE

BROWN

BLACK

YELLOW

BLUE

RED

3L1

B

LACK

RED

3L2

BLACK

RED

1L1

B

ROWN

ORANG

E

1L2

BROWN

ORANG

E

2L1

YELLOW

BLUE

2L2

YELLOW

BLUE

BLACK

RED

BROWN

ORANGE

BLUE

YELLOW

1L2

RED

BLUE

ORANGE

1L1

YELLOW

B

LACK

BROWN

1L1

BROW

N

BLUE

1L2

ORANG

E

BLUE

1L3

ORANG

E

BROW

N

YELLOW

BLACK

YELLOW

RED

BLACK

RED

1L1

BLUE

1L2

ORANGE

1L3

BROW

N

RED

YELLOW

BLACK

RED

YELLOW

BLACK

BLUE

BROWN

ORANGE

NEUTRAL NEUTRAL

1

ORANGE

BROW

N

BLACK

1L21L1

YELLOW

BLUE

RED

YELLOW

BLUE

RED

ORANG

E

BROWN

BLACK

NEUTRAL

1-1PH

2-1PH

3-1PH

1-3PH

2-3PH

.75kW

2.25kW

3.0kW

5.0kW

9.0kW

12kW

18kW

20kW

24kW

40kW

1 CIRCUIT – 3ø (1–3PH)

1 CIRCUIT – 3ø (1–3PH) 2 CIRCUIT – 3ø (2–3PH) 1 CIRCUIT – 3ø (1–3PH)

1 CIRCUIT – 1ø (1–1PH) 2 CIRCUIT – 1ø (2–1PH) 3 CIRCUIT – 1ø (3–1PH)

1 CIRCUIT – 1ø (1–1PH) 1 CIRCUIT – 3ø (1–3PH) 1 CIRCUIT – 3ø (1–3PH) 1 CIRCUIT – 1ø (1–1PH)

SPARES

}

SPARES

}

SPARES

}

2

LIMITED FOR

USE ON WATER

APPLICATIONS

ONLY

{

Sample page of Wiring Diagram Labels. Please apply actual labels to your product.

Before applying rating labels - refer to wiring instructions. Incorrect

wiring could result in an unsafe wattage

Page 7

OPERATION

Important: NWHOSR/NWHSRG Circulation Heaters

are equipped with INCOLOY

®

heating elements and

cast iron heating chambers (galvanized for the

NWHSRG). It is the responsibility of the purchaser of

the heater to know the chemical composition of the

corrosive solution and the character of the materials entering the solution as well as the corrosive

effect of the solution upon the heating elements

and chamber.

Sheath corrosion can result in a ground fault which

depending upon the solution being heated, can

cause an explosion or fire.

If the heater is not properly submerged, the heating elements will overheat and could result in a fire

or damaged equipment.

1. Do not heat solutions that are corrosive to the heating element

sheath or the heating chamber.

2. Terminal ends of heater must be protected from drippings, con-

densation, spray or direct spill-over of material. Their presence

at the terminals may damage heater electrical insulation.

3. If foreign material is carried by the liquid flow, install suitable

filters in the inlet pipeline to the heater. Liquid flow to the

heater should be free of suspended solids.

4. Do not allow heater to operate when liquid flow is interrupted.

5. The NWHSRG/NWHOSR is designed as a flow through

heater. The chamber must be full for safe operation.

PRE-OPERATION

1. Follow the instructions for operation of your application.

Ensure your procedure includes:

A. Make sure all electrical and piping connections are tight.

B. Remove all air from the heater and piping.

MAINTENANCE

ELECTRIC SHOCK HAZARD. Disconnect all power

before servicing heater. Failure to do so could

result in personal injury or property damage.

Heater must be serviced by a qualified person in

accordance with the National Electrical Code.

NFPA 70.

1. Remove heating element assembly periodically to check heater

sheath for sealing, corrosion or excessive oxidation. Correct

operating conditions to minimize sheath deterioration. Refer to

warnings in operation section.

2. Drain heater periodically to remove sludge deposit. Deposits

can act as an insulator and shorten heater life.

Note: User is responsible for maintenance schedule based on

their knowledge of the heated medium and operating conditions.

3. Periodically check temperature control operation to insure

accurate and safe process operation.

4. Check all electrical connections periodically and retighten connections which may have loosened in service. Replace wire

and wire terminals which show signs of oxidation which would

interfere with establishment of reliable electrical connections.

5. Correct any excessive leaking. Also refer to the last step in the

installation section regarding adequate collection/drainage.

6. Reinstallation steps.

A. Reseal thread fittings with adequate seal material for the

pressure/temperature rating on your heater.

B. Refer to the pre-operation section.

7

Page 8

00-003

TA - U0 - ?K

Litho in U.S.A.

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

RENEWAL PARTS IDENTIFICATION

Description Standard PCN

Replacement

Immersion Heater

NWHOSR-06-04P5-E1 100108 156-304748-001

NWHOSR-06-04P5-E1 100116 156-304748-002

NWHOSR-06-005P-E1 100124 156-304748-003

NWHOSR-06-006P-E1 100132 156-304748-004

NWHOSR-06-006P-E1 100140 156-304748-005

NWHOSR-06-010P-E1 100159 156-304748-006

NWHSRG-06-018P-E1 100010 156-304748-001

NWHSRG-06-018P-E1 100028 156-304748-002

NWHSRG-06-020P-E1 100036 156-304748-003

NWHSRG-06-024P-E1 100044 156-304748-004

NWHSRG-06-024P-E1 100079 156-304748-005

NWHSRG-06-040P-E1 100095 156-304748-006

NWHOSR-06-04P5-E2 100255 156-304748-301

NWHOSR-06-04P5-E2 100263 156-304748-302

NWHOSR-06-005P-E2 100271 156-304748-303

NWHOSR-06-006P-E2 100280 156-304748-304

NWHOSR-06-006P-E2 100298 156-304748-305

NWHOSR-06-010P-E2 100300 156-304748-306

NWHSRG-06-018P-E2 100327 156-304748-301

NWHSRG-06-018P-E2 100343 156-304748-302

NWHSRG-06-020P-E2 100351 156-304748-303

NWHSRG-06-024P-E2 100360 156-304748-304

NWHSRG-06-024P-E2 100378 156-304748-305

NWHSRG-06-040P-E2 100386 156-304748-306

Parts Common To All PCNs

Thermocouple 12” (Type “J”) . . . . . . . . . . . . . . . . . . . . . .309-304460-012

Thermocouple 24” (Type “J”) . . . . . . . . . . . . . . . . . . . . . .309-304460-024

Bayonet Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .001-027343-007

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...