Page 1

Chromalox

®

DIVISION 4 SECTION

GTF

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation Instructions

PD444-2

161-562652-001

DECEMBER, 2004

(Supersedes PD444-1)

© 2010 Chromalox, Inc.

GENERAL

FIRE/EXPLOSION HAZARD: This heater is not

intended for use in hazardous atmospheres where

flammable vapors, gases, liquids, or other combustible atmospheres are present as defined in

the National Electrical Code. Failure to comply can

result in explosion or fire.

Chromalox type GTF series of Teflon

®

over-the-side immersion heaters are especially suited for most plating tank and other

corrosive solutions. It is inert to acid baths, anodizing and picking

operations up to 212˚F solution temperatures.

Sheath corrosion can result in a ground fault

which, depending upon the solution being heated,

can cause an explosion or fire.

IMPORTANT: It is the responsibility of the purchaser of the heater to make the ultimate choice

of sheath material based upon his knowledge of

the chemical composition of the corrosive solution, character of the materials entering the solution, and controls which he maintains on the

process. Chromalox cannot warrant any electric immersion

heater against failure by sheath corrosion if such failure is the

result of operating conditions beyond our control.

1. Heater Construction Characteristics

A. High quality resistance wire held in place by compacted mag-

nesium oxide in stainless steel sheath and Teflon

®

covered.

B. Low watt density.

C. Grounded construction.

D. Over-temperature protection.

E. Epoxy filled, vapor tight, plastic terminal enclosure prevents

entry of contaminants.

F. Flexible conduit 3’ long with 6” leadwire extension is stan-

dard.

The system designer is responsible for the safety

of this equipment and should install adequate

back-up controls and safety devices with their

electric heating equipment. Where the consequences of failure could result in personal injury

or property damage, back-up controls are essential.

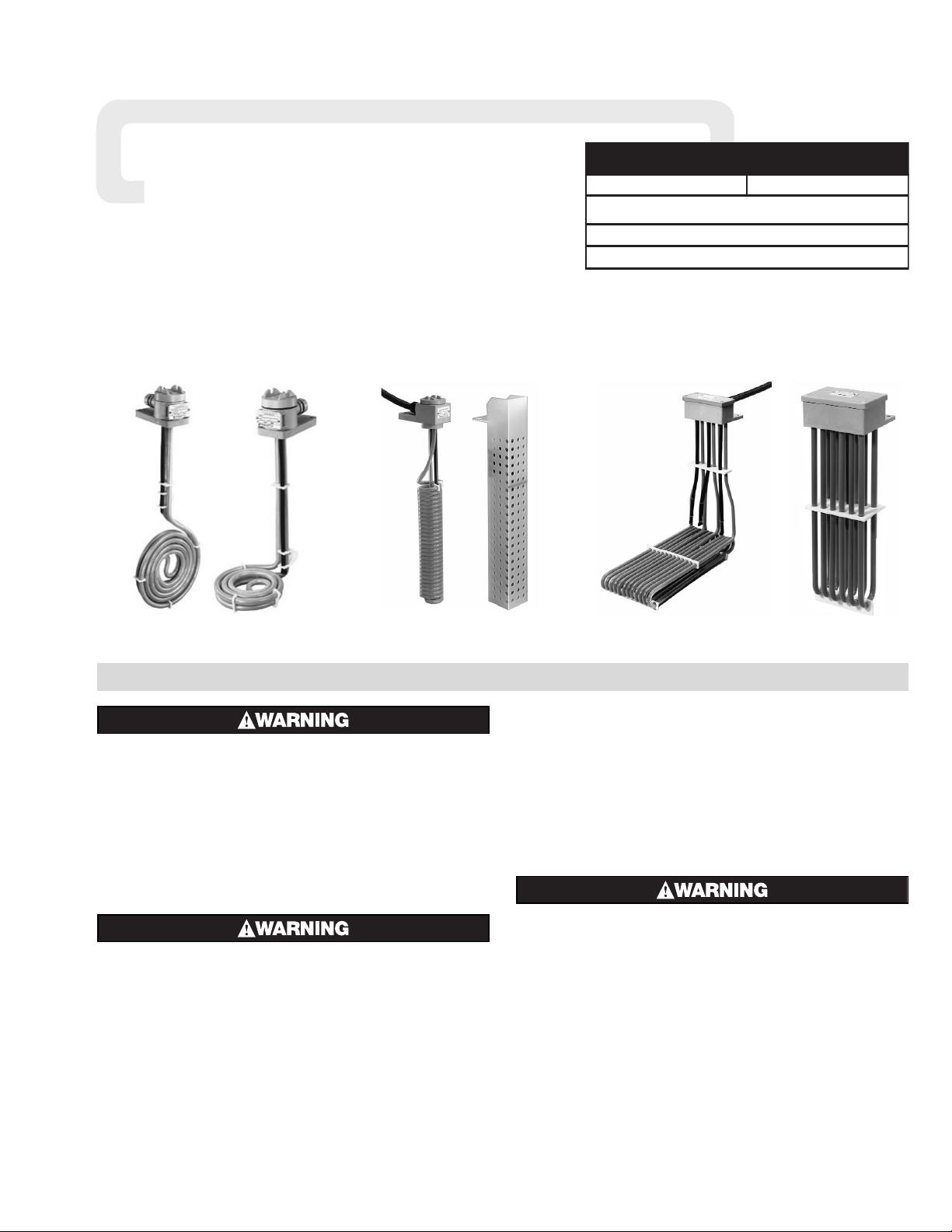

Chromalox®Type GXF/GTF/GTFL Series

Grounded Teflon®Immersion Heaters

GTFL3

GTF6

* Teflon®is a registered trademark of DuPont Co.

GTFGXF/GXFL

Page 2

WIRING

ELECTRIC SHOCK HAZARD. Any installation

involving electric heaters must be performed by a

qualified person and must be effectively grounded

in accordance with the National Electrical Code to

eliminate shock hazard.

1. Electrical wiring to heater must be installed in accordance with

the National Electrical Code and local electrical codes by a qualified person.

2. When element wattages are not equal, heaters must not be con-

nected in series.

3.

Under no condition should the conduit be cut shorter, or fumes will

enter the cable and will be drawn into the heater and condense

inside. The wiring will then be attacked and will shorten heater life.

4. Tamperproof wiring — epoxy imbedded prevents field rewire of

individual elements.

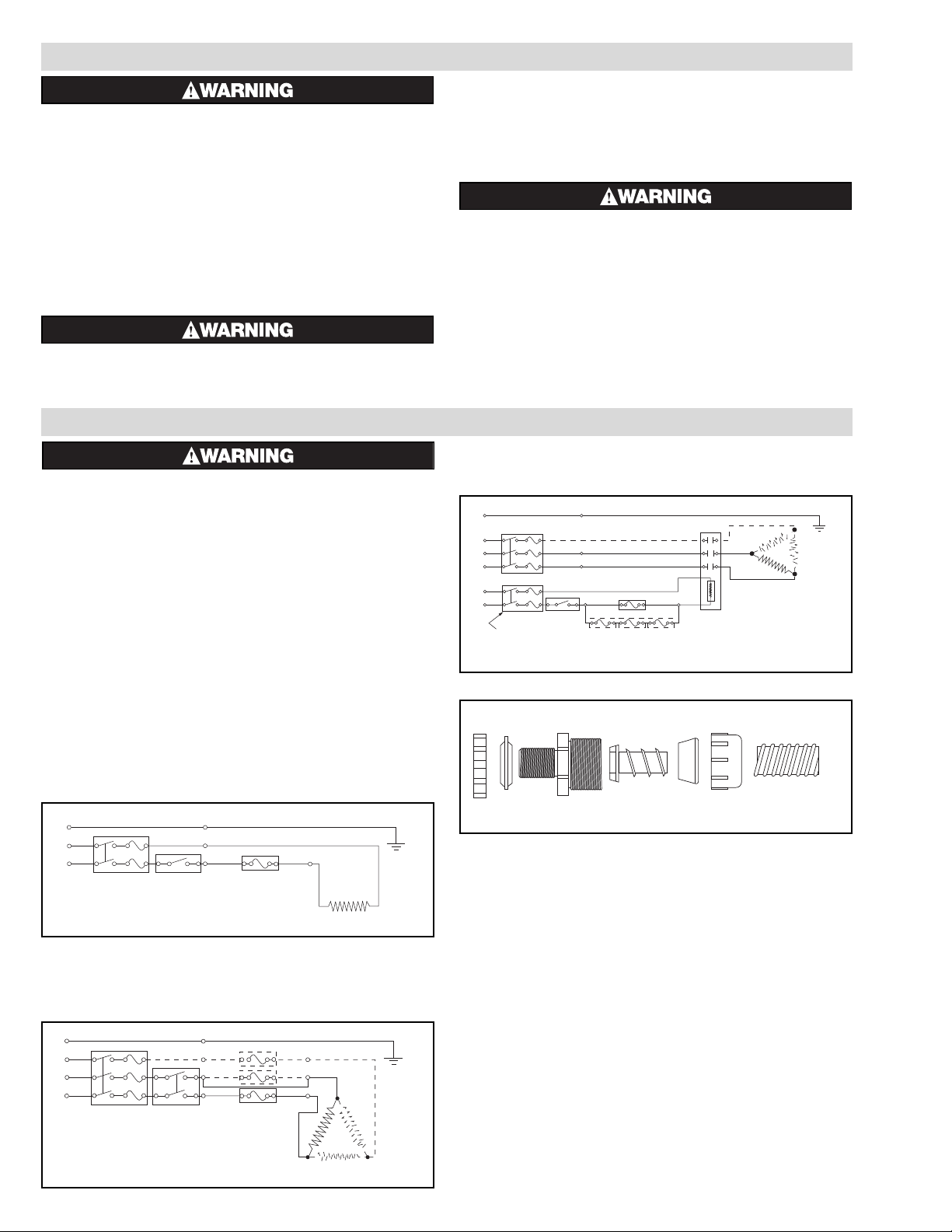

Representative wiring diagrams for heaters with Single use

fuse (F) or Resetable fuse (RF) —

Single phase heater circuit using a SPST thermostat. Line Voltage

and/or current do not exceed thermostat or thermal fuse rating

(Figure 3).

One Single phase heater or (3) single phase heaters equal in size

and each having a thermal fuse wired as a 3 phase heater circuit

using a DPST thermostat. Line voltage and current do not exceed

thermostat or thermal fuse(s) rating (Figure 4). Dotted line and L3

indicates 3 phase connections.

Single phase or 3 phase heater circuit. Line voltage and/or current

exceeds thermostat or thermal fuses ratings (Figure 5). Dotted

line and L3 indicates 3 phase connections.

Flexible Conduit Fittings —

1. Cut conduit. Slide nut and sealing insert onto the conduit.

2. Screw the ferrule insert into one end of the flexible conduit.

3. Seat the ferrule insert inside of the body, seat the sealing insert

and hand tighten the cap onto the body.

4. Repeat steps 1 thru 3 above for the other end of the conduit after

pulling the wires.

5. If the fitting is used in a threaded hole, first thread the body into

the hole then follow steps 1 thru 3.

6. If the fitting is used thru an opening* use the locknut and plastic

washer to fasten it.

* Opening for 1/2” NPT thread is 7/8”.

Ground

L2

Thermostat

Thermal Fuses

Black

Black

Green

Fused

Disconnect

(Customer Supplied)

*

*

*

*

*

*

L3

L1

Heater

Black

Figure 4

Ground

L2

L1

Thermostat

Thermal Fuse

Heater

Black

Black

Green

Fused

Disconnect

(Customer Supplied)

**

Figure 3

Fused Disconnect

(Customer Supplied)

Ground

L3

L2

L1

L2

L1

*

*

Thermostat

Thermal Fuses

Magnetic

Contactor

Black

Black

Heater

Black

Green

Figure 5

Locknut

Washer

Body

Ferrule

Insert

Sealing

Insert

Nut

Conduit

INSTALLATION

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do so

could result in personal injury or property damage.

Heater must be installed by a qualified person in accordance with the National Electrical Code, NFPA 70.

1. Before installing the type GTF heater, inspect it for possible dam-

age which may have occurred during shipment. Also, check to

insure that the line voltage is the same as that stamped on the

nameplate.

2.

IMPORTANT: Mount heater in the tank so the

liquid level will always be above the effective

heated portion of the heater. Provide expansion

tank if necessary.

FIRE HAZARD. If the heater is not properly submerged, the heating elements will overheat and

could result in a fire or damaged equipment.

3. Where work will pass over or near equipment, additional protec-

tion such as a guard, may be needed.

4. In an electroplating operation the heaters are not, under any cir-

cumstance, to be placed between the electrodes and the work.

5. A drip loop is recommended to minimize passage of moisture

along wiring into terminal box and connections.

FIRE HAZARD. Since heaters are capable of developing high temperatures, extreme care should be

taken to:

A. Avoid contact between heater and combustible material.

B. Keep combustible materials far enough away to be free of the

effects of high temperatures.

Page 3

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed by a qualified person in accordance with the National Electrical

Code, NFPA 70.

The Thermal fuse device must be properly installed and these

procedures followed or heater failure or fire may result.

A liquid level control is a must as an additional safety feature

to help minimize the possibility of fire.

1. Make sure all electrical power to the heater is shut-off.

2. Unscrew the head cover. Remove the wire nuts from the fuse

leads and save for re-use.

3. Remove the “Sealing Putty” and pull the Thermal fuse out of its

well. Clean the “putty” out of the well and save for re-use.

4. Check the Thermal fuse and the inside of the well to see if it is

wet. If wet inside, dry out well. Immerse the tube into the solution. If moisture appears again inside the well DO NOT use the

heater! Call the factory for further advice.

5. If the removed Thermal fuse is dry, proceed by using it as a guide

to cut and strip the wires of the new Thermal fuse.

6. Re-connect the Thermal fuse leads to the extension leads using

the original wire nuts.

7. Re-insert the Thermal fuse into the well making sure it is “fully

seated” to the bottom of the well.

8. Re-seal using the original “sealing putty” or an RTV type sealant.

9. Replace the head cover, return the heater to the tank.

10. Turn the power back on.

Thermal Fuse Temperature System —

Be sure and satisfied that your process bath tanks are as well

protected as possible from tank leaks, excessive evaporation, tank

refill failures, and worker error.

Grounded Electric Immersion Heaters are practical, efficient

and safe when used properly and installed in tanks that have

proper solution levels. Good ventilation, trained operators and

safeguards such as liquid level controls and Thermal fuse overtemperature sensors.

Thermal fuse systems help reduce the hazards created by low

liquid levels and when properly seated and wired, they will cut

off the power to the heaters, thus avoiding the extreme temperatures resulting if solution levels are low enough to expose heater

hot zones.

Single Use Fuse (F) —

Sensor consists of a one-time thermal fuse sensor which is

standard on all GTF over-the-side heaters.

The F thermal fuse is wired in series with the controller. To

operate properly the fuse must be fully seated to the bottom of the

thermowell tube. When the fuse “blows”, shut off the main power

to the heater, remove the spent fuse and install the new fuse.

Refill the tank to the proper level prior to turning power back on.

Replacement thermal devices must be purchased from

Chromalox

®

.

Resettable Fuse (RF) —

Sensor consists of a Bi-metallic thermostatic sensor, an audible alarm, alarm relay, and reset button.

The RF System operates on the same principle as the F

except that the sensor does not “blow”. It operates as a Bi-metallic thermostat which “opens” and sounds the alarm. The reset button must be pushed to re-activate the heater and control, after the

solution level in the tank has been raised to the proper level.

FIRE/SHOCK HAZARD: Before replacing fuse,

make sure the cause of the “failure” has been

detected and corrected.

OPERATION

1. Do not operate heater at voltages in excess of that stamped on the

heater since excess voltage will shorten heater life.

2. Always maintain a minimum of 2” of solution above the heated

portion of the element to prevent exposure of the effective heated

length. If the heater is not properly submerged, it may overheat

and shorten heater life. Do not operate heater if dry.

3. Sludge should not be allowed to build-up to the point where it

contacts heater as this can lead to premature heater failure.

Heater must not be operated in sludge.

4. In an electroplating operation the heaters are not, under any cir-

cumstances, to be placed between the electrodes and the work.

MAINTENANCE

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed by a qualified person in accordance with the National Electrical

Code, NFPA 70.

1. Heaters should be checked periodically for coating and corrosion

buildup and cleaned if necessary.

2. Tank should be checked regularly for sediment around the end

of heater as this sediment can act as an insulation and shorten

heater life.

3. Note: Before Teflon heater is removed from solution, it should be

allowed to cool from 15 to 20 minutes.

THERMAL FUSE INSTALLATION/REPLACEMENT

Page 4

TA - Q0 - EF

Litho in U.S.A.

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

Model Number Used On

FT

RFT

Std. Teflon

®

Heaters

FLT

RFLT

L- Shaped Teflon

®

Heaters

F Amp Capacity - 25 Amps; RF Amp Capacity - 5 Amps;

Blank (low) Temp = 180˚F

Low temp. most common for this style heater.

RF sensors require additional Control Components which include a Relay,

Audible Alarm, and Manual Reset Pushbutton.

Specify 120 or 240V when ordering.

For process temperatures above 180˚F, consult factory.

Thermal Fuse Replacement Protection Devices

THERMAL FUSE INSTALLATION/REPLACEMENT (con’t.)

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...