Page 1

Immersion

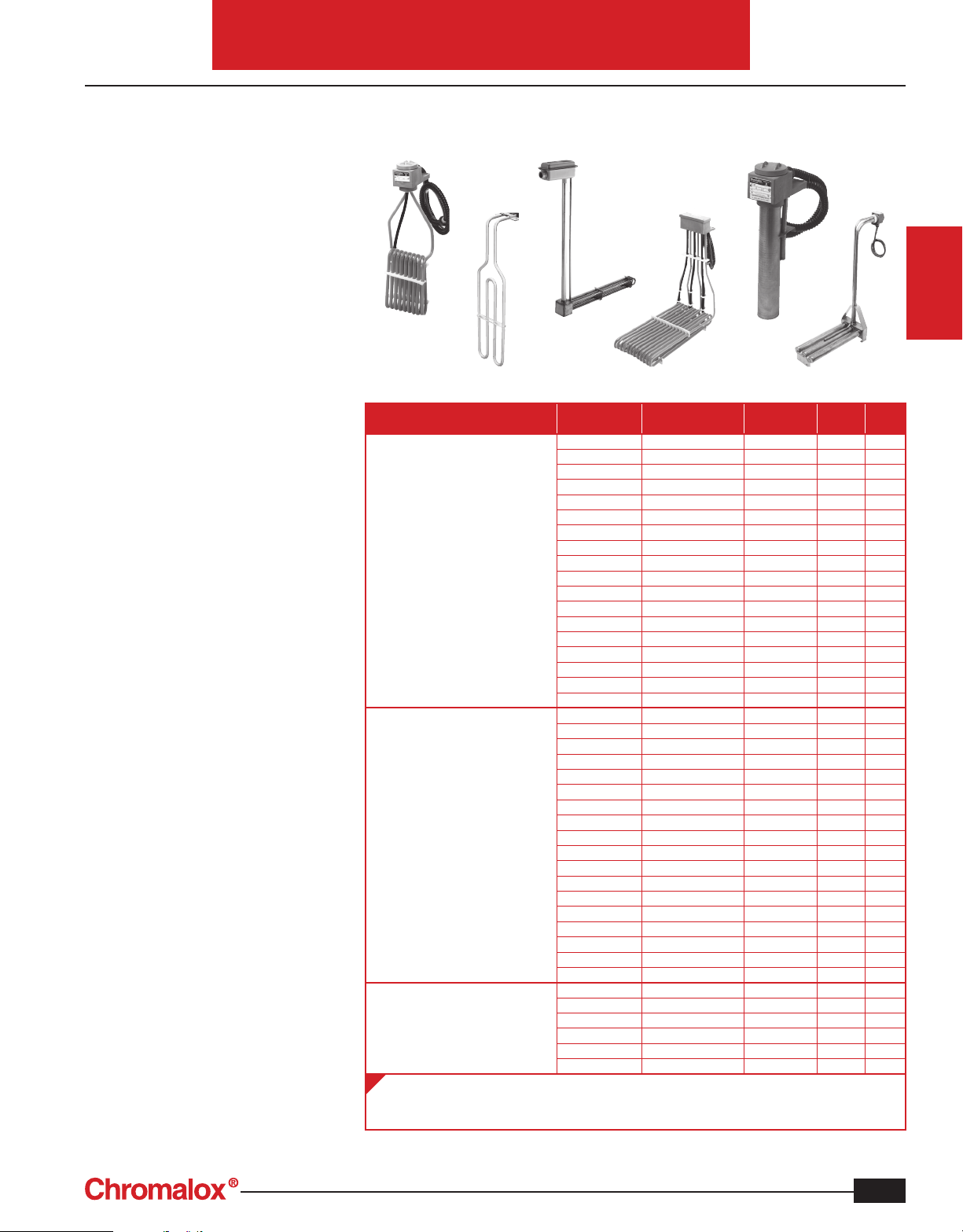

Over-the-Side Immersion Heaters

Overview

Description

Over-the-Side Immersion Heaters are

designed for installing in the top of a tank

with the heated portion directly immersed

along the side or at the bottom. This

provides easy removal of the heater and

ample working space inside the tank.

These heaters are available with heating

elements made of Copper, Steel, Stainless

Steel, Cast Iron, INCOLOY

®

, Titanium,

Fluoropolymer coated, and Quartz. A

wide selection of kW ratings, shapes and

mounting methods are available to suit

many different types of applications.

Over-the-Side Immersion Heaters — Selection Guidelines

Configuration Model

L-Shaped

This type of heater puts the

heat at the bottom of the tank.

The vertical riser is unheated so

lower liquid levels are acceptable. Many types of heating

element materials are available

along with various riser heights

and element congurations.

Legs are provided at the bottom

of most heaters to prevent direct

contact of the heating elements

with the bottom of the tank.

Side Mount/Top Mount

This heater is placed on the side

of the tank with mounting brackets for easy installation. A cold

section is provided at the top of

the heater for various levels of

liquid in the tank (consult heater

specication tables for the specic length of the cold section).

Low prole side mounted heat-

ers provide more working space

in the heated tank.

Heat/Cool Exchangers

Side mounted metal or uoro-

polymer coils provide heat or

cooling of tanks from remote

mounted heating or cooling

sources.

1. Optional Integral Thermostat - requires wiring to remote relay (not included).

2. Integral Overheat Thermal Protection - requires wiring to remote relay (not included).

3. Integral Thermostat and Cutout.

KBLS 304SS 11 1 1

TLS, KTLS 304SS 40 1 or 3 1

GSL 316SS 20 and 40 1 2

GSL3, GSV3 316SS 20 and 40 3 2

CIT Cast Iron 20 1 —

TLC, KTLC Copper 40 1 or 3 1

TBL INCOLOY

TLI INCOLOY

KTLI INCOLOY

KBLC Steel 11 1 1

TBL Steel 20 1 —

TLO, KTLO Steel 20 1 or 3 1

BLCK-MH Steel 12 and 18 1 or 3 1

BLCS Steel 12 and 18 1 or 3 —

GTFL, GXFL Fluoropolymer 10 1 2

GTFNL3 Fluoropolymer 10 3 2

GTL Titanium 20 and 40 1 2

GTL3, GTV3 Titanium 20 and 40 3 2

PTHF 304SS 20 3 2

CTSS 304SS 25 and 40 1 —

PTH 316SS 30 1 —

GS 316SS 20 and 40 1 2

GS3 316SS 20 and 40 1 or 3 2

CTAC Carp 20 SS 25 and 40 1 —

CS Ceramic-SiAlON 70 1 - 3 —

CH-OTS Copper 60 1 3

CTC Copper 25 and 40 1 —

QM Quartz 25 1 2

QM3 Quartz 25 1 or 3 2

GTF, GXF Fluoropolymer 10 1 2

GTF6, GTF9 Fluoropolymer 10 3 2

TPR Fluoropolymer 20 1 2

TPF Fluoropolymer 20 3 2

PTHT Titanium 20 1 —

CTT Titanium 44 1 —

GT Titanium 20 and 40 1 2

GT3 Titanium 20 and 40 1 or 3 2

GHTF Fluoropolymer N/A N/A —

GRS 316SS N/A N/A —

GRT Titanium N/A N/A —

US 316SS N/A N/A —

UT Titanium N/A N/A —

Sheath

Material

over-the-side

Typ. Watt

Density Phase

®

®

®

20 1 —

40 1 or 3 1

40 1 1

See

Note

B-115

Loading...

Loading...