Page 1

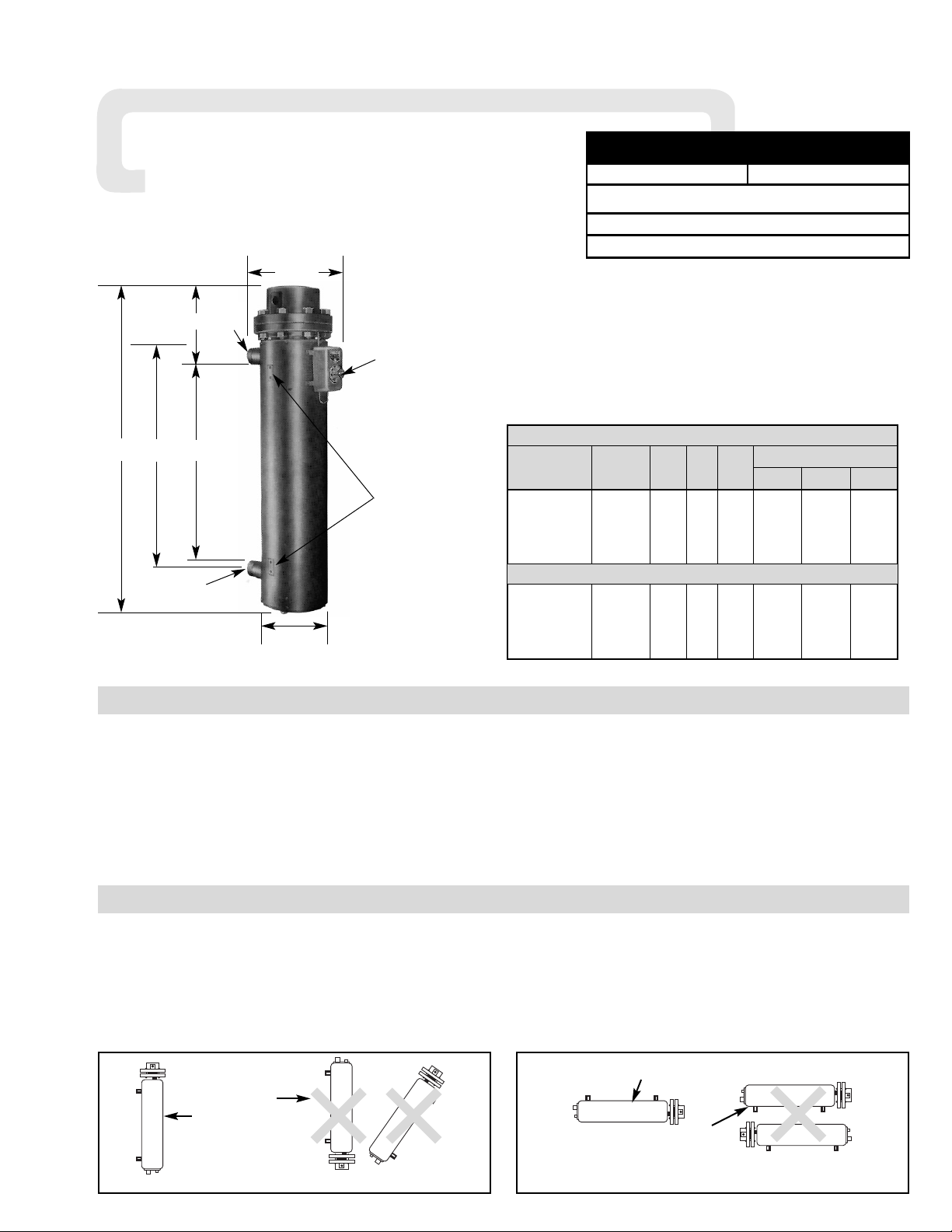

Regular Oil Heaters

Dimensions (In.)

Model Volts Phase kW W/In

2

ABC

NWHO-61215 240 or 480 3 Δ 12 23 41-3/4 30 11-3/8

NWHO-61515 240 or 480 3 Δ 15 23 48-3/4 37 14-1/8

NWHO-62015 240 or 480 3 Δ 20 23 60-1/4 48-1/2 20-5/8

NWHO-62515 240 or 480 3 Δ 25 23 73-5/8 61-7/8 27-5/16

NWHO-63015 240 or 480 3 Δ 30 23 86-5/8 74-7/8 33-7/8

NWHO-60825 240 or 480 1 or 3 Δ 8 15 41-3/4 30 11-3/8

NWHO-61025 240 or 480 3 Δ 10 15 48-3/4 37 14-1/8

NWHO-61225 240 or 480 3 Δ 12 15 60-1/4 48-1/2 20-5/8

NWHO-61525 240 or 480 3 Δ 15 15 73-5/8 61-7/8 27-5/16

NWHO-61825 240 or 480 3 Δ 18 15 86-5/8 74-7/8 33-7/8

Chromalox

®

DIVISION 4 SECTION

NWHO

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation Instructions

and

RENEWAL PARTS IDENTIFICATION

PE408-4

JULY, 1990

(Supersedes PE408-3)

161-048341-001

GENERAL

INSTALLATION

© 2010 Chromalox, Inc.

Type NWHO-6

Circulation Heaters (for

Regular and Fuel Oil Heating)

The NWHO-6 series is a general-purpose regular and fuel oil

solution circulation heater intended for use indoors. It is designed

for 150 psig at 550˚F per ANSI standards.

The 6 steel-sheathed tubular elements are centered in a 5”

diameter galvanized steel heating chamber and welded to a

removable galvanized steel flange. The assembly is surrounded

by 1-1/2” insulation and sheet metal jacket.

Depending upon the order specifications, the NWHO-6 may

or may not be factory equipped with an AR or other Chromalox

thermostat. (Note: UL listed models are factory pre-set with a

212˚F limit stop.) Such thermostats function to control outlet temperatures and to limit internal temperatures under abnormal flow

conditions. These controls do not fail safe.

WARNING: Users should install adequate back-up controls and safety devices with their electric heating equipment. Where the consequences of failure may be severe,

back-up controls are essential. Although the safety of the

installation is the responsibility of the user, Chromalox

will be glad to make equipment recommendations.

Caution: Hazard of Electric Shock. Disconnect all

power before installing heater.

1. Vertical Mounting (Preferred) —

When the heater is vertically mounted, the terminal housing will

be at the top of the heater. The inlet pipe will be located on the side

near the bottom of the heater and the outlet pipe at the top.

The axis of the chamber will be in a vertical position as in the

photo above and as in Figure A.

Note: A drain pipe located at the bottom of the heater should be provided and enough room left, when mounting heater, to allow draining

the heater.

2. Horizontal Mounting (Optional) —

When mounting heater horizontally, inlet and outlet pipes must

be up. In any other position, heater cannot be purged of air, and

elements may be seriously damaged. (See Figure B.)

Incorrect

Correct

Figure A — Vertical Mounting

Figure B — Horizontal Mounting

Correct

Incorrect

A

C

25”

B

8-5/8

16-1/16

Thermostat

Type AR

Mounting Lugs

3/8” - 16

Threaded Holes -

1-1/2” Deep

1-1/4” Centers

2” Pipe Inlet

2” Pipe

Outlet

1-3/8” Conduit

Openings

Specifications — Table A

Fuel Oil Heaters

Page 2

WARNING: Hazard of Electric Shock. Any installation

involving electric heaters must be grounded to earth

to eliminate shock hazard.

1. Be sure line voltage matches heater voltage (on nameplate).

2. Electric wiring to heater must be installed in accordance with

local and National Electrical Codes.

3. Power controllers must be used when heaters are rated 3 phase

and when the heater amperage exceeds to rating of the thermostat.

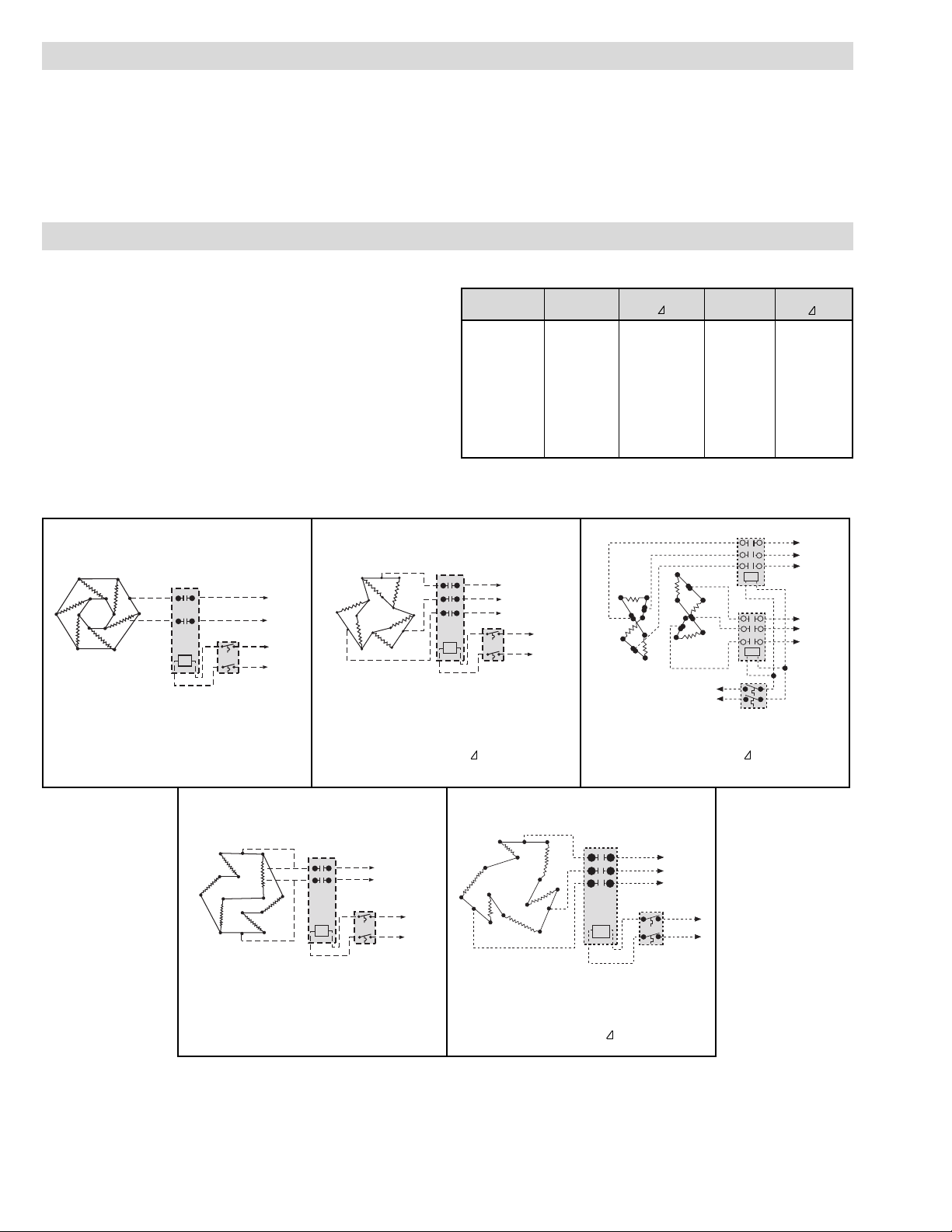

4. Refer to Wiring Diagram Table B, for the proper wiring diagram

for connecting

heater.

Wiring Diagrams - Table B

WIRING

INSTALLATION

3. Whether vertically or horizontally, the heater should be rigidly

mounted so that vibration is at a minimum since excessive

vibration will result in erratic thermostat operation. The

NWHO-6 is provided with mounting lugs to support the heating chamber. (See photo.)

4. By using a slotted mounting assembly on either of the lugs,

the heater chamber will be permitted to expand with increasing temperature.

5. DANGER: Hazard of Fire. Provide minimum of 6” spacing

from chamber and related piping to nearest combustible material.

Avoid operation of heater near combustible fluids or in combustible vapor or gas laden atmosphere. NOTE: Contact factory

for heaters suitable for use in hazardous locations.

6. Provide adequate space at terminal end to permit withdrawal

of the heater from chamber should servicing be required.

Model

240V, 240V, 480V, 480V,

1ø Fig. 3ø Fig. 1ø Fig. 3 ø Fig.

NWHO-61215 – 2 – 5

NWHO-61515 – 2 – 5

NWHO-62015 – 3 – 5

NWHO-62515 – 3 – 5

NWHO-63015 – 3 – 5

NWHO-60825 1 2 4 5

NWHO-61025 – 2 – 5

NWHO-61225 – 2 – 5

NWHO-61525 – 2 – 5

NWHO-61825 – 2 – 5

Note: Use wire size and type specified by N.E.C. 480V and 550V heaters require 600V wire,

per N.E.C. Contactors and wire supplied by customer.

Thermostat

Line

Contactor

120V, 240V

Contactor

Thermostat

120V, 240V

L1

L2

L3

Thermostat

Line

Contactor

120V, 240V

Contactor

Thermostat

L1

L3

L2

120V, 240V

Contactor

Contactor

Thermostat

1L1

1L2

1L3

2L1

2L2

2L3

120V

or

240V

Figure 3 – NWHO6

240V, 2-3ø

Figure 2 – NWHO6

240V, 3ø

Figure 1 – NWHO

240V, 1ø

Figure 5 – NWHO6

480V, 3ø

Figure 4 – NWHO6

480V, 1ø

Note: Dotted lines indicate “customer furnished.” However, Thermostat could have been furnished by Chromalox if so specified on the order.

Page 3

OPERATION

1. Do not heat solutions that are corrosive to the heating element

sheath or the heating chamber.

WARNING: Type NWHO Circulation Heaters are

equipped with steel heating elements and galvanized-steel heating chambers. It is the responsibility of the user to know the chemical composition

of the corrosive solution and the character of the

materials entering the solution as well as the corrosive effect of the solution upon the heating elements and chamber. Chromalox cannot warrant

any electric circulation heater against failure by

sheath corrosion if such failure is the result of

operating conditions beyond our control.

2. Terminal ends of heater must be protected from drippings,

condensation, spray or direct spill-over of material. Their

presence at the terminals may damage heater electrical insulation. Liquid-tight terminal enclosures are available to protect

heater. Contact your Local Chromalox Sales office.

3. If foreign material is carried by the liquid flow, install suitable

filters in the inlet pipe line to the heater.

4. Do not allow heater to operate when liquid flow is interrupted.

MAINTENANCE

1. WARNING:

Hazard of Electric Shock. Disconnect all

power before servicing heater.

2. Remove heating element assembly periodically to check

heater sheath for scaling, corrosion or excessive oxidation.

Correct operating conditions to minimize sheath deterioration.

3. Periodically check temperature control and limit control oper-

ation to insure accurate and safe process operations.

4. Check all electrical connections periodically and retighten

connections which may have loosened in service. Replace wire

and wire terminals which show signs of oxidation which would

interfere with establishment of reliable electrical connections.

RENEWAL PARTS IDENTIFICATION

PARTS COMMON TO ALL HEATERS

Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132-017222-016

Thermostat (AR2525) . . . . . . . . . . . . . . . . . . .300-013863-038

Thermostat (AR5525) . . . . . . . . . . . . . . . . . . .300-013863-039

Model Volts Phase kW Heating Element

NWHO-61215 240 3 LL 12 155-115846-028

NWHO-61215 480 3 LL 12 155-115846-030

NWHO-61515 240 3 LL 15 155-115846-035

NWHO-61515 480 3 LL 15 155-115846-037

NWHO-62015 240 2-3 LL 20 155-115846-042

NWHO-62015 480 3 LL 20 155-115846-044

NWHO-62515 240 2-3 LL 25 155-115846-047

NWHO-62515 480 3 LL 25 155-115846-049

NWHO-63015 240 2-3 LL 30 155-115846-051

NWHO-63015 480 3 LL 30 155-115846-053

Note: When ordering parts for Model Numbers suffixed by “XX” or any other letter or letters not specifically identified on this instruction sheet, order Renewal Parts on special order basis, giving name of part,

part number, model number and description.

Regular Oil Heaters

Model Volts Phase kW Heating Element

NWHO-60825 240 1 8 155-115844-004

NWHO-60825 240 3 Δ 8 155-115844-005

NWHO-60825 480 1 8 155-115844-006

NWHO-60825 480 3 Δ 8 155-115844-007

NWHO-61025 240 3 Δ 10 155-115844-012

NWHO-61025 480 3 Δ 10 155-115844-014

NWHO-61025 240 3 Δ 12 155-115844-019

NWHO-61025 480 3 Δ 12 155-115844-021

NWHO-61525 240 3 Δ 15 155-115844-023

NWHO-61525 480 3 Δ 15 155-115844-025

NWHO-61525 240 3 Δ 18 155-115844-027

NWHO-61525 480 3 Δ 18 155-115844-029

Fuel Oil Heaters

Page 4

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

99 - 063

TA - R9 - EF

Litho in U.S.A.

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...