Page 1

User’s Manual

MaxPac

PK480-5

0037-75428

June 2018

Page 2

Page 3

Thank you for choosing the Chromalox® MaxPac™ - a complete power control solution with industry-best

price and performance.

For more than 100 years, customers have relied on Chromalox for the utmost in quality and innovative solutions for industrial heating applications. Chromalox manufactures the world’s largest and broadest line of

electric heat and control products.

The MaxPac Series SCR Controllers provide the best control for applications where consistent heater/process temperature is critical or where fine resolution of power is required.

Common MaxPac features include:

• 120 - 575 Vac @ 100 - 1200 Amps

• Isolated Control Circuit

• Flexible I/O Power Wiring

• Easy Customer Interface

• Remote Stop

• Compact Size and Construction

• Touch-Safe Design (option on 100 - 650 Amp models)

• dv/dt Transient Voltage Protection

• MOV Protection

• Built-In Power Distribution

• Soft Start

• 100KA SCCR Rating

Features for the MaxPac I, II, and III include:

• Zero Crossover Firing

• Isolated Control Circuit

On/Off Control Inputs:

120 thru 240 Vac

5 - 32 Vdc

Dry Contact Closure

Proportional (DOT Firing) Inputs:

4 - 20 mA, 0 - 20 mA, 0-5 Vdc, 1 - 5 Vdc, 0 - 10 Vdc

Remote Manual Adjust (Optional)

Remote Auto/Manual Switch (Optional)

• Electronically Protected with Temperature Warning and Stop System

• Cycle Resolution 3, 5, 7, 11, 13, 17, 19

• Shorted SCR Detection (Optional)

• Soft Start

• Time proportional switching mode

• Staged Heating

• Rotary wwitch selection of input, leg configuration, modbus

Features for the MaxPac IP include:

• Phase Angle Firing

• Isolated Control Circuit Inputs

0 - 5 mA, 0 - 20 mA

0 - 50 mA, 1 - 5 mA

4 - 20 mA, 10 - 50 mA

0 - 5 Vdc, 0 - 10 Vdc

• Optional Current Limit

• Soft Start

• Line Voltage Compensation

• Zero & Gain Adjustments

• Built-In Manual Adjustment

• Current Limit Adjustment (Optional)

1

Page 4

Table of Contents

Section Topic Page

1................................................. Important Safeguards ..................................................................................... 3

2................................................. Description ..................................................................................................... 4

3................................................. Before You Install ............................................................................................ 5

4................................................. Installation ...................................................................................................... 6

4.1 ................................. Mounting ......................................................................................................... 8

4.2 ................................. Wiring ............................................................................................................ 11

4.2.1 ............. Touch-Safe Design ....................................................................................... 11

4.2.2 ............. Cover Removal and Installation .................................................................... 12

4.2.3 ............. Power/Load Wiring ....................................................................................... 12

4.2.4 ............. Instrument Power ......................................................................................... 16

4.2.5 ............. Grounding ..................................................................................................... 16

4.2.6 ............. Command Signal Wiring ............................................................................... 17

4.2.7 ............. Calibration .................................................................................................... 23

5 ................................................ Specifications ............................................................................................... 24

6 ................................................ Maintenance ................................................................................................. 25

7 ................................................ Troubleshooting ............................................................................................ 26

8 ................................................ Parts and Accessories .................................................................................. 27

9 ................................................ Warranty and Return Information ................................................................. 28

10 .............................................. EC Declaration of Conformity ....................................................................... 37

2

Page 5

Important Safeguards

1

IMPORTANT SAFEGUARDS

The MaxPac User Manual uses this symbol to

alert personnel to potential hazards that may

damage the equipment.

Please read all instructions before installing and operating your MaxPac™.

Before working inside the equipment, confirm that all power has been turned off, locked off, and preferably earthed [grounded] at all points of low and high potential, on both the supply line and load side

circuits, as required / permitted by all codes and standards.

Personnel working with or near high voltages should be familiar with modern methods of resuscitation. Contact an area supervisor or safety personnel for more information.

Throughout the MaxPac User Manual, the safety alert and the international electric shock/electrocution

symbols will alert you to potential hazards. Safety precautions should always be followed to reduce the risk

of personal injury to persons from fire and electrical shock hazards.

Each safety message is preceded by a safety alert symbol and one of three words: DANGER, WARNING, or

CAUTION. These mean:

DANGER You WILL be killed or seriously hurt if you do not follow instructions.

WARNING You CAN be killed or seriously hurt if you do not follow instructions

The MaxPac User Manual uses this symbol to

alert personnel to potential hazards that may

cause injury or death.

CAUTION You CAN be hurt if you do not follow instructions.

Damage Prevention Messages:

You will see other IMPORTANT messages that are proceeded by the word CAUTION that are intended

to help prevent damage to the MaxPac™ or other equipment. Note that Damage Prevention Messages are

NOT accompanied by the Safety Alert Symbol.

Key Safety Practices

All personnel working on high voltage electrical equipment must adhere to all national and local regulations,

codes, and standards.

Only suitably qualified and experienced persons, who are familiar with this equipment, and the work they are

to do, should carry out installation, commissioning, operation, or maintenance of this panel and the associated heater.

Such persons shall adhere to proper high voltage safety procedures, including the use of appropriate personal protective equipment (ppe).

Failure to adhere to any of the above may result in equipment damage, operating losses, injury, or death.

Chromalox will not be liable for failure to adhere to all governing regulations, codes, standards, site procedures and information given in this manual.

3

Page 6

Description

2

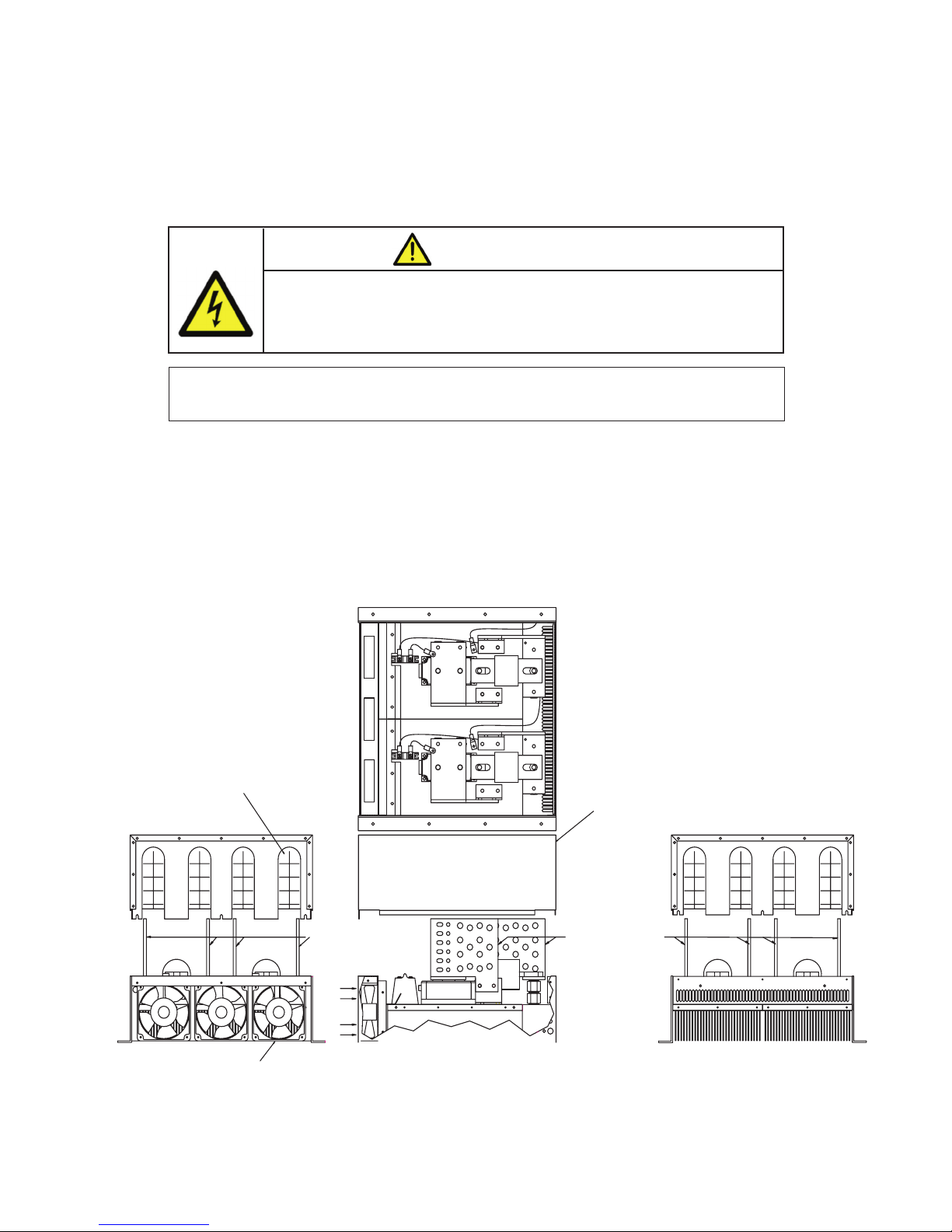

MaxPac I, II, and III

The Chromalox Model MaxPac IP, I, II and III Series are specifically designed for the OEM market. The Chromalox MaxPac I, II and III controllers are highly versatile SCR Power Paks. Firing modes includes On/Off

and DOT proportional zero voltage switching. Chromalox’s exclusive DOT (Demand Oriented Transfer) firing

switches the fewest number of cycles to provide the most precise zero crossover control. At 50% output the

units output alternates between one cycle “On” and one cycle “Off”. At 51% the output continues with one

cycle “On” one cycle “Off” and gradually integrates one extra “On” cycle for the additional one percent. This

DOT fired technique also minimizes temperature overshoot, temperature fluctuations and helps extend the

loads element life due to reduced thermal shock.

The power SCR assemblies consist of one, two or three SCR’s connected back to back with a semiconductor

fuse, RC Snubber and MOV protection. The firing circuit is based on common integrated circuit. Diagnostic

indicators are included as well as plug-in terminal blocks for easy customer interface.

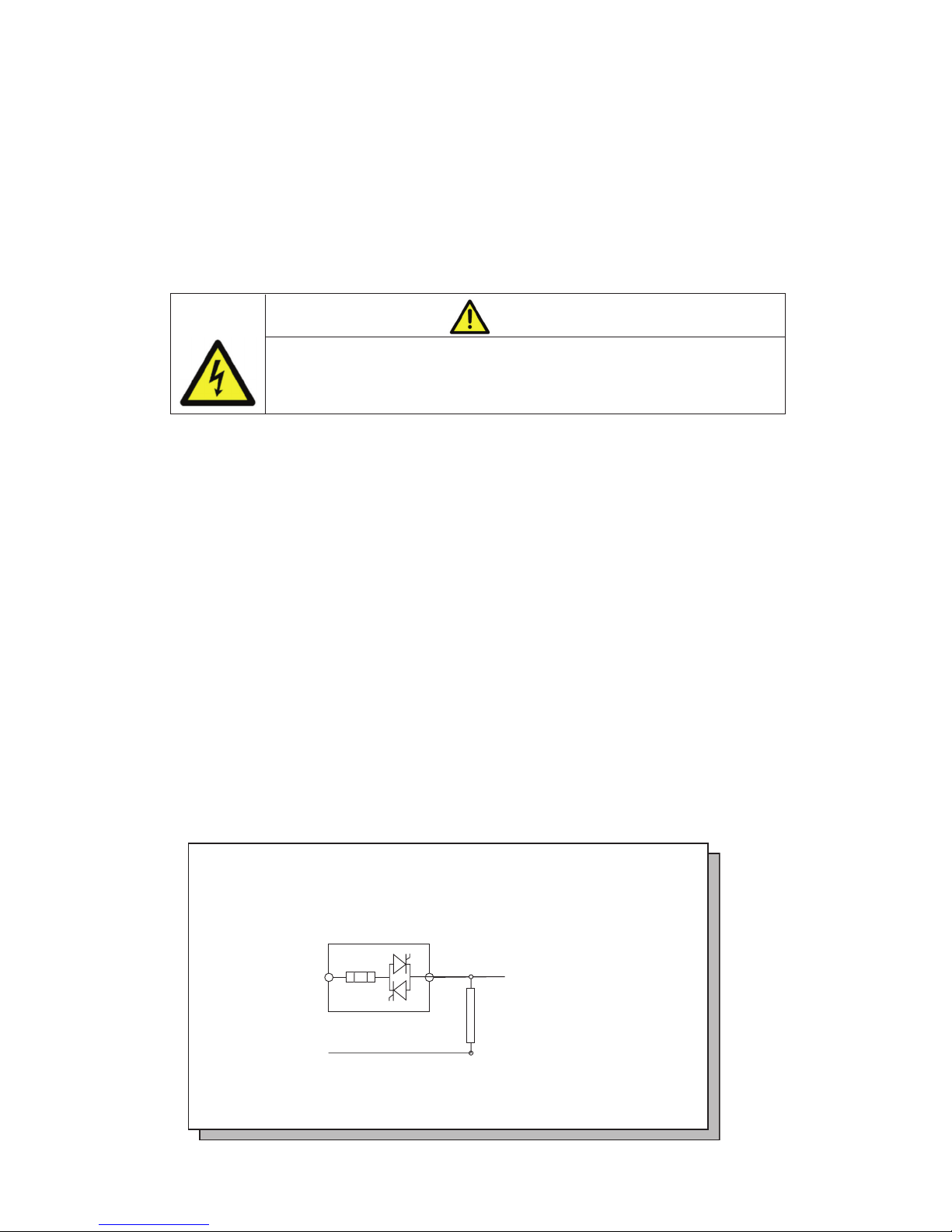

MaxPac IP

The Chromalox MaxPac IP utilizes Single Phase, Phase Angle firing to modulate power to an inductive or

resistive load. Phase Angle control has the advantage of proportioning every cycle thereby providing very

fine resolution of power. Fast responding loads in which the resistance changes as a function of temperature

require Phase Angle control. The MaxPac IP offers a Soft Start feature that assures that the load power is

gradually increased from zero to the value set by the command signal in the event of a power interruption.

In addition, optional Current Limit is used to protect the load, SCR controller and the total system from large

surge currents that could occur at start-up.

† This can be set to three cycles ‘On’ / three cycles ‘Off’ (see section on installation options).

4

Page 7

Before You Install

3

Immediately after receiving your MaxPac I, II, III or IP Series Controller, visually inspect the shipment packaging and record any damage on the shipping documents. Unpack the controller and carefully inspect for obvious damage due to shipment. If any damage has occurred, YOU must file a claim with the carrier company,

since the carrier company will not accept a claim from the shipper (Chromalox).

Be sure to check the model number and verify that you have received the correct Model of controller.

If the controller is not installed and placed into operation immediately, it should be stored in a cool, dry environment. Temperature extremes and excessive moisture can damage the controller.

Before choosing a location in which to mount your MaxPac, please consider the following:

READ AND UNDERSTAND BEFORE

CARRYING OUT THE WORK DETAILED BELOW

Temperature

When mounting the SCR unit in a control panel, attention should be paid to the enclosure temperature. The SCR is rated to perform at its nameplate current rating in temperatures up to 50˚C (122˚F).

Ensure that adequate ventilation is provided or some other method of maintaining the correct cabinet temperature is used.

Cleanliness

Careful attention must be paid in areas subjected to airborne particles. The efficiency of the heat

sinks relies on their conducting surfaces being maintained in a clean manner. (See the Maintenance

Section.)

Dampness

High humidity or hosing down a unit should be avoided.

Clearance

Choose a location that will provide adequate spacing around the unit when mounted. This will ensure proper air flow necessary to cool the device.

WARNING

Hazardous Voltage: Disconnect and lockout power before installing or servicing. Failure to comply could result in personal injury or equipment damage.

5

Page 8

Installation

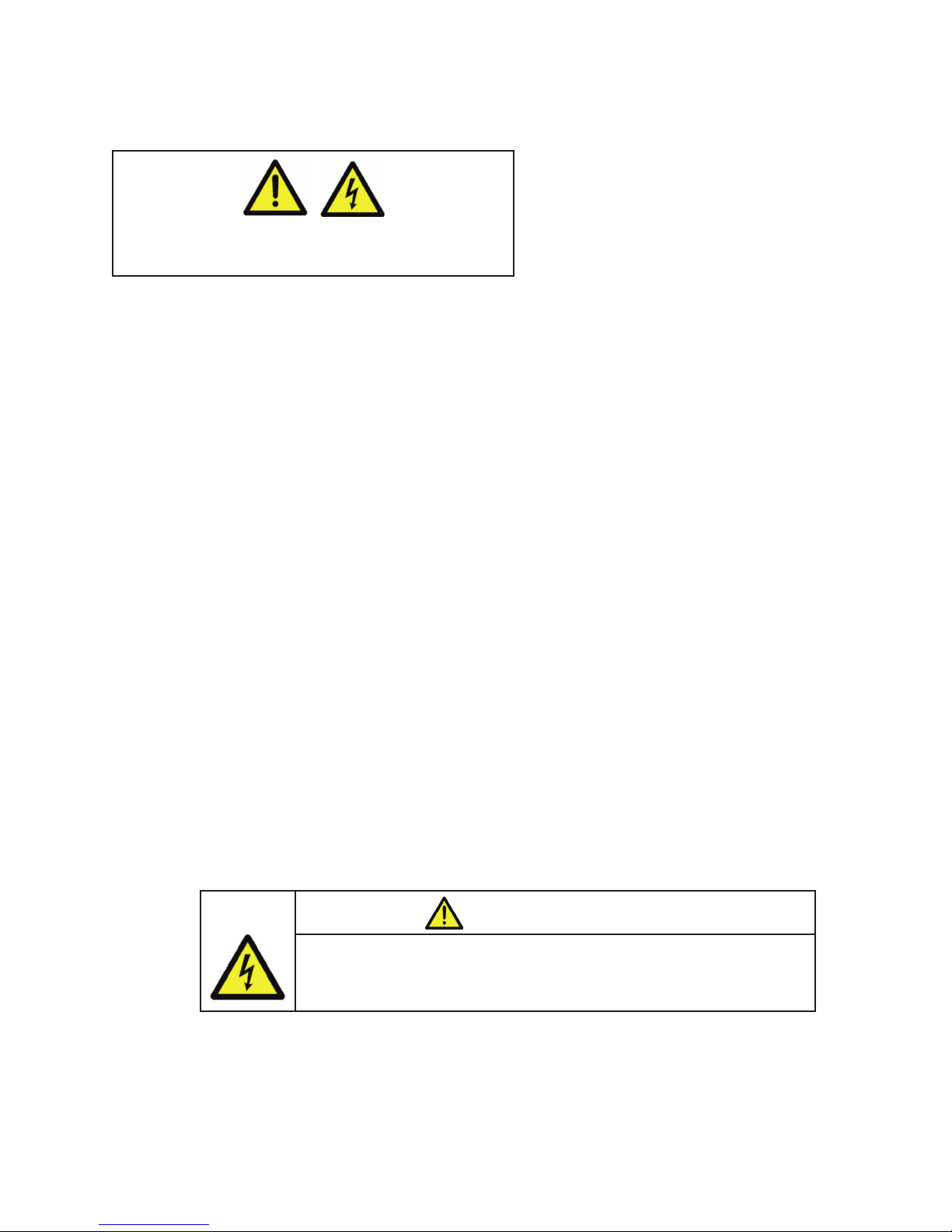

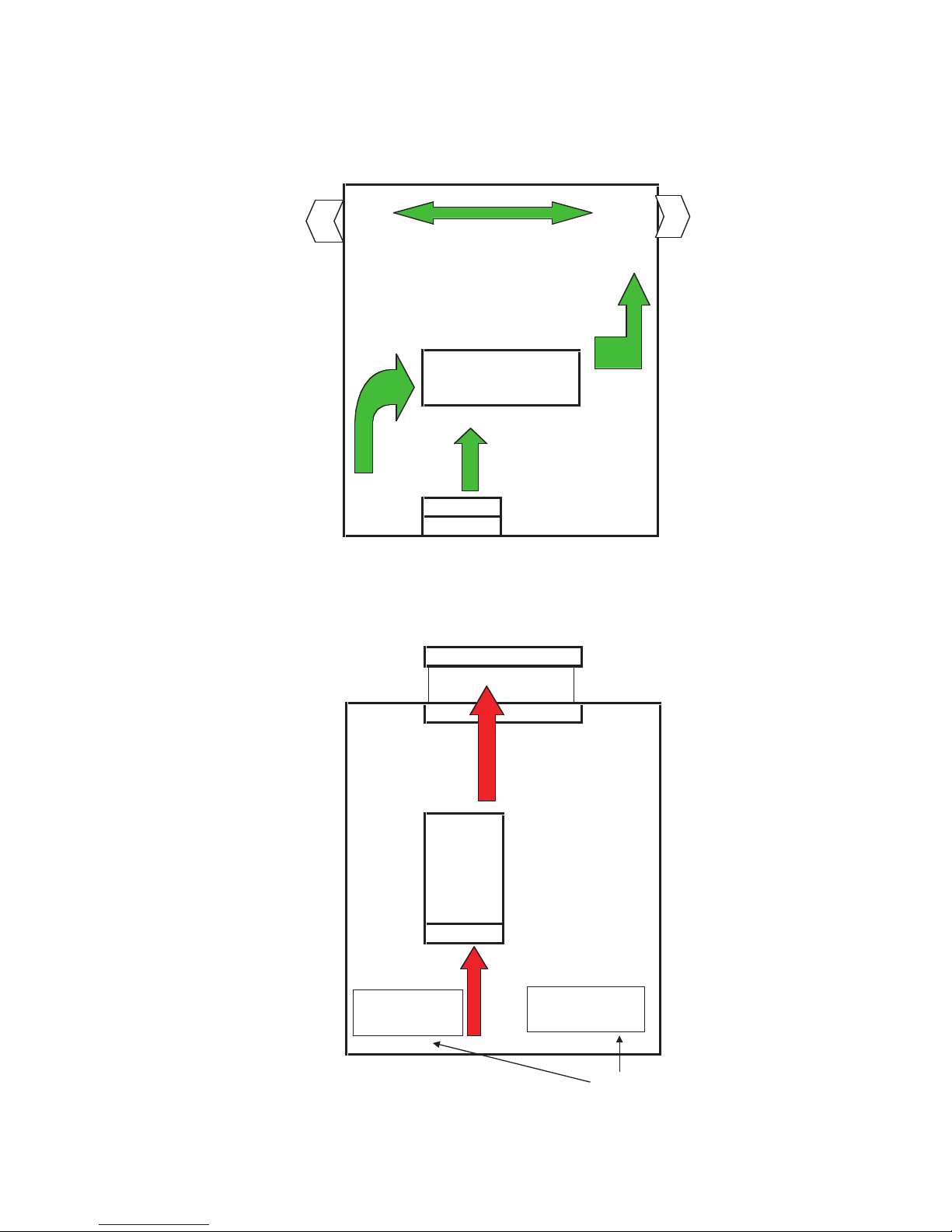

Cool Air In

The forced air design of the MaxPac series allows

mounting in any direction. It is essential that air flow

through the enclosure be planned to insure proper

cooling.

The 100 amp through 300 amp open design MaxPac allow the input line power to connect from

either of two directions.

Configuration One

In In

Warm Air

Fan

Phase 1

or In Out or In Out

Phase 3

The output power can only be connected from one

direction. The three mounting configurations are

shown below (MaxPac II Three-Phase Two-Leg

Shown).

Open designs above 300 amps and all closed designs allow incoming and outgoing wiring in either

direction.

Out

Configuration Three

Warm Air Out

Phase 3

In

Out

or In

Configuration Two

Out Out

Warm Air

Out

Phase 1 Phase 3

or In or In

In In

Fan

Cool Air

In

Out

Phase 1

In or In

Fan

Cool Air In

6

Page 9

Examples of Proper Air Flow

Louvers

Enclosure

(Not Recommended)

Since hot air rises naturally, it is not recommended that cooling air enter from the top and exhaust at the bottom of the enclosure.

Louvers

Air

Fan MaxPac

Enclosure

Fan

Filter

Forced Air In

(Recommended)

Pagoda Top

Fan

Air

MaxPac

Fan

Air

Louvers

Forced Air Out

7

Page 10

Installation

4

READ AND UNDERSTAND BEFORE

CARRYING OUT THE WORK DETAILED BELOW

Please read all information in this section before beginning the installation of your MaxPac.

Installation of the MaxPac requires three steps:

1. Mounting

2. Power wiring

3. 120 or 230 VAC 50/60hz for instrument power. See 4.2.4, pg. 16.

4.1 - Step 1: Mounting

Before mounting your MaxPac, please read the section titled “Before You Install’ on page 5 for a description

of an ideal environment for the unit’s operation.

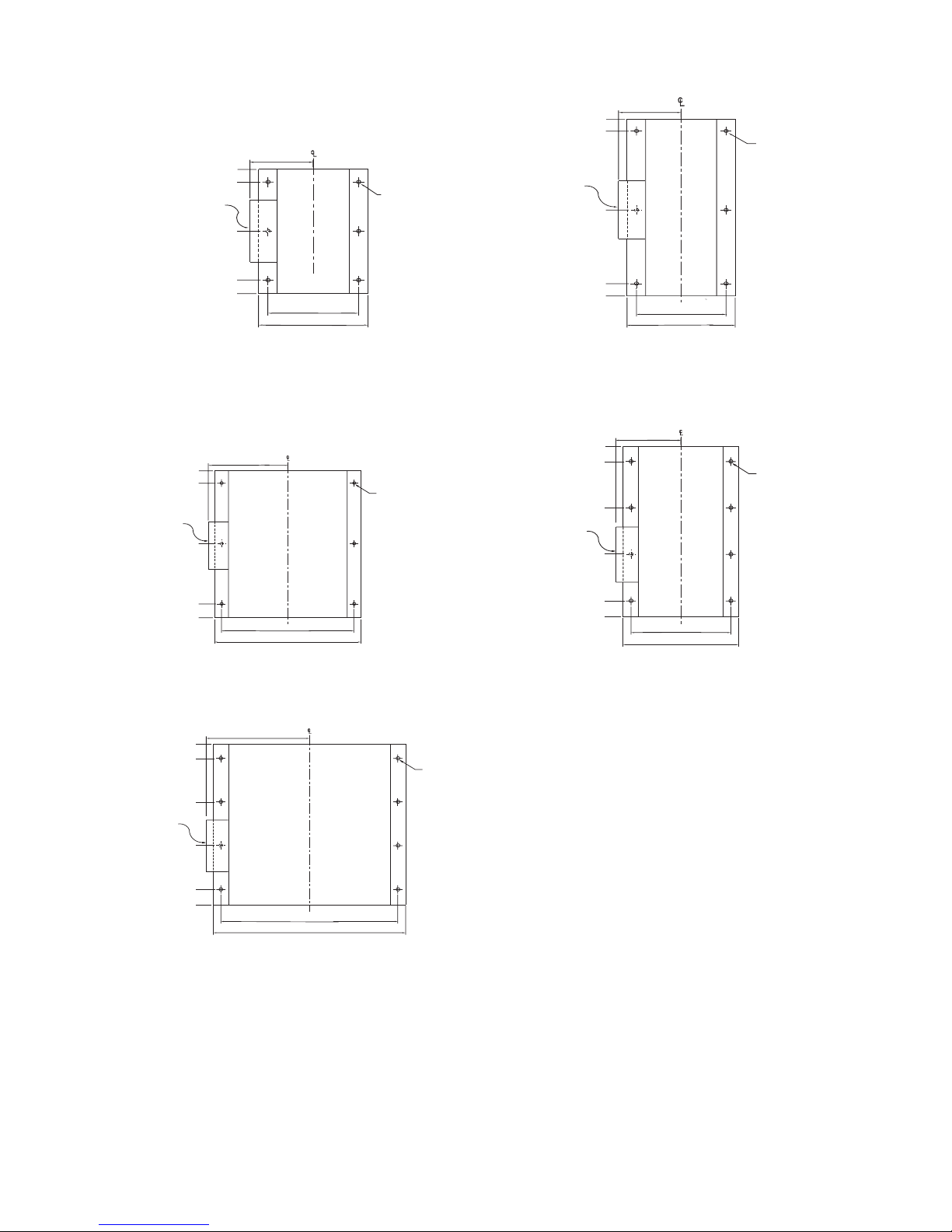

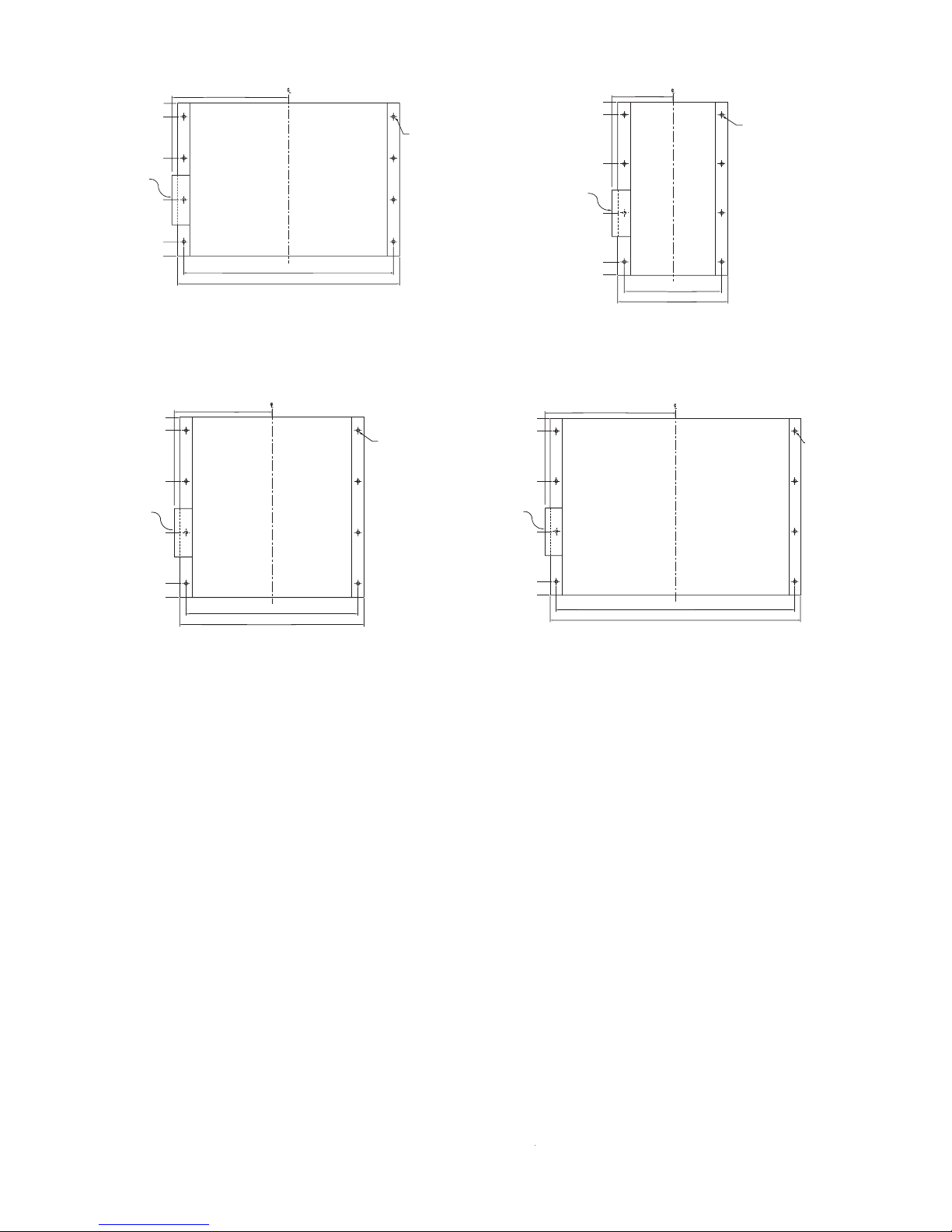

The space required for mounting the MaxPac Power Pak depends upon the model. The table below refers to

the figures on the following pages. These figures illustrate the dimensions and mounting holes for the various MaxPac Power Pak models. Please refer to these figures before mounting your unit.

Figure Model

1................100A, 150A, & 200A 2-Leg Open Type

1................100A, 150A, 200A, & 300A 1-Leg Open Type

2................100A, 150A, & 200A 3-Leg Open Type

3................300A 2-Leg Open Type

4................100A, 150A, 200A, 300A & 400A 1-Leg Touch-Safe

4................400A 1-Leg Open Type

5................100A, 150A, 200A, 300A & 400A 2-Leg Touch-Safe

5................400A 2-Leg Open Type

6................100A, 150A, 200A, 300A & 400A 3-Leg Touch-Safe

6................300A & 400A 3-Leg Open Type

7................550A & 650A 1-Leg Touch-Safe

7................550A & 650A 1-Leg Open Type

8................550A & 650A 2-Leg Touch-Safe

8................550A & 650A 2-Leg Open Type

9................550A & 650A 3-Leg Touch-Safe

9................550A & 650A 3-Leg Open Type

..................800-1200 Amp units, consult factory

IMPORTANT: Please note that the figures on the following pages are

8

not drawn to the same scale.

Page 11

Figure 1

4.7" [107mm]

0.0" [0mm]

1.0" [25mm]

4.75" [121mm]

8.5" [216mm]

9.5" [241mm]

6.0" [153mm]

7.3" [185mm]

FIRING PACKAGE

FAN END

Ø0.280" [Ø7.11mm]

(6 HOLES)

4.2" [107mm]

0.0" [0mm]

1.0" [25mm]

7.2" [184mm]

13.5" [342mm]

14.5" [368mm]

6.0" [153mm]

7.28" [185mm]

FIRING PACKAGE

FAN END

Ø0.280" [Ø7.11mm]

(6 HOLES)

7.2" [183mm]

0.0" [0mm]

1.3" [33mm]

7.3" [185mm]

13.3" [337mm]

14.6" [371mm]

12.0" [305mm]

13.3" [338mm]

FIRING PACKAGE

FAN END

Ø0.280" [Ø7.11mm]

(6 HOLES)

5.12" [130mm]

0.0" [0mm]

1.3" [33mm]

9.3" [237mm]

13.3" [338mm]

14.6" [371mm]

8.1" [206mm]

9.1" [232mm]

FIRING PACKAGE

FAN END

Ø.3125 [Ø7.94mm]

(8 HOLES)

5.3" [135mm]

8.4" [214mm]

0.0" [0mm]

1.3" [33mm]

9.3" [237mm]

13.3" [338mm]

14.6" [371mm]

14.7" [375mm]

15.75" [400mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

5.3" [135mm]

Figure 2

Figure 3

Figure 5

Figure 4

9

Page 12

13.8" [351mm]

0.0" [0mm]

1.3" [33mm]

26.5" [673mm]

16.3" [414mm]

17.6" [448mm]

11.3" [287mm]

25.5" [648mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

6.3" [160mm]

Figure 6 Figure 7

11.7" [298mm]

0.0" [0mm]

1.3" [33mm]

9.3" [237mm]

13.31" [338mm]

14.62" [371mm]

21.4" [543mm]

22.4" [568mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

5.3" [135mm]

5.8" [148mm]

0.0" [0mm]

1.3" [33mm]

11.3" [28mm]

16.3" [414mm]

17.6" [448mm]

9.5" [241mm]

10.5" [267mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

6.3" [160mm]

9.8" [249mm]

0.0" [0mm]

1.3" [33mm]

11.3" [287mm]

16.3" [414mm]

17.6" [448mm]

17.5" [444mm]

18.5" [470mm]

FIRING PACKAGE

FAN END

Ø.3125" [Ø7.94mm]

(8 HOLES)

6.3" [160mm]

Figure 8

Figure 9

10

Page 13

4.2 - Step 2: Wiring

COOLING AIR

COOLING AIR

SCR

FUSE

HEATSINK FINS

COVER PROVIDES FOR TOUCH SAFE FEATURE

TOUCH-SAFE COVER PROVIDES WIRE ENTRANCE AND

EXIT THROUGH SEALS COVERING THE WIRE WINDOW.

REMOVAL OF THE TAPE BEHIND THE WINDOWS TO

BE USED ALLOWS WIRES TO PASS. THE TAPE

REMAINS ON UNUSED WINDOWS TO PROVIDE TOUCH

SAFE FEATURE.

BUS BAR DESIGN ALLOWS

FOR WIRING FROM EITHER

DIRECTION AND MULTIPLE

LOAD CIRCUITS

BUS BAR DESIGN ALLOWS

FOR WIRING FROM EITHER

DIRECTION AND MULTIPLE

LOAD CIRCUITS

LONG LIFE, HIGH OUTPUT BALL

BEARING FANS PROVIDE RELIABLE

COOLING

Careful attention must be paid when attaching the wiring to the MaxPac to ensure proper and safe operation. This section contains detailed information on how to connect the power, resistive load, ground, and

command signal wiring.

WARNING

Hazardous Voltage: Only qualified personnel should perform

electrical wiring for the MaxPac Power Paks. LETHALLY HIGH

VOLTAGES are associated with this equipment and are dangerous if improperly installed.

IMPORTANT: Select installation wiring that is in accordance with the National

Electrical Code and any local standards that may be applicable.

4.2.1 - Touch-Safe Design

If the MaxPac model you purchased is of a Touch-Safe design, follow the steps on the following page to

install the electrical wiring. This will ensure the wiring is done properly while maintaining the Touch-Safe

feature. If your MaxPac is of an Open design below 400 Amps, disregard this subsection.

The following is a detailed drawing of a Touch-Safe unit:

11

Page 14

4.2.2 - Steps for Touch-Safe Design Cover Removal and Installation

MaxPac I

L2

L1

X1

Single Phase

Resistive

Remove Cover:

1. Loosen the thumb screws on both ends of the cover.

2. Lift the cover from the base.

Install Wiring:

3. Attach the wires to the bus bars in accordance with the instructions in the next section.

4. Choose the entrance and exit directions for the wiring as desired.

5. After the wiring is complete, remove the tape from the inside of the wire gaskets of the

windows that the power wiring will enter or exit.

WARNING

Hazardous Voltage: DO NOT remove the tape from the back of

the windows that are not used, as this maintains the TouchSafe feature.

Replace Cover:

6. Angle the end of the cover without screws towards the “fan-end” of the unit.

7. Slip that end into place first while allowing the wiring to pass through the desired windows.

8. Slip the opposite end of the cover into place.

9. Tighten all thumb screws.

4.2.3 - Line/Load Power Wiring

The following illustrations depict how to connect the MaxPac to a resistive load. Make sure you refer to the

correct illustration for the MaxPac series you have purchased.

For the power/load drawings:

On open design units up to 300 Amps, X1, X2, X3, L1, L2, and L3 refer to copper lugs.

On open design units 400 Amps and greater and all Touch-Safe designs, X1, and X2, and X3, L1, L2, and

L3 refer to bus bar connections.

MaxPac I

12

Page 15

MaxPac II

Three Wire

2 Leg Control

MAX PAC II

L1

L3

L2

X1

X3

L2 Connection is

NOT on MaxPac

Four Wire

3 Leg Control

MAX PAC III

L1

L2

L3

X1

X2

X3

N

N Connection is

NOT on MaxPac

MaxPac III

IMPORTANT: The I2t fuses installed on the SCR are designed to protect the SCR

from faults on the load connection side. They are NOT intended to provide wire

protection.

CAUTION

13

Page 16

MaxPac III

Three Wire

3 Leg Control

MAX PAC III

L1

L2

L3

X1

X2

X3

Single Phase

transformer

Coupled

MAX PAC IP

L2

L2

L1

X1

L2 connection to

MaxPac is instrument

power only

MaxPac IP

IMPORTANT: The I2t fuses installed on the SCR are designed to protect the SCR

from faults on the load connection side. They are NOT intended to provide wire

protection.

CAUTION

The bus bars are designed to accept NEMA standard two-hole crimp lugs in accordance with the charts

below.

14

Page 17

The following drawings show proper installation of the crimp lugs on the bus bars:

FUSE

Smaller wire, #1 through #8, often used

for power distribution, can be connected

to both sides of the load bus. Wiring must

be bent slightly to align with the windows

in the top of the touch safe units.

LINE BUS BAR

LOAD BUS BAR

FAN END

SCR

1/0 through 500 mcm

wire must mount on the

fuse side of the bus

bar as shown to

maintain required

electrical clearances

Illustration 1: View From Rear Ventilated Panel

All bolts must mount

with excess bolt lengths

toward the fuse to main-

tain required electrical

clearances.

Input Bus

Up to (3) 1/0 - 300 mcm (70 mm2 — 150 mm2)

Up to (2) 350 - 500 mcm (185 mm2 — 240 mm2)

Input Bus

Up to (4) 1/0 - 300 mcm (70 mm2 — 150 mm2)

Up to (3) 350 - 500 mcm (185 mm2 — 240 mm2)

Input and output bus drilled to accomodate qty (4) 1/0 - 500 mcm NEMA standard two-hole crimp lugs per phase.

Illustration 2: View From Top

Touch-Safe Units

100 - 400 Amps

Up to (10) #8 - #1 (10 mm2 — 50 mm2)

Up to (3) #1/0 - 300 mcm (70 mm2 — 150 mm2)

Up to (2) 350 - 500 mcm (185 mm2 — 240 mm2)

550 - 650 Amps

Up to (12) #8 - #1 (10 mm2 — 50 mm2)

Up to (4) #1/0 - 300 mcm (70 mm2 — 150 mm2)

Up to (3) 350 - 500 mcm (185 mm2 — 240 mm2)

800 - 1200 Amps Open Design

Output Bus

Output Bus

15

Page 18

The power wires must always mount on the fuse side of the bus bar. This is essential for maintaining the

required spacing between phases and the sides and to align with the openings in the top. The only exception to this is when using power distribution using connectors of size #8 to #1. There is adequate spacing for

these connectors to mount on both sides of the bus bar if necessary. The bolt head should always be on the

outside of the bus (side away from the fuse) with the bolt extending toward the fuse. Flat washers should be

used on both the bolt head and the nut and a lockwasher should be under the nut. The Touch Safe MaxPac

is designed to allow both input and output wiring to enter/exit in either direction. On the 550 amp and 650

amp models it is necessary to mount the wire in the holes that maximize the distance for the wire to exit

the enclosure. This maximizes the distance from the cover to the un-insulated connector. When using the

power distribution feature and mounting terminals on both sides of the bus bar, the wires mounted on the

outside of the bus bar must be bent inward slightly to align with the opening in the top. All wiring, especially

the larger wires should be bent prior to mounting to the bus bars. Do not use the bus bars as an anchor to

bend the power cables.

4.2.4 - Instrument Power

MaxPac requires 120 or 230 VAC 50/60Hz for instrument power. This voltage supplies power

for the control circuits, fans, high temperature warning indicator, and shorted SCR Indicators

(see Fig. 1 on page 21).

This supply is fused on the main circuit board.

4.2.5 - Grounding

The MaxPac uses electrically isolated SCR’s. The enclosure will therefore be at the potential of the panel to

which it is mounted. Holes are provided on the back of both sides of the MaxPac for NEMA standard two

hole crimp lugs (the same as used on the bus bars) for additional grounding as may be required.

IMPORTANT

Chasis is provided with hole pattern for standard NEMA two-hole crimp lugs.

WARNING

Hazardous Voltage: This Electrical Equipment must be installed by a qualified person and effectively grounded in accordance to the National Electric Code and local codes.

16

Page 19

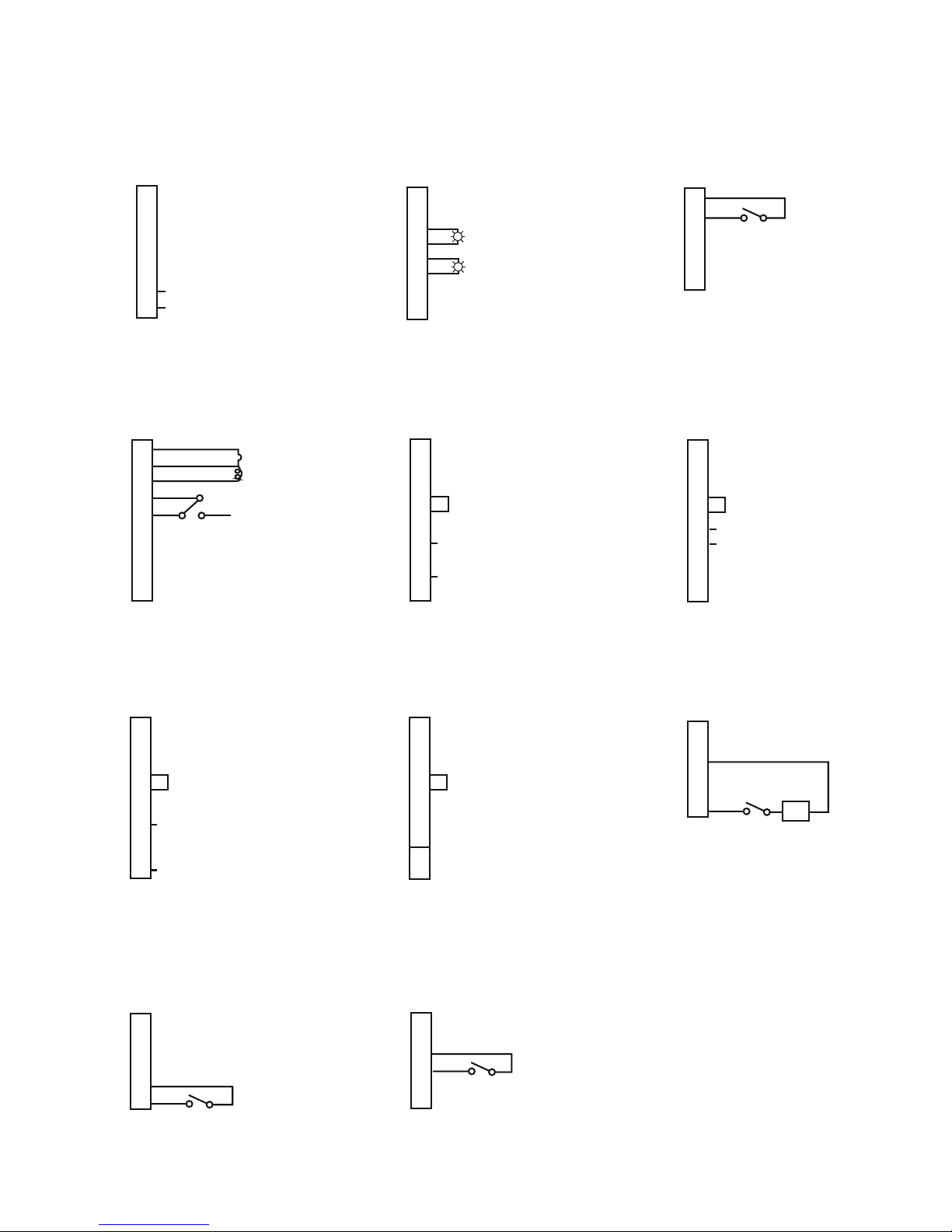

4.2.6 - Command Signal Wiring

Connection

Connection

Please refer to the following figure for illustrations of the 6-, 8-, and 10-pin input terminals.

Not a

Customer

Connection

Outputs

for

Customer

Customer

Input

Outputs

for

Customer

**

Not a

Customer

Customer

Inputs*

Modbus

*Only one customer input is allowed, eg. J3 pins 1 & 2 contact control may not be used at the same time as

J2 pins 6 & 7 (4-20 mA)

**Instrument power 4 VA maximum

MaxPac I, II, and III

On/Off Control Signals

AC Input – The 120 – 230 VAC signal lines are connected to terminal J1-7 & 8. An input voltage of

120 to 230 VAC turns the power On. The turn OFF voltage for the power control is 0 VAC.

DC Input – The 5 – 32 VDC signal lines are connected to terminal J3-1&4. An input voltage of 5 to 32

VDC turns the power On. The turn OFF voltage for the power control is 0 VDC.

NOTE: For AC or DC input to be used for ON/OFF control, SWI rotary switch must be set to position 0 and

unit must be jumpered for AUTO

Contact Closure Input – The dry contact signal lines are connected to terminal J3-1&2. A closed

contact turns the power On. The turn OFF is an open contact.

17

Page 20

Process Analog Control Signals

NC NO

CONTACT

NORMALLY CLOSED

(SWNC)

CONTACT

NORMALLY OPEN

(SWNO)

SWITCH

ASSEMBLY

(SW)

PANEL TO BE

MOUNTED TO

LEGEND

PLATE

(LP)

AUTO

HAND

SWITCH KNOB

(SW)

AUTO

HAND

The MaxPac II accepts 0 –5/1 – 5/0 – 10

VDC and 4 – 20 mA input signals, they

are factory calibrated. The following signals are connected to:

0 - 5 VDC: Terminal J2 9(+) & 7(-)

1 - 5 VDC, 11 - 5 VDC: Terminal J2 5(+) & 7(-)

0 - 10 VDC: Terminal J2 10(+) & 7(-)

4 - 20 mA, 10 - 20 mA: Terminal J2 6(+) & 7(-)

Auto/Manual Input

Illustration 3

The MaxPac I, II and II can be wired to make it possible to select an input from either a temperature/

process controller or a manual input potentiometer. A switch is used to select between the input

from a 1K potentiometer or a linear control input (see input connections).

The unit is shipped with a jumper from terminals 4 and 5 of terminal block J2. This jumper must be

removed when connecting the auto/manual switch and potentiometer.

Demand Indicator

The LED demand indicator is located on the main PC board and is viewable through the cover. With

the On/Off control option, the indicator will display steady “on” and steady “off”. With the DOT Firing

or Time-Proportional options, the indicator will display the firing sequence.

SCR Control Board

The control board provides the following functions:

The low voltage dc to operate the circuitry:

A switching regulator circuit converts the instrument power to +8 VDC.

The power distribution for the cooling fans:

The incoming instrument power is routed to the fan power terminals.

Add fusing as required for fan power requirement.

The signal condition for the on/off input and analog inputs:

The 120 to 240 on/off input is isolated by an opto-coupler. The DC and contact

closure inputs are buffered by the circuitry.

18

Page 21

The drive signal to the SCR trigger boards:

riggering

LD3-SCR1 LD4-SCR2 LD5-SCR3 LD2-Demand

The temperature alarm:

The heat sink temperature is derived from a resistive temperature detection (RTD)

sensor mounted on the heat sink. This is then compared to two set points.

The first alarm is a warning and activates the externally connected device.

This allows time to correct the problem before the second alarm inhibits the firing circuit.

The Shorted SCR Alarm:

When a short is detected the externally connected device output is activated.

SW3 - Phase/T

Selection

SW1 - Input Selection

19

Page 22

The method of setting the MaxPac for desired mode of operation is as follows:

Input Command Selection

The unit can be set to drive its output in response to the following command inputs:

• Analog potentiometer

• Analog inputs: 4-20mA (or 0-20mA), 0-5Vdc (or 1-5Vdc), 0-10V

• Digital ON/OFF inputs: AC ON/OFF, DC ON/OFF

To select between any of these inputs, set the MaxPac as indicated in the table below:

Input Command Select Method of Selection

Potentiometer Select MANUAL mode by leaving no connection

between J2.4 & J2.5. The rotary switch selection at

SW1 is ignored when in MANUAL mode

OR

Select AUTO mode by jumpering J2.4 & J2.5, and

then set rotary switch at SW1 to position 1

ON / OFF (will turn output in if either AC or DC ON/

OFF inputs are energized)

0-10Vdc Select AUTO mode by jumpering J2.4 & J2.5, and

0-5Vdc Select AUTO mode by jumpering J2.4 & J2.5, and

1-5Vdc Select AUTO mode by jumpering J2.4 & J2.5, and

0-20mA Select AUTO mode by jumpering J2.4 & J2.5, and

4-20mA Select AUTO mode by jumpering J2.4 & J2.5, and

Select AUTO mode by jumpering J2.4 & J2.5, and

then set rotary switch at SW1 to position 0

then set rotary switch at SW1 to position 2

then set rotary switch at SW1 to position 3

then set rotary switch at SW1 to position 4

then set rotary switch at SW1 to position 5

then set rotary switch at SW1 to position 6

Note: SW1 position 7 is reserved for factory use, and should not be used

Phase Selection and Firing Mode

SW3 selects the phase selection and firing method of the MaxPac.

Normally, this switch should be left in its factory-installed position. If it should become necessary to change it, set only accordance to the table below. Choosing a setting that does not

match your unit’s number of phases and legs will result in the unit entering alarm mode and

turning the output off after an initial attempt to turn outputs on.

20

Page 23

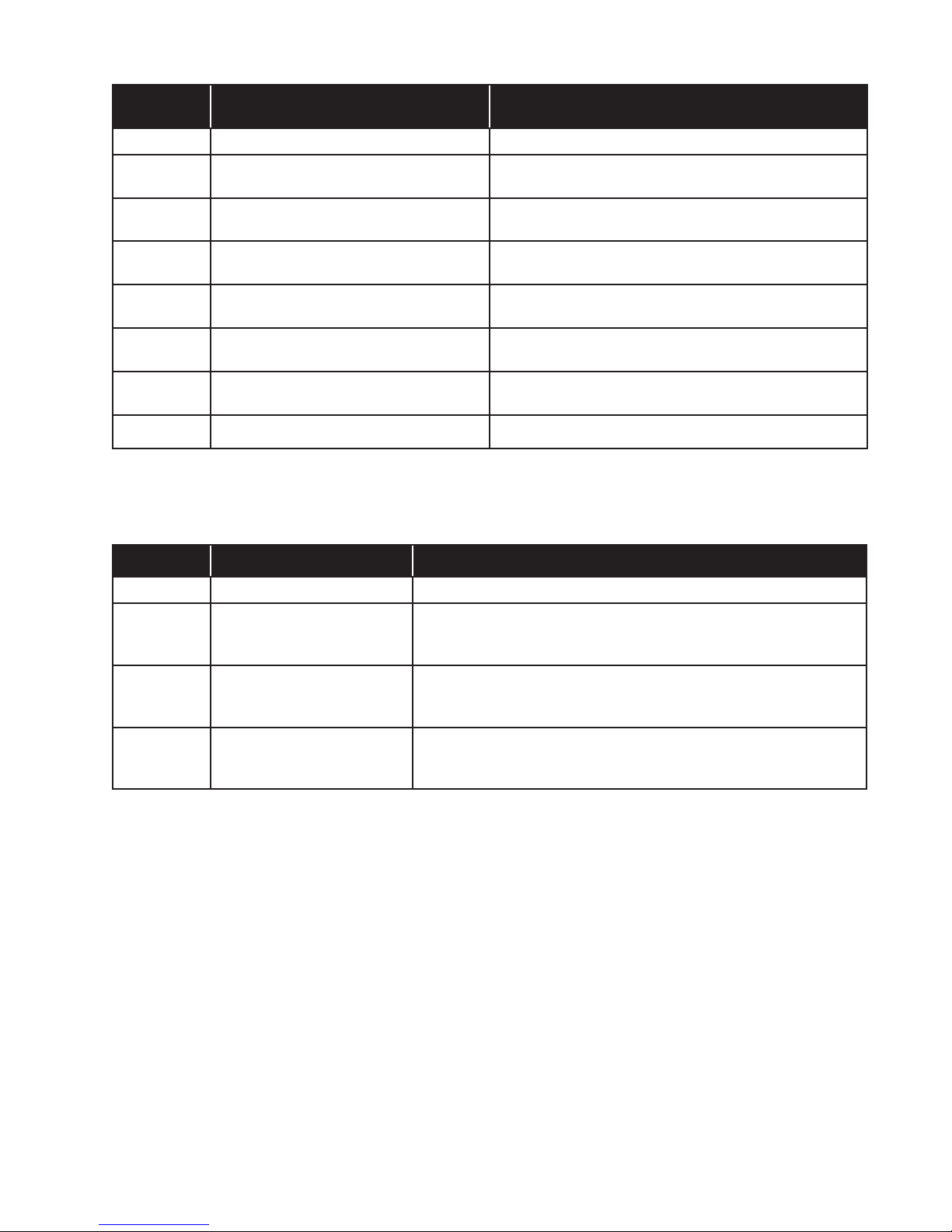

SW3

Position Selection Note

0 Reserved for factory use Do Not Use this Selection

1 DOT for MXPCI Caution: Do not choose this setting if your unit is a

MXPCII or MXPCII type

2 DOT for MXPCII Caution: Do not choose this setting if your unit is a

MXPCI or MXPCII type

3 DOT for MXPCIII Caution: Do not choose this setting if your unit is a

MXPCI or MXPCII type

4 Time Proportional for MXPCI Caution: Do not choose this setting if your unit is a

MXPCII or MXPCII type

5 Time Proportional for MXPCII Caution: Do not choose this setting if your unit is a

MXPCI or MXPCII type

6 Time Proportional for MXPCIII Caution: Do not choose this setting if your unit is a

MXPCI or MXPCII type

7 Reserved for factory use Do Not Use this Selection

LED Indicators

LEDs and their function are as follows:

Designator Name Description

LD2 Output Demand Indication This LED blinks on according to the switching of output

LD3 Switch SCR1 OFF in normal operation. Turns ON if shorted SCR is detected

in one direction. Blinks rapidly if phase voltage is not present or

if SCR is shorted in both directions.

LD4 Switch SCR2 OFF in normal operation. Turns ON if shorted SCR is detected

in one direction. Blinks rapidly if phase voltage is not present or

if SCR is shorted in both directions.

LD5 Switch SCR3 OFF in normal operation. Turns ON if shorted SCR is detected

in one direction. Blinks rapidly if phase voltage is not present or

if SCR is shorted in both directions.

Alarm Output

The form C contact at J14 will be in the alarmed state in any of the following conditions:

• If any shorted SCR is detected. One or more of the shorted SCR LEDs LD3-LD5 will be lit in this case

• If missing Zero Cross transitions are detected at the SCRs. Typically, this is caused by missing power on

one or more phases, or from incorrect detection of phase sequence. One or more of the shorted SCR

LEDs LD3-LD5 will be blinking in this case

• If sensed temperature of the heat sink at an SCR junction exceeds 200 degrees Fahrenheit or 93 degrees

Celsius. The Overtemp output will also be engaged in this case.

• If sensed phase sequence does not match the setting of selector SW3. (Normally, SW3 should be left in

its factory-set state. See caution in section titled, “Phase Selection and Firing Mode“).

21

Page 24

Remote Stop

SHORTED SCR DETECTION

DEMAND

123

When it is necessary to disable or enable the output, connect a dry contact between J3 – 3 & 4.

When it is closed, the power control will disable the output.

IMPORTANT: This stop overrides the control input only. It will NOT protect against

faulted or damaged SCRs.

Shorted SCR Detection (optional)

This features provides a means of alerting an operator to a problem with the system. An external

indicated lamp or relay can be connected to J1 – 5 & 6 (See Fig. 2). This indicator must be rated for

the instrument power applied to J1 -1 & 2. Three diagnostic LEDs show which SCR pair is faulted.

These lights are synchronized with the demand indicator and can only indicate while the demand is

active.

The latching alarm means that if the alarm activates and the system subsequently returns to normal,

the alarm will remain latched until a reset button (external – customer provided) is pressed. A nonlatching alarm resets automatically.

CAUTION

Heat Sink Over-Temperature

An external lamp or relay may be connected to J1 – 3 & 4 (see Figure 2) (this must be rated for the instrument power applied to J1 – 1 & 2). This will provide an indication to the operator that the heat sink has approached an unsafe temperature level of 200˚F (93˚C) The unit will enter a stop mode if the temperature rises

to 212˚F (100˚C).

22

Page 25

Input Terminals (MaxPac I, II, and III):

FIG 1

FIG 2

FIG 3

TIONAL INPUT

FIG

DRY CONTACT ON/OFF

REMOTE SHUTDOWN

J1

8

7

6

5

4

3

2

120-230 INSTRUMENT POWER

1

120-230 INSTRUMENT POWER

REQUIRED ON ALL CONFIGURATIONS

FIG 4

J2

COMMON

1

2

3

4

5

6

7

8

9

10

MANUAL CONTROL INPUT SIG

MANUAL

0-5 / 1-5 VDC INPUT

J1

8

7

6

5

4

3

2

1

SHORTED SCR AND

HI TEMP INDICATORS.

SHORTED SCR INDICATOR

HI TEMP INDICATOR

These are AC voltage outputs at 100 mA max.,

not contact closures. See model number

for voltage rating

FIG 5

J2

1

2

3

4

JUMPER

5

6

COMMON

7

8

0-5 / 1-5 VDC INPUT

9

10

0-5 / 1-5 VDC PROPORTIONAL INPUT SIG

J3

6

5

4

3

2

1

SHORTED SCR INDICATOR RESET

FIG 6

J2

1

2

3

4

JUMPER

5

4-20mA PROPOR

6

7

COMMON

8

9

10

4-20mA PROPORTIONAL INPUT SIG

7

J2

1

2

3

4

JUMPER

5

6

7

COMMON

8

9

0 +10 VDC PROPORTIONAL INPUT

10

0 +10 VDC PROPORTIONAL INPUT SIG

FIG 10

J3

6

5

4

3

2

1

+

FIG 8

J1

8

L1 – EXTERNAL 120-230

7

L2 – ON/OFF CONTROL

6

5

JUMPER

4

3

2

1

120-240 ON/OFF CONTROL

FIG 11

J3

6

5

COMMON

4

3

2

1

FIG 9

J3

6

5

COMMON

4

3

2

1

EXTERNAL +5-32 VDC ON/OFF

+

23

Page 26

MaxPac IP

0-5MA

(0-10V)

4-20mA

10-50mA

COM

CLOSE FOR

REMOTE

STOP

N/C

N/C

JUMPER 4 TO 5

WHEN NOT USING

REMOTE POT

UNIT SHIPPED WITH JUMPER INSTALLED

INSTRUMENT

WIRE

L

O

A

D

SCR

FUSE

X1

L2

L1

CT

TB1CON1P

JB1

JUMPER JB1 FOR 0-5mA

OPEN JB1 FOR 0-10V

The Chromalox MaxPac IP is a solid-state proportional power controller that utilizes a Phase Angle firing

technique to modulate power to an inductive or resistive load. Separate adjustable Zero, Gain, Manual Bias,

and Current Limit potentiometers are provided along with screw type plug-in connectors for input signals,

Emergency Stop, and optional Remote Manual Bias with 0 - 100% dial. All units have thermostat protection

with N.C. contacts.

Start-up

The MaxPac IP has been factory calibrated for 4 - 20mA input. Be sure the operating voltage and signal

input are correctly applied. Also, make sure the Emergency Stop, if used, has N.O. contacts and jumper

pins 4 & 5 on the 10-pin connector if remote manual bias are not used. Please read the information on

calibration at the end of this section for current limit settings for loads with extreme hot to cold ratios or

those that are overrated. Other ranges may be field calibrated by use

of zero and gain potentiometers.

CAUTION

IMPORTANT: With the Current Limit option, the current transformer must be termi-

nated properly to prevent it from being damaged.

24

Customer Connection

Page 27

4.2.6 - Calibration (MaxPac IP):

Many high-temperature heating elements exhibit extreme hot to cold resistance ratios. Heating elements composed of Platinum,

Molybdenum, Tungsten, and Tantalum, to name a few, draw excessive current on start-up. Depending on the mass of the elements,

these “high starting currents” may exist for extended periods of time. Generally, once the elements have achieved their normal operating temperatures, the current drawn through the MaxPac Power Pak will fall within the rating of the unit. For these types of loads, we

recommend adjusting the I LIM (Current Limit) to 50% or less. This will decrease voltage as well as current.

1. Set Current Limit (I LIM) pot to 0% for full current output (CCW).

Current Limit is for limiting current for loads that have

extreme hot to cold resistance ratios or are overrated. We

recommend for these types of loads to adjust I LIM (Current Limit) to 50% or less. This will also decrease voltage as

well as current. 0% Current Limit gives 100% current output

(CCW). 100% Current Limit gives 10% current output (CW).

2. Set Manual (MAN) pot to zero so unit will not be biased above

input (CCW).

Manual control adjustment provides a means of setting the

output level of the MaxPac Power Pak in the absence of

controlling instrumentation. The manual control signal value

“adds” to the controlling instrument to set minimum output.

The desired output power level may be set by adjusting the

manual control. This value of output will then be present even

in the absence of a control signal.

3. Set Remote Manual pot to zero output so unit will not be biased

above input (CCW). (Jumper pins 4 & 5 if not used.)

Remote Manual control adjustment provides a means of

setting the output level of the MaxPac Power Pak in the

absence of controlling instrumentation. The Remote Manual

control is also effective when a control signal is connected.

The Remote Manual control signal value “adds” to the

controlling instrument to set minimum output. The desired

output power level may be set by adjusting the Remote

Manual control. This value of output will then be present even

in the absence of a control signal. Connect Remote Manual

pot wire to Pin 4 (CCW), Pin 5 (W), and Pin 6 (CW) of plug-in

connector.

4. Check for open contact for Emergency Stop.

Emergency Stop inhibits all SCR trigger pulses regardless

of the level of the input signal or manual potentiometer. For

Emergency Stop, close contact Pin 7 to Pin 8 of plug-in connector. Leave contacts open for operation.

5. Check for polarity of input signal.

6. Adjust input signal to low end of scale.

Zero Adjust control sets the power output starting point or

reference. Thus, it effectively cancels positive inputs to the

MaxPac Power Pak.

EXAMPLE: 0 - 5 mA input à set to 0 mA input

4 - 20 mA input à set to 4 mA input

7. With power off, connect line voltage and load as shown.

8. Connect meter to input and output.

WARNING: Set meter to correct scale to read proper

input or output.

9. Apply power to unit.

10. Adjust input signal to low end of scale.

11. Using the Zero pot, adjust the output voltage just to zero volts.

12. Adjust input signal to top end of scale.

Gain Adjust Control sets the maximum power output for

maximum input signal.

EXAMPLE: 0 - 5 mA input: set to 5 mA input

4 - 20 mA input: set to 20 mA input

13. Using the Gain pot, adjust output voltage just to maximum

volts.

14. Repeat steps 11, 12, 13, and 14 until no adjustment is

necessary of Zero and Gain pots for proper output voltage

indication. Voltage output should increase proportionally to the

signal input applied.

15. Adjust input signal to low end of scale (zero voltage output).

16. With Manual pot at zero for zero voltage output, adjust (CW)

to 100% for full voltage output. Voltage output should

increase proportionally. Return to CCW position and output will

decrease to zero output.

17. With Remote Manual at zero for zero voltage output, adjust

(CW) to 100% for full voltage output. Voltage output should

increase proportionally. Return to CCW position and output will

decrease to zero output.

18. With Manual pot (CW) at 100% and I LIM (Current Limit)

at 0%, adjust I LIM towards 100% noting that voltage output

decreases with the adjustment of the Current Limit pot. Adjust

Current Limit pot for your application, if needed.

19. Turn POWER OFF and remove meters. TEST COMPLETE.

25

Page 28

Controller Configuration

5

26

Page 29

27

Page 30

Specifications

6

MaxPac I, II, and III

Control Inputs

Accepts all of the following as standards:

On/Off Control

Signal Input

120 thru 230 VAC ± 10% (4 VA Maximum)

5-32 VDC

Contact Closures

Proportional Control

Signal Input Input Impedance

4 - 20 mA ...................... 50 Ohms

1 - 5 VDC ...................... 10k Ohms or greater

0 - 5 VDC ...................... 9k Ohms or greater

Remote Manual Adjust

Auto/Manual Switch

Instrument Power ...... 120 or 230 VAC

50/60 Hz

Output Voltage ........... 0 - 99% RMS line voltage

(Eo-Vsupply - 1.5V SCR

forward drop)

Resolution (proportional) Better than 0.1%

Line Voltage ...................120 - 575 VAC, 60 Hz

CE 400 VAC 50 Hz

Load Current Rating ......100, 150, 200, 300, 400,

550, 650, 800, 1000, 1200A

Ambient Temperature ....0 - 50°C (32 - 122°F)

SCR Capability

Dielectric .................Withstand capability

Surge Rating 1500V RMS min.

Typically fifteen (15) times

nominal RMS rating for

8.3 milliseconds

Isolation .....................SCRs isolation 2500V

Input-output isolation 1500V

Heat Sink ........................Ground potential up to

650 Amps

High Temperature ..........AC Voltage Output

Indicator Output 100 mA @ Instrument Power

Shorted SCR ..................AC Voltage Output

Indicator Output 100 mA @ Instrument Power

MaxPac IP

Control Inputs

Accepts all of the following as standards:

Phase Angle Control

Signal Input Input Impedance

1 - 5, 0 - 5mA 1K Ohms

4 - 20, 0 - 20mA ........ 250 Ohms

10 - 50, 0 - 50mA ...... 100 Ohms

Optional Remote Manual Adjust

Fan Power .................. 120 or 230 VAC

50/60 Hz

Output Voltage ........... 0 - 99% RMS line voltage

(Eo=Vsupply - 1.5V SCR

forward drop)

Resolution (proportional) Better than 0.1%

Line Voltage ............... 120, 208, 240, 277, 380,

...................................... 480 and 575 VAC

± 10% 50/60 Hz

Load Current Rating .. 100, 150, 200, 300, 400,

550, 650, 800, 1000, 1200A

Ambient Temperature ....0 - 50°C (32 - 122°F)

SCR Capability ...............Withstand capability

1500V RMS min.

Typically fifteen (15) times

nominal RMS rating for

8.3 milliseconds

Surge Rating ..................Typically fifteen (15) times

nominal RMS rating for

8.3 milliseconds

Isolation ..........................SCRs isolation 2500V

Input-output isolation 1500V

Heat Sink ........................Ground potential up to

650 Amps

Thermostat .....................4 Amps @ 120V resistive

2 Amps @ 240V resistive

N.C. Contact Standard

Current Limit ..................10 - 100% of rated

output current

Soft Start ........................25% demand per second

typical reset speed

8.3 milliseconds

28

Page 31

Maintenance

7

Environmental Issues:

Temperature:

When mounting the SCR unit in a control panel attention should be paid to the enclosure temperature. The

SCR is rated to perform at it’s nameplate current rating in temperatures up to 50˚C (122˚F). Ensure that adequate ventilation is provided or some other method of maintaining the correct cabinet temperature is used.

READ AND UNDERSTAND BEFORE

CARRYING OUT THE WORK DETAILED BELOW

WARNING

Hazardous Voltage: Disconnect all power before performing

any maintenance or examining the power module. Exposed

terminals may carry LETHALLY HIGH VOLTAGES when power

is applied.

Cleanliness:

Careful attention must be paid in areas subjected to airborne particles The efficiency of the heatsinks rely on

there conducting surfaces being maintained in clean manner. (See Maintenance Section)

Dampness:

High humidity or hosing down should be avoided.

Connections:

Ensure that all electrical connections are secure and tight. (See Maintenance Section)

Fusing:

The I2t fuses installed on the SCR are designed to protect the SCR’s from faults on the load connection side.

They are NOT intended to provide wire protection.

Maintenance

Connections:

Loose connections in the power wiring will generate hot spots, which will cause degradation of electronic

equipment. Periodically inspections should be made to to ensure that connections are secure and that there

are no signs of excessive heating such as discoloration etc.

Filters:

Many high power control enclosures rely on blowers or fans to maintain a safe operating temperature. The

filters used with these devices should be changed on a periodic basis to insure adequate enclosure cooling

is maintained.

29

Page 32

Troubleshooting

8

READ AND UNDERSTAND BEFORE

CARRYING OUT THE WORK DETAILED BELOW

The following guidelines cover most of the common problems that could occur with the MaxPac. They are

not intended to be, nor can they be, absolutes to cover every possible failure.

Problem

Note: Heater load must be conntected to Test.

No Power or unbalanced power to the load.

If Demand Light is “Off”

1. Check incoming line power. Verify that fans are running

2. Check the instrument power.

3. Check the fuse on the main board.

4. Verify the input signal.

5. Check that remote stop J3 - 3 to 4 is open.

6. Check that the J2 - 4 to 5 is Jumpered.

7. Verify that heat sink is not in over temperature mode.

If Demand Light is “On”

1. Check the connections to SCR trigger board.

2. Check the power fuses (I2t).

3. Look for damage on the trigger board.

Observation Possible Root Cause

LD3 – SCR1 light is ON and Alarm relay engaged Shorted SCR1

LD4 – SCR2 light is ON and Alarm relay engaged Shorted SCR2

LD5 – SCR3 light is ON and Alarm relay engaged Shorted SCR3

LD3 – SCR1 light is blinking and Alarm relay engaged Missing phase or phase error, SCR1

LD4 – SCR2 light is blinking and Alarm relay engaged Missing phase or phase error, SCR2

LD5 – SCR3 light is blinking and Alarm relay engaged Missing phase or phase error, SCR3

Over temp output conducts, Alarm relay engaged,

and heater output still functions

Over temp output conducts, Excessive temperature

of heat sink and Alarm relay engaged, heater output

still functions

Diagnostics with Safety Cover Removed

Observation Possible Root Cause

Heartbeat LED not blinking Loss of electronics AC power. Check fuse.

Heat Sink Temperature greater than 200˚F (93˚C)

detected but all outputs less than 212˚F (100˚C)

Heat Sink Temperature greater than 200 ˚F (93˚C)

detected but all outputs less than 212˚F (100˚C)

30

Page 33

Parts and Accessories

9

Instrument Power Fuse

Chromalox Part Number Description

0024-01312 Fuse, 0.125A, 2 AG

500 VAC I

0024-07634 200 Amp I

0024-07630 250 Amp I

0024-07632 400 Amp I

0024-03116 500 Amp I

0024-07633 700 Amp I

0024-03118 800 Amp I

0024-03200 1000 Amp I

600 VAC I2T Fuse

0024-07644 125 Amp I

0024-07645 175 Amp I

0024-07636 250 Amp I

0024-07637 400 Amp I

0024-07638 500 Amp I

0024-07639 700 Amp I

0024-07640 800 Amp I

0024-07646 1000 Amp I

0024-01191 1200 Amp I

Fans

Chromalox Part Number Description

0045-00231 120 VAC rated Fan

0045-00235 230 VAC rated Fan

Crimp Lug Chart

For Open Design 400 - 1200 Amp and all Touch-Safe Models:

SCR Replacement

Be sure to replace thermstrate interface material and torque as follows:

MaxPac I, II, and III

Accessories:

2

T Fuse

Conductor Size Chromalox Part # Panduit Part #

#8 AWG (10mm

#6 AWG or #6 Weld (16mm

#4 AWG or #4 Weld (25mm

#2 AWG (35mm

#1 AWG or #2 Weld (50mm

#1/0 AWG or #1 Weld (70mm

#2/0 AWG or #1/0 Weld (70mm

#3/0 AWG or #2/0 Weld (95mm

2

) 0135 - 10002 LCD8 - 14A - L

2

) 0135 - 10005 LCD2 - 56B - Q

2

) 0135 - 10003 LCD6 - 14A - L

2

) 0135 - 10004 LCD4 - 14A - L

2

) 0135 - 10006 LCD1 - 56C - E

2

) 0135 - 10007 LCD1/0 - 12 - X

2

2

#4/0 AWG or #3/0 Weld (120mm

250 MCM or #4/0 Weld (150mm

300 MCM (150mm

350 MCM (185mm

400 MCM (240mm

500 MCM (240mm

2

) 0135 - 10012 LCD300 - 12 - X

2

) 0135 - 10013 LCD350 - 12 - 6

2

) 0135 - 10014 LCD400 - 12 - 6

2

) 0135 - 10015 LCD500 - 12 - 6

MFG Part # SCR Part # Thermstrate Part # Torque inch/lb Torque inch/lb

to Heat Sink to Terminals

SKKT92 0002 - 47560 0029 - 00700 44 inch/lb (5 Nm) 26 inch/lb (3Nm)

SKKT162 0002 - 47559 0029 - 00822 44 inch/lb (5 Nm) 44 inch/lb (5 Nm)

SKKT250 0002 - 47537 0029 - 00719 44 inch/lb (5 Nm) 80 inch/lb (9 Nm)

SKKT500 0002 - 47557 0029 - 00814 44 inch/lb (5 Nm) 106 inch/lb (12 Nm)

Part Number Description

0135 - 28193 SCR Trigger Board

0135 - 28194 On/Off Main Firing Board

0135 - 20117 Potentiometer & Remote/Manual Switch

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

2

t Fuse

) 0135 - 10008 LCD2/0 - 12 - X

) 0135 - 10009 LCD3/0 - 12 - X

2

) 0135 - 10010 LCD4/0 - 12 - X

2

) 0135 - 10011 LCD250 - 12 - X

MaxPac IP

Accessories:

Part Number Description

0135 - 28002 Firing Circuit 120, 240 VAC

0135 - 28006 Firing Circuit 208, 277, 480 VAC

0135 - 28037 Firing Circuit 380 VAC

31

Page 34

Warranty and Return Information

10

Warranty Notice

The Warranty below complies with the federal law applicable to products manufactured after December 31,

1976. This warranty gives you specific legal rights and you may also have other rights which vary from state

to state.

Chromalox Warranty

Chromalox instruments and controls are warranted against defects in workmanship and materials. No other

express warranty, written or oral, applies with the exception of a written statement from an officer of Chromalox®, Inc.

Warranty Period

This warranty extends for one year from date of shipment from the factory or authorized distributor.

Limitations

Products must be installed and maintained in accordance with Chromalox instructions. Users are responsible for the suitability of the products to their application. There is no warranty against damage resulting from

corrosion, misapplication, improper specification or other operating conditions beyond our control. Claims

against the carrier company for damage in transit must be filed by the buyer.

Returns

Items returned to Chromalox must be accompanied by a Return Authorization Number. This number may be

obtained from Chromalox’ Customer Service Department at the phone number listed below.

The Return Authorization Number must appear on the exterior of the shipping carton and on the shipping

documents.

Defective items will be repaired or replaced at our option and at no charge.

Return the defective part or product, freight prepaid, to the following address:

Chromalox, Inc.

1347 Heil Quaker Blvd.

LaVergne, TN 37086-3536

Phone: (615) 793-3900

Fax: (615) 793-3563

32

Page 35

Ordering Information for MaxPac I

Model SCR Power Pack

MXPC I Single Phase SCR Power Pack

Code Control Configuration

5 Proportional Control, DOT Zero-Crossover Firing, Command Input Signals: 4-20mA, 0-5

VDC, 1-5 VDC (via Modbus RTU/485 only), 0-10 VDC, Remote 0-1000 OHM Potentiometer

w/Manual Override, Modbus RTU/RS485 Communications. RTD Heat Sink Temperature

Sensor with Two Set-Points, Automatic Line Sensing 50/60HZ, Remote Permissive Stop

Input, Form “C” Dry Contact Alarm Output, Staged Heating w/Digital Calibration Zero /

Span Adjustments(4-8 mA, 8-12 mA,12-16 mA,16-20 mA (via Modbus RTU/RS485 only),

LED Diagnostics: Command Input, Main/Trigger Boards Running, SCR Status per Phase,

Diagnostic Kit via Modbus RTU/RS485: Highest Heat Sink Temperature, Last Heat Sink

Temperature, Highest and Lowest Ambient Temperature, Line Frequency Monitoring, Third

Party Certifications: UL, cUL, CE, DEMKO (650 A and below).

Code Current at 50°C (122°F)

01 100 Amp Open Design

02 100 Amp Touch Safe Design

03 150 Amp Open Design

04 150 Amp Touch Safe Design

05 200 Amp Open Design

06 200 Amp Touch Safe Design

07 300 Amp Open Design

08 300 Amp Touch Safe Design

09 400 Amp Open Design

10 400 Amp Touch Safe Design

11 550 Amp Open Design

12 550 Amp Touch Safe Design

13 650 Amp Open Design

14 650 Amp Touch Safe Design

15 800 Amp Open Design

16 1000 Amp Open Design

17 1200 Amp Open Design

Code Line Voltage

1 120 VAC - 480 VAC

2 575/600 VAC

Code Instrument Power

1 120 VAC 50/60 Hz

2 230 VAC 50/60 Hz

Code Compression Lug Kits (Open Design up to 300 Amps)

For Other Ranges See Crimp Lug Chart

L0 None

L1 100 - 150 Amp PAK 1(#2 - 4/0)/connection

L2 200 - 300 Amp PAK 1(1/0 - 500mcm)/connection

MXPC I - 5 03 1 1 L1 (Continued on next page)

33

Page 36

Ordering Information for MaxPac I (continued)

Code Fusing Option (1)

For < 500VAC Applications, Select One

F00 None

F01 100 -150 Amp PAK (200 Amp Fuse)

F02 200 Amp PAK (250 Amp Fuse)

F03 300 Amp PAK (400 Amp Fuse)

F04 400 Amp PAK (500 Amp Fuse)

F05 550 Amp PAK (700 Amp Fuse)

F06 650 Amp PAK (800 Amp Fuse)

F07 800 Amp PAK (1000 Amp Fuse)

F08 1000 Amp PAK (1200 Amp Fuses)

F09 1200 Amp PAK (Two 1000 Amp Fuses)

F10 100 Amp PAK (125 Amp Fuse)

F11 150 Amp PAK (175 Amp Fuse)

F12 200 Amp PAK (250 Amp Fuse)

F13 300 Amp PAK (400 Amp Fuse)

F14 400 Amp PAK (500 Amp Fuse)

F15 550 Amp PAK (700 Amp Fuse) W

F16 650 Amp PAK (800 Amp Fuse)

F17 800 Amp PAK (1000 Amp Fuse)

F18 1000 Amp PAK (1200 Amp Fuse)

F19 1200 Amp PAK (Two 1000 Amp Fuses)

Code Remote Man. Adjust/Auto Man. Switch

0 None

1 Pot with 0 - 100% dial and Local/Re-

700 V Fuses for 575/600 V Applications, Select One

mote Single Turn 1K Potentiometer (Proportional Control Only) (Supplied loose

for customer mounting)

MXPC I - 5 03 1 1 L1 F01 1 Typical Model Number

Crimp Lug Chart

1) SCR Fusing is for semiconductor

protection only, not wire protection.

2) Supplied Loose for Customer

Mounting.

Note:

Storage Temperature 14ºF to 158ºF

(-10ºC to 70ºC).

CE application requires filters.

Chromalox # Panduit # Conductor Size

0135-10002 LCD8-14A-L #8 AWG 180 20

0135-10003 LCD6-14A-L #6 AWG or #6 Weld 180 20

0135-10004 LCD4-14A-L #4 AWG or #4 Weld 180 20

0135-10005 LCD2-56B-Q #2 AWG 180 20

0135-10006 LCD1-56C-E #1 AWG or #2 Weld 180 20

0135-10007 LCD1/0-12-X #1/0 AWG or #1 Weld 480 54

0135-10008 LCD2/0-12-X #2/0 AWG or #1/0 Weld 480 54

0135-10009 LCD3/0-12-X #3/0 AWG or #2/0 Weld 480 54

0135-10010 LCD4/0-12-X #4/0 AWG or #3/0 Weld 480 54

0135-10011 LCD250-12-X 250 MCM or #4/0 Weld 480 54

0135-10012 LCD300-12-X 300 MCM 480 54

0135-10013 LCD350-12-6 350 MCM 480 54

0135-10014 LCD400-12-6 400 MCM 480 54

0135-10015 LCD500-12-6 500 MCM 480 54

Note: NEMA standard two hole copper crimp lugs only.

Torque

In-Lb. Nm

34

Page 37

Ordering Information for MaxPac IP

Model SCR Power Pack

MXPC IP Single Phase SCR Power Pack

Code Control Configuration

1 Phase Angle Control (Accepts: 0-5 mA, 0-20 mA, 0-50 mA, 1-5mA, 4-20 mA, 10-50 mA,

0-5Vdc, 0-10 VDC)

2 Phase Angle Control with Current Limit

Code Current at 50°C (122°F)

01 100 Amp Open Design

02 100 Amp Touch Safe Design

03 150 Amp Open Design

04 150 Amp Touch Safe Design

05 200 Amp Open Design

06 200 Amp Touch Safe Design

07 300 Amp Open Design

08 300 Amp Touch Safe Design

09 400 Amp Open Design

10 400 Amp Touch Safe Design

11 550 Amp Open Design

12 550 Amp Touch Safe Design

13 650 Amp Open Design

14 650 Amp Touch Safe Design

15 800 Amp Open Design

16 1000 Amp Open Design

17 1200 Amp Open Design

Code Voltage

1 120 VAC

2 208 VAC

3 240 VAC

4 277 VAC

5 480 VAC

6 575 VAC

Code Fan Power

1 120 VAC 50/60 Hz

2 230 VAC 50/60 Hz

Code Compression Lug Kits (Open Design up to 300 Amps)

For Other Ranges See Crimp Lug Chart

L0 None (Select for all Touch Safe Designs and for over 30

Amp Open Design)

L1 100 - 150 Amp PAK 1(#2 - 4/0)/connection

L2 200 - 300 Amp PAK 1(1/0 - 500mcm)/connection

MXPC IP - 2 03 1 1 L1 (Continued on next page)

35

Page 38

Ordering Information for MaxPac IP (continued)

Code Fusing Option (1)

For < 500VAC Applications, Select One

F00 None

F01 100 -150 Amp PAK (200 Amp Fuse)

F02 200 Amp PAK (250 Amp Fuse)

F03 300 Amp PAK (400 Amp Fuse)

F04 400 Amp PAK (500 Amp Fuse)

F05 550 Amp PAK (700 Amp Fuse)

F06 650 Amp PAK (800 Amp Fuse)

F07 800 Amp PAK (1000 Amp Fuse)

F08 1000 Amp PAK (1200 Amp Fuses)

F09 1200 Amp PAK (Two 1000 Amp Fuses)

700 V Fuses for 575 V Applications, Select One

F10 100 Amp PAK (125 Amp Fuse)

F11 150 Amp PAK (175 Amp Fuse)

F12 200 Amp PAK (250 Amp Fuse)

F13 300 Amp PAK (400 Amp Fuse)

F14 400 Amp PAK (500 Amp Fuse)

F15 550 Amp PAK (700 Amp Fuse)

F16 650 Amp PAK (800 Amp Fuse)

F17 800 Amp PAK (1000 Amp Fuse)

F18 1000 Amp PAK (1200 Amp Fuse)

F19 1200 Amp PAK (Two 1000 Amp Fuses)

Code Remote Man. Adjust/Auto Man. Switch

0 None

1 Pot with 0 - 100% dial and Local/Remote

Switch(2) Single Turn 1KW Potentiomete

MXPC IP - 2 03 1 1 L1 F01 1 Typical Model Number

Crimp Lug Chart

1) SCR Fusing is for semiconductor

protection only, not wire protection.

2) Supplied Loose for Customer

Mounting.

Note:

Storage Temperature 14ºF to 158ºF

(-10ºC to 70ºC).

CE application requires filters.

Chromalox # Panduit # Conductor Size

0135-10002 LCD8-14A-L #8 AWG 180 20

0135-10003 LCD6-14A-L #6 AWG or #6 Weld 180 20

0135-10004 LCD4-14A-L #4 AWG or #4 Weld 180 20

0135-10005 LCD2-56B-Q #2 AWG 180 20

0135-10006 LCD1-56C-E #1 AWG or #2 Weld 180 20

0135-10007 LCD1/0-12-X #1/0 AWG or #1 Weld 480 54

0135-10008 LCD2/0-12-X #2/0 AWG or #1/0 Weld 480 54

0135-10009 LCD3/0-12-X #3/0 AWG or #2/0 Weld 480 54

0135-10010 LCD4/0-12-X #4/0 AWG or #3/0 Weld 480 54

0135-10011 LCD250-12-X 250 MCM or #4/0 Weld 480 54

0135-10012 LCD300-12-X 300 MCM 480 54

0135-10013 LCD350-12-6 350 MCM 480 54

0135-10014 LCD400-12-6 400 MCM 480 54

0135-10015 LCD500-12-6 500 MCM 480 54

Note: NEMA standard two hole copper crimp lugs only.

Torque

In-Lb. Nm

36

Page 39

Ordering Information for MaxPac II

Model SCR Power Pack

MXPC II Three Phase SCR Power Pack

Code Control Configuration

5 Proportional Control, DOT Zero-Crossover Firing, Command Input Signals: 4-20 mA, 0-5

VDC, 1-5 VDC (via Modbus RTU/485 only), 0-10 VDC, Remote 0-1000 OHM Potentiometer

w/Manual Override, Modbus RTU/RS485 Communications. RTD Heat Sink Temperature

Sensor with Two Set-Points, Automatic Line Sensing 50/60HZ, Remote Permissive Stop

Input, Form “C” Dry Contact Alarm Output, Staged Heating w/Digital Calibration Zero /

Span Adjustments(4-8 mA, 8-12 mA,12-16 mA,16-20 mA(via Modbus RTU/RS485 only),

LED Diagnostics: Command Input, Main/Trigger Boards Running, SCR Status per Phase,

Diagnostic Kit via Modbus RTU/RS485: Highest Heat Sink Temperature, Last Heat Sink

Temperature, Highest and Lowest Ambient Temperature, Line Frequency Monitoring, Third

Party Certifications: UL, cUL, CE, DEMKO (650A and below).

Code Current at 50°C (122°F)

01 100 Amp Open Design

02 100 Amp Touch Safe Design

03 150 Amp Open Design

04 150 Amp Touch Safe Design

05 200 Amp Open Design

06 200 Amp Touch Safe Design

07 300 Amp Open Design

08 300 Amp Touch Safe Design

09 400 Amp Open Design

10 400 Amp Touch Safe Design

11 550 Amp Open Design

12 550 Amp Touch Safe Design

13 650 Amp Open Design

14 650 Amp Touch Safe Design

15 800 Amp Open Design

16 1000 Amp Open Design

17 1200 Amp Open Design

Code Line Voltage

1 120 VAC - 480VAC

2 575/600 VAC

Code Instrument Power

1 120 VAC 50/60 Hz

2 230 VAC 50/60 Hz

Code Compression Lug Kits (Open Design up to 300 Amps)

For Other Ranges See Crimp Lug Chart

L0 None

L1 100 - 150 Amp PAK 1(#2 - 4/0)/connection

L2 200 - 300 Amp PAK 1(1/0 - 500mcm)/connection

MXPC II - 5 03 1 1 L1 (Continued on next page)

37

Page 40

Ordering Information for MaxPac II (continued)

Code Fusing Option (1)

For < 500VAC Applications, Select One

F00 None

F01 100 -150 Amp PAK (200 Amp Fuse)

F02 200 Amp PAK (250 Amp Fuse)

F03 300 Amp PAK (400 Amp Fuse)

F04 400 Amp PAK (500 Amp Fuse)

F05 550 Amp PAK (700 Amp Fuse)

F06 650 Amp PAK (800 Amp Fuse)

F07 800 Amp PAK (1000 Amp Fuse)

F08 1000 Amp PAK (1200 Amp Fuses)

F09 1200 Amp PAK (Two 1000 Amp Fuses)

700 V Fuses for 575 V Applications, Select One

F10 100 Amp PAK (125 Amp Fuse)

F11 150 Amp PAK (175 Amp Fuse)

F12 200 Amp PAK (250 Amp Fuse)

F13 300 Amp PAK (400 Amp Fuse)

F14 400 Amp PAK (500 Amp Fuse)

F15 550 Amp PAK (700 Amp Fuse)

F16 650 Amp PAK (800 Amp Fuse)

F17 800 Amp PAK (1000 Amp Fuse)

F18 1000 Amp PAK (1200 Amp Fuse)

F19 1200 Amp PAK (Two 1000 Amp Fuses)

Code Remote Man. Adjust/Auto Man. Switch

0 None

1 Pot with 0 - 100% dial and Local/Remote

Single Turn 1KW Potentiometer

(Proportional Control Only)

(Supplied loose for customer mounting)

MXPC II - 5 03 1 1 L1 F01 1 Typical Model Number

Crimp Lug Chart

1) SCR Fusing is for semiconductor

protection only, not wire protection.

2) Supplied Loose for Customer

Mounting.

Note:

Storage Temperature 14ºF to 158ºF

(-10ºC to 70ºC).

Chromalox # Panduit # Conductor Size

0135-10002 LCD8-14A-L #8 AWG 180 20

0135-10003 LCD6-14A-L #6 AWG or #6 Weld 180 20

0135-10004 LCD4-14A-L #4 AWG or #4 Weld 180 20

0135-10005 LCD2-56B-Q #2 AWG 180 20

0135-10006 LCD1-56C-E #1 AWG or #2 Weld 180 20

0135-10007 LCD1/0-12-X #1/0 AWG or #1 Weld 480 54

0135-10008 LCD2/0-12-X #2/0 AWG or #1/0 Weld 480 54

0135-10009 LCD3/0-12-X #3/0 AWG or #2/0 Weld 480 54

0135-10010 LCD4/0-12-X #4/0 AWG or #3/0 Weld 480 54

0135-10011 LCD250-12-X 250 MCM or #4/0 Weld 480 54

0135-10012 LCD300-12-X 300 MCM 480 54

0135-10013 LCD350-12-6 350 MCM 480 54

0135-10014 LCD400-12-6 400 MCM 480 54

0135-10015 LCD500-12-6 500 MCM 480 54

Note: NEMA standard two hole copper crimp lugs only.

Torque

In-Lb. Nm

38

Page 41

Ordering Information for MaxPac III

Model SCR Power Pack

MXPC III Three Phase Six SCR Power Pack

Code Control Configuration

5 Proportional Control, DOT Zero-Crossover Firing, Command Input Signals: 4-20 mA, 0-5

VDC, 1-5 VDC (via Modbus RTU/485 only), 0-10 VDC, Remote 0-1000 OHM Potentiometer

w/Manual Override, Modbus RTU/RS485 Communications. RTD Heat Sink Temperature

Sensor with Two Set-Points, Automatic Line Sensing 50/60HZ, Remote Permissive Stop

Input, Form “C” Dry Contact Alarm Output, Staged Heating w/Digital Calibration Zero /

Span Adjustments(4-8 mA, 8-12 mA,12-16 mA,16-20 mA(via Modbus RTU/RS485 only),

LED Diagnostics: Command Input, Main/Trigger Boards Running, SCR Status per Phase,

Diagnostic Kit via Modbus RTU/RS485: Highest Heat Sink Temperature, Last Heat Sink

Temperature, Highest and Lowest Ambient Temperature, Line Frequency Monitoring, Third

Party Certifications: UL, cUL, CE, DEMKO (650A and below).

Code Current at 50°C (122°F)

01 100 Amp Open Design

02 100 Amp Touch Safe Design

03 150 Amp Open Design

04 150 Amp Touch Safe Design

05 200 Amp Open Design

06 200 Amp Touch Safe Design

07 300 Amp Open Design

08 300 Amp Touch Safe Design

09 400 Amp Open Design

10 400 Amp Touch Safe Design

11 550 Amp Open Design

12 550 Amp Touch Safe Design

13 650 Amp Open Design

14 650 Amp Touch Safe Design

15 800 Amp Open Design

16 1000 Amp Open Design

17 1200 Amp Open Design

Code Line Voltage

1 120 VAC - 480VAC

2 575/600 VAC

Code Instrument Power

1 120 VAC 50/60 Hz

2 230 VAC 50/60 Hz

Code Compression Lug Kits (Open Design up to 300 Amps)

For Other Ranges See Crimp Lug Chart

L0 None

L1 100 - 150 Amp PAK 1(#2 - 4/0)/connection

L2 200 - 300 Amp PAK 1(1/0 - 500mcm)/connection

Note: 550-1200 Amp and all Touch-Safe Designs: Buss

MXPC III - 5 04 1 1 L1 (Continued on next page)

39

Page 42

Ordering Information for MaxPac III (continued)

Code Fusing Option (1)

For < 500VAC Applications, Select One

F00 None

F01 100 -150 Amp PAK (200 Amp Fuse)

F02 200 Amp PAK (250 Amp Fuse)

F03 300 Amp PAK (400 Amp Fuse)

F04 400 Amp PAK (500 Amp Fuse)

F05 550 Amp PAK (700 Amp Fuse)

F06 650 Amp PAK (800 Amp Fuse)

F07 800 Amp PAK (1000 Amp Fuse)

F08 1000 Amp PAK (1200 Amp Fuses)

F09 1200 Amp PAK (Two 1000 Amp Fuses)

700 V Fuses for 575 V Applications, Select One

F10 100 Amp PAK (125 Amp Fuse)

F11 150 Amp PAK (175 Amp Fuse)

F12 200 Amp PAK (250 Amp Fuse)

F13 300 Amp PAK (400 Amp Fuse)

F14 400 Amp PAK (500 Amp Fuse)

F15 550 Amp PAK (700 Amp Fuse)

F16 650 Amp PAK (800 Amp Fuse)

F17 800 Amp PAK (1000 Amp Fuse)

F18 1000 Amp PAK (1200 Amp Fuse)

F19 1200 Amp PAK (Two 1000 Amp Fuses)

Code Remote Manual Adjust

0 None

1 Pot with 0 - 100% dial and Local/Remote

Single Turn 1KW Potentiometer

(Proportional Control Only)

(Supplied loose for customer mounting)

MXPC III - 5 04 1 1 L1 F02 1 Typical Model Number

Crimp Lug Chart

1) SCR Fusing is for semiconductor

protection only, not wire protection.

2) Supplied Loose for Customer

Mounting.

Note:

Storage Temperature 14ºF to 158ºF

(-10ºC to 70ºC).

Chromalox # Panduit # Conductor Size

0135-10002 LCD8-14A-L #8 AWG 180 20

0135-10003 LCD6-14A-L #6 AWG or #6 Weld 180 20

0135-10004 LCD4-14A-L #4 AWG or #4 Weld 180 20

0135-10005 LCD2-56B-Q #2 AWG 180 20

0135-10006 LCD1-56C-E #1 AWG or #2 Weld 180 20

0135-10007 LCD1/0-12-X #1/0 AWG or #1 Weld 480 54

0135-10008 LCD2/0-12-X #2/0 AWG or #1/0 Weld 480 54

0135-10009 LCD3/0-12-X #3/0 AWG or #2/0 Weld 480 54

0135-10010 LCD4/0-12-X #4/0 AWG or #3/0 Weld 480 54

0135-10011 LCD250-12-X 250 MCM or #4/0 Weld 480 54

0135-10012 LCD300-12-X 300 MCM 480 54

0135-10013 LCD350-12-6 350 MCM 480 54

0135-10014 LCD400-12-6 400 MCM 480 54

0135-10015 LCD500-12-6 500 MCM 480 54

Note: NEMA standard two hole copper crimp lugs only.

Torque

In-Lb. Nm

40

Page 43

EC Declaration of Conformity

We, Chromalox Precision Heat and Control

1347 Heil Quaker Boulevard

LaVergne, Tennessee 37086-3536

Phone: +1 (615) 793-7561

Fax: +1 (615) 213-8091

declare under sole responsibility that the following described product in our delivered version complies with

the appropriate basic safety and health requirements of the EC Low Voltage Directive (2006/95/EC) and EC

Electromagnetic Compatibility Directive (2004/108/EC) based on its design and type, as brought into circulation by us. In case of alteration of the machine, not agreed upon by us, this declaration will lose its validity.

Description of the Electrical Equipment: MaxPac SCR controllers

Model Number: MaxPac Series; MaxPac I, II, III

Applicable Harmonized Standards:

Low Voltage Directive EMC Directive

Specification: EN60947-4-3:2000 1. Radiated Disturbance Emissions – 30 to 1000

Low-voltage switch gear and MHz Electric Field

control gear EN 61000-6-4:2001 / EN 55011:2007

Part 4-3: Contactors and 2. Conducted Disturbance Emissions – Voltage

motor-starters EN 61000-6-4:2001 / EN 55011:2007

AC semiconductor controllers

and contactors for non-motor loads 3. Conducted Disturbance Immunity

Utilization AC-51 Non-inductive or slightly EN 61000-6-2:2005 / EN 61000-4-6:1996

Category: inductive loads, resistive

furnaces 4. Radiated Disturbance Immunity

EN 61000-6-2:2005 / EN 61000-4-3:1995

Pollution Normally only non-conductive

Degree 2 pollution occurs. Occasionally, 5. Electrical Fast Transients/Bursts Immunity

a temporary conductivity EN 61000-6-2:2005 / EN 61000-4-2:1995

caused by condensation may

be expected. 6. Voltage Dips and Interrupts Immunity

EN 61000-6-2:2005 / EN 61000-4-11:1994

Voltage Rating: 400 VAC 50 Hz Line

230 VAC 50 Hz Instrument max 7. Electrostatic Discharge Immunity

75 watts EN 61000-6-2:2005 / EN 61000-4-2:1995

Impulse Rating: 2.5 KV for 5 seconds 8. Voltage Fluctuations/Flicker

EN 61000-3-3 / A2:2005

Overload 140% for 1 second

Current Profile: 9. Harmonic Current Emissions

EN 61000-3-2:2006

Fuses: 500 Volt, 200KA RMS

symmetrical interrupting rating,

I2t fusing provided with all CE

units.

41

Page 44

Filters Required: Instrument power filter: 10. Surge Immunity

Chromalox P/N 0005-60057 EN 61000-6-2:2005 / EN 61000-4-5:1995

Line Filter, single phase:

Chromalox P/N 0005-60055

Line Filter, three phase:

Chromalox P/N 0005-60056

The Technical documentation required by Annex IV (3) of the Low Voltage Directive is maintained by (Name)

of (company and location in the European Union)

Year in which CE Marking was affixed: 2002

Authorized Signature/Date: ________________________________________ __________________________

Jim Birnie Date

Engineering Manager

Title of Signatory: ________________________________

Chromalox, International

Unit 1.22, Lombard House

2 Purley Way

Croydon CRO 3JP

Surrey

U.K.

42

Loading...

Loading...