Page 1

Installation and

Operating Instructions

LIMIT

Temperature Controller

PK523-2

0037-75551

September 2018

1

Page 2

LIMIT Temperature Control

The LIMIT protects expensive heaters and sensitive

materials from damaging over temperature conditions.

It is designed for industrial and commercial applications

that require high temperature protection.

The LIMIT features a Form C latching, manually resettable relay output that de-energizes whenever the sensed

temperature exceeds the set point temperature.

The DIN Rail mounting feature allows quick installation

without drilling or extra hardware. Slots are also provided for direct panel mounting.

Two methods are provided to reset an alarm condition.

(1) The Limit alarm has a reset pushbutton on the unit

and (2) reset terminals are provided for resetting the

alarm from a remote pushbutton.

Mounting

ELECTRIC SHOCK HAZARD. Read and understand

all instructions before installing, servicing or operating LIMIT controller. Failure to do so could result

in personal injury or property damage.

The Heating system designer is responsible for the

safety of the equipment and must determine the

suitability of this temperature LIMIT controller with

other electric heating equipment. Where the conse

quences of failure could result in personal injury or

property damage, back-up controls are essential.

-

The LIMIT can be surface mounted or DIN rail mounted. It can be mounted to any suitable flat surface using

two #6 screws (not supplied). To install simply position

the top set of rear clips over the top of the DIN rail.

Then swing the bottom of the controller toward the rail

applying pressure until the lower clips snap on to the

bottom of the DIN rail. To remove apply pressure to the

top of the controller’s base and move the bottom of the

controller toward you. Then lift the top of the controller

off the upper DIN rail. The housing rating is NEMA 1.

This controller must be mounted in an enclosure

suitable for protection against normally expected

operation environments and to minimize unauthorized tampering with the limit settings.

FIRE/EXPOSION HAZARD. This heater is not intended for use in hazardous atmospheres where flammable vapors, gases, liquids or other combustible

atmospheres are present as defined in the National

Electrical Code. Failure to comply can result in personal injury or property damage.

2

Page 3

Dimensions

*Each LIMIT requires its own contact input for reset. A single contact input cannot be used to reset multiple LIMITS.

Operation

The set point temperature is adjustable by turning the

integral dial. If the set point is exceeded, contacts 4

and 5 will open. It will remain in this state until the temperature drops below the set point and the controller is

manually reset. Manual reset can be accomplished by

one of the following means:

a) Press the “reset button”.

b) A momentary switch closure between terminals 8

and 9.

c) Interrupt power to the control.

Troubleshooting

Experience has proven that many control problems

are not caused by a defective instrument. Some of the

common causes of failure are broken sensors, open

fuses and poor wire connections. If these points have

been checked and the control still does not function,

it is suggested that the instrument be returned for inspection. Use adequate packing materials to prevent

damage in shipment.

Maintenance

No specific maintenance is required. However, it is

recommended that all wiring be checked periodically

for loose connections and damaged wires. Disconnect

power to the panel before any maintenance is performed. Check wires and tighten connections.

ELECTRIC SHOCK HAZARD. Disconnect all power before

installing or servicing LIMIT controller. Failure to do so

could result in personal injury or property damage.

Custom Controllers

Custom temperature ranges and fixed set point units

are available to meet your specific application needs.

3

Page 4

Control

Contactor

Wiring

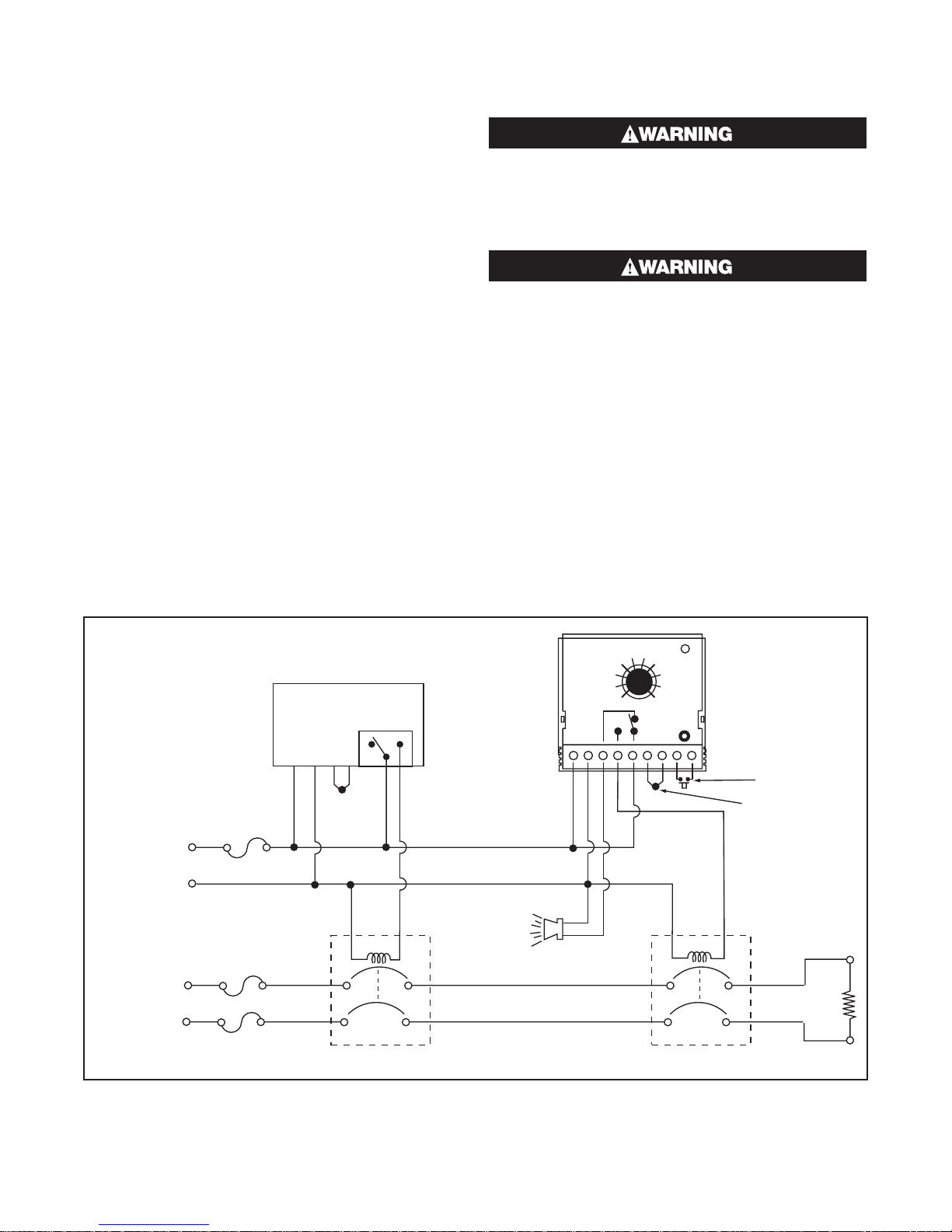

Carefully follow the terminal diagram pictured on the

controller’s housing and shown above. The power and

load wiring should be 18 AWG or larger size. Be sure to

observe that the ratings for voltage and current are not

exceeded. All local and national electrical codes must

be followed.

Use only the sensor type as indicated on the control

and maintain correct polarity. THE RED THERMOCOUPLE LEAD ALWAYS CONNECTS TO THE NEGATIVE (–)

TERMINAL. To reduce electrical noise, the thermocouple wire must be isolated from any power or heater wiring. Shielded thermocouple wire may be necessary in

high noise environments or when lead lengths exceed

10 feet (3 m). Thermocouples are tip sensitive and must

be in good mechanical contact with the load.

The remote reset terminals allow for a remote pushbutton (on the panel door) to reset the LIMIT alarm. If

multiple units are mounted in a panel, the remote reset

terminals cannot be wired in parallel. The remote pushbutton needs a separate contact block for each LIMIT.

A single contact input cannot be used to reset multiple

LIMITs.

ELECTRIC SHOCK HAZARD. Any installation involving

LIMIT temperature controllers must be performed by

a qualified person and must be effectively grounded

in accordance with the National Electrical Code to

eliminate shock hazard. Failure to do so could result

in personal injury or property damage.

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing LIMIT controller. Failure to do so could result in personal injury or property damage.

Typical Wiring Diagram

Primary

Temperature

Control

120VAC

Control

Fuse

H

5A

120V

Control

Power

N

Heater Power

1 or 3 Phase

Heater

Fuses

T/C

or

RTD

NC

C

Coil

Primary

NO

Optional Alarm

or Warning

Lamp

LIMIT-10100L

234

1

˚F/˚C

NC

NO

C

+

56789

Alarm

Reset

–

Optional N.O.

Remote Reset

Switch

T/C or RTD

Coil

Heater(s)

Limit

4

Page 5

Specifications

Power Input: ........................120VAC or 24VAC ±15%,

50/60Hz, 3VA max. standard

Control Output: .......SPDT Relay rated 3.8 Amps Res.

and 1.5 Amps Pilot Duty 120 VAC.

100,000 cycles.

Control Mode: ................. Latching with Manual Reset

or power off.

Reset Function: ........... Integral reset switch standard;

terminals available for

optional remote reset switch

Set Point Adjustment: ........Local SP dial adjustment.

Compensation (TC only): ......Automatic cold junction

compensation.

Control Stability: .............................Typically less than

±5μV/°F ambient and 0.1% of

SPAN/% rated line voltage.

Set Point Accuracy: ...................±3% of FS maximum

at 25°C and rated line voltage.

Sensor Break Protection: ..... Contacts 4 & 5 open for

thermocouple or RTD break.

Ordering Information

Ambient Operating Temperature:................. 0 - 55°C

(32 - 131°F).

Noise Rejection: ................ Common Mode Rejection

60dB Series Mode Rejection 120dB

Trip Inidcator: .... LED Illuminates when controller trips

Mechanical

Enclosure Material: .......................... Noryl, Black color.

Field Terminations: ......................Screw Terminals with

wire clamping plates and

touch safe shield.

Mounting: ............ 35mm DIN rail or surface mounting.

Sensor Inputs

Sensor Range

J T/C 0 to 1400°F, -20 to 760°C

K T/C 0 to 2300˚F, -20 to 1260°C

RTD 0-850°F / -20˚C - 455˚C

Model PCN Temperature Range Input Type Input Power

LIMIT-10100L 309200 0-1400°F / -20˚C - 760˚C J T/C 120 Vac

LIMIT-10200L 309219 0-2300°F / -20˚C - 1260˚C K T/C 120 Vac

LIMIT-10400L 309243 0-850°F / -20˚C - 455˚C RTD 120 Vac

LIMIT-10101L 309235 0-1400°F / -20˚C - 760˚C J T/C 24 Vac

5

Page 6

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Chromalox

103 Gamma Drive

Pittsburgh, PA 15238

(412) 967-3800

www.chromalox.com

© 2018 Chromalox, Inc. All rights reserved.

6

Loading...

Loading...