Page 1

Installation Manual & Set-Up Guide

Ordinary Area

ITAS Ambient Sensing Control Panel

ITAS-EXT Ambient Sensing Extender Control Panel

ITLS Line Sensing Control Panel

ITLS-EXT Line Sensing Extender Control Panel

Hazardous Area

ITASC1D2 Ambient Sensing Control Panel

ITASC1D2-EXT Ambient Sensing Extender Control Panel

ITLS C1D2 Line Sensing Control Panel

ITLS C1D2-EXT Line Sensing Extender Control Panel

PK497-5

0037-75514

June 2018

1

Page 2

Safety Precautions

IMPORTANT SAFEGUARDS

Throughout the IntelliTrace® Setup Guide, these symbols will alert you to potential hazards. Safety precautions should always be followed to reduce the risk of

fire, electrical shock, injury and even death to persons.

Please read all instructions before operating your

IntelliTrace® ITLS, ITAS, ITLS-EXT or ITAS-EXT Control

Panel.

WARNING

HIGH VOLTAGE is used in the operation of this equipment; DEATH ON

CONTACT may result if personnel fail

to observe safety precautions.

Learn the areas containing high-voltage connections when installing or

operating this equipment.

To avoid electrical shock or injury, always remove power before servicing a circuit. Personnel working with

or near high voltages should be familiar with modern

methods of resuscitation. Contact an area supervisor

or safety personnel for more information.

WARNING

ELECTRIC SHOCK HAZARD

Any installation involving control

equipment must be performed by a

qualified person and must be effectively grounded in accordance with

the National Electrical Code to eliminate shock hazard.

Be careful not to contact high-voltage connections when installing or

operating this equipment.

Before working inside the equipment,

turn power off and ground all points

of high potential before touching

them.

ii

Page 3

Table of Contents

Contents Page Number

Safety Precautions .................................................................................................................................................ii

Table of Contents .................................................................................................................................................iii

Introduction ............................................................................................................................................................ 1

Model Overview ..................................................................................................................................................... 2

Theory of Operation .............................................................................................................................................. 3

Types of Sensing Control ..................................................................................................................................... 4

Pre-Service Storage .............................................................................................................................................. 5

Before Powering Up ............................................................................................................................................. 5

General Panel Notes ............................................................................................................................................ 6

Installation ............................................................................................................................................................. 7

Main Menu Screen ............................................................................................................................................... 8

Temp Setup Menu.. .............................................................................................................................................. 9

Security Levels & Password Screen ................................................................................................................. 10

Temp Setup Menu (Cont.) ................................................................................................................................. 11

Apply Settings Globally .................................................................................................................................... 13

Soft Start Feature .............................................................................................................................................. 13

Load Setup Menu .............................................................................................................................................. 14

Tuning Menu ......................................................................................................................................................... 16

Control Modes: ON/OFF, Autotune & PID ......................................................................................................... 17

Sensor Mapping ................................................................................................................................................ 18

System Properties ............................................................................................................................................. 19

Auto Cycle Feature ............................................................................................................................................ 20

Communications ............................................................................................................................................... 21

Remote Monitoring & System Management ................................................................................................... 21

Alarm Log ........................................................................................................................................................... 22

Active Alarms ..................................................................................................................................................... 23

Clearing Alarms ................................................................................................................................................ 23

Alarm Troubleshooting ..................................................................................................................................... 24

Extension Panels – Connection & Considerations ......................................................................................... 25

Connecting the Extension panel to the Main Panel ......................................................................................... 25

Extension Panel Considerations ....................................................................................................................... 25

Wireless Temperature Sensing ......................................................................................................................... 26

Appendix A ......................................................................................................................................................... 37

Panel Specifications ......................................................................................................................................... 37

Default Settings ................................................................................................................................................ 38

Appendix B ......................................................................................................................................................... 44

ModBus Specification ...................................................................................................................................... 44

Service Contact Information .......................................................................................................................... 106

iii

Page 4

Page 5

Introduction

For nearly 100 years, customers have relied upon Chromalox for premiere quality and innovative solutions for

industrial heating applications. Chromalox manufactures the world’s largest and broadest line of electric heat and

control products.

The IntelliTrace® ITLS & ITAS Series Multiple Circuit Panels and Extender Panels are a complete temperature

control and system management solution for electrical heat trace applications. They are designed for industrial

applications in Hazardous (Class I, Division 2) or Non-Hazardous environments.

IntelliTrace® provides the user with an easy to navigate touch-screen interface, system parameter monitoring, off

duty preventative maintenance, application flexibility and system customization.

The ITAS and ITASC1D2 provide Ambient Sensing control while the ITLS and ITLSC1D2 provide either Line Sensing control or a hybrid of both Line and Ambient Sensing control.

IntelliTrace® Features:

• 40 Amps/Circuit @ 100 – 600 VAC

• SSR Output Power Control

• 2 to 72 Circuit

• Large Touch Screen HMI

• Integral Control Panel and Circuit Breaker Distribution (non-hazardous areas)

• 1-pole or 2-pole Designs

• Soft Start, On/Off, PID and Manual (Hand) Control

• Modbus RTU/RS485 or TCP/Ethernet Communications

• Full Monitoring & Alarms (Lo/Hi Current & Temperature, Sensor, Transmitter Battery, Communications & GFEP)

• Hazardous (Class I, Division 2) and Non Hazardous Environments

• NEMA 4 Enclosure (Optional NEMA 4X 304 SS)

• UL, cUL Listing (CE available)

Touch Screen Computer:

• 10” on 6 – 72 Circuit Systems and 7” On 2 – 8 Circuit Systems

• 2 or 6 Circuit Circuit Detail Displayed at a Time

• Quick Launch to any 2 or 6 Circuit Group Display

• Remote Desktop Monitoring

• Extremely Intuitive Navigation, User Setting and Operation

• Fully Customizable Circuit Naming and Parameter Programming

Options:

• Powerful and Flexible Sensor Mapping (ITLS, ITLSC1D2 only)

• Enclosure Heater

• Fully Integrated Wireless Temperature Sensing

• IntelliTrace® Supervisory Control (ISC) for Central Command of Multiple Systems

1

Page 6

Model Overview

The Chromalox line of IntelliTrace® Heat Trace Control

Panels provides a significant amount of application

and feature flexibility.

vide the flexibility for the owner to meet their process

expansion needs. Simply connect the Extension Panel

to its matching ITLS, ITLSC1D2 or ITAS, ITASC1D2

Base Panel and circuit capacity is seamlessly in-

The ITAS and ITASC1D2 are designed for Ambient

Sensing applications while the ITLS and ITLSC1D2 are

creased. The Extension Panels do not have a HMI, but

otherwise are identical.

designed for Line Sensing applications. Additionally,

the ITLS and ITLSC1D2 have the capability to function

as both a Line Sensing control panel and an Ambient

Sensing control panel should the Customizable Sensor

These panels are UL and cUL Listed for Ordinary (Non

Hazardous ITLS/ITAS) and Hazardous (Class I, Division

2 ITLS/ITAS C1D2) Environments. CE is available.

Mapping feature be selected.

Please see Table 1 below for applicable features and

The IntelliTrace® matching ITAS-EXT, ITASC1D2-EXT

capabilities by model type.

and ITLS-EXT, ITLSC1D2-EXT Extension Panels pro-

Table 1

ITLS

Standard Features/Capabilities

Ordinary, Non-Hazardous Area X n/a X n/a X n/a X n/a

Hazardous Area (Class I, Division 2) n/a X n/a X n/a X n/a X

7" Touch Screen HMI (2-4 Loop Versions) X X X X n/a n/a n/a n/a

10" Touch Screen HMI (6-48 Loop Versions)

40 Amps/Loop @ 100-600 VAC X X X X X X X X

Circuits 2, 4, 6, 8, 12, 18, 24, 30, 36, 42, 48 (Expandable to 72 with -EXT Panel)

SCR Control X X X X X X X X

NEMA 4 Enclosure X X X X X X X X

Integral Circuit Panel with Circuit Breakers X n/a X n/a X n/a X n/a

Soft Start Feature X X X X 1 1 1 1

Full Communications X X X X 1 1 1 1

Full Alarm Capabilities X X X X 1 1 1 1

Complete GFEP Monitoring & Alarms X X X X 1 1 1 1

Load Monitoring & Alarms X X X X 1 1 1 1

Sensor Mapping X X X X 1 1 1 1

UL, cUL Listing X X X X X X X X

ITLS

C1D2 ITAS

X X X X n/a n/a n/a n/a

Options

Enclosure Heater X X X X X X X X

Wireless Temperature Sensing X X X X 1 1 1 1

Main Breaker/Disconnect X n/a X n/a X n/a X n/a

Nema 4X 304 SS Enclosure X X X X X X X X

HMI Sunshield X X X X n/a n/a n/a n/a

Panel Weathersheild X X X X X X X X

Heater Power and RTD Terminal Blocks X X X X X X X X

Z-purge system X n/a X n/a X n/a X n/a

Panel Light (on separate breaker) X X X X X X X X

Powered Receptacle (on separate breaker) X X X X X X X X

Copper Ground Bar X X X X X X X X

CE available X X X X X X X X

X - Available as a standard or option for this model

1 - This feature is enabled when paired with matching base panel

n/a - This feature is not available for this model

ITAS

C1D2 ITLS-EXT

ITLS

C1D2-EXT ITAS-EXT

ITAS

C1D2-EXT

2

Page 7

Theory of Operation

The set-up of the individual and global circuit parameters is explained in the Temp/Load Set-up sections of this

manual. This Theory of Operation overview is intended to give a quick summary of how it all works together.

• Each circuit of the system may be enabled (active) or disabled (inactive). A disabled loop will have no

output and will not map into the common alarm. It will display “Circuit #” and “Disabled” text above

the process temperature. Alarms for disabled circuit will not be monitored or displayed on the screen.

• Each circuit of the system may use unique individual control parameters or the control parameters may

be alike. The Global Settings function facilitates this action.

• The GFEP and Load current are automatically and continuously being calculated. The horizontal orange

bar indicates the average output current for that circuit. The GFEP current value is not displayed on

the screen but its value is compared to the GFEP setpoint. A GFEP alarm condition will occur when

the GFEP current value exceeds the GFEP setpoint value.

• If a ground fault that exceeds the GFEP setpoint value is detected during normal operation and “Trip”

button on the Load Setpoints screen is checked, the output of the defective circuit is set to 0% and

that circuit goes into an alarm condition. If “Trip” button is not selected, the operation of that circuit

continues and that circuit goes into alarm condition. The GFEP alarm may be either Latching or NonLatching.

• During extended periods of time where the output of all circuits are off, such as during warmer seasons, the Auto Cycle feature may be engaged. This feature initiates power to each circuit and checks

for alarms. Each output is tested for one minute within the desired Auto Cycle Interval. The Auto Cycle

feature may be disabled by setting the Auto Cycle Interval time to “0 Hours”.

• To limit inrush current on the overall system, a proprietary Soft Start algorithm is applied during system start-up. This will ONLY occur while the operation mode is set to AUTO. The Soft Start program

will increment output % by 1% every 1 second until the desired temperature is reached or the output

% achieves 100%. After the Soft Start program completes its cycle, the Control Mode of the system

will either be PID or ON/OFF Control Mode, depending what was selected by the user. The Soft Start

Program will not function if the control mode is set to Manual.

• Centralized control of multiple ITAS or ITLS panels is accomplished via the ISC-IntelliTrace Supervisory

Controller.

3

Page 8

Types of Sensing Control

Ambient Sensing Control

Strict ambient-sensing control utilizes a thermostat or a simple electronic controller which senses the ambient temperature via an RTD, Thermocouple or Bulb & Capillary sensor. This is the simplest type of control as the heating

circuit is energized only when the ambient temperature drops below the setpoint of the controlling device. This is

also known as On/Off control. A relatively large temperature variation around the setpoint is anticipated. Mechanical thermostats are often employed due to their low cost and acceptable accuracy. Multiple heater circuits are

controlled by a singular ambient sensed temperature. This is the least efficient type of control and it is typically

limited to freeze-protection applications.

PASC - Proportional Ambient Sensing Control

Proportional ambient sensing control (PASC) utilizes an electronic controller which continuously compares ambient

temperature and the rate of the change of the ambient temperature to the desired temperature setpoint and regulates

the heater output power accordingly. The result is a smaller temperature variation around the desired setpoint and

a much smoother response to changing weather conditions. Like ambient sensing control, multiple heater circuits

are controlled by a singular ambient sensed temperature. PASC control is therefore significantly more energy efficient than ambient sensing control. PASC control can be employed in a variety of heat trace temperature control

applications but is typically used for freeze protection.

Line Sensing Control

Line sensing control is where each heated section of pipe (or heated surface area) is controlled independently of

other sections of pipe and therefore must have its own controller. Multiple sections of pipe may also be independently

controlled by an electronic multiple circuit control system. The control method may be either proportional or On/

Off control. Each section may have different setpoints and different allowances around the setpoint temperature.

Line sensing control is typically found in process temperature maintenance applications. These applications are

typically more critical and thus demand tighter temperature control. Electronic control is highly recommended over

thermostat control. Like PASC, the pipe surface temperature and the rate at which it is changing is continuously

compared to the setpoint temperature. The controller responds to these variations and regulates the heater output

power accordingly. Mission critical applications should only be managed by controllers which monitor all parameters

and present alarms both locally and remotely via communications or supervisory control means.

4

Page 9

Pre-Service Storage

If this equipment cannot be placed into service upon receipt, prevent damage caused by impact, harsh environmental

conditions, condensation or liquid ingress. Preferably store in a clean, dry, air conditioned, or ventilated building.

During storage, assemblies should be placed on a firm, level surface to prevent distortion.

Outdoor storage of indoor equipment is not recommended. The covering provided during shipment of indoor assemblies is NOT adequate for outdoor storage.

Cover the equipment to keep it free from dust, dirt, and corrosive elements. The covering must protect the assembly,

but permit adequate ventilation. Blocking placed between the roof of the equipment and the cover will help keep

covering material from restricting the air flow.

If the storage area is subject to humidity and significant temperature changes, energize the anti-condensation heaters provided in the equipment, or add heat from a separate source to prevent condensation inside the equipment.

The internal temperature must be at least 5˚C (9˚F) above the ambient.

If storage temperatures fall below 0°C (32°F), energize the internal equipment heaters provided, or add sufficient

heat from a separate source to keep the internal temperature of the panel to at least 0°C (32°F).

In areas with high humidity, inspect the equipment regularly, and add additional heat if necessary to keep the

equipment dry.

Remove all loose packing, documents, and flammable materials before energizing heating elements.

Heat from a separate source must be removed before the equipment is put into service.

WARNING: Care must be taken that integral control power transformers are not accidentally

back-fed from the heater circuits. Disconnect primary and secondary fuses.

Summer Standby Operation

If equipment is switched off during warm periods, and they are subject to humidity and significant temperature

changes, energize the anti-condensation heaters provided in the equipment, or add heat from a separate source to

prevent condensation inside the equipment. The internal temperature must be at least 5˚C (9˚F) above the ambient.

Before Powering Up

Chromalox takes great pride in knowing that we have provided to you a product of premium quality and workmanship. We have taken every precaution to ensure that your equipment arrives safe and secure.

However, vibration and temperature changes during shipping can cause some components to become loose.

Additionally, throughout the life span of this product, other environmental and application conditions may have

affected the mechanical and electrical continuity of several internal components. Therefore, for your safety and

overall product performance, please take the time to familiarize yourself with the MAINTENANCE, OPERATION,

AND INSTALLATION INSTRUCTIONS technical manual that was shipped with your panel.

Since it is not uncommon for electrical wiring and mechanical connections to become slightly loosened during

shipment, we ask that you pay particular attention to section 4-5.3 Wiring and Connections:

4-5.3 WIRING AND CONNECTIONS. Check wiring and connections as follows:

a. Inspect wiring for wear, fraying, chipping, nicks, and evidence of over-

heating. Repair minor defects with a good grade of electrical tape, or

replace if needed.

b. Inspect for loose electrical and mechanical connections. Tighten or

replace defective crimp-style lugs. Re-solder loose solder connections.

Tighten or replace all loose or missing hardware.

5

Page 10

General Panel Notes

1. This panel is designed to UL508A to facilitate NEC and CEC compliance, However it is the responsibility of

installer(s) and end user(s) to make sure that the installation wiring and all equipment, including this panel,

fulfill appropriate national and local electrical code requirements.

2. Incoming and outgoing branch circuit conductors may not be protected by fuses or breakers in this panel.

Consult appropriate national and local electrical codes and device specifications for selective coordination.

3. Protection relays must be set on site according to the requirements of the site engineer’s protection study.

Low-level ground fault protection, if required, should be provided.

4. Consult all applicable instruction manuals.

5. Customer interlocks are provided for use of external shutdown device(s). Interlocks require contacts that open

to trip or shutdown.

6. Contacts are shown in the de-energized state. Controller contacts shown on electrical schematics are internal

to the controller. Most of these contacts are programmable to suit the mode of operation. Consult the appropriate user manual(s).

7. Dashed lines indicate user field wiring connections.

8. The panel installer must ground the panel according to appropriate national and local electrical code requirements.

9. Conduit openings in enclosure are to be user installed, sized and located as required. Hubs or fittings must be

of the same environmental rating as the enclosure to maintain integrity.

10. Unless fitted with an HMI sun sheild, do not place this equipment in direct sunlight.

11. Unless panel is properlly equipped with an enclosure heater for ambient temps below 0°C (32°F), the ambient

temperature outside this panel must be between 0°C (32°F) and 40°C (104°F).

12. If the panel cannot be placed into service upon receipt, an anticondensation heater must be used to prevent

condensation from forming inside the panel. This heater can be user supplied or factory supplied but must be

used to prevent damage to the panel.

13. Dimensions are for reference only, and are nominal unless otherwise specified.

6

Page 11

Installation

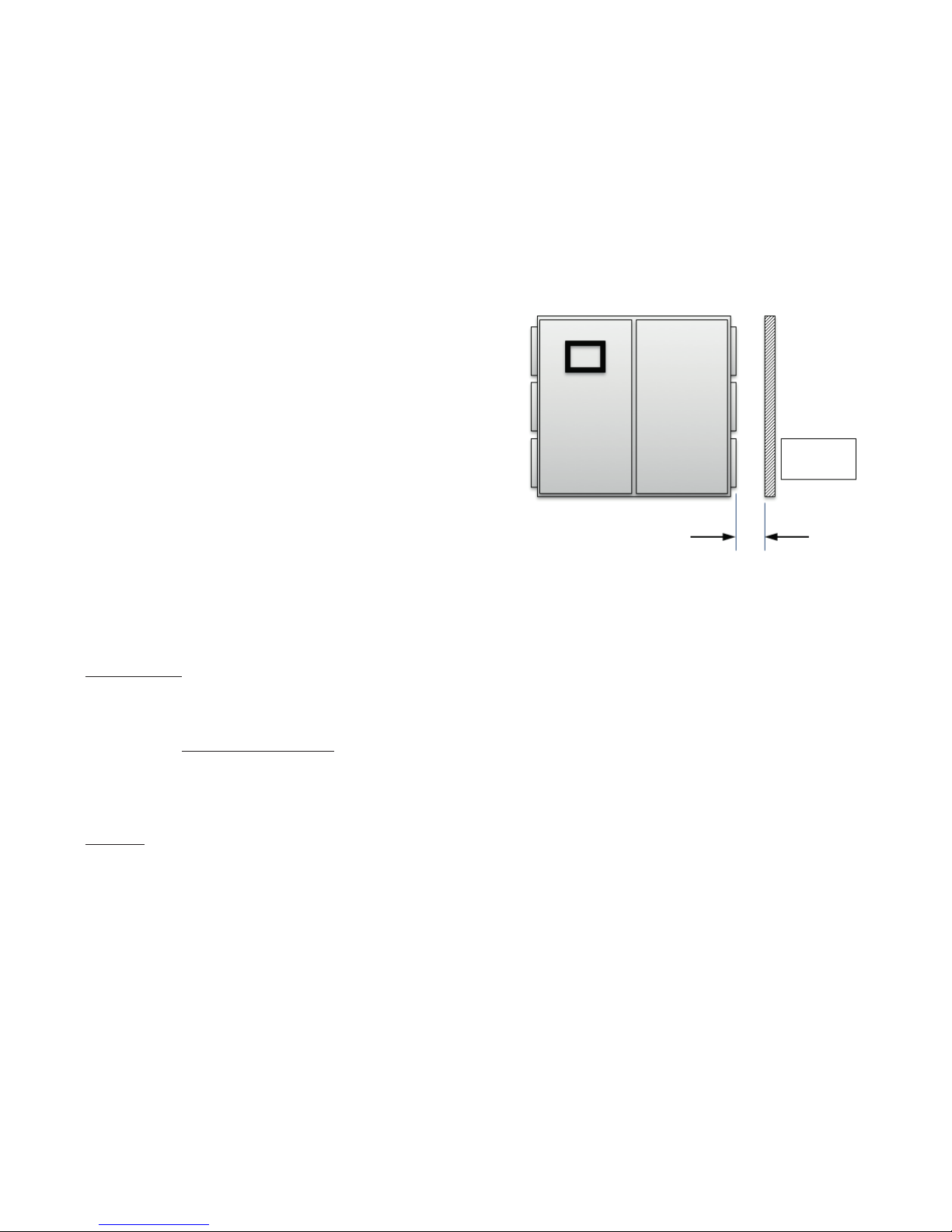

Heat Sink Considerations – Heat Dissipation

The Chromalox ITLS, ITLSC1D2, ITAS & ITASC1D2 Multiple Loop Heat Trace panels employ SSRs (Solid State

Relays) as a means to switch the heating load power. Inherently, SSRs produce heat when operating. This heat

is dissipated through the heat sinks which are typically mounted on the sides of the enclosures. These heat sinks

must be mounted such that the fins are vertically orientation in order to allow the heat sink to properly dissipate the

heat from the controller. The air flow around these heat sinks must in no way become restricted.

To maintain UL/cUL listing, the heat sinks must be inspected

prior to and during every season, or no more than every 12

months, to confirm that no debris or objects are in contact

with the heat sink. All debris must be removed from the

heat sink fins. High pressure blasts of clean, dry air or

other means which will not damage the fins are to be used

to dislodge all debris from the fins.

Servicing Heat Sinks

Adjacent Panel

or Wall

In the rare occurrence that the Power Board assembly, which

includes the Heat Sink, needs to be removed or inspected,

a minimum of 7 inches (18 cm) of clearance is needed to

externally withdraw the assembly from the enclosure.

7 Inches

(18 cm)

Outdoor Applications

Equipment protection from the environment must be carefully considered when installing these systems outdoors.

Both Solar Loading and UV Rays from the sun can impact the performance of these systems.

Solar Loading

The panel ratings, per UL/cUL, are based on operating the panel within the listed Ambient Environmental temperatures and under NO SOLAR LOAD (exposure to direct sunlight).

Therefore, it is highly recommended to install an adequately designed Solar Shield to provide shade across the entire

top of the panel so no solar load is realized. This Shield will also provide some protection to the HMI Touchscreen.

See the appendix for Solar Shield design options offered by Chromalox.

UV Rays

The IntelliTrace® Heat Trace Panels employ an HMI Touch Screen with LED backlit technology. UV Rays are known

to be damaging to these types of HMI touch screens. Chromalox insists on installing HMI Sunscreens in all outdoor

applications to protect the HMI Touch screen from these harmful rays.

See the appendix for HMI Sunscreen design options offered by Chromalox.

Please note that warranties will only be honored if all of the following conditions are met:

1. Suggested options are adequately designed are properly employed

2. These designs must either meet or exceed the designs suggested by Chromalox

3. This Optional Equipment must be installed prior to initial equipment commissioning

7

Page 12

Main Menu Screen

Circuit Number and Circuit Identification

(1-6, 7-12 for 5 Cir

Sensor Mapping Menu

Active Alarms Menu

Alarm Log Menu

The ITAS/ITLS Touch Screen Computer is extremely user friendly and quite intuitive. Navigation to any other

screens or any 2 or 6 circuit grouping of circuts is accomplished by selecting the blue labeled buttons along the

bottom of the screen or in the upper right or left hand corners.

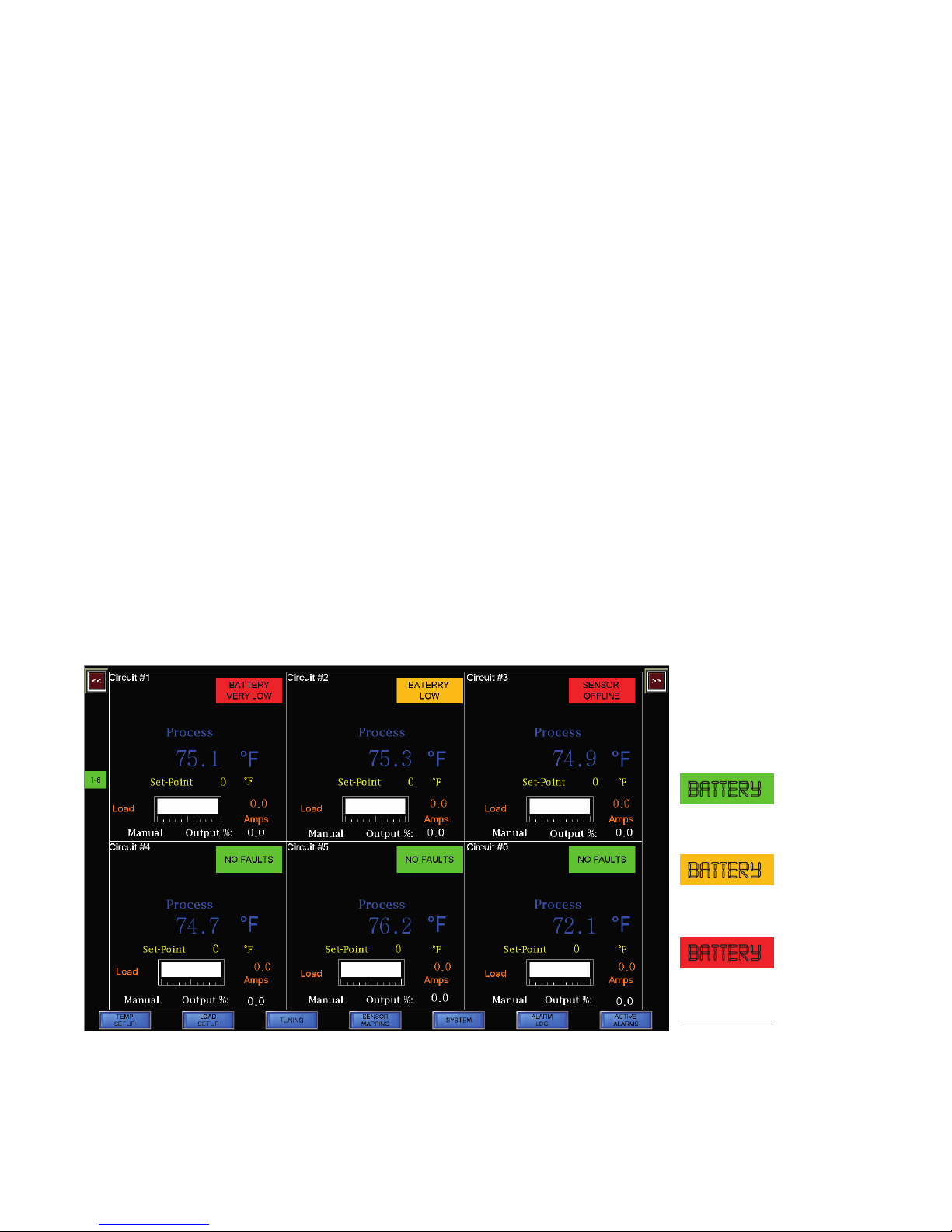

The main menu screen displays alarm status, circuit number, circuit name, process and set point temperatures,

current load demand, manual/auto control state and output percentage for 2-6 circuits at a time. See Figure 1.

Figure 1

Alarm Status & Type

2-6 Circuit

Navigation

Buttoon (x2)

Process

Temperature

Alarm Status by

2-6 Circuit Grouping

and up Systems

or 1-2, 3-4 for 2-4

Circuit Systems

up to 72 Circuits)

cuit

Temperature

Setpoint

Current Load

Control State

& Output %

Quick Launch to

Temperature Menu

Quick Launch to

Load Setup Menu

Quick Launch to

Tuning Menu

Quick Launch to

Quick Launch to

SystemMenu

Quick Launch to

Quick Launch to

8

Page 13

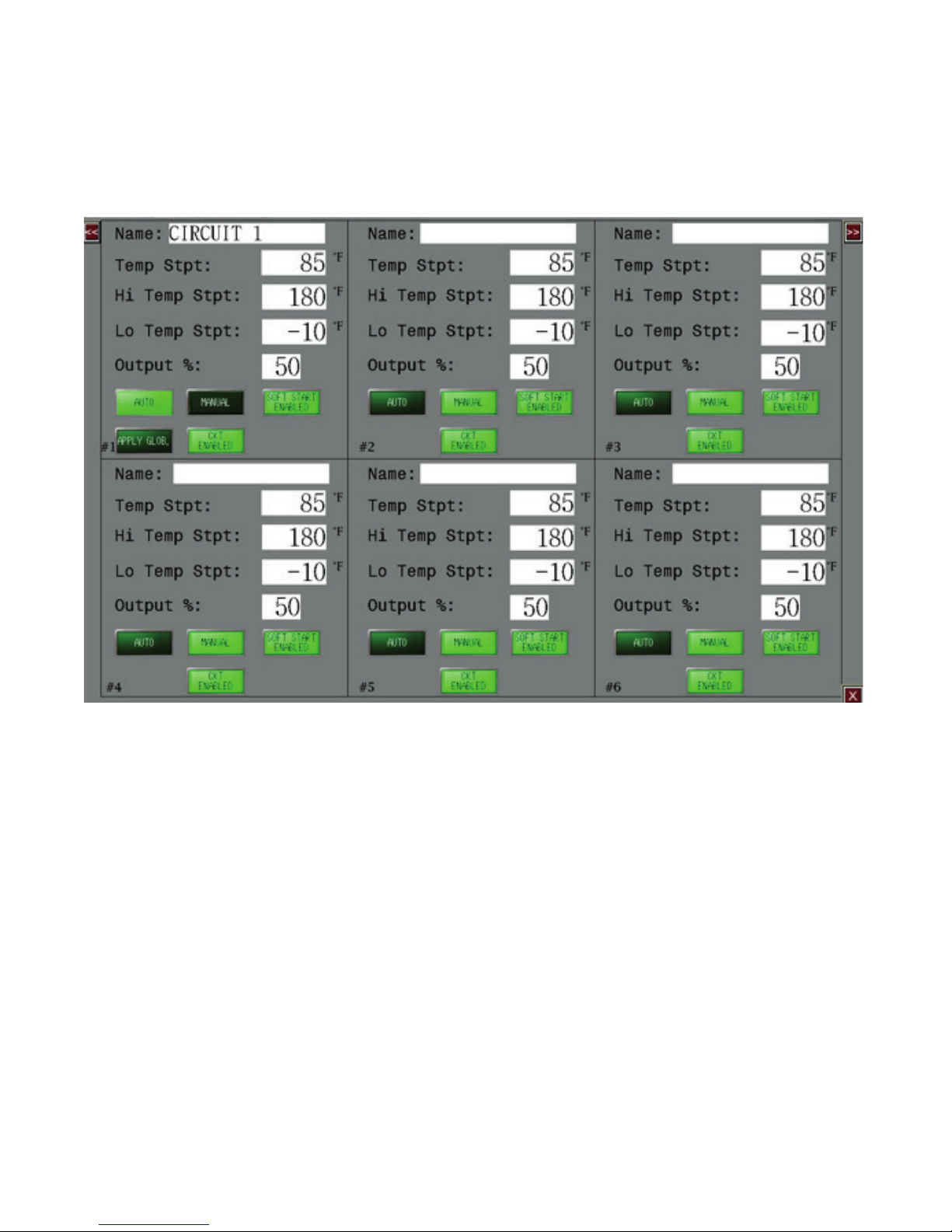

Temp Setup Menu

The Temp Setup button at the bottom of the screen is a quick launch to the Temperature Property Sheet which is

simply a series of tabaulated screens. See Figure 2.

Figure 2

Each block contains input cells for the panel operation. For example, temperature and overide controls are located

within the Temp Setup Screen.

Navigation notes:

1. Each screen illustrates 2 or 6 circuits at a time. To make setting changes to circuits beyond the current screen

within the menus, one must select the Circuit Navigation buttons in the upper right or left of screen.

2. For most screens, to save your settings and exit back to the mail screen, select the “X” button in the lower right

corner of the screen.

9

Page 14

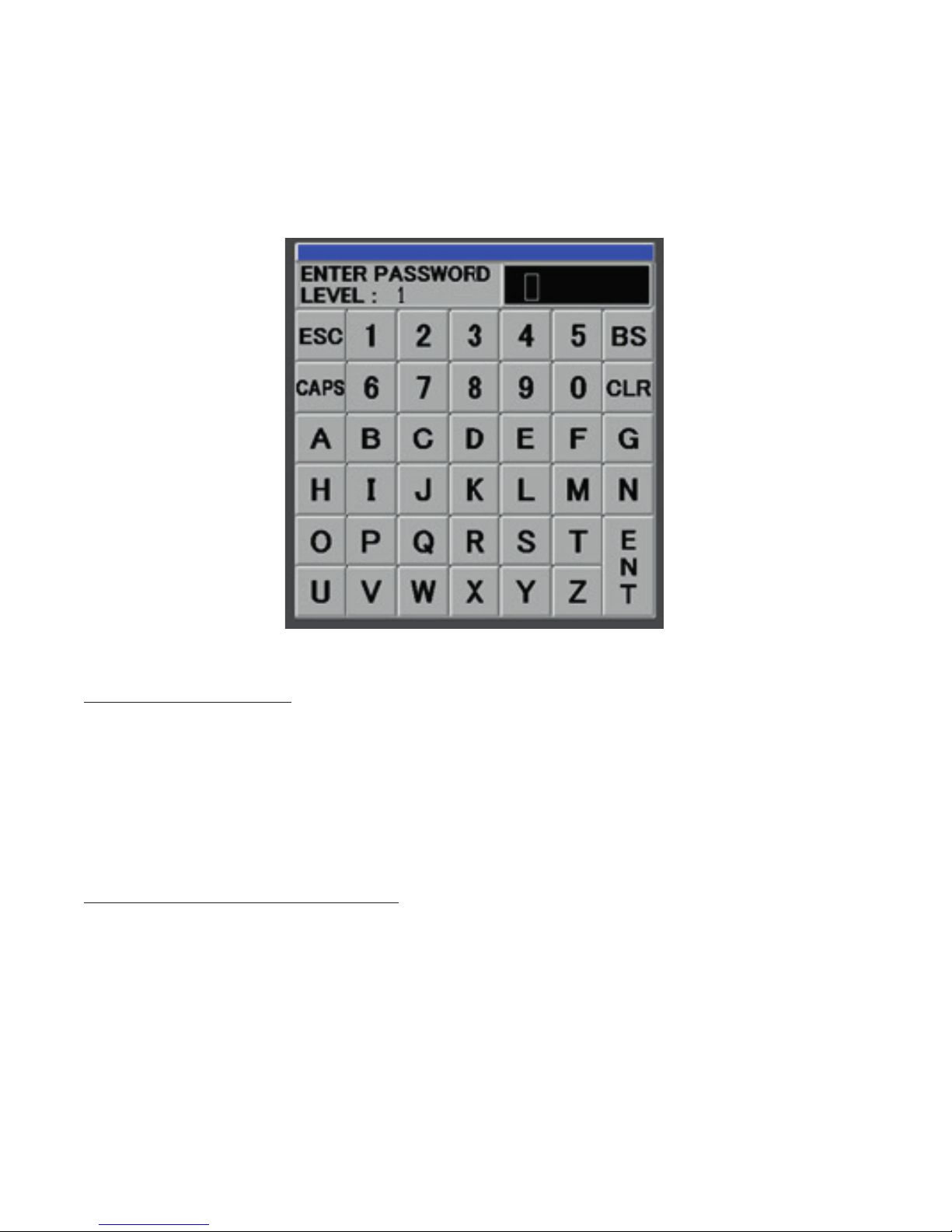

Security Levels & Password Screen

After touching the Temp Setup button, but before the Temp Setup Menu is presented, a pop-up screen requesting a password will appear. See Figure 3:

Figure 3

Initial factory set passwords for the below levels of Security are:

Level Title Code

4. Manager 999

3. Engineering 55

2. Supervisor 20

1. Operator 100

Enter the appropriate password and then hit ENT to continue to the setup screen.

Each of the above Security Levels has predefined accessibility and rights within the programming of the control

panel. They include:

Level Title Accessibility/Rights

4. Manager All customer pages, all passwords and Setpoints editing

3. Engineering All customer pages, Engineering password and All Setpoints editing

2. Supervisor Setpoints, Tuning and Sensor Mapping Tabs & All Setpoints editing

1. Operator Setpoints Tab. Temperature Set Point editing

Changes to specific areas within the menus can only be made once the correct security level code has been

selected.

10

Page 15

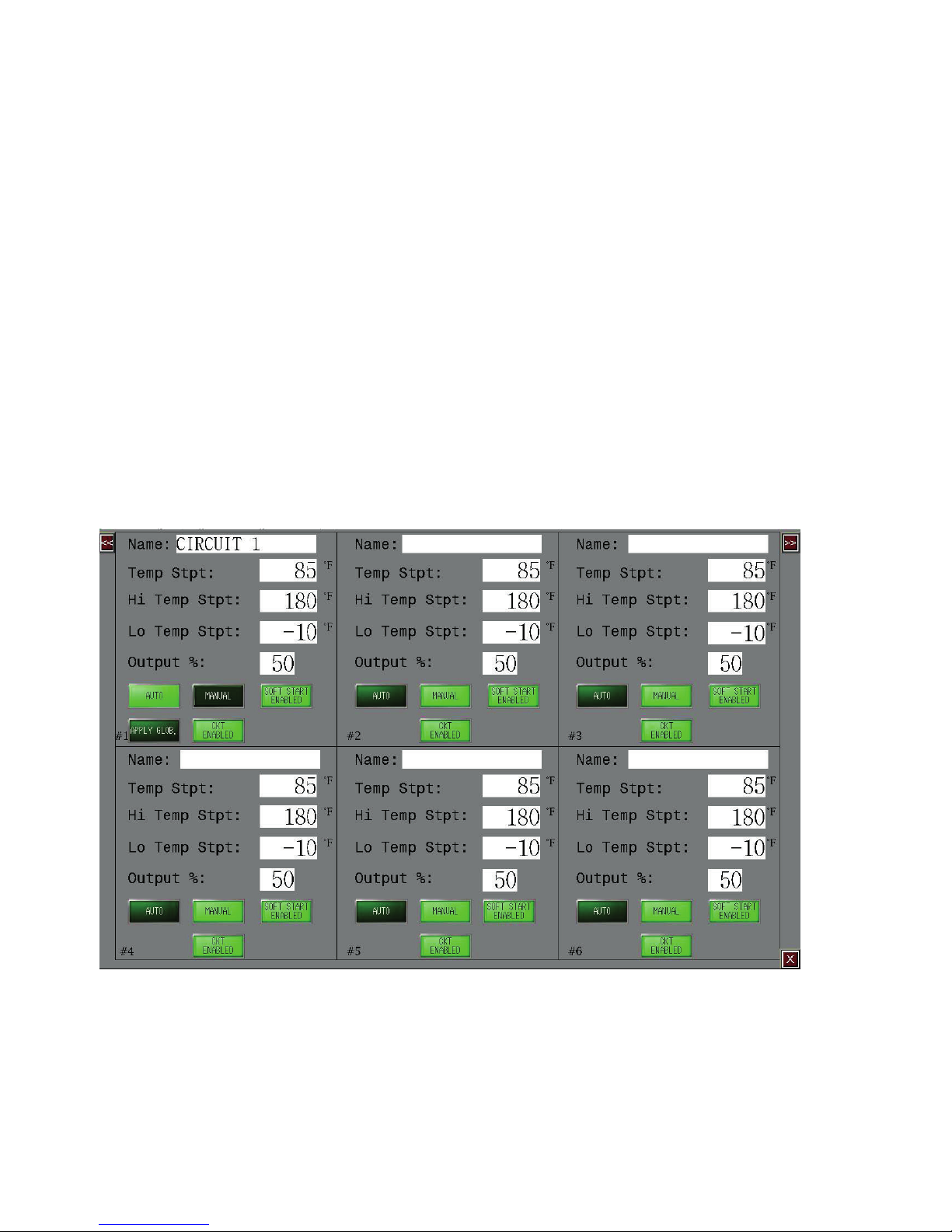

Temp Setup Menu

The Temp Setup Menu tab (See Figure 4) contains input cells for the following settings for each circuit:

• Customized Naming of each Circuit

• Process Temperature Set Point

• High & Low Temperature Alarm Limits

• Maximum allowable GFEP (Ground Fault Equipment Protection) Alarm Limit

• Output behavior, whether Automatically or Manually

• Manual Output Load Percentage (if enabled)

• Circuit Output Override (Enable or Disable Each Circuit)

Additionally, there exists a “Global Setting” within the Circuit# 1 Grid

• Apply Globally Setting

Figure 4

11

Page 16

Temp Setup Menu Navigation notes:

Apply T

1. Each screen illustrates 2 or 6 circuits at a time. To make setting changes to circuits beyond the current screen

within the Temp Setup Menu, one must select the Circuit Navigation buttons in the upper right or left of screen.

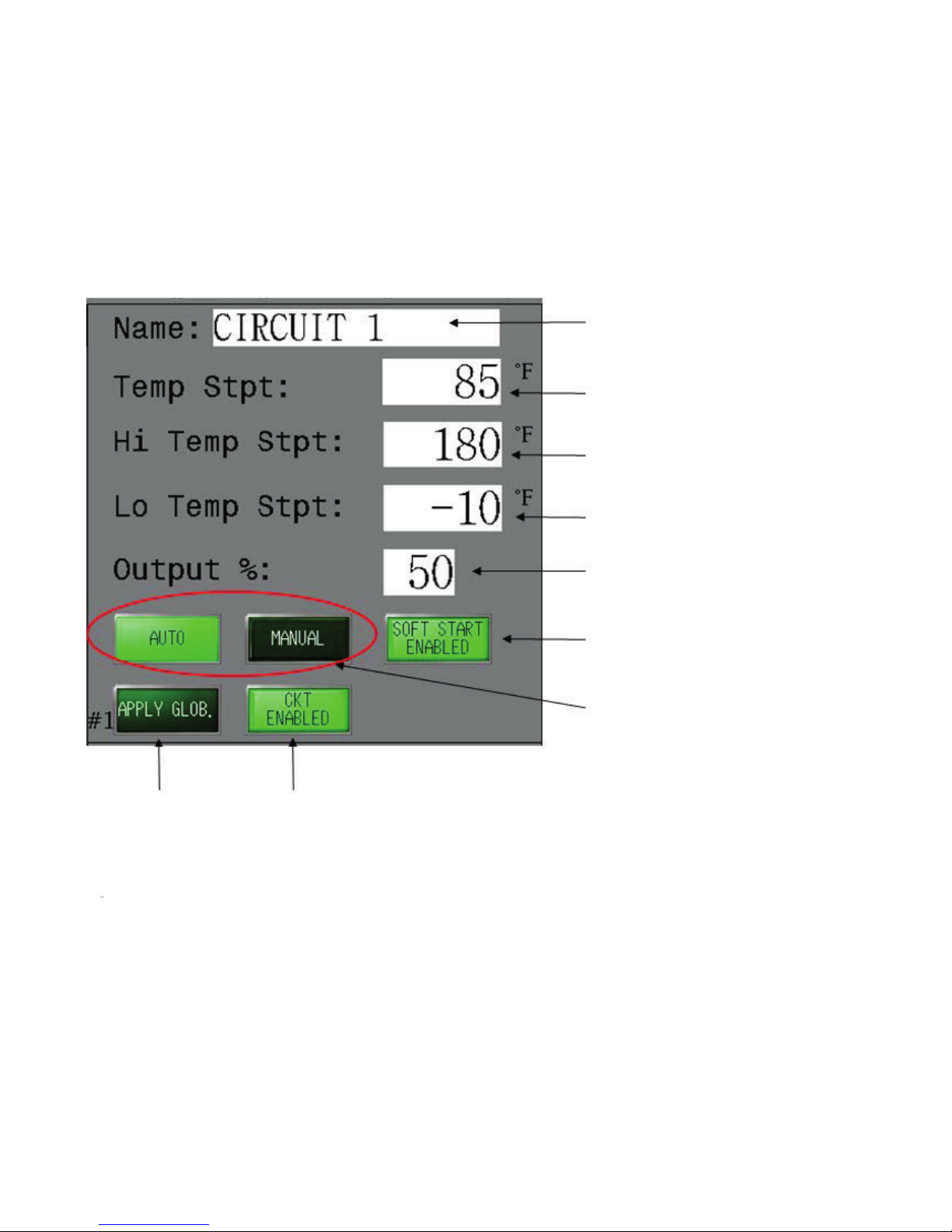

Figure 5 illustrates the input cell identification and location for a single circuit within the Temp Setup Menu:

Figure 5

Circuit Name

Temperature Setpoint

High Temperature

Alarm Limit

Low Temperature

Alarm Limit

emperature

Settings to all

Circuits

Manual Output

Load Percentage

Soft Start

Enable/Disable

Auto/Manual

Output Operation

Enable/Disable

Circuit

12

Page 17

Definitions for each of the Temp Setup Input Cells:

Name: Customize the Name of this individual circuit or loop

Temp STPT: Process Temperature Set Point (degrees F or C)

HI STPT: High Temperature Alarm Limit (degrees F or C)

LO STPT: Low Temperature Alarm Limit (degrees F or C)

Auto/Manual: Select Auto if you wish the Output behavior to be a function of a PID Algorithm or ON/OFF

Control (See Tuning Tab for selection)

Select Manual if you wish the Output to be driven by a pre-determined Output Percentage.

Enter the desired % output.

Disable Output: Select this check box if you wish to turn off or disable this circuit.

Apply Globally: This allows the user to copy all of the settings or Circuit Parameters from Circuit #1 to all other

available circuits.

Apply Settings Globally

The ITLS/ITAS has a feature which allows the user to apply settings from a single circuit to all of the remaining

circuit within the system. Within Circuit #1 on the Load Setup Menu (See Figure 6), complete the input of the parameters and select the “Apply Glob” button to mirror these settings across all circuits.

Soft Start Feature

These control panels are ideal for controlling heat trace

cable. Certain heating cables exhibit inherent current

inrush in colder temperatures. This inrush can cause

nuisance breaker tripping. To limit inrush current on

the overall system, a proprietary soft start algorithm is

applied during system start-up. This will ONLY occur

while the operation mode is set to AUTO.

The soft start program will increment output % by

1% every 1 second until the desired temperature is

reached or the output % achieves 100%. After the soft

start program completes its cycle, the control mode of

the system will either be PID or ON/OFF Control Mode,

depending what was selected by the user.

The soft start program will not function if the control

mode is set to Manual.

The default setting of the proprietary soft start feature

for each circuit is “enabled”. However, the soft start

feature may be disabled if so desired by the owner. The

owner has the option to manage the soft start feature

on each circuit individually.

See Figure 5.

13

Page 18

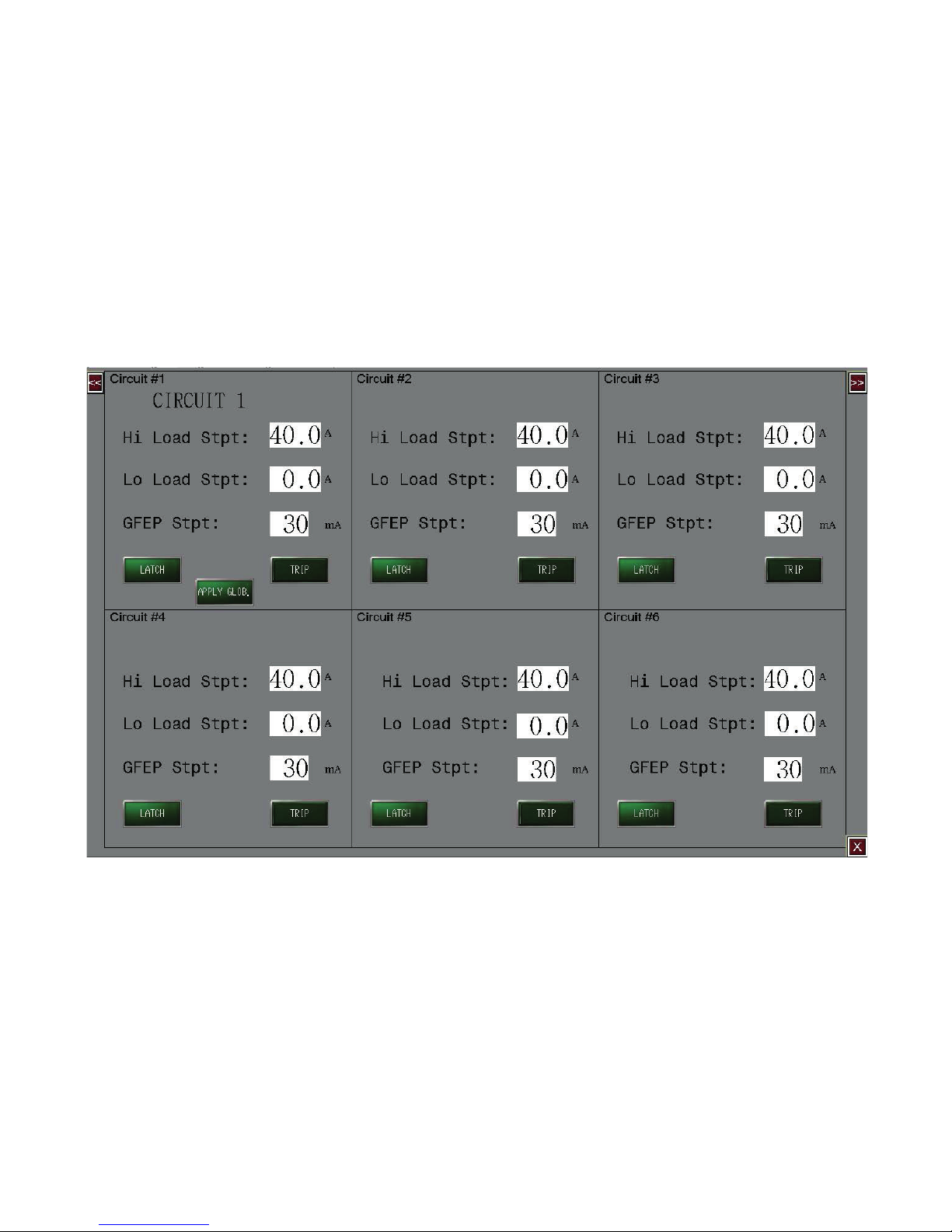

Load Setup Menu

The Load Setup Menu (See Figure 6) contains input

cells for the following settings for each circuit:

• High & Low Load Alarm Limits

• Trip and/or Latch Enabled/Disabled (Output Permis-

sion) upon GFEP Violation

• Maximum allowable GFEP (Ground Fault Equipment

Protection) Alarm Limit

Figure 6

Additionally, there exists a “Global Setting” within the

circuit# 1 Grid

• Apply Glob. Setting

14

Page 19

Definitions for each of the Load Setup Menu Input Cells

Load HI Stpt ................. High Current Alarm Limit (Amps)

LoadLO Stpt ................. Low Current Alarm Limit (Amps)

GFEP: ........................... Maximum Allowable Leakage Current setpoint (milliamps)

Trip (GFEP): .................. Enabled: If the GFEP limit is met, the output will be 0%.

Disabled: If the GFEP limit is met, the output is unaffected.

Latch (GFEP): ............... Enabled: If the GFEP limit is met, the alarm condition will remain until it is manually cleared.

Disabled: If the GFEP limit is met, the alarm condition will be cleared once the GFEP vari-

able is less than the GFEP setpoint

Apply Globally: ............. This allows the user to copy all of the settings or Circuit Parameters from Circuit #1 to all

other available Circuits.

Apply Settings Globally

The ITLS/ITAS has a feature which allows the user to apply settings from a single loop to all of the remaining loops

within the system. Within Loop #1 on the Setpoints Tab (See Figure 4), complete the input of the parameters and

select the “Apply Globally” button to mirror these settings across all loops.

15

Page 20

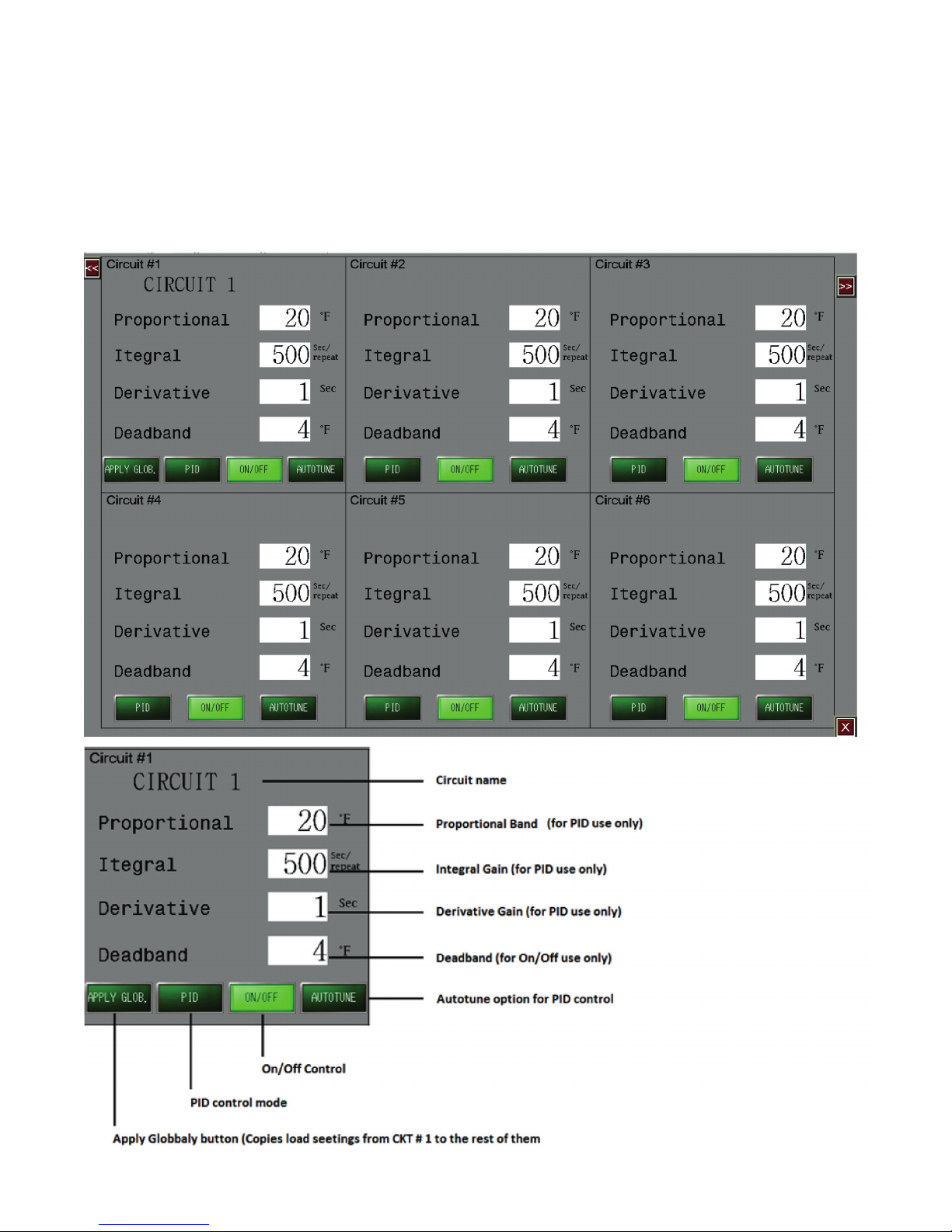

Tuning Menu

The owner has a choice of how the output is to be operated: Auto, Manual or Off. These selections are made within

the Temp Setup Menu. If “Auto”, or Automatic Control Operation is desired, then the tuning of the automatic control is accomplished via the Tuning Menu.

Figure 7

16

Page 21

Control Modes: ON/OFF, PID & Autotune

ON/OFF

• Select ON/OFF if you wish the operation of the heat-

ers to be 100% ON when a demand for heat exists

and 0% once the Set Point Temperature of the Process is achieved.

• The Deadband is enabled while in ON/OFF control

mode.

• The Deadband is the temperature range equally

divided above & below the temperature set point,

where the controller will not take corrective action.

o Example: A setting of “10” for the deadband will

result in a deadband that is 5 degrees above and

below the temperature setpoint.

• The deadband is adjustable in 2 degree increments.

It’s default is 10.

PID

• Select PID if you desire PID Control of the load.

• The Proportional Band (P), the Integral (I) & Deriva-

tive (D) are modes of control that work in union to

bring the process variable to setpoint as smoothly

and quickly as possible. They are enabled while in

PID Control mode.

• The P, I & D will be automatically established during

the Autotune procedure (see above).

• Additionally, the P, I & D may all be manually estab-

lished by the user. Great care should be taken when

manually establishing the P, I & D.

• Proportional Band: The temperature band expressed

in degrees within which the controller‘s proportioning action takes place. (Note: The wider the proportional band, the greater the area around the setpoint

in which the proportional action takes place.) This is

sometimes referred to as gain, which is the reciprocal of proportional band.

Autotune

• If the Autotune Feature is selected, then the PID parameters will be calculated and entered by the system once the Autotune function has completed its

demand profile function.

• The Autotune function establishes the individual P, I

& D (Proportional Band, Integral & Derivative) control

modes. These modes help to bring the process variable to the setpoint temperature as quickly as possible.

• In order to properly calculate the P, I & D modes,

the Autotune program requires a 25 degree rise in

sensed temperature after initiating the program. If

within 30 minutes the temperature will not reach its

setpoint, the Autotune algorithm will be canceled

and old PID values will be used.

• Once the Autotune feature is activated, you must not

change the menu page until the Autotune algorithm

is completed. Changing the page will cause the Autotune algorithm to shut down.

• The Autotune function is a one-time algorithm set up

of the P, I & D control modes. Should your process

variables change significantly, it is suggested to that

the Autotune feature be turned off and then reinitiated.

Tuning Tab Navigation Notes:

1. Each screen illustrates 6 loops at a time. To make

setting changes to loops beyond the current screen

within the Tuning tab, one must select the Loop Navigation buttons in the upper right or left of screen.

17

Page 22

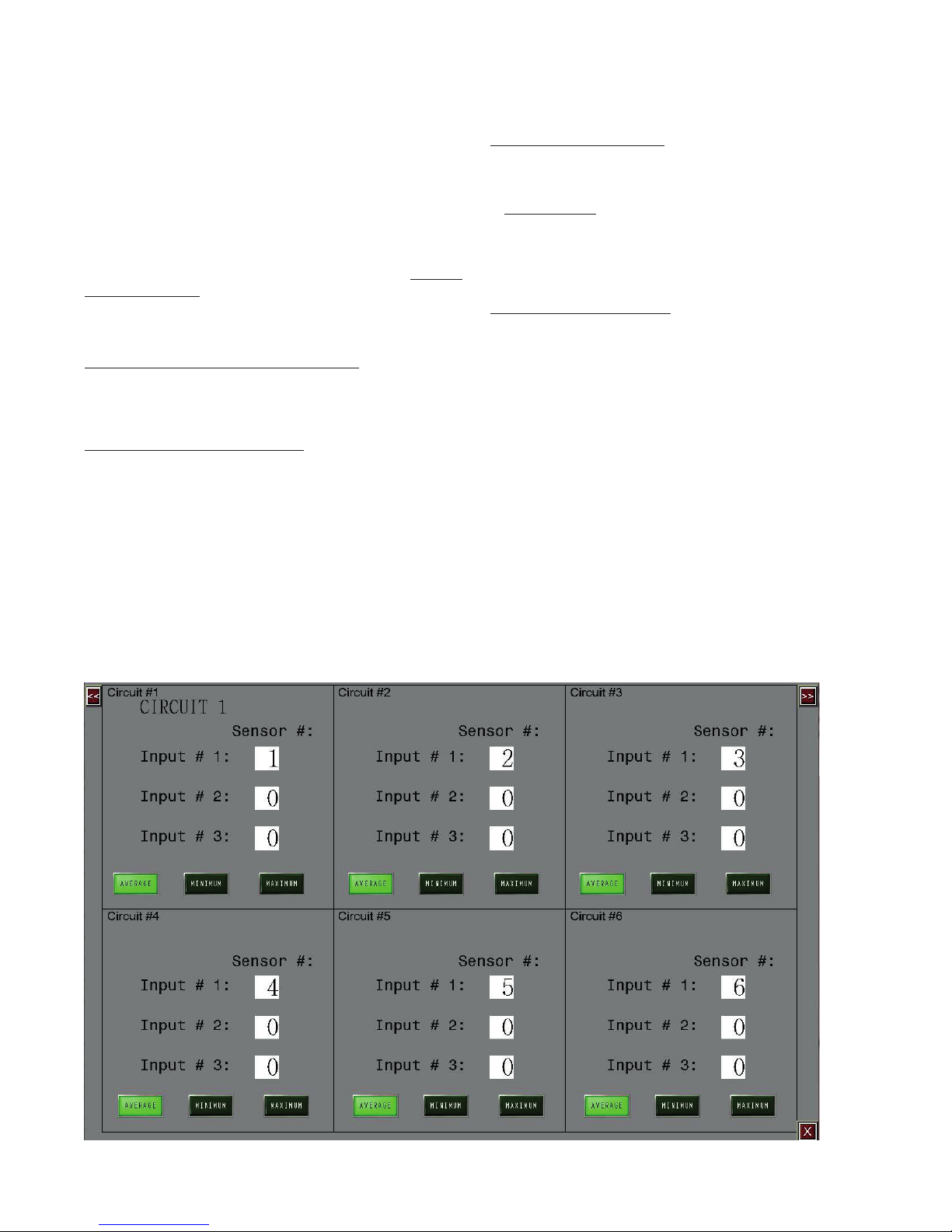

Sensor Mapping

The ITLS and ITLSC1D2 models provide the owner

with customizable sensor mapping. This becomes a

very powerful and desirable feature when the owner

needs added flexibility in controlling the circuit outputs

beyond the standard single sensor input.

1. Sensor Mapping is the assignment of one or more

Sensor Inputs to one or more output circuits.

Sensor (Input) Mapping is accessed via the Sensor

Mapping Menu.

Sensor Mapping

Ambient or Line Sensing, Single Sensor

A single sensor (RTD) may be mapped (or linked) to

multiple output circuits. This allows several circuits to

be controlled by a single sensor.

Minimum, Maximum, Averaging

Several sensors may be mapped to a single output circuit. This allows a single circuit to be controlled by the

minimum, or the maximum or the average temperature

of all of the sensors mapped to that output circuit. This

may be desirable on long runs or zones which realize

varying temperatures or weather conditions at different

times of the day.

Multiple Sensor Mapping

A single sensor may be used independently or combined with other sensors to control more than one circuit.

For Example:

The average temperature of Sensors 1, 3 and 5

is used to control Circuit 1 while simultaneously

the maximum Temperature of Sensor 3, 4 and 5 is

used to control Circuit 2.

Combining Sensing Types

The owner may need to have multiple line and/or ambient sensing control scenarios occurring simultaneously.

For example, these may be occurring simultaneously:

1. Circuits 1, 2, 3, 4, and 5 are all controlled by a single

RTD (Sensor 1) that is sensing the ambient temperature (Ambient Sensing)

2. Circuit 6 is controlled by Sensor Input 2 which is

strapped to a process pipe. (Line Sensing)

Sensor mapping is accomplished within the Sensor

Mapping Menu. See Figure 8.

This does not apply when only 1 Input/Circuit selection

is made from the Order Table.

Figure 8

18

Page 23

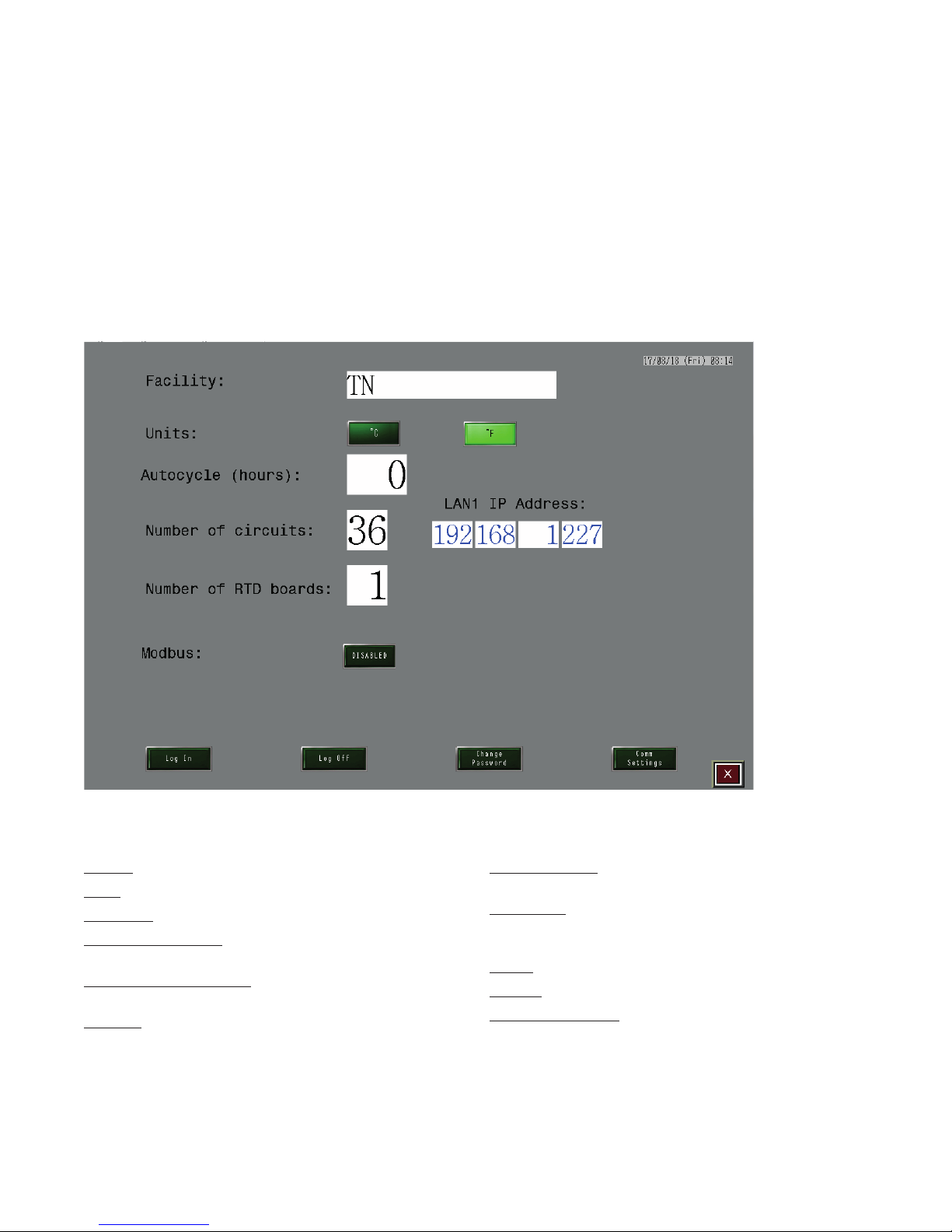

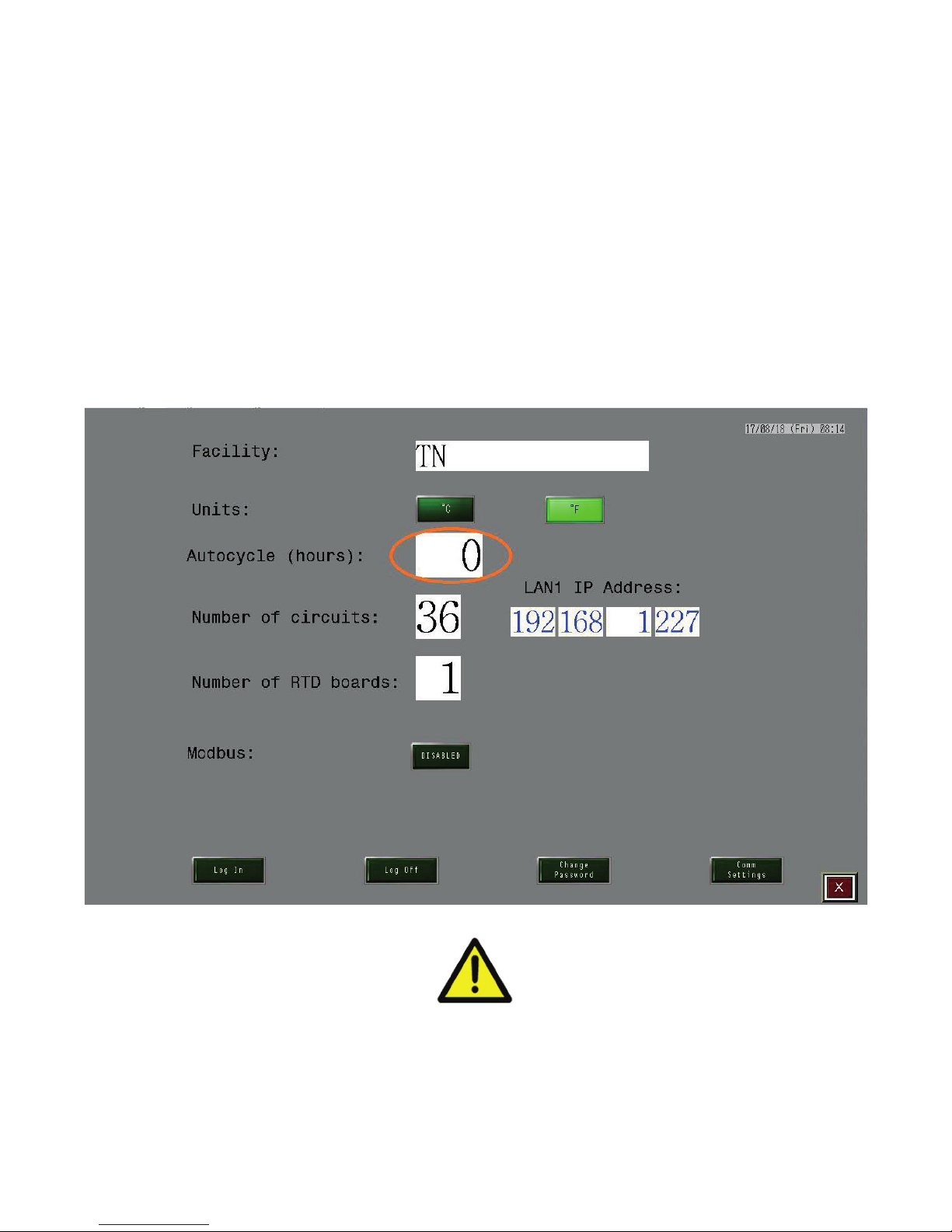

System Properties

Several informative items and general settings are

available within the System Menu.

The System tab is only available to the two highest

owner security levels: Manager and Engineer.

The Autocycle function is reviewed in the Autocycle

Feature section.

Figure 9

Here, one can enter/revise the Facility Name, Date,

Time, Temperature Units, Auto Cycle Interval and Security Codes. The Manager has access to all security

codes while the Engineer has access to only the Engineering Security Code. See Figure 9.

The Security Passwords and the respective rights for

each security level are reviewed in the Security Level

and Password Screen Section.

System Page Definitions

Facility – name of the facility

Units – degree Celsius or Fahrenheit

Autocycle – Autocycle feature. Value of 0 disables it

Number of circuits – number of SSR circuits (not

boards) installed in the panel

Number of RTD boards – Number of RTD boards installed in the panel

Modbus – Modbus feature can be disabled or enabled

to speed up processing and screen update current security level password

Comm Settings – used to select correct Modbus communication parameters (baud rate, parity, stop bits, etc)

IP Address – present IP address of the HMI screen. IP

address can be changed by pushing Comm Settings

button.

Log In – used to change current security level

Log Off – used to log off from the system

Change Password – used to change current security

level password

19

Page 24

Auto Cycle Feature

During prolonged down time periods, typically during

the summer months, it advisable to intermittently exercise the loops. This exercising of the loops is accomplished via the Autocycle feature.

To enable the Auto Cycle feature, select an Auto Cycle

Interval greater than 0 hours within the System tab.

See Figure 9. The Auto Cycle feature is disabled when

the Auto Cycle Interval equals 0 hours.

Figure 10

On a sequential circuit basis, the Autocycle feature periodically monitors system performance between 1-999

hours. The minimum and maximum values for Current

Load, GFEP and Temperatures are stored. Once the

new high or low value is attained the old value is overwritten and displayed in the Autocycle tab text boxes.

See Figure 10.

This provides a certain level of preventative maintenance of the system as Faults (Alarms) will present

themselves accordingly. Problem areas can be addressed during non-essential operating periods.

It is NOT advisable to engage the Auto Cycle

feature during normal operating periods. The

heating cables will become fully energized for

approximately 2 minutes throughout the Auto

Cycle Interval which could cause undesirable

temperature overshoot.

WARNING:

20

Page 25

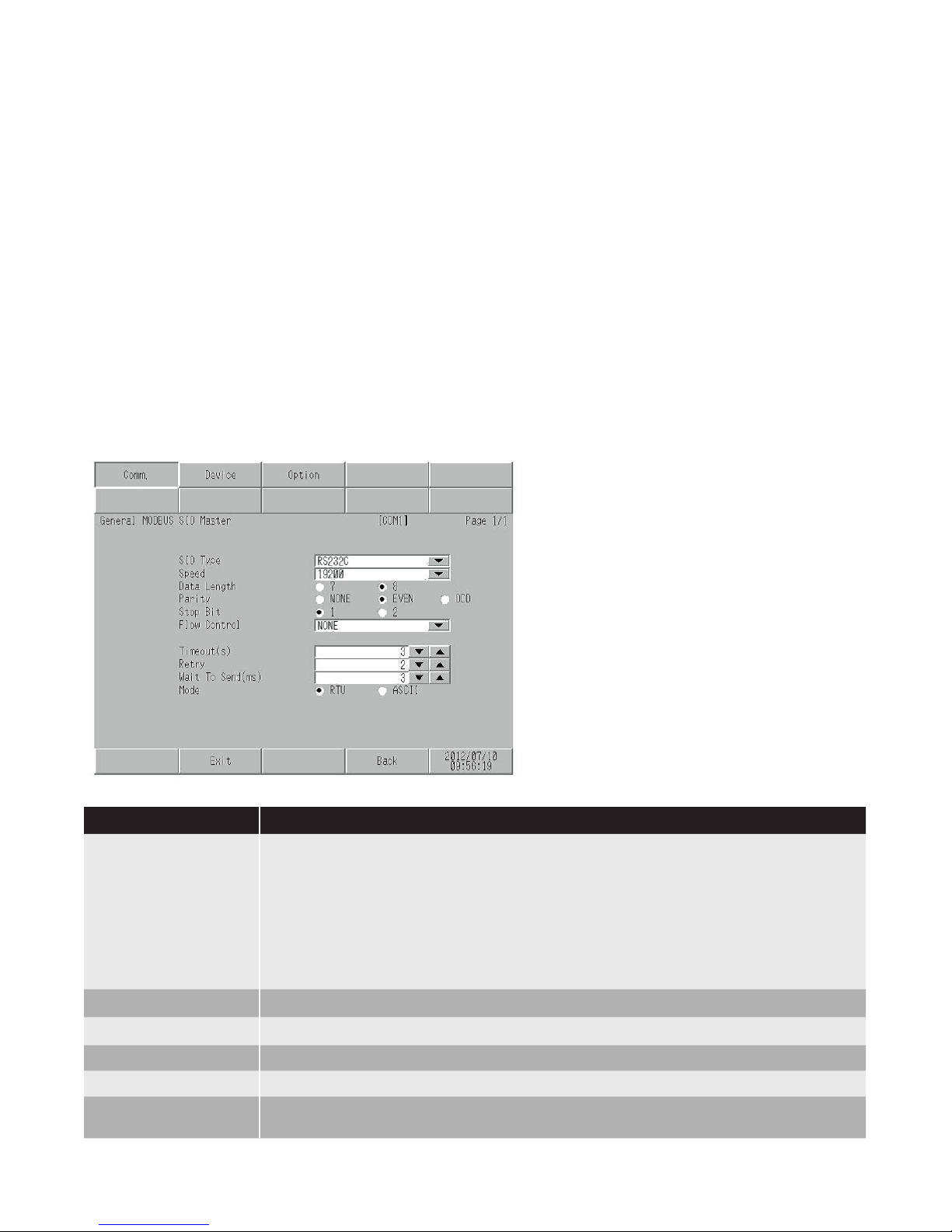

Communications

All changes to the MODBUS settings are achieved via

the COMMS screen. See Figure 11.

The Comms (Communications) screen may be accessed by selecting the COMMS button located at the

bottom of the System screen. The MODBUS Address,

Communication Speed, Parity and Stop parameters

are set within the Communications screen.

For complete communications specification details on

ModBus messaging, Registers and Sensor Mapping,

please reference our “ModBus Wiring and Registry

Map Instructions Document A-60682-04. This is an addendum to the PK497 manual. Go to the ITLS or ITAS

product pages and search in the Technical Resources

Tab at: www.chromalox.com.

Figure 11

Remote Monitoring

& System Management

Users may monitor as well as adjust the System Parameters settings of the panel remotely. The files required for this feature are available to the owner. Due to

the frequent program updates, we ask that you contact

the factory for the most recent release version.

Communication Settings

To display the setting screen, touch (Device/

PLC Settings) from (Peripheral Equipment Settings) in offline mode.

Touch the External Device you want to set from

the displayed list.

Setup Items Setup Description

SIO Type Select the SIO type for communicating with the External Device.

IMPORTANT

In the communications settings, set (SIO Type) correctly according to interface specifications of the Display.

If you select an SIO type that the serial interface does not support, proper operation

cannot be guaranteed.

Refer to your Display Manual for details on the serial interface specifications.

Speed Select the communications speed between the External Drive and the Display

Data Length Select a data length

Parity Select how to check parity.

Stop Bit Select a stop bit length.

Flow Control Select the communications control methond to prevent overflow of transmission and

reception data

21

Page 26

Alarm Log

The purpose of Alarm Log is to record every alarm

condition with a date and time stamp. This log may be

viewed via the ALARM LOG button at the bottom of the

main screen. See Figure 12.

Alarm condition example: Sensor Error alarm on circuit

18 will be recorded as “11/08/12 – 13:38:48 SENSOR

ALRAM CKT 18”. Every alarm event is saved into a text

file (\Storage Card\log5.txt). Each event is appended to

the file string on a new line.

This table holds up to 750 events (alarms). If the number of entries exceeds 750 then the event that is last

Figure 12

on the list (by date) will be removed from the table. This

process repeats indefinitely. Once an alarm has been

recovered, it can be removed from the list by pushing

the clear recovered alarm button.

To extract these files, one must:

1. Plug a USB flash drive into the USB port located on

the back of the ITLS/ITAS computer. Go to Alarm

Log Screen and push green button on the right of

the screen labeled “Write Alarms to USB.”

Move Upward – moves cursor one position up

Move Downward – moves cursor one position down

Clear All Recovered Alarms – clears all recovered

alarms from the alarm log

Clear Recovered Alarm – clears selected recovered

alarm from the log

Acknowledge All – acknowledge all present alarms

Acknowledged – acknowledge selected alarm

Roll Up – move cursor one position up

Roll Down – move cursor one position down

Write Alarms to USB – saves alarm log into USB thumb

drive

View USB – reads previously recorded alarm log from

the USB thumb drive

22

Page 27

Active Alarms

Alarms within any 6-circuit or 2-circuit grouping are indicted by RED squares in the left and right panels on

any screen. If the square is GREEN, then no faults exist

within that 6-circuit grouping. Once a fault is realized

within any 6-circuit grouping, one may view the individual alarm circuit or circuits in two different ways:

1. When in the Main Display screen, one may navigate

to the desired 6-circuit grouping via the Navigation

buttons found in the upper right hand or upper left

hand corner. Alarm conditions are illustrated within

each circuit window. Up to three alarm conditions

can be illustrated for any single circuit on the Main

Menu screen.

2.

One may view the status of all fault conditions by selecting the ACTIVE ALARMS MENU button located

at the bottom of the main display screen. To navigate

to the desired 6-circuit grouping, one must press the

Circuit Navigation but-tons found in the upper right

or left corner of any screen. See Figure 13.

Figure 13

Clearing Alarms

Except for a Communications Alarm and a Latched

GFEP Alarm, all other alarms are cleared once the acceptable parameters are achieved.

23

Page 28

Alarm Troubleshooting

The Alarm Condition, the resultant Output and the Design Behavior for each Alarm type can be found in Table 2

below.

Table 2

Alarm Type Condition Output Design Behavior

HIGH TEMP

LOWTEMP

GFEP

HI CURRENT

(LOAD on Faults

Screen)

LO CURRENT

(LOAD on Faults

Screen)

SENSOR

COMM

Sensed Temp

=> Hi Temp

Setpoint

Sensed Temp

<= Lo Temp

Setpoint

Sensed GFEP

Current =>

GFEP Setpoint

Sensed Load

Current =>

Hi Current

Setpoint

Sensed Load

Current <= Lo

Current

Setpoint

Sensor Open,

Sensor Shorted,

Sensor Fault

Communication

Error

No change Alarm will be cleared automatically when

Sensed Temp < Hi Temp Setpoint

No change Alarm will be cleared automatically when

Sensed Temp > Lo Temp Setpoint

Trip Latch

No No

Yes No

No Ye s

Yes Ye s

Output will switch to Manual

Mode

No change Alarm will clear automatically when

Output will switch to Manual

Mode

Output will switch to Manual

Mode

Output will remain at selected

output %.

Output will go to

0% (OFF) while in

alarm state

Output will remain at selected

output %.

Output will go to

0% (OFF) until

alarm is reset

Alarm will be cleared automatically when

sensed GFEP Current < GFEP Setpoint

The Alarm condition may only be cleared

with a manual RESET of the GFEP Alarm.

Alarm will be cleared automatically when

sensed Load Current < Hi Current Setpoint

Sensed Load Current > Lo Current Setpoint. If your output is turned OFF, GFEP

and Load values will not be updated.

Alarm will clear automatically when the

RTD resistance is between 75.44W -

311.56W. Check if your sensor wire is not

damaged and that it is properly connected

to the Sensor board.

Make sure that the communication cable

that connects the Touchscreen computer

with boards inside enclosure is properly

connected and/or not broken.

Press “RESET ALM” to reset this alarm.

24

Page 29

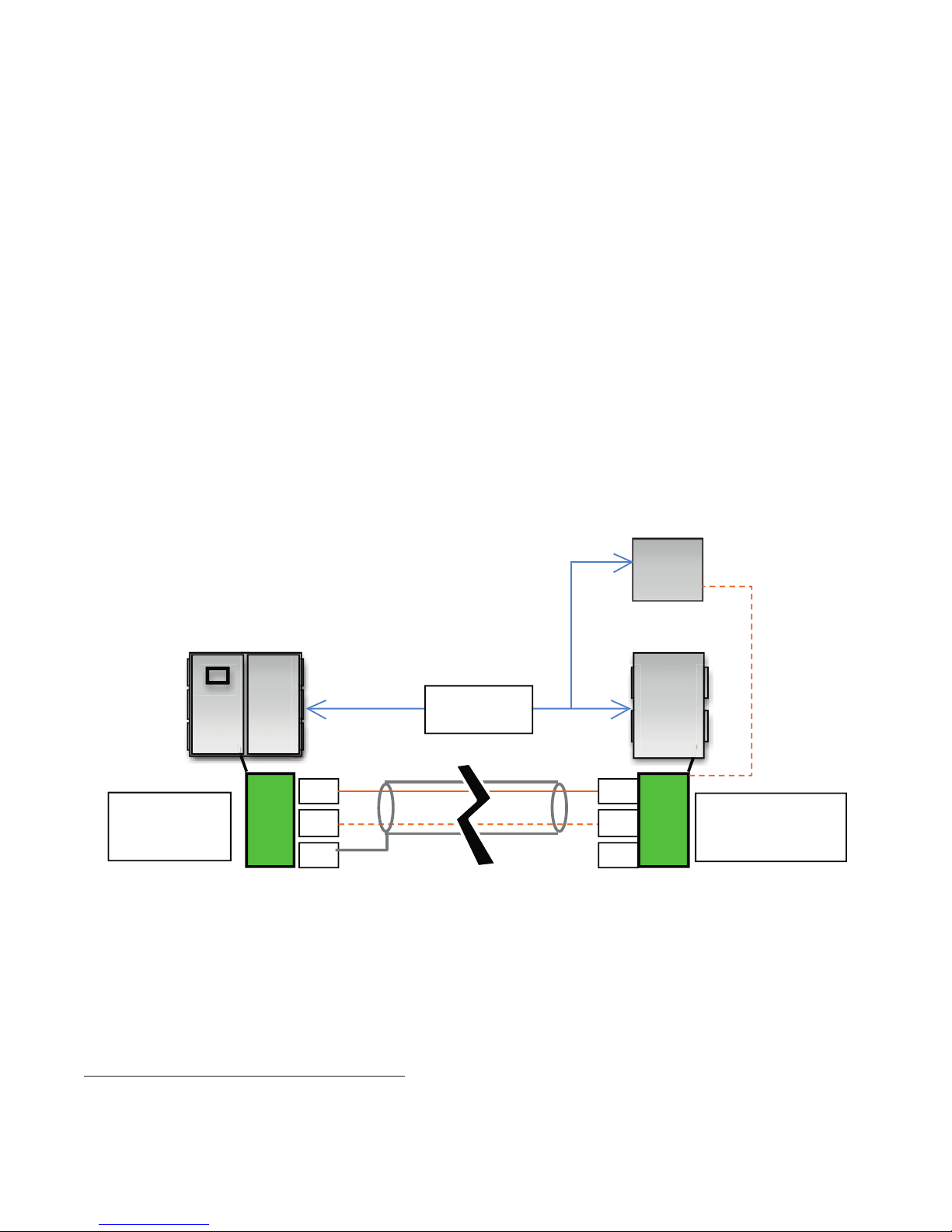

Extension Panels

D

Connecting an Extension panel or a

Remote Sensor Panel to the Main Panel

Below is the procedure to connect an Extension or

a Remote Sensor Panel to the Main Panel. The Main

Panel will manage the circuits in the Extension Panel

and the inputs of the Remote Sensor Panel.

Procedure:

1. Turn off the power to the system.

2. In the main panel (the one with a touch screen computer) locate the distribution board (0113-10246)

and verify that jumpers J.16 and J.17 are set in positions 1 & 2.

3. Connect one end of the twisted pair cable into connectors J15.1 (RX+) and J15.2 (RX-) on the distribution board of the Main Panel. Connect the other end

of the twisted pair cable into connector J15.1 RX+

and J15.2 (RX-) on the distribution board of the Extension panel.

Figure 14

Make sure that RX+ is connected to RX+ and RX- to

RX-. (See Diagram Below)

4. Connect the metallic shielding material (see wire

specification below) to the ground of the base panel

Distribution Module. However, DO NOT connect

the metallic shielding to the Extension Panel Distribution Module. (See Diagram Below)

5. If the number of loops needs to be changed, power

up the system and login into the setup menu using

5731 as the password. Go to the “System” tab and

select the desired number of loops and press “OK”.

6. Cycle power to the system.

**Note - a 2 or 4 Circuit Extension Panel may be

added to a 6-48 Circuit system but not vice versa.

Remote Sensor Panel

Main Panel

2,500 FT

(775 M) Max

RX+

Main Panel

Distribution

Module

RX-

GN

Extension Panel or Remote Sensor Panel

Considerations

Environmental influences such as EMI/RFI can compromise the communication signal between the Extension

or Remote Sensor Panel and the Main Pane. The use of

properly designed cable will protect against and minimize

these influences.

Here is a design guide for extension panel wiring:

RS-485 Max. total cable length ........... 2,500 ft (800 M)

RS-485 Wire specification .........T1/E1/DSL compatible

24-AWG shielded cable

Extension Panel

RX+

-

RX

GND

Chromalox uses the following vendor and cable item

as a viable reference:

Example Vendor: ................................................L-com

Typical Specification: ...2 - 120 Ohm (E1) Shielded Pair

Vendor Item Number: .................................... TSC9928

Available at: .............................. http://www.l-com.com

Extension or Remote

Sensor Panel

Distribution Module

25

Page 30

Wireless Temperature Sensing

No Maintenance Needed.

Overview

Chromalox now provides fully integrated Wireless Temperature Sensing Solutions for Heat Trace applications

in ordinary and hazardous locations.

The components of the Chromalox Heat Trace Wireless

Temperature Sensing system include the IntelliTrace

ITLS or ITAS Series Heat Trace Control Panel and specific industrial wireless transmitters which are paired

with appropriate temperature sensors.

Control Panel

When the wireless temperature sensing feature is selected, the IntelliTrace Control Panel is properly configured at the factory and internally equipped with

an industrial-duty WirelessHART® certified wireless

gateway, antenna and the necessary communication

accessories.

The panel facilitates both wired and wireless temperature sensor inputs and the touchscreen computer HMI

distinguishes wireless circuits from wired ones. Several of the IntelliTrace HMI screens are impacted when

Wireless Temperature Sensing is ordered and enabled

at the factory: The Main Screen and Sensor Mapping

Menu.

Main Menu

On the main menu screen, the alarm status will appear

as BATTERY when the transmitter battery of a wireless circuit is due to be changed. Each wireless circuit

has its own transmitter battery life meter. This provides

three levels of remaining battery life so that you may

properly plan service before it is needed.

Wirless Transmitter

Battery Meter

BATTERY

Battery Life Good.

BATTERY

Battery Life Low.

Plan for Maintenance.

BATTERY

Battery Life Very Low.

Perform Maintenance

Immediately.

26

Page 31

Sensor Mapping Tab

Wireless sensors will automatically show up in the SENSOR window of the I/O Mapping Tab. They are labeled as

WS #1, WS #2, etc., and can be assigned to any output circuit.

Faults Page

The BATTERY fault state on the Faults page will change from Green to either Orange or Red depending on the

remaining battery life of the Wireless Transmitter.

Wireless Transmitter

Chromalox has chosen the Rosemount® 248 Wireless Temperature Transmitter. This transmitter is WirelessHART®

certified and it may be pipe or structure mounted. When deployed in a Mesh network, this transmitter is actually

both a transmitter and a receiver (also known as a Bi-Directional Wireless Device).

The 248 Transmitter is offered in either aluminum or polymer housing and is available with or without a matching

universal mounting bracket. A battery is also required and ordered as a separate item. Manufacturer’s data sheets

and user manuals are available in the technical resources tab within the Heat Trace products / Wireless Temperature Sensing section at www.chromalox.com

27

Page 32

Rosemount 248 Wireless Temperature

Transmitter Features

• Output - WirelessHART 2.4 GHz

• IEC 62591 Compliant

• Update Rate – 1 sec to 60 min - user selectable

• Accuracy +/- 0.45oC @ 20oC

• Wireless radio

o 2.4 – 2.485 GHz

o 15 channels

o IEEE 802.15.4 compliant

• Power Module

o Lithium Thionyl Chloride with PTB enclosure

o 7 to 10 year life (1 minute update rate)

• Housing

o IP66/67

o NEMA 4X

• Self-Calibrating Unit

• Direct Pipe or Flat Surface Mounting

• Accepts RTD & Thermocouple Sensors & mV input

• The following approvals/certifications:

Polymer Housing

F

Aluminum Housing

Please see the Rosemount 248 Data Sheet and Instruction Manual for completed details. Manufacturer’s data

sheets and user manuals are available in the technical resources tab within the Heat Trace products / Wireless

Temperature Sensing section at www.chromalox.com

Ordering Information:

There are many design and feature options available on

the Rosemount 248 model. Chromalox has standardized on the following:

Wireless Temperature Transmitter

Rosemount 248 Wireless Temperature Transmitter,

USA Intrinsically Safe and Non-incendive, Aluminum or

Polymer Housing, with 1/2-14 NPT Conduit Entry Size,

WirelessHART, 2.4 GHz, External Omni-directional Antenna (Aluminum Housing only), 5-point Calibration,

External ground lug, 60Hz & 3 Year Warranty

Desription (Manufacturer Model No.)

Aluminum Housing with universal mounting bracket

(248DXI5D2NSWA3WK1B5C4Q4G1WR3)

Aluminum Housing without universal mounting bracket

(248DXI5D2NSWA3WK1C4Q4G1WR3)

Part Number

0108-70477

0108-70478

Polymer Housing with universal mounting bracket

(248DXI5P2NSWA3WP5B5C4Q4WR3)

Polymer Housing without universal mounting bracket

(248DXI5P2NSWA3WP5C4Q4WR3)

Battery for 248 Wireless Trans0mitter with Aluminum Housing Only 0108-70432

Battery for 248 Wireless Transmitter with Polymer Housing Only 0108-70481

0108-70479

0108-70480

28

Page 33

Universal Mounting Bracket

The Rosemount 248 Wireless Temperature Transmitter may be ordered with or without a matching Universal

Mounting Bracket (see above table). This bracket eases and enables transmitter mounting to either pipe structures or flat structural surfaces.

Rosemount 248 Wireless Temperature Transmitter with Universal Mounting Bracket

(Shown With Aluminum Housing Model)

Pipe Mounting

Structure Mount

29

Page 34

Transmitter Power Module (Battery)

Aluminum

The transmitter power module must be installed prior to device configuration and device use. It may be removed

from the device in between configuration and commissioning.

The Polymer housing transmitter utilizes the Green Power Module while the Aluminum housing transmitter uses

the Black Power Module. These are dramatically different in physical dimensions and may not be used universally.

Exploded view of the two models:

Housing

Transmitter

Base

Power

Module

Temperature Sensor

Although other RTD sensors may be utilized, Chromalox has standardized on the RBF185M type Heat Trace

Sensor. This industrial duty RTD is designed to be Pipe

Mounted and it comes complete with either an Aluminum or 316L Stainless Steel connection head.

Polymer

Housing

Power Module

Housing Cover

This sensor is suitable for NEMA 4X or IP66 environments and designed for ordinary or hazardous areas

(Class I, Divisions 1 & 2).

Heat Trace Temperature Sensor - 100 Ohm, 3-Wire RTD

Pipe Mounted Heat Trace Sensor with Connection Head

• 316 SS Sheath, 1/2” or 3/4” NPT Connection Port

Desription (Manufacturer Model No.)

RBF185M-HT30418RD31SB/C

Aluminum - NEMA 4X

RBF185M-HT30418RD91SB/C

316L Stainless Steel - NEMA 4X

RBF185M-HT30418RD93SB/C

Aluminum - Class I, Div's 1 & 2, NEMA 4X, IP66

RBF185M-HT30418RD94SB/C

316L Stainless Steel - Class I, Div's 1 & 2,

NEMA 4X, IP66

Part

Number

317315

317323

317340

399550

30

Page 35

Wireless Transmitter Pipe Mounting Kit

To simplify co-location installation of the RBF 185M Type pipe mounted heat trace temperature sensor and Rosemount 248 Wireless transmitter, Chromalox has developed a pipe mounting kit.

This kit may be installed in both ordinary and hazardous areas (Class I, Divisions 1 or 2).

Desription Part Number

Pipe Standoff Kit, Divisions 1 & 2 394337

Item Qty. Component Div. 1 Div. 2

A 1 3/4” Seal Fitting Yes Yes

B 1 Sealing Compound & Fiber Yes No

C 1 Pipe Standoff Yes Yes

D 2 3/4” To 1/2” NPT Reducer Yes Yes

E 1 All-thread Yes Yes

F 1 1/2” NPT X 1” Nipple Ye s Ye s

31

Page 36

Wireless Transmitter Pipe Mounting Kit Detail:

Installation Notes:

1. The conduit (customer supplied) from the seal fitting to the sensor must be rated for the environment in which

it is being installed.

2. Pipe clamps are required to secure the RBF sensor and Kit Pipe Standoff ( C ) to the piping.

3. DIVISION 1 AREA: The Sealing Compound is required for Div. 1 areas. It is used to seal off the Seal Fitting ports,

ensuring that no gas ingress occurs within the Wireless Transmitter or the Sensor. The Fiber is used as a dam

for the sealing compound.

RBF 185M

Heat Trace

Sensor

Environment approved

conduit / connection

(not provided)

Rosemount 248

Wireless Transmitter

3/4” x 1/2” NPT Reducer

(comes with RBF Sensor)

3/4” NPT

Port

1/2” NPT Port

plugged

1/2” NPT

Port

1/2” Nipple

3/4” x 1/2”

NPT Reducer

3/4” NPT

Port

Sealing

Compound

3/4” NPT

3/4” x 1/2”

NPT Reducer

Port

1” all thread

(for 3/4” NPT port)

Pipe clamps are required

(not supplied with kit)

32

Page 37

Installation Example –

Wireless Transmitter and Universal Mounting Bracket to Pipe Mounted Heat Trace Sensor

Rosemount 248

Wireless Transmitter

1/2” NPT port

1/2” NPT port,

plugged

RBF 185M

Heat Trace Sensor

Pipe clamp is required

(not supplied with sensor)

3/4” NPT Reducer

(comes with RBF Sensor)

3/4” NPT

Port

Environment approved

conduit / connection

(not provided)

Rosemount 248 Universal

Mounting Bracket

33

Page 38

Wireless Network Planning

Figure A

Figure B

Figure C

It is generally expected that the user / installer has

substantial knowledge of wireless networking whereby

they fully understand wireless topology, component

capabilities and system-wide organization. To ensure

complete system integrity, the Chromalox specified

core components must be properly employed and wireless network design best practices must be followed.

Chromalox will not be held responsible otherwise.

For support, Chromalox provides optional professional

startup and commissioning services as well as the following wireless sensing information and guidelines:

Wireless Network Topology

When it comes to industrial wireless sensor networks

(WSN), two types of topologies, (or the way wireless

components interact with each other), exist: Infra-

structure and Ad hoc. Each has their own strengths

and limitations.

In the Infrastructure or Star topology, there is one central coordinator, typically a hub (or switch). In this topology, the sensor devices communicate via the hub

rather than directly with each other as shown in Figure

A below. Communication rates are relatively high while

complexity, reliability and distances between components are relatively low.

In an Ad hoc or Mesh topology, however, all devices are

capable of communicating with all other devices within

radio range, creating the topology shown in Figure B.

The benefits of this topology include increased reliability and the distance between components whereas latency and complexity becomes greater.

It is also possible to have a hybrid topology called Star-

Mesh, in which there is a combination of both Mesh

and Star topologies such as in Figure C.

In reality, most Industrial Sensor Networks combine

internal wired and wireless topologies, which employ

routers, gateways and firewalls with external Mesh topologies that are comprised of multiple bi-directional

wireless sensors tied to a common wireless gateway.

See the Site Installation Guidelines for component

considerations within a Mesh or Ad hoc wireless sensor network.

One Direction

Star

Bi-Directional

Mesh

One Direction

& Bi-Directional

Star-Mesh

34

Page 39

Site Installation Guidelines

Many factors, such as component positioning, equipment density, site obstructions, and environmental

conditions, will impact wireless communication integrity. Network reliability and latency may be maximized

by better understanding component limitations and

adhering to fundamental installation guidelines. The

following guidelines are biased towards an Ad hoc or

Mesh Sensor Network Topology.

Communication Range

The effective wireless communication range between

nodes, under ideal conditions (clear line of sight), is

600-750 feet (200-250 meters). Most environments

have obstructions, which may compromise signal performance below commonly acceptable levels. An obstruction vs. distance guideline to consider would be:

− Heavy obstructions (high density industrial plant environment): 100 feet (30 meters)

− Medium obstructions (light processing or manufacturing facility): 250 feet (80 meters)

− Light obstructions (remotely located structures,

such as a tank farm): 500 feet (160 meters)

− Clear line-of-sight, with antenna mounted above

obstructions and angle of terrain change less than 5

degrees : 600-750 feet (200-250 meters)

Antenna Positioning

Signal strength will be improved when the antenna of

wireless transmitters and /or gateways is unobstructed and kept away from the ground or bodies of water.

Quite often, by utilizing a directional antenna or having

the antenna be remotely mounted to the gateway (or

control panel) the communication strength becomes

greater. Antenna extension cables are available to accommodate most structure challenges such as penetrating walls or rooftops. In most situations, the optimum design is to have the gateway antenna as close

to the center of the system as possible.

− Devices (antenna) should be mounted >0.5m from

any vertical surface

− Wireless transmitter antenna should always be positioned vertically, either straight up or straight down.

− Devices should be mounted >1.5m off of the ground

− Avoid having devices mounted inside and outside

of a building. The signal does not transmit well

through wood or cement walls.

Redundancy

A mesh network obtains its reliability by having multiple

or redundant communication paths between wireless

devices, such as transmitters and gateways.

Additional environmental and material factors which

can shorten effective wireless communication distance:

Environmental

− Device proximity to the ground or water.

− Barrier isolation (walls). Having a mesh network

both inside and outside of a building.

Material

− Metals - Potentially the greatest impact

− Wood, soil or anything with water content – moderate impact

− Fiberglass - slight impact

To increase the distance a network can cover, you can

add Repeaters or Nodes. In a Mesh network, a node is

merely a bi-directional wireless transmitter, such as the

Rosemount 248.

− Each wireless transmitter device in the network

should have a minimum of three neighbors.

− Place five or more wireless devices within effective

communication range of the gateway itself.

− For networks with considerably more than five devices, have at least 25% of them within range of the

gateway. This minimizes latency in the network.

35

Page 40

Below is a representation of a typical industrial wireless sensor network:

Commissioning the Wireless Network

To most efficiently setup and commission your wireless network, please refer to the RMT 248 Quick Install

Guide 00825-0200-4248, RMT 248 Product Data Sheet

00813-0100-4248 and RMT 248 Reference Manual

00809-0100-4248 for complete commissioning details

and guidance. These documents are available in the

technical resources tab within the Heat Trace products

/ Wireless Temperature Sensing section at www.chromalox.com.

36

Page 41

Appendix A

Specifications

Input

Input Types - 3-wire RTD, 100 W PT, 0.00385 W/W/˚C, 20 W balanced lead wire,

- Dry Contact Closure (Thermostat)

- Snow or Ice Sensor (voltage drop)

Number of Sensor Inputs 1 to 252 per Circuit

Sensing Configuration 1: Sensed Reading 2 (or more): Min, Max, Average

Output

Power Switching SSR Zero Cross Fired, DOT (Demand on Transfer) Timing

Number of Circuits 2-72 Per ITAS or ITLS system

Capacity 40 Amps per Circuit (Breaker size shall be 50 Amps maximum per

circuit or 125% of anticipated load)

Control Types

PID Control mode must be set to Auto

Autotune On or Off

Proportional Band, (˚F) Range: 1 – 100

Integral (sec/repeat) Range: 0 – 9,999

Rate or Derivative, (seconds) Range: 0 – 500

On/Off Control mode must be set to Auto

Dead band, (˚F) Range: 2 – 100

Manual Range: 0 – 100%

Soft Start, Current Clamping Enable or Disable

Settings

Temperature (SP) Range: -80˚F to +1100˚F

Range: -62˚C to +593˚C

Low Temperature Alarm Range: -80˚F to +1050˚F, Off

Range: -62˚C to +566˚C, Off

High Temperature Alarm Range: -80˚F to +1150˚F, Off

Range: -62˚C to +621˚C, Off

Low Current Alarm Range: 0.0 A – 50.0 A, Off

High Current Alarm Range: 0.1 A – 50.0 A, Off

GFEP Range: 30mA – 150 mA, +/-2.5% of Span or +/- 3mA

GFEP Alarm Condition

Output on Sensor Failure Mode Range: 0 – 100%, Bumpless Transfer to Manual Mode

Security 4 Levels of password protected security

Alarm State Normal Operation: Closed (default), Open

Display, HMI, Indication

Display 10 in. (25 cm) or 7 in. (18 cm) diagonal measurement, depending on the

Human Interface Touchscreen Display

Alarm Only or Alarm & Trip. (These conditions are latching or non-latching)

panel selection

37

Page 42

Alarms

Alarm Types Low & High Temperature, Low & High Current, High GFEP,

Sensor Failure, Communications, Wireless Transmitter Battery

Alarm Relay 5 Amps, Customer Supplied 2-30 VDC or 12-240 VAC

Alarm Contact State

Mode Default

Normal Operation Closed

Alarm Condition Open

Power Off Open

Communications

ModBus RTU/RS485 (2 or 4 wire), TCP/Ethernet

Baud Rate, Hz 2400, 4800, 9600, 19200, 38400, 56000

Parity Range: Even, Odd, None

ModBus ID Range: 1 – 255

BacNET Available, Contact Sales

Operating & Environmental

Temperature

-40˚F to 104˚F (-40˚C to 40˚C) *Enclosure heater required for below 0°C (32°F)*

Humidity Relative Humidity 0% to 90%

Power Supply

100-600 Vac 50/60Hz

Protection IEC IP66 (Front Panel)

Enclosure Rating NEMA 4 or Optional NEMA 4X 304SS

Approvals UL/cUL Ordinary and Class I, Division 2, Groups A,B,C,D Hazardous loca-

tions (UL file Number: E165116)

Temperature Rating T4 (Derate to T3 & Groups B,C,D when using enclosure heater)

Default Settings

Below is the parameter settings chart organized by Menu Screen. It includes the default, minimum, maximum and/

or the range of settings, where applicable.

Parameter Default Min Max

Temperature Setpoint 0˚F (-18˚C) -80˚F (62˚C) 1100˚F (593˚C)

Hi Temp Setpoint 200˚F (93˚C) -80˚F (62˚C) 1100˚F (593˚C)

Lo Temp Setpoint 32˚F (0˚C) -80˚F (62˚C) 1100˚F (593˚C)

HI Current 50 Amp 0.2 Amp 50 Amp

Lo Current 0.2 Amp 0 Amp 50 Amp

GFEP 30 mA 20 mA 150 mA

Control Mode Manual Manual Auto

Output % 0 0 100

Integral 8 0 100

Derivative 2 0 500

PID or ON/OFF On/OFF PID On/OFF

Soft Start Enabled Enabled Disabled

38

Page 43

Solar Shield Options

Piece

Equipment protection from the environment must

be carefully considered when installing these systems outdoors. Both Solar Loading and UV Rays

from the sun can impact the performance of these

systems.

which provide solar load protection to the control

panel enclosure itself. In addition, it also provides

some UV protection to the HMI / Touchscreen.

The Solar Shield spans the entire width of the panel.

Cut outs are provided for the Lifting Eye Hooks.

Chromalox offers optional industrial duty, heavy

gage Stainless Steel canopy type Solar Shields

Construction includes:

Piece Description

A 12 Gage x 30” (76 cm) x Panel Width - 304 SS Sheet for solar shield

B 0.250” (6.5 mm) thick 304 SS plate for tubing base and cap

C 1.0” (25 mm) 304 SS structural square support tubing

Piece A

Piece B

C

Piece B

Piece D

Part Number Panel Width

Enclosure Side

HMI / Touchscreen Note:

The Solar Shield will provide some UV protection to

the HMI / Touchscreen. However, without complete

UV protection, the life of the HMI / Touchscreen

will be compromised. For outdoor installations,

Chromalox insists on installing an HMI Sunscreen

to fully protect the HMI / Touchscreen from harmful

Front

0006-84026 24 inch (61 cm)

0006-84021 36 inch (91 cm)

0006-84022 48 inch (122 cm)

0006-84023 60 inch (152 cm)

UV rays. HMI warranty claims will not be honored

on outdoor installations which do not employ

Chromalox-recommended Sunscreens.

See HMI Sunscreen Options.

39

Page 44

HMI Sunscreen Options

The HMI Sunscreen provides complete protection

from the harmful effects of UV Ray exposure. When

installed properly, along with the supplied hardware

and accessories, the NEMA 4/4X control panel rating is maintained.

The Sunscreen collapses nearly flush with the front

of the enclosure when not in use and it may be

secured shut with a common padlock.

Part Number Applicable Control Panel Material

0076-15392 ITLS/ITAS-6-72 Painted Steel

0076-15488 ITLS/ITAS-2-4 Painted Steel

40

Page 45

Retrofitting control panels with the HMI Sunscreen is done as follows:

1. Use the mounting template below to establish the drill hole locations.

2. Install the provided gas-tight sealing washers and sealing gasket along with the cap screws and nuts.

Field Installation

Below is the mounting template for the larger Sunscreen, 0076-15392 for the ITLS/ITAS-6-72 designs:

41

Page 46

Wiring Considerations

All standard IntelliTRACE panels will have the same core components. Please see the table and pictures

below to understand basic wiring needs. Refer to the wiring diagram(s) supplied with your specific panel

for reference.

ITAS-EXT,