Page 1

Installation & Operation Manual

ITC 1 & 2 Circuit

Heat Trace Controller

Line or Ambient Sensing

Ordinary Areas &

Class I, Division 2

PK509-10

0037-75516

June 2018

1

Page 2

Table of Contents

Section Page

Table of Contents .................................................................................................................................................... 2

Safety Precautions ..................................................................................................................................................3

Introduction .............................................................................................................................................................4

Model Overview ....................................................................................................................................................... 5

Theory of Operation ................................................................................................................................................ 6

Before Powering Up ................................................................................................................................................ 6

Installation ............................................................................................................................................................... 7

Operating the ITC .................................................................................................................................................... 8

HMI (Human – Machine Interface) .................................................................................................................... 8

Main Window ................................................................................................................................................... 8

Navigating the ITC ................................................................................................................................................... 9

The Keypad .................................................................................................................................................... 10

Programming the ITC ............................................................................................................................................ 11

Security Levels ............................................................................................................................................... 11

The Temperature Menu ..................................................................................................................................12

The Current Menu ..........................................................................................................................................12

The Control Menu ..........................................................................................................................................12

The Soft Start Function .................................................................................................................................. 14

The Comms Menu (Communications) ............................................................................................................ 14

The System Menu .......................................................................................................................................... 15

Current Sampling ..................................................................................................................................................19

Alarms ..................................................................................................................................................................19

Dimensions ............................................................................................................................................................ 20

Default Settings ..................................................................................................................................................... 21

Specifications ........................................................................................................................................................ 23

Equipment Ratings ................................................................................................................................................ 25

Field Wiring Considerations .................................................................................................................................. 25

Modbus Wiring Considerations ............................................................................................................................. 25

Customer Wiring .................................................................................................................................................... 26

Modbus Serial Communications ........................................................................................................................... 28

Service Contact Information .................................................................................................................................. 32

2

Page 3

Safety Precautions

Throughout the intelliTRACETM Setup Guide, these

symbols will alert you to potential hazards. Safety precautions should always be followed to reduce the risk

of fire, electrical shock, injury and even death to persons. Please read all instructions before operating your

intelliTRACE

move power before servicing a circuit. Personnel working with or near high voltages should be familiar with

modern methods of resuscitation. Contact an area supervisor, registered electrician or safety personnel for

more information.

TM

ITC1 or ITC2 Heat Trace Controller.

To avoid electrical shock or injury, always re-

Before working inside the equipment, turn

power off and ground all points of high potential before touching them.

Users should install adequate controls and

safety devices with their electric heating equipment. Where the consequences of failure may

be severe, back-up controls are essential. Although the safety of the installation is responsibility of the user, Chromalox will be glad to

assist in making equipment recommendations.

A disconnect device and circuit breaker should

be provided in the end installation. The installation and proximity for the disconnect device

must satisfy the electrical Authority having jurisdiction for the installation, such as NEC.

Branch circuit protection should be set for 40

amps or lower.

HIGH VOLTAGE is used in the operation of this

equipment; DEATH ON CONTACT may result if

personnel fail to observe safety precautions.

Learn the areas containing high-voltage connections when installing or operating this

equipment.

Be careful not to contact high-voltage connections when installing or operating this equipment.

ELECTRIC SHOCK HAZARD. Any installation involving control equipment must be performed

by a qualified person and must be effectively grounded in accordance with the National

Electrical Code to eliminate shock hazard.

Should the equipment be used in a manner not

specified by Chromalox, the protection provided may be impaired.

3

Page 4

Introduction

For nearly a century, customers have relied upon Chromalox for premiere quality and innovative solutions for

industrial heating applications. Chromalox manufactures the world’s largest and broadest line of electric

heat and control products.

The intelliTRACETM family of heat tracing products

continues to expand with its latest single or two circuit

controllers the ITC1 & ITC2. These are a complete temperature control and system management solutions for

electrical heat trace applications. They are designed

for industrial applications in ordinary or Class I, Division

2. Groups A,B,C & D hazardous locations.

The intelliTRACETM ITC1 & ITC2 provides the user with

an easy to navigate menu system, continuous critical

parameter monitoring, application flexibility and equipment safety precautions.

The ITC is an ideal solution either Freeze Protection or

Process Temperature control. Whether you have Ambient or Line Sensing or a combination of both, the ITC is

the affordable and complete system for you.

intelliTRACETM ITC Features:

• 1 & 2 Circuit Models

• 100 – 277 VAC, 50/60 Hz

• SSR Control, 40 Amps per Circuit

• PID, On/Off or Manual Control Modes

• Selectable Soft Start Feature

• ModBus Communications

• RTU/RS485 (& 422)

• TCP/Ethernet

• Full Monitoring & Alarms

• High / Low Temperature

• High & Low Current

• GFEP & Sensor Failure

• Programmable Duty Cycle On Sensor Failure

• Alarm Indication & Announcement

• Password Protected Security Levels

• NEMA 4X Fiberglass or 316 SS Wall Mount Enclosure

• LED Indication for Power, Load & Alarm per Circuit

• Front Panel Capacitive Touch Switches

• One or two Sensor Inputs / Circuit – Min, Max & Averaging

• 2 Circuit Ambient control from a single RTD sensor

• High Resolution TFT Display:

• 2 Circuits displayed / screen (on 2 Circuit unit)

• Displayed Parameters: Process Variable, Set

Point Temperature, Control Mode, Soft Start status, Load demand, Alarm Status

Agency Approvals:

• UL, cUL Ordinary Areas, Class I Division 2 areas

• CE

Options:

• Ethernet Communications (TCP/Ethernet or web

server/Ethernet)

• Wireless Communications (Consult Sales)

•

12” x 10” x 8” NEMA 4X 316SS Wall Mount Enclosure

IMPORTANT: To comply with NEC code,

one of the following must apply.

1.

Customer supplied 2 pole GFEP breaker in branch

circuit breaker box upstream of the controller

2.

Requirement shall not apply in industrial establishments where there is alarm indication of

ground faults and the following conditions apply:

a. conditions of maintenance and supervison

ensure that the qualified person(s) service the

installed heater.

b. continued circuit operation is necessary for

safe operation of equipment or process.

4

Page 5

Model Overview

The ITC series IntelliTRACE Controller is designed

for industrial Heat Trace Line and/or Ambient Sensing applications in Hazardous (Class I, Division 2) or

Non-Hazardous areas. The ITC series controller will

control 1 or 2 circuits and is a wall mounted device

that operates at 100 to 277 VAC and offers the following standard design features: NEMA 4X FG enclosure,

3.5” High Resolution TFT Display with integral display

heater, front panel capacitive touch switches & LED Indication of Power, Load & Alarm.

It also offers PID, ON/OFF or Manual SSR power control, is rated at 40A per circuit in a -40˚F to 104˚F Ambient, employs a Soft Start program and accepts up to 2

RTD sensors per circuit to provide Ambient and/or Line

Sensing type control. When 2 sensors are employed,

the minimum, maximum or average of the two sensor

temperatures may be used to control each circuit.

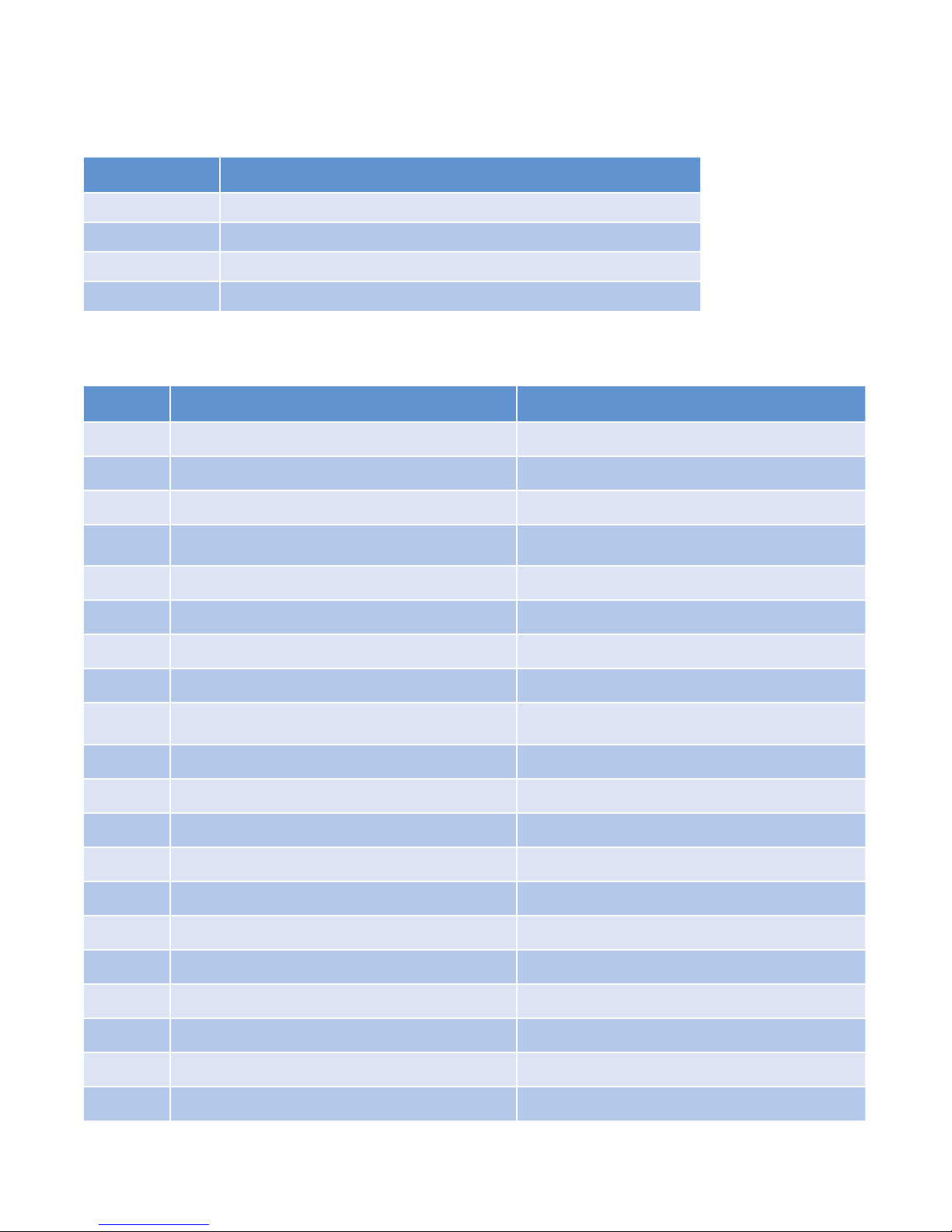

Table 1

Features / Capabilities ITC1 ITC2

40 Amps/ Loop @ 100 to 277 Volts X X

Number of Circuits 1 2

SSR (Solid State Relay) Control X X

3.5” 320x240 RGB Full color graphic TFT module X X

10” x 8” x 6” NEMA 4X FG Enclosure X X

Soft Start Feature X X

PID, ON/OFF or Manual Control X X

RTU/RS485 & /RS422 ModBus Communications X X

Up to Two RTD Sensors per Circuit X X

Temperature Monitoring and Alarms X X

GFEP Monitoring and Alarms X X

Current Load Monitoring and Alarms X X

Sensor Failure Monitoring and Alarms X X

Three Levels of Security X X

Optional 12” x 10” x 8” (30 x 25 x 20mm) 316 SS Enclosure X X

Optional TCP/Ethernet Communication X X

The ITC2 may also be used as a 2-channel ambient

sensing controller that uses only one RTD to control

both circuits.

Other standard features include: Alarms (1xAC & 1xDC)

for High & Low Current, GFEP (Ground Fault Equipment Protection), High & Low Temperature & Sensor

Failure, ModBus RTU/RS485 & /RS422 Communications. Alarms may be set up to be normally open or

normally closed.

Options Include: TCP/Ethernet Communications, Wireless Temperature Sensing and 316 Stainless Steel Enclosure

Please see Table 1 below for applicable features & capabilities by Model type.

5

Page 6

Theory of Operation

The detailed set up of the individual circuit parameters

is explained throughout the various sections of this

manual. This Theory of Operation overview is intended

to give a quick summary of how it all works together.

• Parameter setpoints (High/Low Temperature, High/

Low Current & GFEP), Control Modes (Auto or Manual) and operation modes under alarm conditions

(GFEP limit violation & Sensor Loss) are entered for

each circuit. Each circuit is designed to operate independently.

• Active loops are individually tested for 2 seconds

every 2 minutes. During the test, a current load value is updated on the yellow bar located on the Main

Window and a new GFEP current is automatically

and continuously calculated.

• If the Ground Fault (GFEP) limit is surpassed, the

ITC has four options of behavior:

1. Alarm, non-latching – No change in output.

2. Alarm and Trip, non-latching – Ouput goes to

0% (off) while in alarm state.

Note (1&2): Alarm will be cleared when sensed GFEP

is 5mA less than GFEP setpoint.

3. Alarm, latching – No change in output.

4. Alarm & trip, latching – Output goes to 0% (off)

while in alarm state.

Note (3&4): Alarm condition may only be cleared with

a manual reset of the alarm

• Similarly, should a failed sensor condition appear,

the ITC will go into alarm state and display a flashing

sensor error. The ITC will automatically be switched

into Manual mode. The output % may be adjusted

by the user within the SYSTEM MENU Parameter:

“Failed Sensor Output 1 (or 2)”. See Temperature

Sensing & Failed Sensor Output parameters in the

System Menu definitions below.

• To limit inrush current on the overall system, a pro-

prietary Soft Start algorithm is applied during system start-up. This will ONLY occur while the operation mode is set to AUTO. The Soft Start program

will increment the output by 1% every 1 second

until the desired temperature is reached or the output % achieves 100%. After the Soft Start program

completes its cycle, the Auto Control Mode of the

system will return to either PID or ON/OFF Control

Mode, depending what was selected by the user.

The Soft Start Program will not function if the control

mode is set to Manual.

Before Powering Up

Chromalox takes great pride in knowing that we have

provided to you a product of premium quality and

workmanship. We have taken every precaution to ensure that your equipment arrives safe and secure.

However, vibration and temperature changes during

shipping can cause some components to become

loose. Additionally, throughout the life span of this

product, other environmental and application conditions may have affected the mechanical and electrical continuity of several internal components. Therefore, for your safety and overall product performance,

please take the time to familiarize yourself with the

MAINTENANCE, OPERATION, AND INSTALLATION

INSTRUCTIONS technical manual that was shipped

with your control product.

Since it is not uncommon for electrical wiring and mechanical connections to become slightly loosened during shipment, we ask that you pay particular attention

to section 4-5.3:

Wiring and Connections

Check wiring and connections as follows:

a. Inspect wiring for wear, fraying, chipping, nicks, and

evidence of overheating. Repair minor defects with

a good grade of electrical tape, or replace if needed.

b. Inspect for loose electrical and mechanical connec-

tions. Tighten or replace defective crimp-style lugs.

Re-solder loose solder connections. Tighten or replace all loose or missing hardware.

These precautions must be adhered to when the product is received as well as before every season or on an

annual basis, whichever is shortest.

6

Page 7

Installation

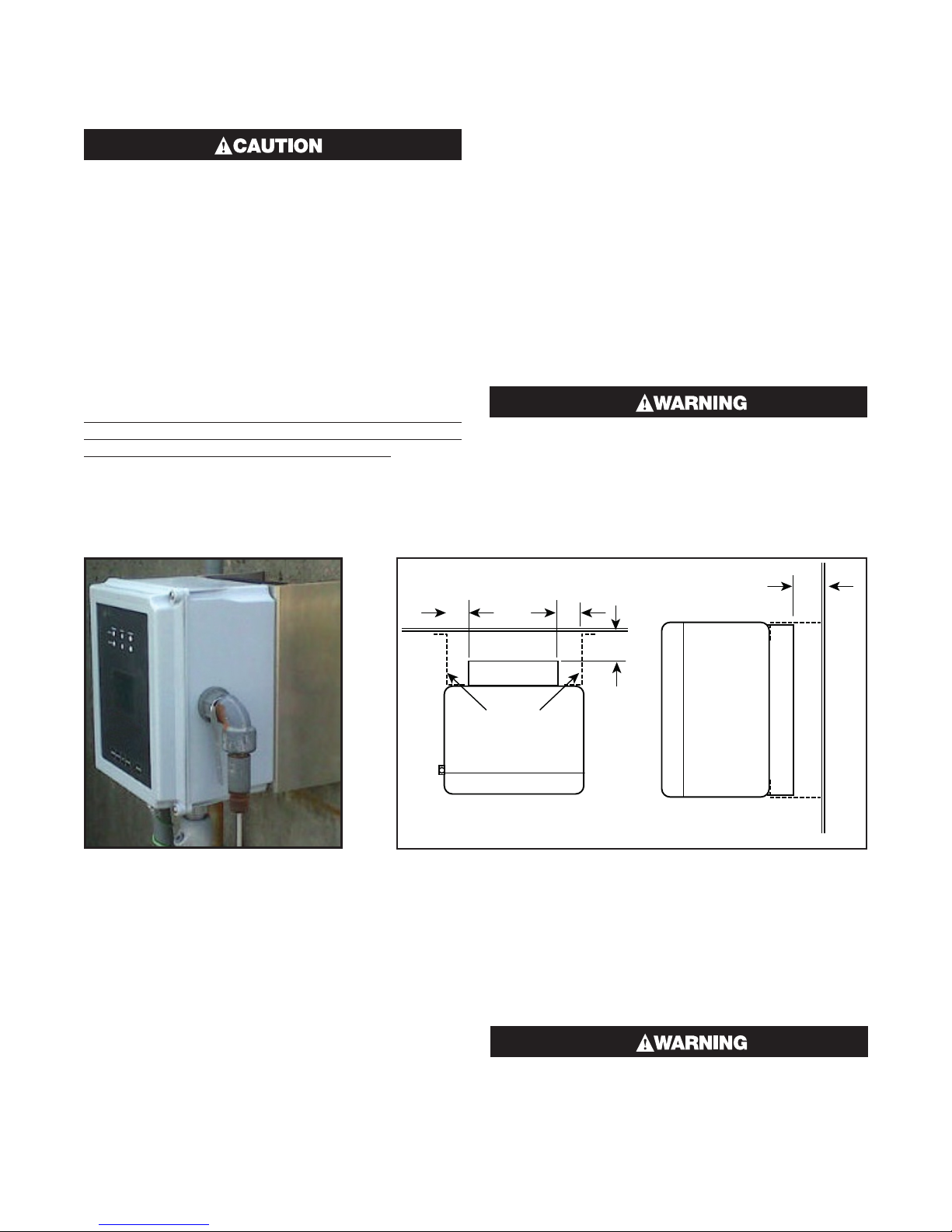

The ITC employs a SSR (Solid State Relay) as a

means to switch the heating load power. Inherently, SSR’s produce heat when operating. Heat

is dissipated at the rear of the ITC through a

heat sink. By design, the ITC must be mounted

in a vertical orientation in order to allow the

heat sink to properly dissipate the heat from

the controller. See Figure 1.

The ITC is shipped with one set of stainless steel

mounting brackets. These brackets were specifically

designed to allow sufficient airflow in and around the

heat sink. The air flow above or below this heat sink

must in no way become restricted. See Figure 1.

To maintain UL compliance, the heat sink must be

inspected every season to confirm that no debris or

objects are in contact with the heat sink. All debris

must be removed from the heat sink fins. High pressure

blasts of clean, dry air or other means which will not

damage the fins are to be used to dislodge all debris

from the fins.

Should the owner decide not to use the provided brackets, mounting of the ITC must incorporate all of the following dimensional safeguards (Refer to Figure 2):

1. Maintain a minimum of 1.5” (3.8 cm) of free air space

on either side of the heat sink (K)

2. Maintain a minimum of 1.8” (4.6 cm) of free air space

directly behind the heat sink (C)

3. Zero air flow restriction above and below the heat

sink.

4. The mounting surface, customer mounting bracket

and fasteners must be of suitable structural design

to support four times the weight of the equipment.

Violating any of the heat sink clearance dimensions or if the equipment is used or mounted in

a manner not specified by Chromalox, the protection provided may be impaired. This could

result in equipment damage, personal injury or

both.

K K

Figure 1

Mounting Surface Considerations

The preferred materials of the mounting surface include metals, concrete or wood products. If the ITC

is to be mounted outdoors, then the metals shall have

corrosion resistant properties and the wood products

shall be treated for outdoor use. If the mounting surface is plaster (drywall), it shall be of the following minimum construction: 1/2”, +/-1/16” (10 mm, +/-2mm) in

thickness and supported by nominal 2” x 4” (50mm

x 100mm, +/-10 mm) studs that are on 16”, +/- 1/2”

(400mm, +/- 10mm) centers. See Dimensions section

for wall mount layout and hole location. Mounting shall

be performed by experienced professionals.

C

C

Heat Sink

Mounting

Brackets

Front

Top View of ITC

Controller

Figure 2

Front

Heat Sink

Right Side View

of ITC Controller

Fasteners

The fasteners shall be of 300 series (304 or 316) stainless steel and they shall be a #8 or #10 (or metric equivalent) bolt or screw configuration. If anchors are to be

used, ensure that they match the fastener specification.

Improper mounting may cause an unsafe condition resulting in equipment damage or failure

which could cause personal injury.

Mounting Surface

7

Page 8

Operating the ITC

Set Point T

HMI (Human – Machine Interface)

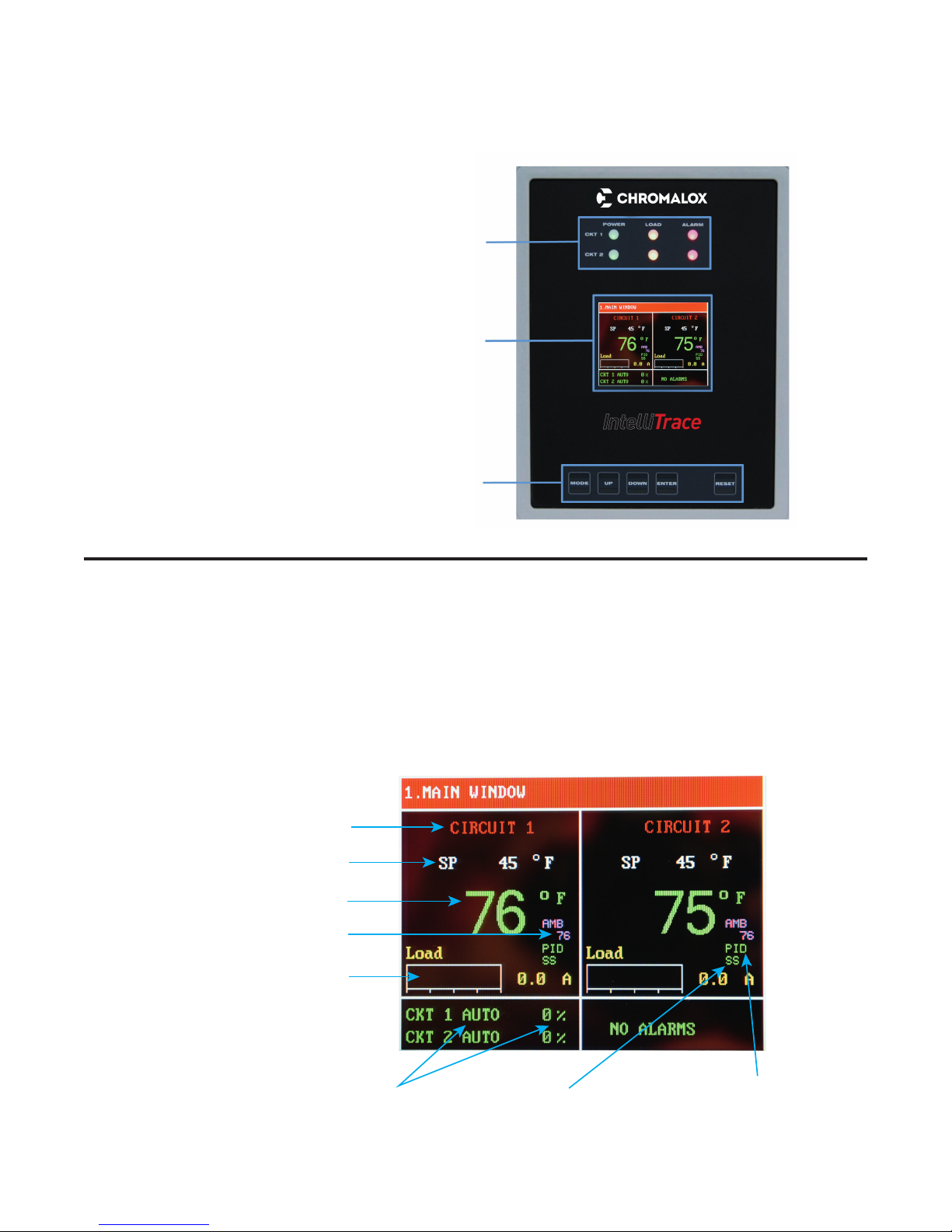

There are three areas on the front panel of the ITC in

which the User may visually receive information or provide input to the controller:

1. LED status indication for Power,

Load & Alarm for each circuit

2. Hi Resolution TFT displays the parameter settings,

alarm type, mode of operation, current load

demand, program menu screen

and menu selection items

3. Capacitive touch keypad

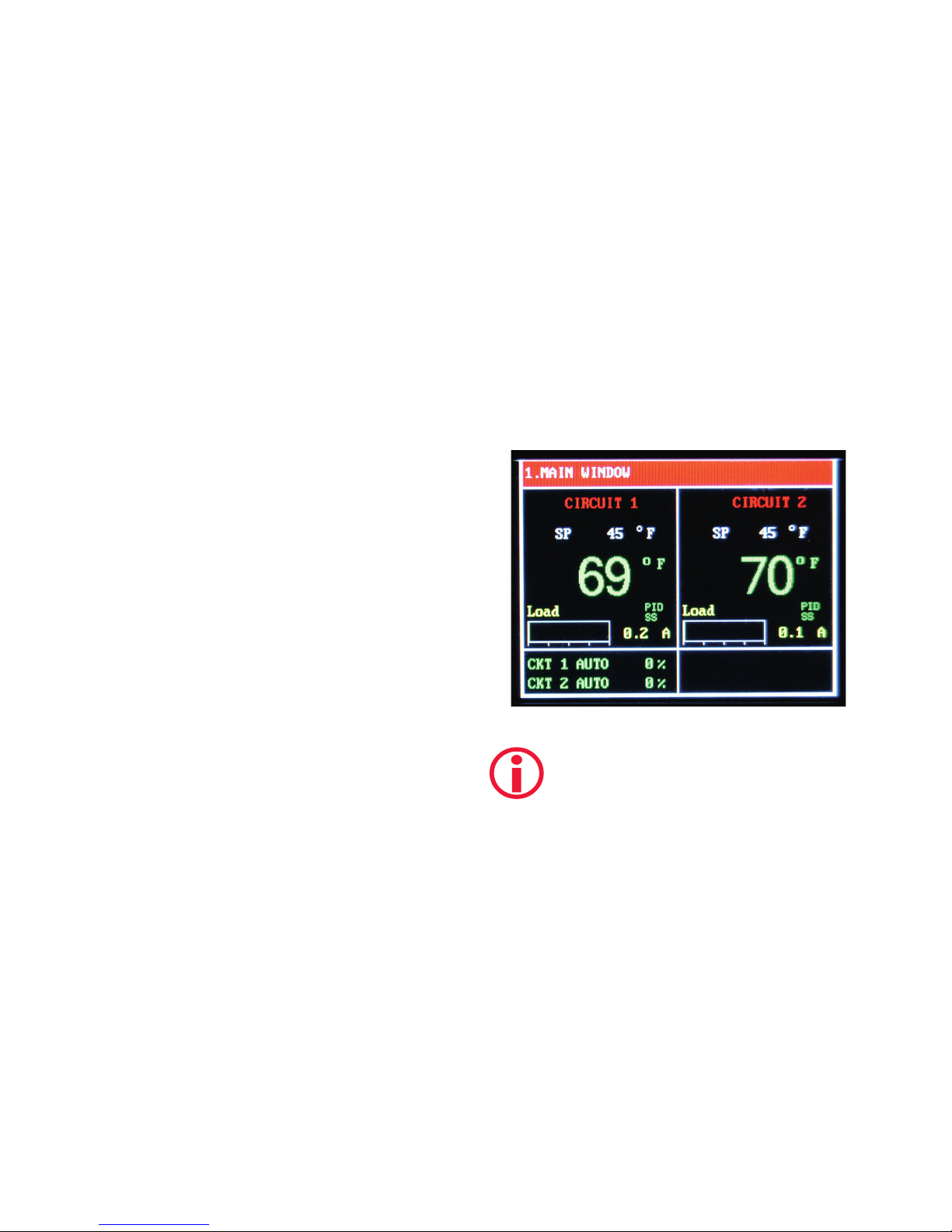

Main Window

In normal operating mode, the main window screen on

the ITC displays the circuit number, set point temperature, process temperature, current load demand, soft

start status, mode of operation, output % and alarm

type for each active circuit.

Below is the Main Window for a 2 Circuit ITC.

Circuit Number

emperature

Process Temperature

Ambient Temperature

Current Load,

Bar Graph & Value

Mode of Operation

& Output % per Circuit

Soft Start Status

8

Auto Mode Type

(PID or On/Off)

Page 9

Navigating the ITC

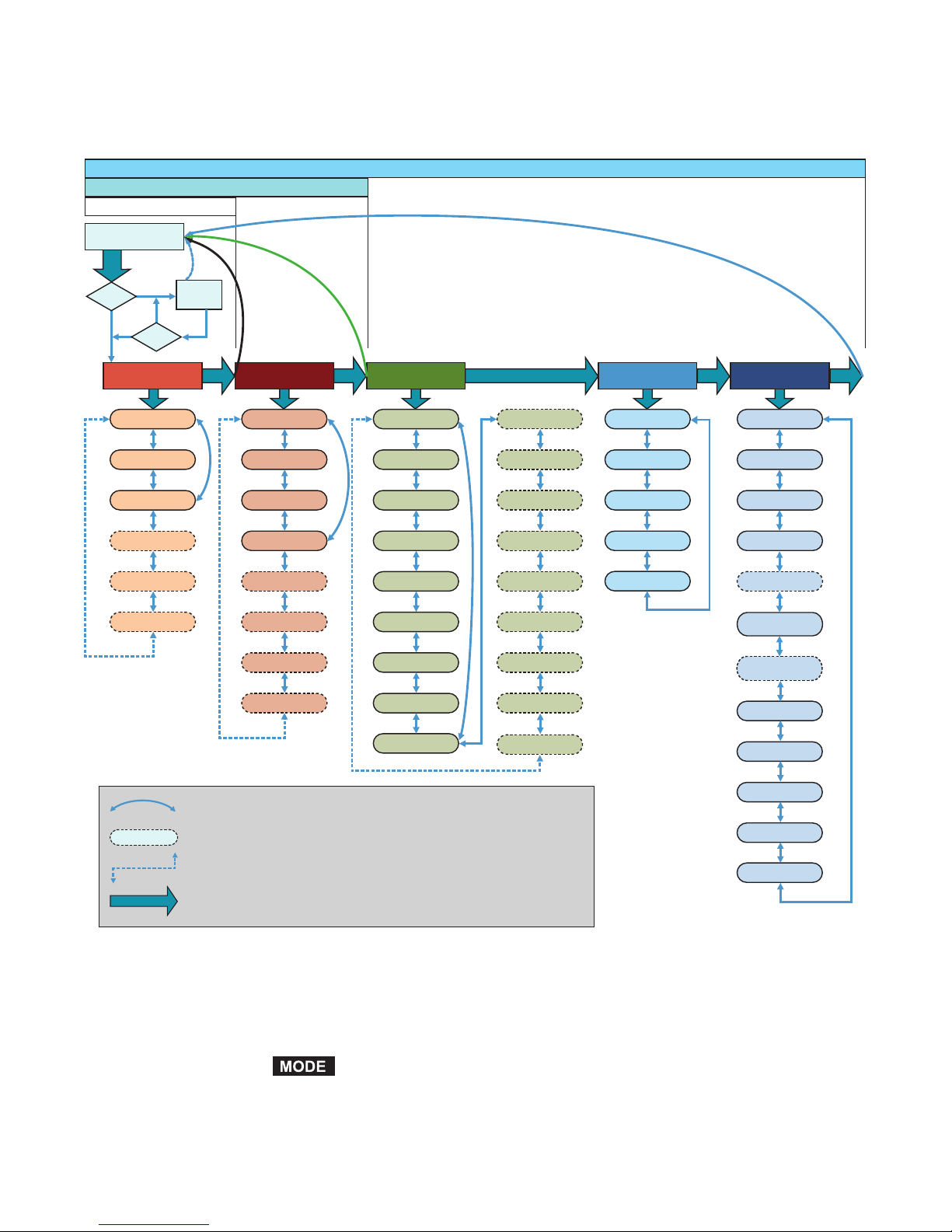

Visually, here is how one navigates through the ITC Menus & Parameters:

Security Level 3

Security Level 2

Security Level 1

1. Main Window

Mode

No

Logged?

Yes

Yes

2. Login

No

Correct?

3. Temperature Menu

Temp Setpoint 1

Lo Temp Alarm 1

Hi Temp Alarm 1

Temp Setpoint 2

Lo Temp Alarm 2

Hi Temp Alarm 2

Mode Mode Mode ModeMode

Lo Current Alarm 1

Hi Current Alarm1

GFEP Setpoint 1

GFEP Alarm/Trip 1

Lo Current Alarm 2

Hi Current Alarm 2

GFEP Setpoint 2

GFEP Alarm/Trip 2

5. Control Menu

Auto Control Mode 1

Auto/Man/Off 1

Deadband 1

Autotune 1

Prop. Band 1

Integral 1

Rate 1

Soft Start 1

Manual Offset 1

Curved Double Arrow - continuation path for 1-Circuit Units Only

Auto Control Mode 2

Auto/Man/Off 2

Deadband 2

Autotune 2

Prop. Band 2

Integral 2

Rate 2

Soft Start 2

Manual Offset 2

6. Comms Menu

Baud Rate

Parity

Modbus ID

IP Address

DHCP

7. System Menu 4. Current Menu

Firmware Version

Button Sound

Units

Temp. Sensing 1

Temp. Sensing 2

Failed Sensor

Output 1

Failed Sensor

Output 2

Password Level 1

Password Level 2

Password Level 3

GFEP Alarm/Trip 2

Dashed Parameter Ovals appear on 2-Circuit Units Only

Dashed, Angled Connector - continuation path for 2-Circuit Units Only

Mode

Mode arrow represents pressing the MODE Key

The horizontal security level bars, which are above the

ITC Menu & Parameter navigation map, illustrate the

available menus within that security level. The Main Window is presented when the

Alarm State

Restore to Default

while the operator is at the last available menu screen

within the current security level.

button is selected

9

Page 10

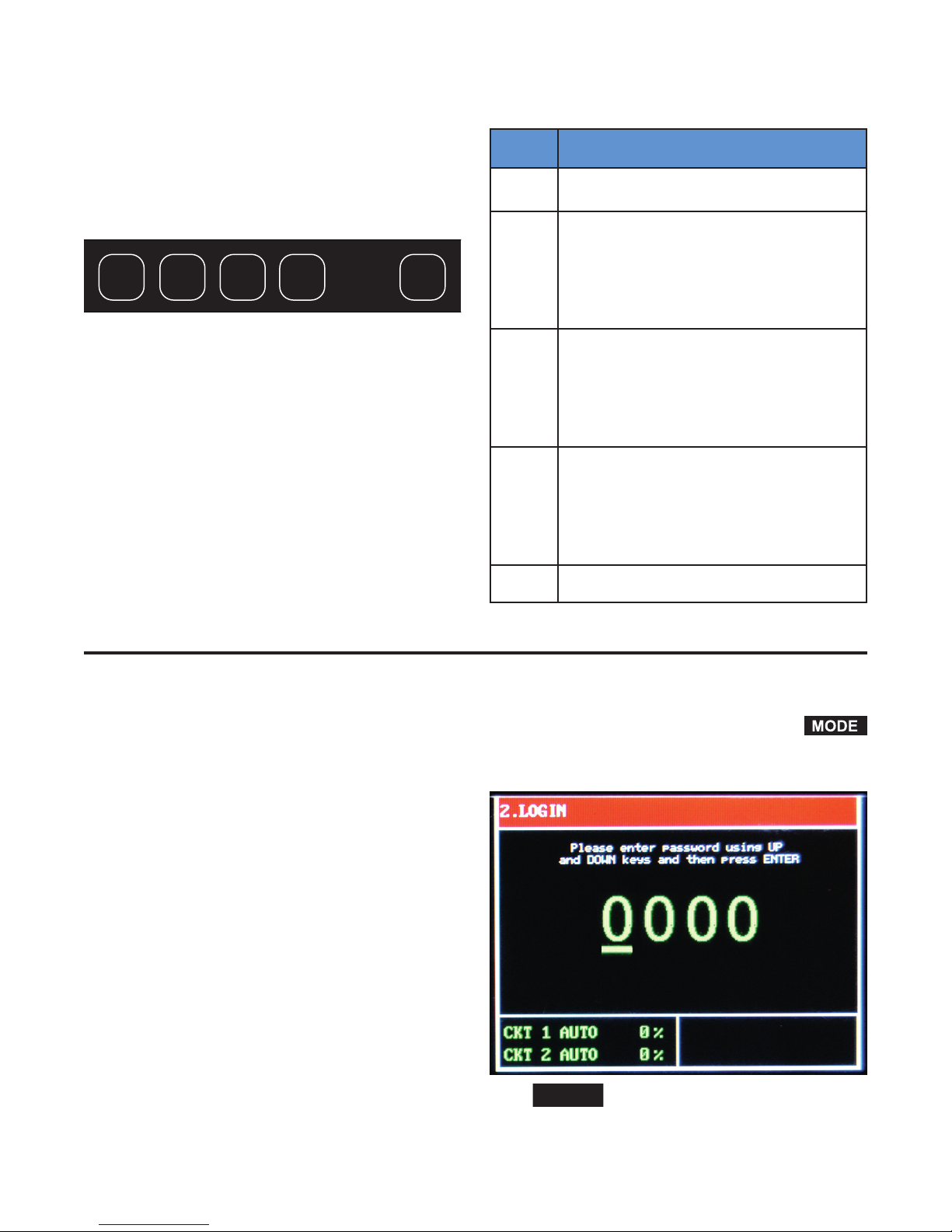

The Keypad

ENTER

RESET

There are five capacitive touch keys or buttons on the

front panel. The keypad allows the user to select or

change parameters & settings, clear alarms and navigate

throughout the ITC programming areas. See Figure 3

shown below:

MODE UP

DOWN

Figure 3

ENTER

RESET

The function of each key is as follows:

KEY FUNCTION

MODE

UP

DOWN

ENTER

Allows the user to Navigate between

Menus & Main Window

1. Within a Menu, Scroll UP to next Parameter or Setting within that Menu

2. When viewing an adjustable parameter

or setting, increments that parameter

UP to the next available value. For a

quick scroll, push and hold the key.

1. Within a Menu, Scroll DOWN to next

Parameter or Setting within that Menu

2. When viewing an adjustable parameter

or setting, increments that parameter

DOWN to the next available value. For a

quick scroll, push and hold the key.

1. To accept a parameter or setting that

has been entered or changed.

2. Press to accept the change when viewing an adjustable parameter or setting.

3. When in LOGIN Screen, press to advance to next security digit.

Programming the ITC

The ITC is pre-programmed with default parameters and

settings that allow it to function “right out of the box”.

To change any of the parameters or settings on the ITC,

you must access the appropriate menu(s): Temperature

Menu, Current Menu, Control Menu, Comms (communications) Menu or System Menu.

RESET

To access any of these menus, press the

button on the keypad. You will be presented with the

Login screen:

Resets or clears all alarms

10

Press

to advance to the next digit.

Page 11

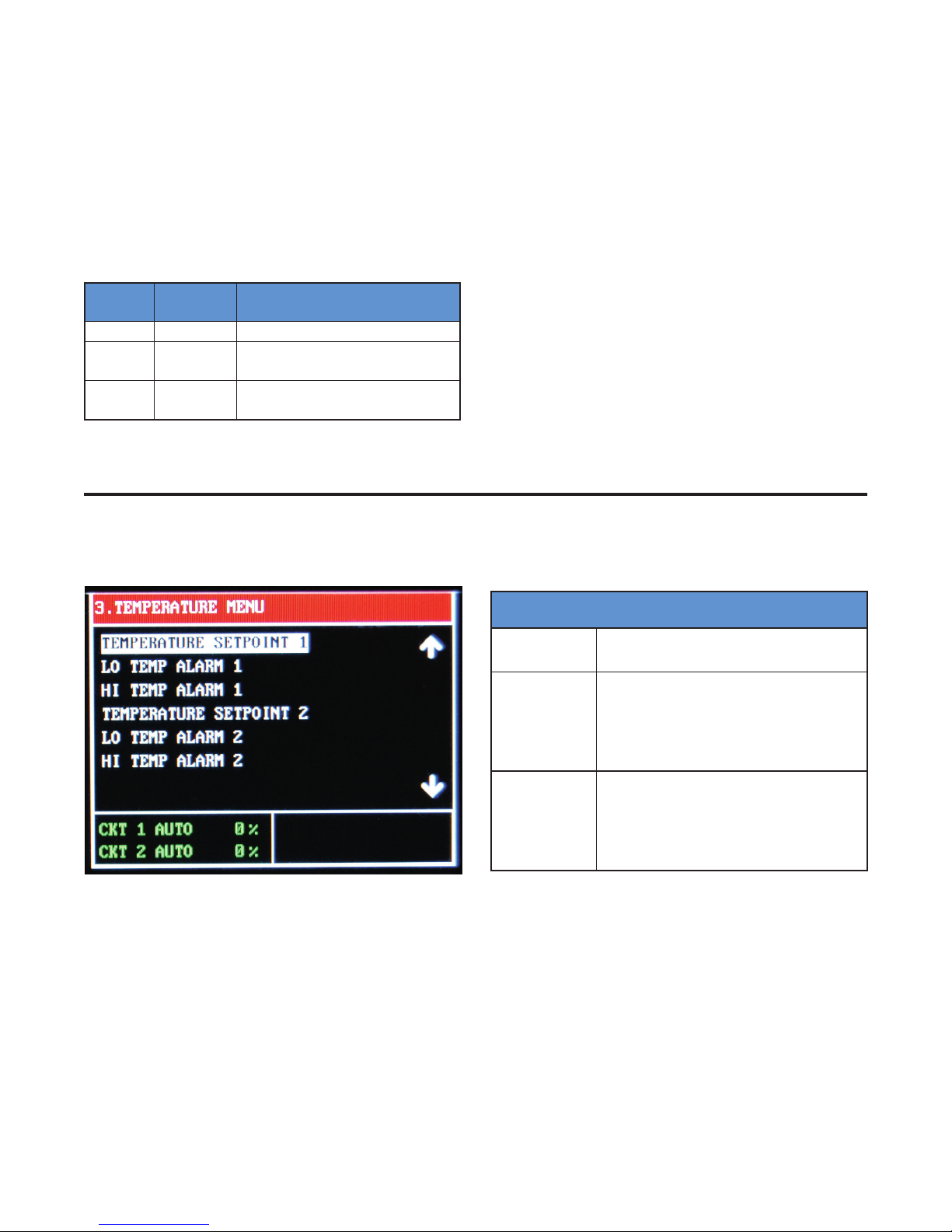

Security Levels

You must first enter a passcode that is aligned with the

menu that you wish to access. In most cases, limited

access to certain programming areas is desired. The

most frequently used parameter settings have the lowest level of security. Invalid passcodes will not be accepted and you will be returned to the LOGIN Screen.

Initial factory set passcodes for the Security levels below are:

Security

Level Passcode

1 0011 Temperature Menu Only

2 0034

3 0063

Temperature & Current

Menus Only

Temperature, Current, Control,

Comms & System Menus

Available

Programming Menus

The Temperature Menu

Security Levels 1, 2 & 3

You will be returned to the main screen if no buttons

are depressed within a 30 second time frame.

Passcodes may be reprogrammed within the Systems

Menu. These codes should be kept in a secure place.

The Temperature Menu provides access to the Temperature based parameters: Temperature Setpoint,

Low Temperature Alarm & High Temperature Alarm for

Circuits 1 and 2 (when available).

3. Temperature Menu

Temperature

Setpoint

Low

Temperature

Alarm

High

Temperature

Alarm

Process Temperature Variable

Lower limit of the Process Temperature

Variable at which the system goes into

alarm state. This alarm may be turned

OFF by going one increment beyond

the Lowest setting.

Upper limit of the Process Temperature

Variable at which the system goes into

alarm state. This alarm may be turned

OFF by going one increment beyond

the Highest setting.

11

Page 12

The Current Menu

Security Levels 2 & 3

4. Current Menu

The Current Menu provides access to the current and

GFEP based parameters: Low Current Alarm, High

Current Alarm, GFEP Setpoint & GFEP Alarm/Trip for

Circuits 1 and 2 (when available).

Low

Current

Alarm

High

Current

Alarm

GFEP

Setpoint

GFEP

Alarm/Trip

Lower limit of the Load Current Variable at

which the system goes into alarm state.

This alarm may be turned OFF by going

one increment beyond the Lowest setting.

Upper limit of the Load Current Variable at

which the system goes into alarm state.

This alarm may be turned OFF by going

one increment beyond the Highest setting.

Upper limit of the Ground Fault Equipment

Protection Variable at which the system

goes into alarm state

Action taken by controller when the GFEP

Setpoint alarm condition is achieved.

The options are:

Output remains at

selected output %.

1. Alarm Only,

Non-Latching

2. Alarm & Trip,

Non-Latching

3. Alarm Only,

Latching

4. Alarm & Trip,

Latching

Alarm clears when

sensed GFEP cur

rent is 5mA < GFEP

setpoint

Output goes to 0%

(off) while in alarm

state. Alarm clears

when sensed GFEP

current is 5mA <GFEP

setpoint

Output remains at

selected output %.

Alarm condition may

only be cleared with a

manual reset.

Output goes to 0%

(Off) while in alarm

state. Alarm condition

may only be cleared

with a manual reset.

-

The Control Menu

Security Level 3

12

Page 13

The Control Menu provides access to the types of Automatic Control, Mode of Operation, the parameters which

influence the control algorithms and the Soft Start function: Auto Control Mode, Auto/Manual/Off Control, Dead-

band, Autotune, Proportional Band, Integral, Rate (Derivative), Soft Start function and Manual Offset.

5. Control Menu

Auto Control Mode

Auto/Manual/Off

(Mode of Operation)

Autotune

Deadband

When the ITC is in AUTO Mode (see AUTO/MANUAL/Off parameter), the choice of

Automatic Control is either PID or ON/OFF Mode.

Determines the type of Control Operation: Automatic, Manual or Off.

Automatic Control: Select Auto. This allows PID or On/Off control.

Manual Control: Select 1 – 100. This is the % power output.

Off: Select 0. This equates to 0% output, which turns off that circuit.

NOTE: The Soft Start function will only engage when the ITC is in AUTO Mode

The ITC Autotune function establishes the individual P, I & D (Proportional Band, Integral

& Derivative) control modes. These modes help to bring the process variable to the

setpoint temperature as quickly as possible.

In order to properly calculate the P, I & D modes, the Autotune program requires a 25

degree rise in sensed temperature after initiating the program. If within 30 minutes the

temperature will not reach its setpoint, the Autotune algorithm will be canceled and old

PID values will be used.

Once the Autotune feature is activated, you must not change the menu page until the

Autotune algorithm is completed. Changing the page will cause the Autotune algorithm

to shut down.

The Autotune function is a one-time algorithm set up of the P, I & D control modes.

Should your process variables change significantly, it is suggested to that the Autotune

feature be turned off and then reinitiated.

Active ONLY when the ITC is in Auto Mode & under On/Off Control

The temperature range equally divided above & below the temperature set point, where

the controller will not take corrective action.

Example: A setting of “10” for the deadband will result in a deadband that is 5 degrees

above and below the temperature setpoint.

Proportional Band, P

Integral, I

(Automatic Reset)

Derivative, D

(Rate)

Soft Start

Manual Offset

Active ONLY when the ITC is in Auto Mode & under PID Control

The Proportional Band (P), the Integral (I) & Derivative (D) are modes of control that work

in union to bring the process variable to setpoint as smoothly and quickly as possible.

The P, I & D will be automatically established during the Autotune procedure (see above).

Additionally, the P, I & D may all be manually established by the user. Great care should

be taken when manually establishing the P, I & D.

Proportional Band: The temperature range above and below the temperature set point.

Will only be available while the Mode of Operation is set to AUTO.

Options are On or Off.

Only available while the Mode of Operation is set to AUTO & under PID Control

The Manual Offset may be used in conjunction with the PID variables to assist in Tuning the controller. Typically, heat trace applications will not require any Manual Offset

adjustment.

Manual Offset allows the user to preprogram the approximate power output (%) requirement at the setpoint. This has been proven to reduce the time needed to align the

process temperature with the setpoint temperature. As a rule of thumb, relatively light

heating loads will require smaller Manual Offset values.

The Manual Offset is a percentage output with a range of 0 (0%) to 1000 (100%) and a

default of 500 (50%).

13

Page 14

The Soft Start Function

The Soft Start function is located within the Control

Menu page. The Soft Start function will operate independently on each circuit.

To limit inrush current on the overall system, an inherent characteristic of self-regulating/limiting heating cable, a proprietary Soft Start algorithm is applied during

system start-up. This will ONLY occur while the mode

of operation is set to AUTO and Soft Start feature is

turned ON. The Soft Start program will increment output by 1% every 1 second until the desired temperature is reached or the output % achieves 100%.

After the Soft Start program completes its cycle, the

Automatic Control Mode of the system will return to

either PID or ON/OFF control, depending on what was

selected by the user. The Soft Start Program will not

function if the control mode is set to Manual.

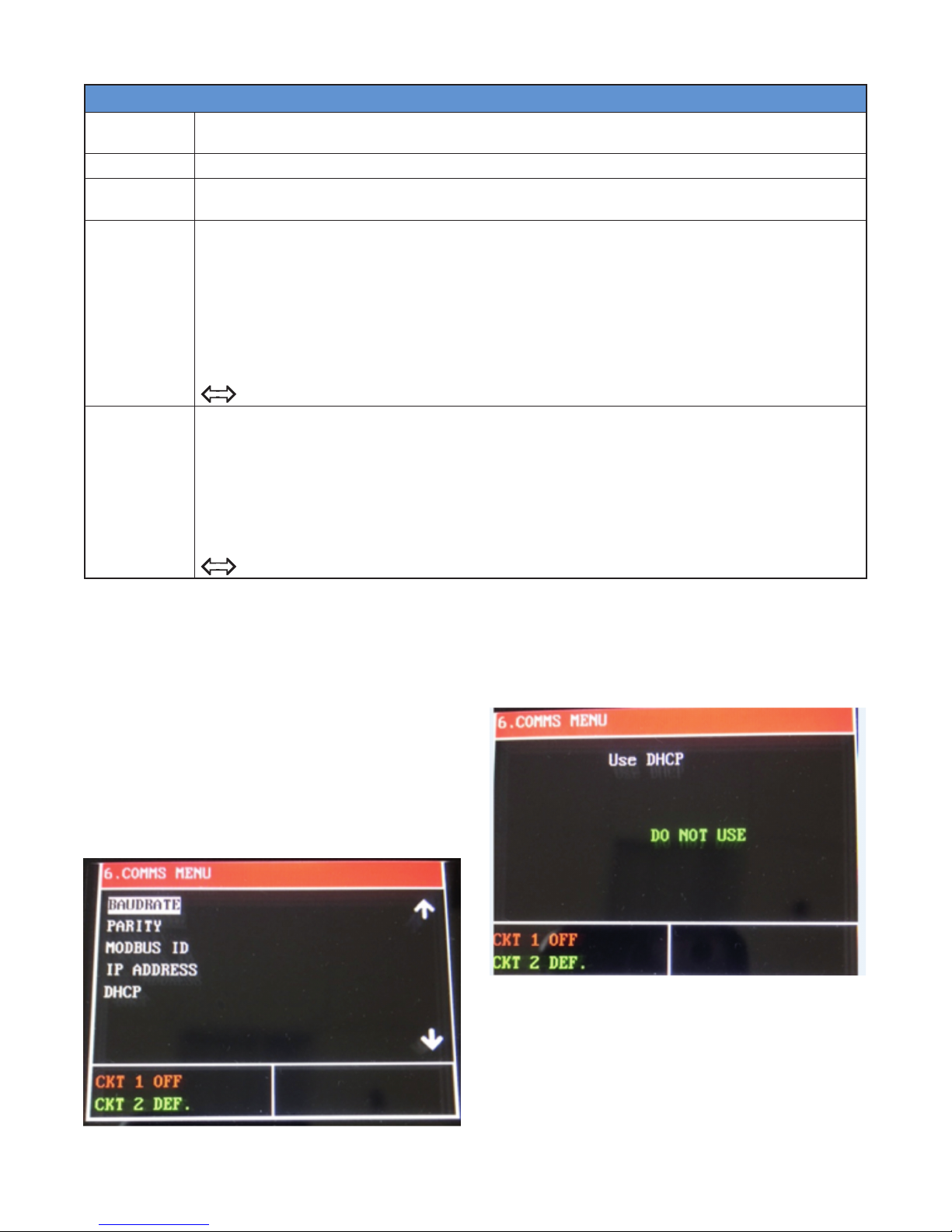

The Comms Menu (Communications)

Security Level 3

The Comms Menu provides access to the settings for

Serial Communications, Modbus RTU/RS-485 or the

optional TCP/Ethernet Communications. These communications settings include: Baud Rate, Parity, Modbus ID, IP Address and DHCP.

Modbus RTU requires that you know or define baud

rate, character format (Parity), and slave ID (aka slave

address, unit number, unit ID). A mismatch in any of

these will result in no communication. Likewise, an incorrect IP address will result in no communication on

an IP Network.

Note: See Modbus Communications Addendum for

detailed register addresses and other Modbus settings.

14

Page 15

6. Comms Menu

Baud Rate

Data transmission speed in Serial Communications, in Hertz (Hz).

The range offered by the ITC is 2.4k, 4.8k, 9.6k, 19.2k, 38.4k, 56.0k

Parity The parity bit is to be set to NONE, EVEN or ODD.

ModBus ID

This is the Identification or Address of the ITC Unit on a Modbus Network. The ID shall be any

number from 1 to 255.

The Internet Protocol (IP) Address is the address or identifier of a device on a network, such as

Modbus TCP/Ethernet, which employs the internet protocol to communicate. Assignment of the

IP address may be accomplished in one of two ways:

1. Automatically assign (Default). (The DHCP Selection must be “USE”)

IP Address

The IP address will be automatically established via the customer’s DHCP.

2. Manually assign. (The DHCP Selection must be “DO NOT USE”)

Select “DO NOT USE” when in the DHCP menu, then enter the appropriate IP Address via

the UP/DOWN arrow keys & ENTER button to accept.

NOTE: One MUST cycle power to the unit AFTER changing the status of the DHCP (USE

DO NOT USE) and prior to obtaining a new IP Address.

DHCP (Dynamic Host Configuration Protocol) Status: Use or Do Not Use.

This impacts whether the IP Address is to be automatically assigned by the host DHCP Server

or manually entered by the operator. See IP Address above.

DHCP

USE – Select USE if you desire to have the IP Address automatically assigned to the unit by the

resident DHCP.

DO NOT USE – Select DO NOT USE if you desire to manually assign an IP Address to the ITC unit.

NOTE: One MUST cycle power to the unit AFTER changing the status of the DHCP (USE

DO NOT USE) and prior to obtaining a new IP Address.

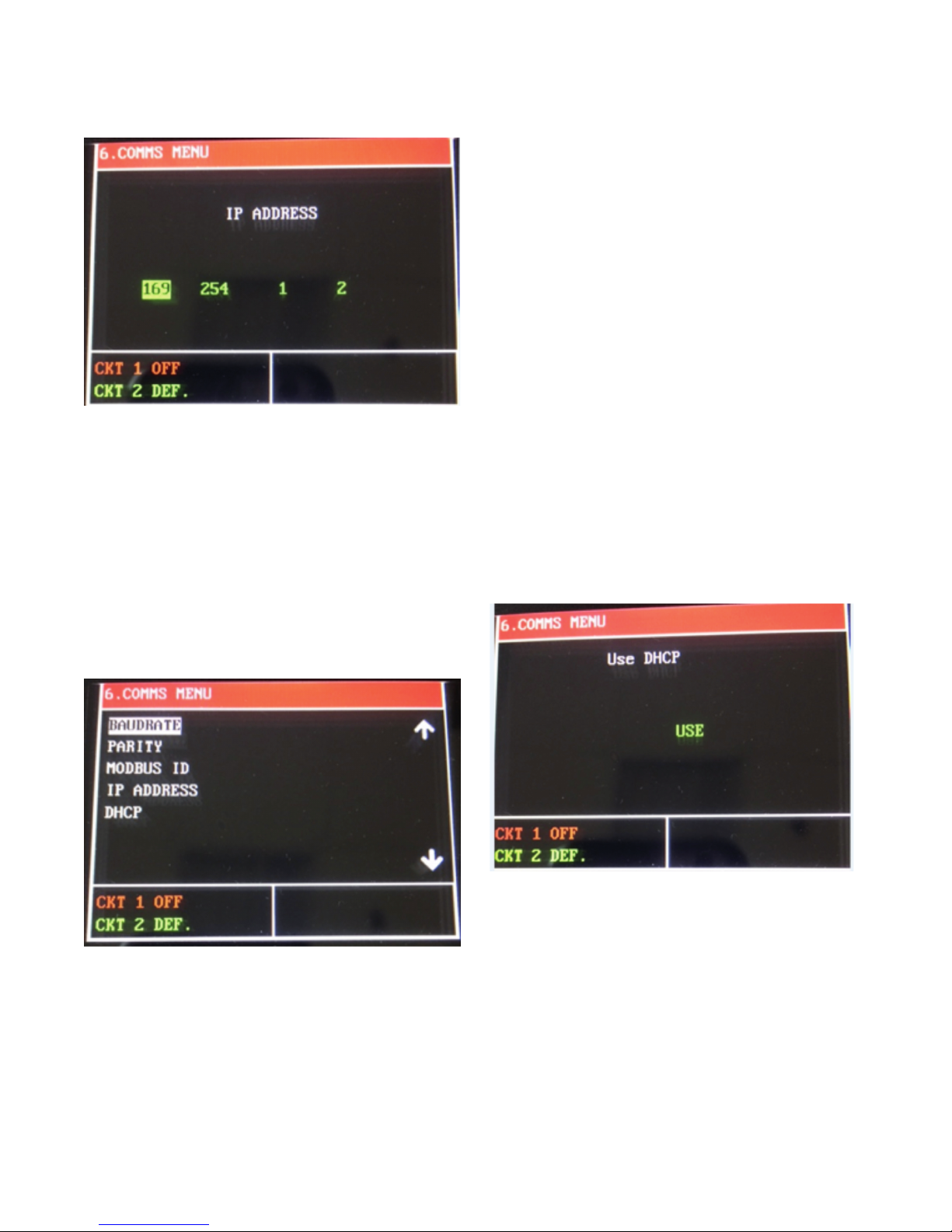

Manually Assign IP Address (Static IP Address)

The factory default of the ITC is to have the IP Address

assigned automatically by the host DHCP Server. However, one may wish to manually assign or establish a

Static IP Address. Follow these instructions below to

accomplish this:

1. To manually assign the IP address (if not using

DHCP server), navigate to the COMMS menu by

logging in and then pressing the MODE key until the

COMMS menus is observed.

2. Use the DOWN or UP keys to navigate down to

DHCP within the COMMS menu, and then press

ENTER.

3. Use the DOWN or UP keys to toggle the selection

between USE and DO NOT USE. Make sure that

DO NOT USE is displayed, then press ENTER to

confirm selection.

NOTE: After pressing ENTER, power to the

controller must be cycled for the change in the

DHCP setting to take effect.

15

Page 16

4. Use the DOWN or UP keys to highlight IP ADDRESS, then press ENTER key to edit the IP Ad-

dress:

Automatically Assign IP Address

a. The IP ADDRESS is composed of four fields,

each with a value range from 0 to 255.

b. Use the UP and DOWN keys to adjust a field val-

ue.

c. Use the RESET key to toggle between any of the

four fields being edited.

d. To complete and establish a new IP Address,

press the ENTER key to return to the COMMS

MENU.

As previously mentioned, the factory default of the ITC

is to have the IP Address assigned automatically by the

host DHCP Server. However, if the IP Address was obtained manually and now the desire is to have it established automatically from a DHCP server, the following

steps must be taken:

1. Navigate to DHCP within the COMMS menu, and

then press ENTER.

2. Use the DOWN or UP keys to toggle the selection

between USE and DO NOT USE. Make sure that

USE is displayed and then press ENTER to confirm

selection.

NOTE: After pressing ENTER, power to the

controller must be cycled for the change in the

DHCP setting to take effect.

16

Page 17

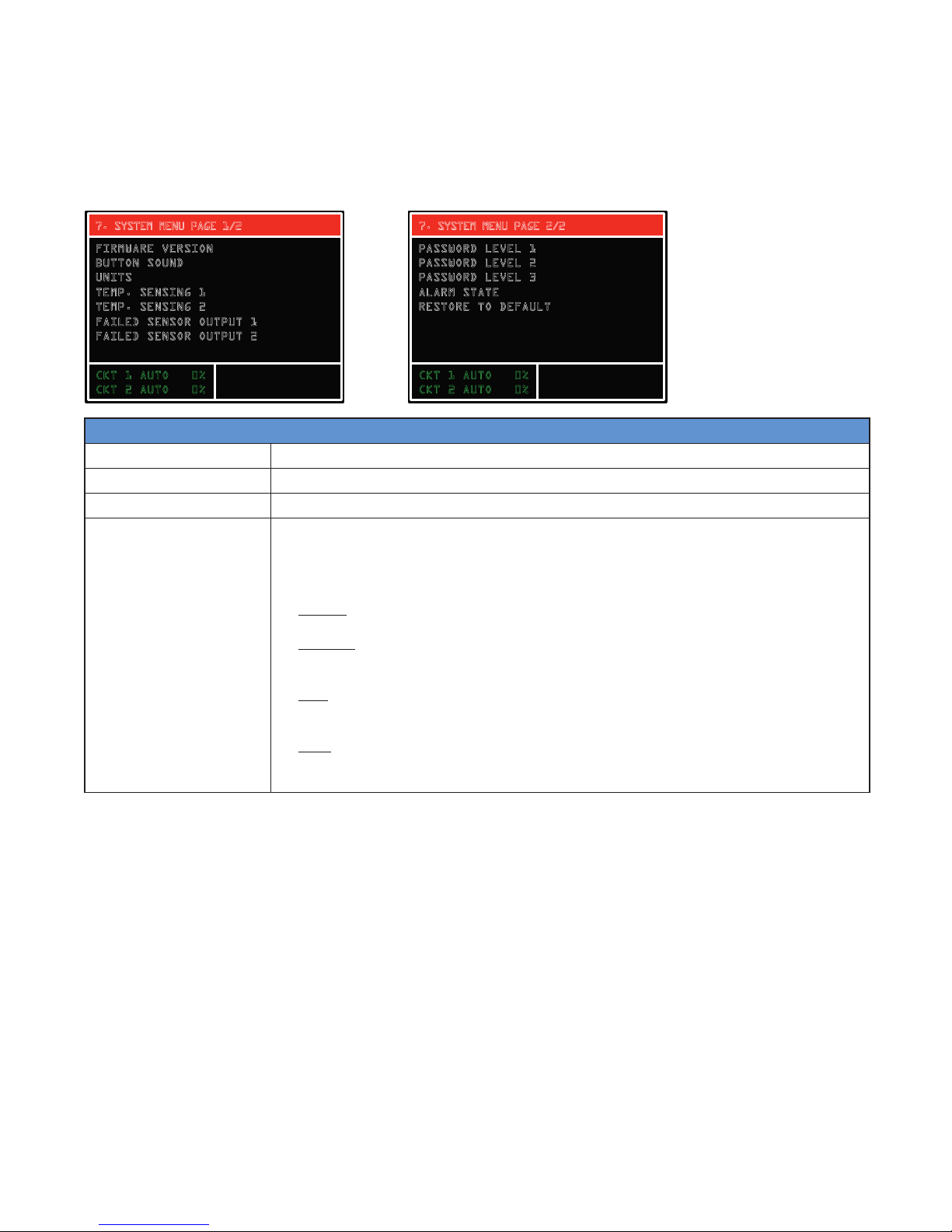

The Systems Menu

Security Level 3

The System Menu provides access to system information and system settings for the ITC. Items contained in the

System Menu include: Firmware Version of the ITC, Button Sound for Keypad interaction, Units (Temperature), Temperature Sensing Type, Failed Sensor Output, (Security) Password for Levels 1, 2 & 3, Alarm State (normally open or

normally closed) Restore to Default (Settings & Parameters).

7. SYSTEM MENU PAGE 1/2

FIRMWARE VERSION

B

UTTON SOUND

NITS

U

EMP. SENSING 1

T

EMP. SENSING 2

T

AILED SENSOR OUTPUT 1

F

F

AILED SENSOR OUTPUT 2

CKT 1 AUTO 0%

C

KT 2 AUTO 0%

7. SYSTEM MENU PAGE 2/2

PASSWORD LEVEL 1

P

ASSWORD LEVEL 2

ASSWORD LEVEL 3

P

LARM STATE

A

ESTORE TO DEFAULT

R

CKT 1 AUTO 0%

C

KT 2 AUTO 0%

7. System Menu

Firmware Version Identifies the Firmware Release of your ITC.

Button Sound The Button Sound may be kept ON or turned OFF

Units Temperature Units, Fahrenheit or Celsius

The ITC accepts up to two RTD inputs per channel. In Auto Control Mode, the output

of each circuit will function according to the Temp Sensing Setting. However, when

in Manual Mode, the Output will only consider the Output % as selected by the User.

The following settings and their respective function are available when in AUTO Mode:

• Single – Output is based on the sensed temperature of only one RTD sensor. The

2nd RTD Sensor is not recognized.

• Average – Output is based on the average sensed temperature of the two RTD Sen-

Temp Sensing 1

sors. If Average is selected and only one sensor is employed, the unit will sense

an open sensor. See Failed Sensor Operation below.

• Low – Output is based on the lowest sensed temperature of the two RTD Sensors.

If Low is selected and only one sensor is employed, the unit will sense an open

sensor. See Failed Sensor Operation below.

• High – Output is based on the highest sensed temperature of the two RTD Sensors.

If High is selected and only one sensor is employed, the unit will sense an open

sensor. See Failed Sensor Operation.

17

Page 18

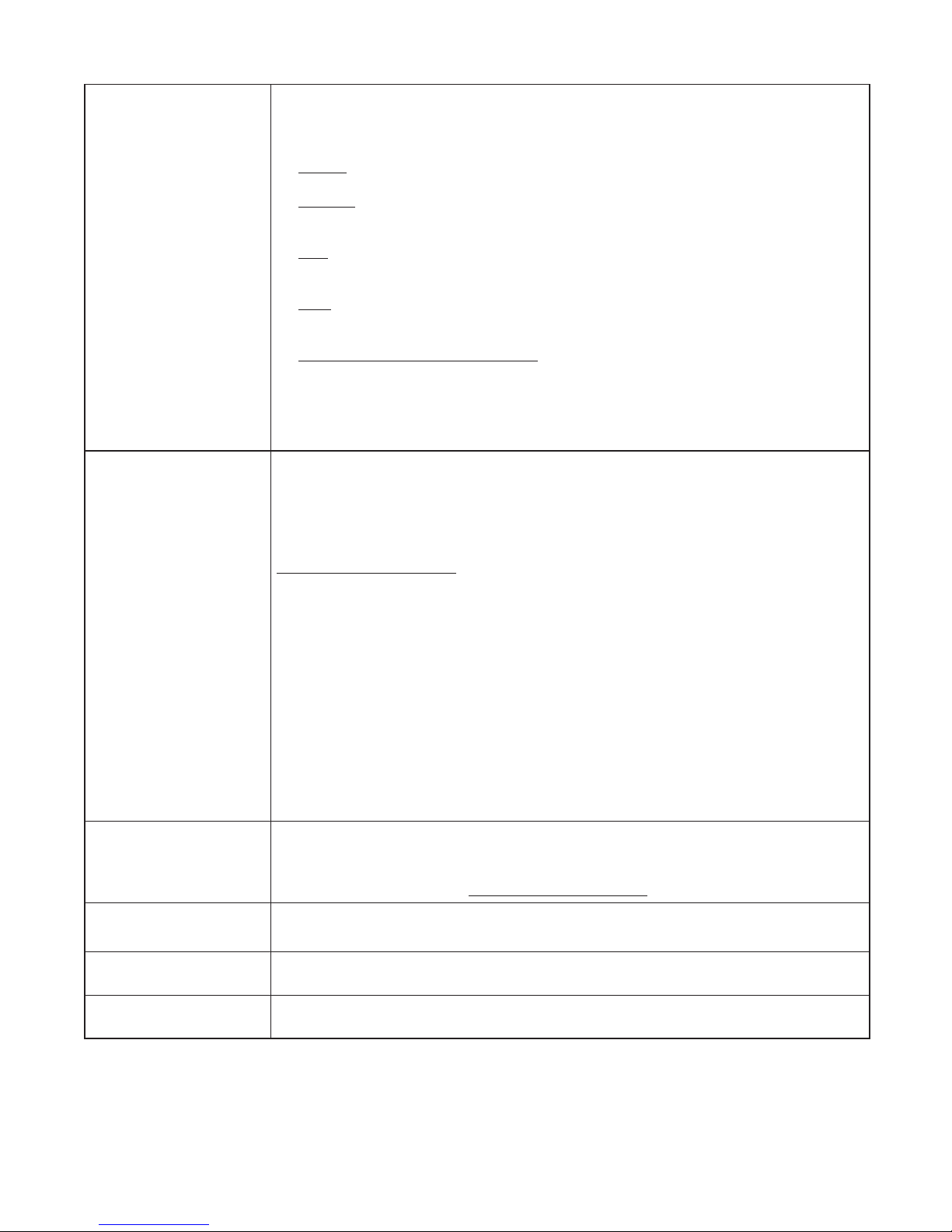

Temp Sensing 2

The ITC accepts up to two RTD inputs per channel. In Auto Control Mode, the output

of each circuit will function according to the Temp Sensing Setting. However, when

in Manual Mode, the Output will only consider the Output % as selected by the User.

The following settings and their respective function are available when in AUTO Mode:

• Single – Output is based on the sensed temperature of only one RTD sensor. The

2nd RTD Sensor is not recognized.

• Average – Output is based on the average sensed temperature of the two RTD Sensors. If Average is selected and only one sensor is employed, the unit will sense

an open sensor. See Failed Sensor Operation below.

• Low – Output is based on the lowest sensed temperature of the two RTD Sensors.

If Low is selected and only one sensor is employed, the unit will sense an open

sensor. See Failed Sensor Operation below.

• High – Output is based on the highest sensed temperature of the two RTD Sensors.

If High is selected and only one sensor is employed, the unit will sense an open

sensor. See Failed Sensor Operation.

• Use RTD 1 to control both circuits - The output of circuits 1 & 2 will be governed

by the “RTD1 Input” sensor which is located on the Circuit 1 main ITC board.

Notes:

a. This option is only available on 2 circuit ITC’s

b. The RTD sensor must be connected to “RTD1 Input” on Circuit 1 Main ITC

Board. See customer wiring section.

**IMPORTANT CONSIDERATIONS**

The ITC assumes a failed sensor condition if the realized temperature is either below

-100˚F or above 1500˚F. A failed RTD sensor (shorted or open) will send a faulty sensed

temperature to the controller that exceeds these thresholds. Therefore, the user must

understand the output of the ITC when a sensor fails.

Failed Sensor Output

Passwords 1, 2 & 3

Alarm State

Restore to Default

Failed Sensor Operation

1. Single – In Failed (Open or Shorted) RTD condition, the ITC will switch to Manual

Mode. Output will be per specified % by user. Failed Sensor condition will be flashing on the LCD screen and alarm LED will illuminate.

2. Average (when using two RTDs per circuit)

a. Individual Failed RTD (Open or Shorted) – ITC Unit will operate in Auto Mode

with a Single Sensor. The temperature reading from the failed RTD sensor will be

ignored. Failed Sensor condition will be flashing on the LCD screen and alarm

LED will illuminate.

b. When both sensors fail, the ITC will switch to Manual Mode. Output will be per

specified % by user. Failed Sensor condition will be flashing on the LCD screen

and alarm LED will illuminate.

3. Low – Same as Average above.

4. High – Same as Average above.

When using a single RTD - The ITC will automatically switch into Manual Output Mode

when a Failed Sensor Condition is realized. The output % range is 0% to 100% in 1%

increments.

When using two RTDs, see Failed Sensor Operation above.

Default Security Level Passwords may be changed by the user within the System Menu.

See “Security Levels” above for more detail.

Select normal state of alarm. Choices include Normally Closed (default) or Normally

Open.

This operation allows the user to clear all custom settings and parameters and restore

the ITC to its original factory state.

18

Page 19

Current Sampling

All active loops are individually tested for 2 seconds

every 2 minutes. During the test, a current load value is

updated on the yellow bar located on the Main Window

Alarms

Any alarm condition will be displayed in the bottom

right corner of the Main Screen. Additionally, a red LED

will be illuminated on the front panel under “ALARM”.

Alarm Type Display Solution

Check if your RTD is correctly connected to the unit or damaged.

Open Sensor SENS #X ERROR

Shorted Sensor SENS #X ERROR

Low Temperature LO TEMP CKT #!

Alarm clears automatically. Output will switch to Default Mode. Replace RTD if necessary.

Check if your RTD is correctly connected to the unit or damaged.

Alarm clears automatically. Output will switch to Default Mode. Replace RTD if necessary.

Sensed temperature is below Lo Temp Alarm Setpoint. Alarm will be

cleared automatically when the sensed temperature is greater than

the Low Temperature Alarm Setpoint, + 5 deg

and a new GFEP current is automatically and continuously calculated. The Yellow Load LEDs will be illuminated during the sampling test.

The table below illustrates the different types of alarm

where “#” represents circuit number and “X” repre-

sents either sensor A or B

High Temperature HI TEMP CKT #!

High Load HI LOAD CKT #!

Low Load LO LOAD CKT #!

High GFEP HI GFEP CKT #!

Sensed temperature is above High Temp Alarm Setpoint. Alarm will

be cleared automatically when the sensed temperature is less than

the High Temperature Alarm Setpoint, - 5 deg

Sensed load current is above Hi Current Alarm Setpoint. Alarm will

be cleared automatically when the sensed current < Current Hi Setpoint – 0.5 Amp

Sensed load current is below Current Lo Setpoint. Alarm will be

cleared automatically when the sensed current > Current Hi Setpoint

+ 0.5 Amp

Sensed GFEP current is above the GFEP Hi Setpoint. Alarm will be

cleared automatically when the sensed current < Current Hi Setpoint

- 5 mA

19

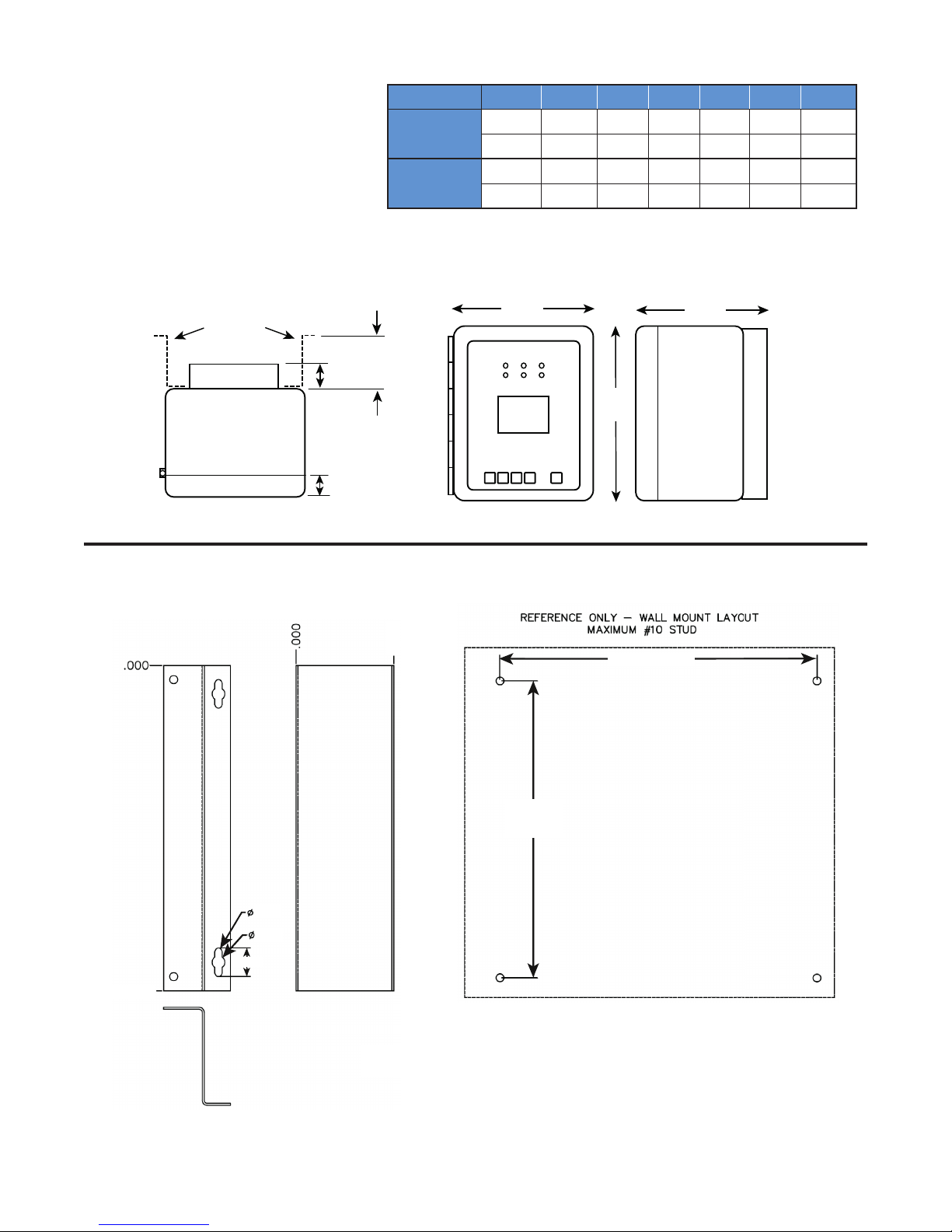

Page 20

Dimensions

10

ITC Controller

316 SS

Enclosure

Fiberglass

Enclosure

H W D F B M

Inch 11.8 9.9 7.6 0.7 1.8 3.0

cm 30.2 25.1 19.4 1.7 4.4 7.6

Inch 10.3 8.5 8.0 1.2 1.8 3.0

cm 26.2 21.3 19.7 3.2 4.4 7.6

Mounting

Brackets

W

D

M

B Heat Sink

H

Heat Sink

F

Wall Mount Brackets

.000/11.813

(25.4/30.0)

.218

(0.55)

.390

(0.99)

.875 (2.2)

Dimensions are given for both enclosure types: Fiberlgas/316SS

(7.62)

3.000

8.250/10.188

(21.0/25.9)

Wall Mount Bracket Dimensions are in Inches

Wall Mount Bracket Dimensions are in Inches (cm)

8.750/10.625

(22.2/27.0)

20

Page 21

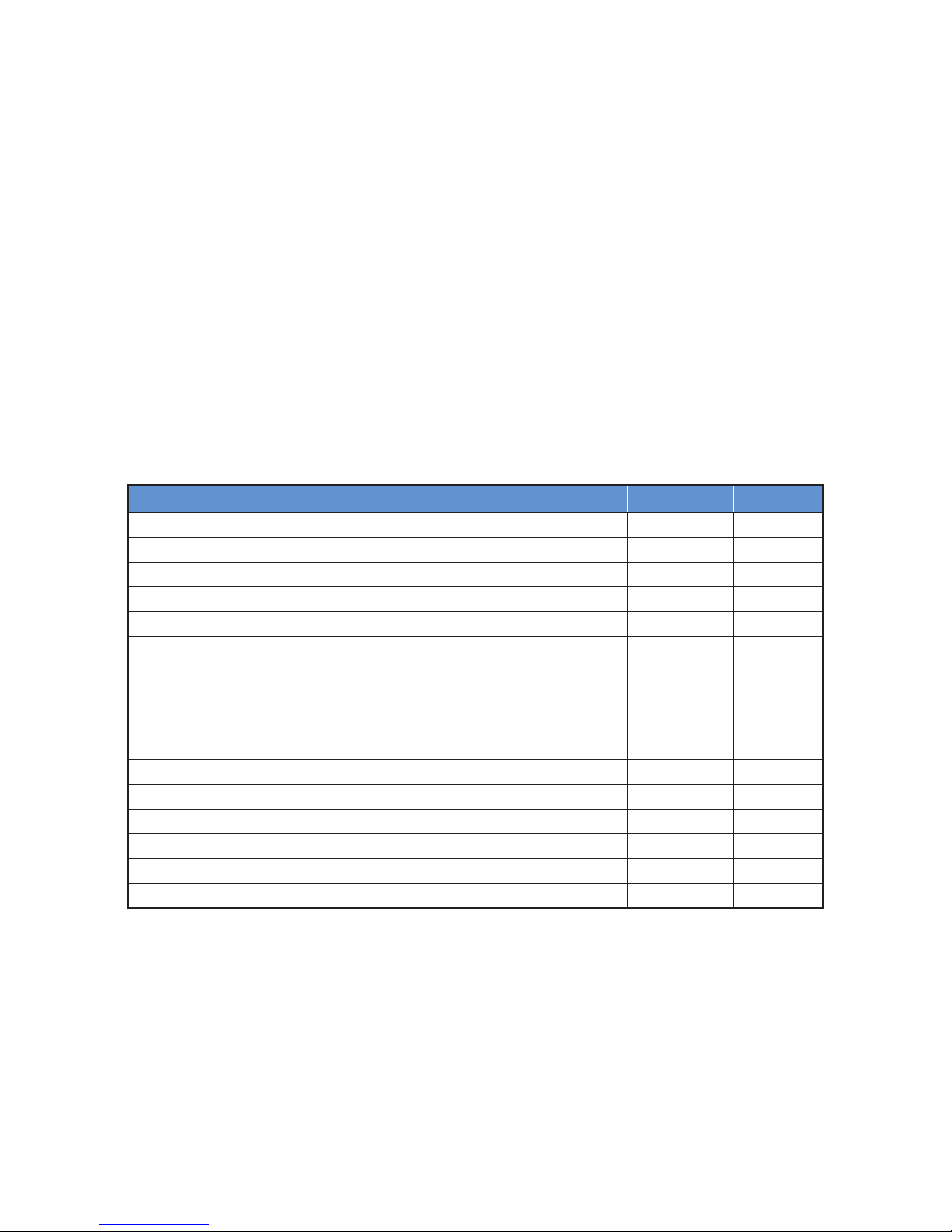

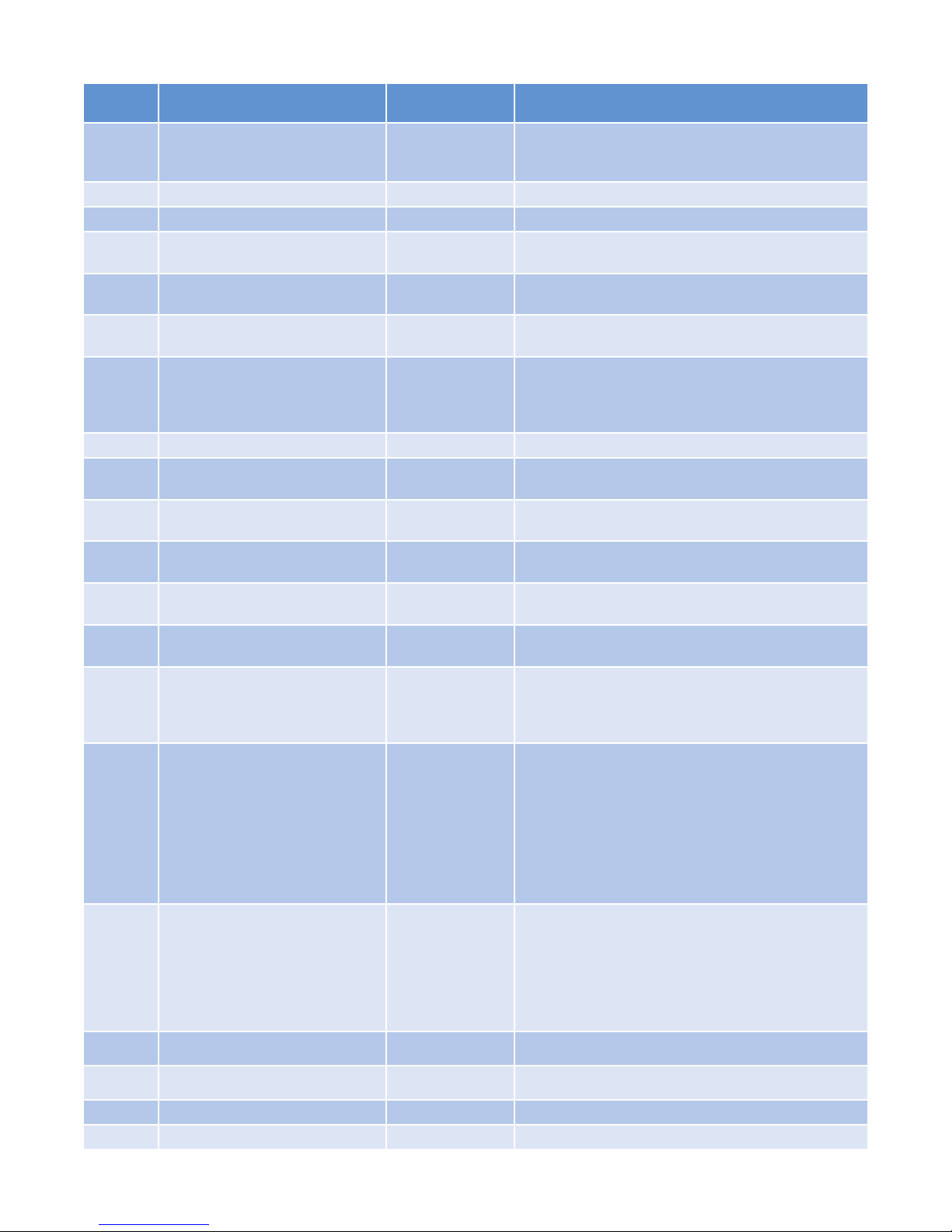

Default Settings

Below is the ITC parameter settings chart organized by Menu Screen. It includes the default, minimum, maximum

and / or the range of settings, where applicable.

The chart is for either 1 or 2 circuit units.

Parameter Defaults, Min., Max. & Range & User Settings

Screen Menu & Parameter

3. Temperature Menu Default Min. Max. Also User Settings

Temp Setpoint 1 45˚F -80˚F 1,100˚F

Lo Temp Alarm 1 40˚F -80˚F 1,050˚F Off

Hi Temp Alarm 1 180˚F -80˚F 1,150˚F Off

Temp Setpoint 2 45˚F -80˚F 1,100˚F

Lo Temp Alarm 2 40˚F -80˚F 1,050˚F Off

Hi Temp Alarm 2 180˚F -80˚F 1,150˚F Off

4. Current Menu Default Min. Max. Also User Settings

Low Current Alarm 1 0.1 A 0.1 A 50.0 A Off

Hi Current Alarm 1 40.0 A 0.1 A 50.0 A Off

GFEP Setpoint 1 30 mA 30 mA 150 mA

GFEP Alarm/Trip 1 Alarm Only Alarm Only, Alarm & Trip; Latching & Non Latching

Low Current Alarm 2 0.1 A 0.1 A 50.0 A Off

Hi Current Alarm 2 40.0 A 0.1 A 50.0 A Off

GFEP Setpoint 2 30 mA 30 mA 150 mA

GFEP Alarm/Trip 2 Alarm Only Alarm Only, Alarm & Trip; Latching & Non Latching

5. Control Menu Default Min. Max. Also User Settings

Auto Control Mode 1 PID On / Off PID

Auto / Manual / Off 1 Auto 0 100 Off

Deadband 1 10 2 100

Autotune 1 Off Off On

Proportional Band 1 20 1 100

Integral 1 500 0 9999

Rate 1 1 0 500

Soft Start 1 On Off On

Manual Offset 1 500 0 1000

Auto Control Mode 2 PID On / Off PID

Auto / Manual / Off 2 Auto 0 100 Off

Deadband 2 10 2 100

Autotune 2 Off Off On

Proportional Band 2 20 1 100

Integral 2 500 0 9999

Rate 2 1 0 500

Soft Start 2 On Off On

Manual Offset 2 500 0 1000

21

Page 22

Parameter Defaults, Min., Max. & Range & User Settings

Screen Menu & Parameter

6. Comms Menu Default Min. Max. Also User Settings

Baud Rate 9.6k 2.4k, 4.8k, 9.6k, 19.2k, 38.4k, 56.0k

Parity None Even Odd None

ModBus ID 1 1 255

IP Address Optional Feature

DHCP Use Use Do Not Use

7. Systems Menu Default Min. Max. Range User Settings

Firmware Version Current Firmware Version

Button Sound On Off On

Units Fahrenheit Fahrenheit Celsius

Temperature Sensing 1 Single Single, Average, Low, High

Temperature Sensing 2 Single

Single, Average, Low, High,

Use 1 RTD to control both circuits

Failed Sensor Output 1 50% 0% 100%

Failed Sensor Output 2 50% 0% 100%

Password Level 1

Password InputsPassword Level 2

Password Level 3

Alarm State

Normally

Closed

Normally

Open

Normally

Closed

Restore to Default Disabled Up / Down Up / Down

22

Page 23

Specifications

Input

Sensor Type 3-wire RTD, 100 W PT, 0.00385 W/W/˚C, 20 W balanced lead wire

Number of Sensor Inputs 1 or 2 per Circuit

Sensing Configuration Range: Single, Low, High, Average

Output

Power Switching SSR

Number of Circuits 1 or 2

Capacity 40 Amps per Circuit (Breaker size shall be 50 Amps maximum per

circuit or 125% of anticipated load)

Control Types

PID Control mode must be set to Auto

Autotune On or Off

Proportional Band, (˚F) Range: 1 – 100

Integral (sec/repeat) Range: 0 – 9,999

Rate or Derivative, (seconds) Range: 0 – 500

Manual Offset 0 - 1000 (0% - 100%)

On/Off Control mode must be set to Auto

Dead band, (˚F) Range: 2 – 100

Manual Range: 0 – 100%

Soft Start, Current Clamping Enable or Disable

Settings

Temperature (PV) Range: -80˚F to +1100˚F

Range: -62˚C to +593˚C

Low Temperature Alarm Range: -80˚F to +1050˚F, Off

Range: -62˚C to +566˚C, Off

High Temperature Alarm Range: -80˚F to +1150˚F, Off

Range: -62˚C to +621˚C, Off

Low Current Alarm Range: 0.1 A – 50.0 A, Off

High Current Alarm Range: 0.1 A – 50.0 A, Off

GFEP Range: 30mA – 150 mA, +/-2.5% of Span or +/- 3mA

GFEP Alarm Condition Alarm Only or Alarm & Trip

Output on Sensor Failure Mode Range: 0 – 100%, Bumpless Transfer to Manual Mode

Audible button depress Range: On, Off

Security 3 Levels of password protected security

Alarm State Normal Operation: Closed (default), Open

Display, HMI, Indication

Display 3.5” 320 x 240 RGB Full color graphic TFT module

Human Interface 5 Capacitive Touch Input Buttons

LED Indication Power (Green), Load (Amber), Alarm (Red) – Per Ckt

23

Page 24

Alarms

Alarm Types Low & High Temperature, Low & High Current, High GFEP,

Sensor Failure

Alarm Relays 1 x DC Alarm Output, 1.8 Amp, Customer Supplied 0 - 50 VDC

1 x AC Alarm Output, 1.8 Amp, Customer Supplied 12-240 VAC

Alarm Contact State

Mode Default Optional

Normal Operation Closed Open

Alarm Condition Open Closed

Power Off Open Open

Communications

ModBus RTU/RS485 (2 or 4 wire) & RTU/RS422, TCP/Ethernet

Baud Rate, Hz 2400, 4800, 9600, 19200, 38400, 56000

Parity Range: Even, Odd, None

ModBus ID Range: 1 – 255

DHCP Range: Use, Do Not Use

Ethernet IP Webserver over Ethernet

Operating & Environmental

Temperature -40˚F to 104˚F (-40˚C to 40˚C)

Humidity Relative Humidity 0% to 90%

Power Supply

100-277 Vac 50/60Hz

Protection IEC IP66

Enclosure Rating NEMA 4X FG

Approvals UL/cUL Ordinary and Class I, Division 2, Groups A,B,C,D Hazardous loca-

tions (UL file Number: E347725), CE

Temperature Rating T4

24

Page 25

Equipment Ratings

Field Wiring

Voltage Rating: ........................

Current Rating: .............................. 40 amps per Circuit

Number of Circuits .............................................. 1 or 2

Ambient Temperature Rating: ..............-40°F to +104°F

Altitude Rating: ......................Fully rated up to 6,500 Ft

VA consumption rating on electronics:............... 6.0 VA

The electronics are protected by a 0.5 Amp 350 VAC

2AG fuse.

Maximum RTD output ...............1.25 volts, 7 milliamps

Pollution Rating .............................................. Degree 2

Over Voltage ..............................................Category III*

* Overvoltage note: Category III is maintained only when a UL

Listed VZCA type 2 surge protector is employed between the

power source and the ITC unit. The surge protector must be

rated at 277 Vac (min) with a maximum surge protection rating of

2500 Vpk. Otherwise the ITC is rated at overvoltage Category II.

100-277 VAC, 50/60 Hz

(-40°C to +40°C)

(2,000 Meters)

Considerations

Torque values for line/load wiring

terminals: .................................................. 10-13 in/lbs.

(1.1-1.5 N-m)

Torque values for RTD 1 & 2 wiring

terminals: ...................................................... 6-8 in/lbs.

(.67-.90 N-m)

Torque values for shield grounding/alarm wiring

terminals: ...................................................... 3-4 in/lbs.

(.33-.45 N-m)

Terminal Block Gauge Range:

Line & Load .................................6-18 AWG, Copper

Alarm & Sensor ........................................12-24 AWG

Power Wire Rating

Max Load Min Breaker Size (AWG, 90˚C)

40A 50A 8

30A 40A 10

20A 25A 12

15A 20A 14

Modbus Wiring

Considerations

Environmental influences such as EMI/RFI can compromise the communication signal. Properly designed

cables will minimize their influences.

RS485 Max Length ............................. 2,500 ft. (800 m)

RS485 Wire Specification ......... T1/E1/DSL compatible

Example Vendor ..................L-Com (www.L-com.com)

Vendor Item ....................................................TSC9928

25

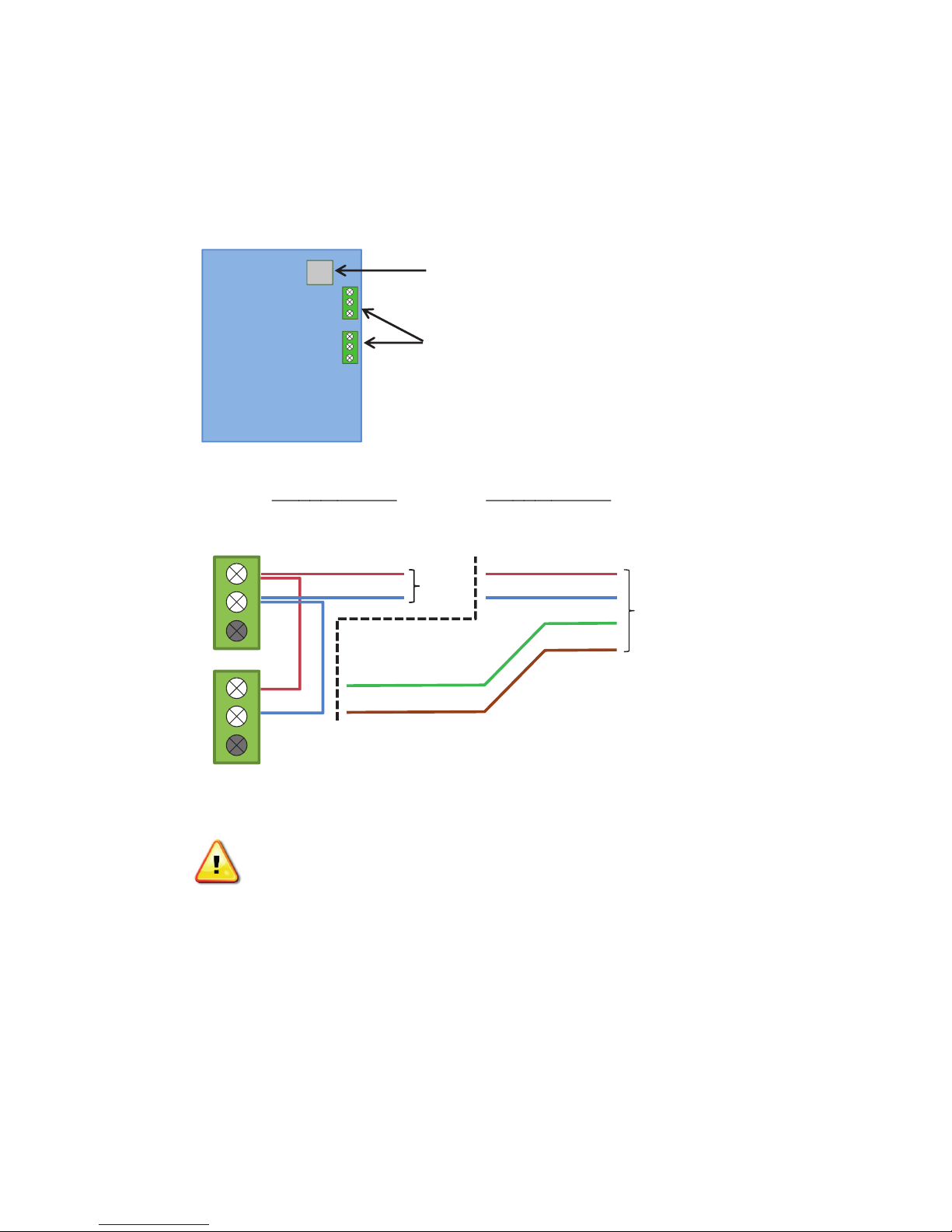

Page 26

Customer Wiring

RTD 2A RTD 2B

2-Circuit Ambient Sensing Control:

T

Sensor

Circuit 1 Main ITC Boar

d

Power, Heater, Alarms & Sensors

These connections are facilitated via the main ITC Board(s)

SENSOR

INPUTS

COM

–

RTD 1

INPUT

+

COM

–

RTD 2

INPUT

+

Only

Shield

Ground

o control both circuits with one RTD, the

MUST be wired to RTD 1A INPUT on

d

RTD 1A RTD 1B

Only

Shield

Ground

Upper board

applicable on 2

circuit units only

SENSOR

INPUTS

Circuit 2

Main ITC Board

EARTH

Max 40 Amps

HEATER

LOAD

HEATER

AC INPUT

100-277 VAC

AC HIGH

Breaker must be

rated at 125% of

max heater load,

but not to exceed

50 Amps

AC LOW

RTD Wiring

+

White

Red

Com

-

Re

COM

–

RTD 1

INPUT

+

COM

–

RTD 2

INPUT

+

LOAD

Customer Supplied

Shield

Ground

DC

0 - 42 VDC

Only

Shield

+ –

DC

ALARM

ALARM

OUTPUTS

Circuit 1

(RBF Type RTD Sensor)

Main ITC Board

AC INPUT

100-277 VAC

EARTH

Only

Ground

LOAD

AC

ALARM

AC

12 -240 VAC

Customer Supplied

HEATER

LOAD

Max 40 Amps

AC LOW

HEATER

AC HIGH

26

Breaker must be

rated at 125% of

max heater load,

but not to exceed

50 Amps

Page 27

Modbus TCP/Ethernet or Web Server/Ethernet

RX+

Communications

These connections are facilitated via the Display Board.

(when ordered) uses the RJ45 connector

RX-

N/A

TX+

TX-

N/A

Display

Board

RS485 2-Wire

Must Jumper

(RX+/TX+) & (RX-/TX-)

The lowest pin on the Green terminal blocks has no use

Modbus RTU/RS485 or /RS422 use the

Green Terminal Blocks (Detail Below)

RS422 4-Wire

Use RX+, RX-, TX+ & TX-

RS485

2 Wire

RS422

4 Wire

All other Display Board connectors are for factory use

ONLY. Connection to these may damage the ITC Unit

27

Page 28

Modbus Addendum

MODBUS

Modbus Serial Communications

The ITC supports Modbus serial communications. For

a complete description of the Modbus protocol refer to

the description provided at http://www.modicon.com/

or http://www.modbus.org/

Physical Layer

The Base address, bit rate and character format are

configured via menu interface.

Physical layer configuration settings possible are:

Data rate: 2400, 4800, 9600 (default), 19200,

38400, 56000 bps

Parity: None (default), Even, Odd

Character format: Always 8 bits per character.

The transmitter must not start transmission until 3

character times have elapsed since reception of the

last character in a message, and must release the

transmission line within 3 character times of the last

character in a message.

Note: Three character times = 1.5ms at 19200, 3ms at

9600, 6ms at 4800, 12ms at 2400

Link Layer

A Query (or command) is transmitted from the Modbus

Master to the Modbus Slave. The slave instrument assembles the reply to the master. All of the instruments

covered by this manual are slave devices, and cannot

act as a Modbus Master.

SLAVE

MASTER

INSTRUMENT

QUERY

A message for either a QUERY or RESPONSE is made

up of an inter-message gap followed by a sequence of

data characters. The inter-message gap is at least 3.5

data character times.

Data is encoded for each character as binary data,

transmitted LSB first.

For a QUERY the address field contains the address

of the slave destination. The slave address is given

together with the Function and Data fields by the Application layer. The CRC is generated from the given

address, function and data characters.

For a RESPONSE the address field contains the address of the responding slave. The Function and Data

fields are generated by the slave application. The CRC

is generated from the address, function and data characters.

The standard MODBUS RTU CRC-16 calculation employing the polynomial 216+215+22+1 is used.

Intermessage

gap

Device Addressing

The instrument is assigned a unique device address

by the user in the range 1 (default) to 255. To change

Modbus address, navigate to page 6 of the ITC Menu

page and select “MODBUS ID” parameter. Use Up and

Down keys to change the value. This address is used

to recognize Modbus Queries intended for this instrument. The instrument does not respond to Modbus

Queries that do not match the address that has been

assigned to it.

The instrument will also accept global Queries using

device address 0 no matter what device address is

assigned. No responses are returned for globally addressed Queries.

Address

1 char.

Function

1 char.

Data n

char.

CRC

Check 2

char.

RESPONSE

Figure 1. Modbus Link Layer

28

Page 29

Description of Modbus Register Set

Modbus defines several function types; these instruments support the following types:

Table 1 - Modbus Function Code Set

Function Code Function Name

03 Read Holding Registers

04 Read Input Registers

06 Write Single Holding Register

16 Write Multiple Holding Registers

Input Registers

Table 2 - ITC-FS 1&2 Circuit Input Registers

Address Description Comments

30000 Sensed Temperature Ckt 1 Sensed Temperature Circuitl 1

30001 Setpoint Ckt 1 Setpoint Circuit 1

30002 Sensed ground fault current on Ckt 1 Sensed ground fault current on circuit 1

30003

Sensed load on Ckt 1 (expressed as integer

number ion tenths of Amp e.g. 154 = 15.4 Amp)

Sensed load on circuit 1 (expressed as integer

number ion tenths of Amp e.g. 154 = 15.4 Amp)

30004 Control Output Command on Ckt 1 Control Output Command on Circuit 1

30005 Sensed Temperature on Ckt 2 Sensed Temperature on Circuit 2

30006 Setpoint circuit 2 Setpoint circuit 2

30007 Sensed ground fault current on Ckt 2 Sensed ground fault current on circuit 2

30008

Sensed load on Ckt 2 (expressed as integer

number ion tenths of Amp e.g. 154 = 15.4 Amp)

Sensed load on circuit 2 (expressed as integer

number ion tenths of Amp e.g. 154 = 15.4 Amp)

30009 Control Output Command on Ckt 2 Control Output Command on Circuit 2

30010 Sensed Ambient Temperature Sensed Ambient Temperature

30011 Reserved

30012 Reserved

30013 Reserved

30014 Reserved

30015 Reserved

30016 Reserved

30017 Reserved

30018 Firmware ver CPU 1

30019 Firmware ver CPU 2

29

Page 30

Holding Registers

Table 3 - ITC-FS 1&2 Circuit Holding Registers

Address Description Range Comments

40000 Units 0-1 0-F; 1-C

40001 Setpoint Circuit 1 -80-1100 Expressed as an integer number

40002 Setpoint Circuit 2 -80-1100 Expressed as an integer number

40003 Control Mode for Circuit 1 0-1 0=PID; 1=ON/OFF

40004 Control Mode for Circuit 2 0-1 0=PID; 1=ON/OFF

40005 Deadband 1 0-10 Expressed as an integer number

40006 Deadband 2 0-10 Expressed as an integer number

40007 Commanded Power Ckt 1 0-100 & 101

40008 Commanded Power Ckt 2 0-100 & 101…

Expressed as an integer number e.g 50= 50%

(101= Circuit in AUTO mode)

Expressed as an integer number e.g 50= 50%

(101= Circuit in AUTO mode)

40009 Hi Temp Alarm for Ckt 1 -80 - 1150 Expressed as an integer number

40010 Hi Temp Alarm for Ckt 2 -80 - 1100 Expressed as an integer number

Bit state: 1 -alarm , 0 -no alarm

Bit # 1 - Sensor 1A Error

Bit #2 - Hi Temp Ckt 1 Alarm

Bit #3 - Lo Temp Ckt1 Alarm

40011 Alarm Register Ckt 1 0

Bit #4 - GFEP Ckt 1 Alarm

Bit #5 - Lo Current Ckt1 Alarm

Bit #6 - Hi Current Ckt1 Alarm

Bit #7 - Reserved

Bit #8 - Sensor 1B Error

Bit state: 1 -alarm , 0 -no alarm

Bit # 1 - Sensor 2A Error

Bit #2 - Hi Temp Ckt 2 Alarm

Bit #3 - Lo Temp Ckt2 Alarm

40012 Alarm Register Ckt 2 0

Bit #4 - GFEP Ckt 2 Alarm

Bit #5 - Lo Current Ckt2 Alarm

Bit #6 - Hi Current Ckt2 Alarm

Bit #7 - Reserved

Bit #8 - Sensor 2B Error

40013 Proportional Band Ckt 1 1-100 Expressed as an integer number

40014 Proportional Band Ckt 2 0-100 Expressed as an integer number

40015 Integral for Ckt 1 0-100 Expressed as an integer number

40016 Integral for Circuit 2 1-100 Expressed as an integer number

40017 Derivative for Ckt 1 0-500 Expressed as an integer number

40018 Derivative for Ckt 2 0-500 Expressed as an integer number

40019

40020

Low Temp Alarm Threshold for

Ckt 1

Low Temp Alarm Threshold for

Ckt 2

-80 - 1150 Expressed as an integer number

-80 - 1150 Expressed as an integer number

0 - 240

1 - 480

40021 Baudrate 0-4

2 - 9600 (default)

3 - 38400

4 - 56000"

30

Page 31

Address Description Range Comments

0 - NONE

40022 Parity 0-2

1 - EVEN

2 - ODD

40023 Modbus Slave Address 0-255 Expressed as an integer number

40024 Reserved

40025

40026

40027

GFEP Alarm Threshold for

Ckt 1

Low Current Alarm for

Ckt 1

HI Current alarm for

Ckt 1

30-150

0.0- 100.0

0.0 – 100.0

Expressed as an integer number

(in mA e.g. 75 = 75mA)

Expressed as an integer number in tenths of

Amp (e.g. 250 = 25.0 Amp)

Expressed as an integer number in tenths of

Amp (e.g. 250 = 25.0 Amp)

0 - Alarm Only, non latching

40028 GFEP Alarm behavior Ckt 1 0-3

1 - Alarm and Trip, non latching

2 - Alarm and Trip, Latching

3 - Alarm Only, Latching

40029 Reserved

40030

40031

GFEP Hi Alarm Threshold for

Circuit 2

Low Current Alarm for

Circuit 2

30-150

1.0- 100.0

40032 HI Current alarm for Circuit 2 0.0 – 100.0

40033 Soft Start Circuit 1 0-1

40034 Soft Start Circuit 2 0-1

Expressed as an integer number

(in mA e.g. 75 = 75mA)

Expressed as an integer number in tenths of

Amp (e.g. 250 = 25.0 Amp)

Expressed as an integer number in tenths of

Amp (e.g. 250 = 25.0 Amp)

0 - No

1 - Yes

0 - No

1 - Yes

0 - Alarm Only, non latching

40035 GFEP Alarm behavior Ckt 2 0-3

1 - Alarm and Trip, non latching

2 - Alarm and Trip, Latching

3 - Alarm Only, Latching

0 - Controller will take the highest reading out of

two RTDs (1A and 1B)

1 - Controller will take the lowest reading out of

two RTDs (1A and 1B)

2 - Controller will take the average reading out

of two RTDs (1A and 1B)

40036

Temperature sensing

( Circuit 1)

0-4

3 - Controller will use RTD # 1A

4- Controller will use one RTD 1A to control both

circuits

0 - Controller will take the highest reading out of

two RTDs (2A and 2B)

1 - Controller will take the lowest reading out of

40037 Temperature sensing (Circuit 2) 0-3

two RTDs (2A and 2B)

2 - Controller will take the average reading out

of two RTDs (2A and 2B)

3 - Controller will use RTD # 2A

40038 Default output 1 0-100% Expressed as an integer number (e.g. 75 = 75%)

40039 Default output 2 0-100% Expressed as an integer number (e.g. 75 = 75%)

40040 Reserved

40041 Reserved

31

Page 32

Service Contact

Information

Chromalox is a global supplier, providing the highest

level of customer support. If you should have questions

concerning your intelliTRACE™ ITC Controller or need

information, you may contact Chromalox at:

Corporate Headquarters

Chromalox, Inc.

103 Gamma Drive

Pittsburgh, PA 15238

Phone: (412) 967-3800

Customer Service Hotline: 1-800-443-2640

For application questions, you can:

1. Call one of our application engineers for personal

assistance at 1-888-996-9258.

2. Visit the technical reference section of our website

at www.chromalox.com for downloadable manuals

in PDF format.

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

© 2018 Chromalox, Inc.

Limited Warranty:

Chromalox, Inc.

1347 Heil Quaker Boulevard

Lavergne, TN 37086

(615) 793-3900

www.chromalox.com

32

Loading...

Loading...