Page 1

HWM

Hot Water Maintenance

Heating Cable

D

Heat Trace Cable

• Hot Water Maintenance for

Temperatures up to 140°F

• Heat Output Varies Along Pipe

Length to Deliver Heat Where

Needed

• Circuit Lengths up to 800 ft

• 16 Awg Buss Wires

• Self-Regulating Conductive Core

• Fluoropolymer Jackets

• Wattages at 5 and 10 w/ft

• 120 and 208-277 V Cable

Available from Stock

Description

The HWM hot water temperature maintenance system utilizes self-regulating heat

trace technology. The system, consisting of

the self-regulating cable, connection kits and

specialized electronic controls, provides commercial buildings with immediate hot water

availability without expensive recirculation

systems. It provides a simple, yet energy efficient approach by providing heat at the point

where heat loss occurs. Due to the parallel

construction of the self-regulating cable, it can

be cut to any length, spliced, tee-branched and

terminated on site. With this product, energy

savings may be derived from multiple sources,

such as lower supply line heat loss, eliminated

return line heat loss, no pump operating costs

and no supply water overheating costs.

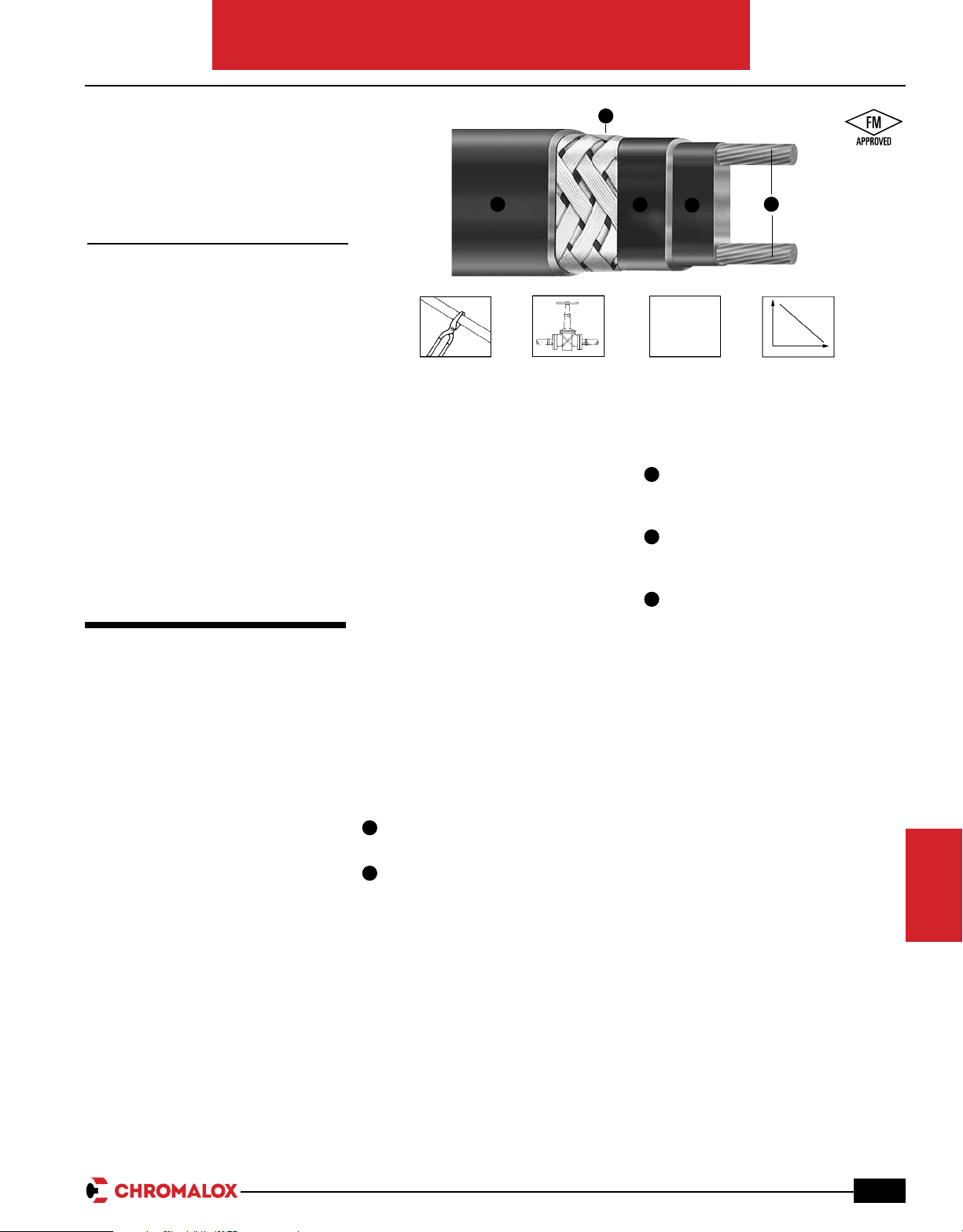

E C B A

Cut to Length

in Field

Can be

Overlapped

Features

• Energy efficient, self-regulating HWM uses

less energy when less heat is required.

• Easy to install, HWM can be cut to any

length (up to max. circuit length) in the field.

• Field splices can be performed easily in minutes with no scrap or wasted cold sections.

• HWM can be overlapped without burnout,

which simplifies heat tracing of in-line equipment such as valves.

• Because HWM is self-regulating, over-temperature conditions are minimized.

• Chromalox termination, splice, tee and end

seal kits reduce installation time.

Construction

A

Twin 16 AWG Copper Buss Wires – Pro-

vide reliable electric current capability.

B

Semiconductive Polymer Core Matrix

– “Self-Regulating” component of the

cable its electrical resistance varies with

temperature. As process temperature

drops,the core’s heat output increases; as

process temperature rises, the heat output

decreases.

Maintains up to

140°F

Withstands up to

275°F

Medium Tem-

perature

C

Flame Retardant – Electrically insulates

the matrix and provides corrosion resistance.

D

Metallic Grounding Braid – Provides

additional mechanical protection and a

positive ground path.

E

Fluoropolymer Outer Jacket – Corrosion

resistant, flame retardant overjacket is

highly effective in many environments.

Protects against exposure to organic or

corrosive solutions. The overjacket also

protects against abrasion and impact

damage.

Output

Temperature

Self Regulating

Output

Approvals

FM approved for hot water maintenance applications

FREEZE

PROTECTION

WARNING — A ground fault protection device

is required by NEC to minimize the danger of

fire if the heating cable is damaged or improperly installed. A minimum trip level of 30mA is

recommended to minimize nuisance tripping.

G-43

Page 2

Heating Cable

HWM

Hot Water Maintenance

Heat Trace Cables

(cont’d.)

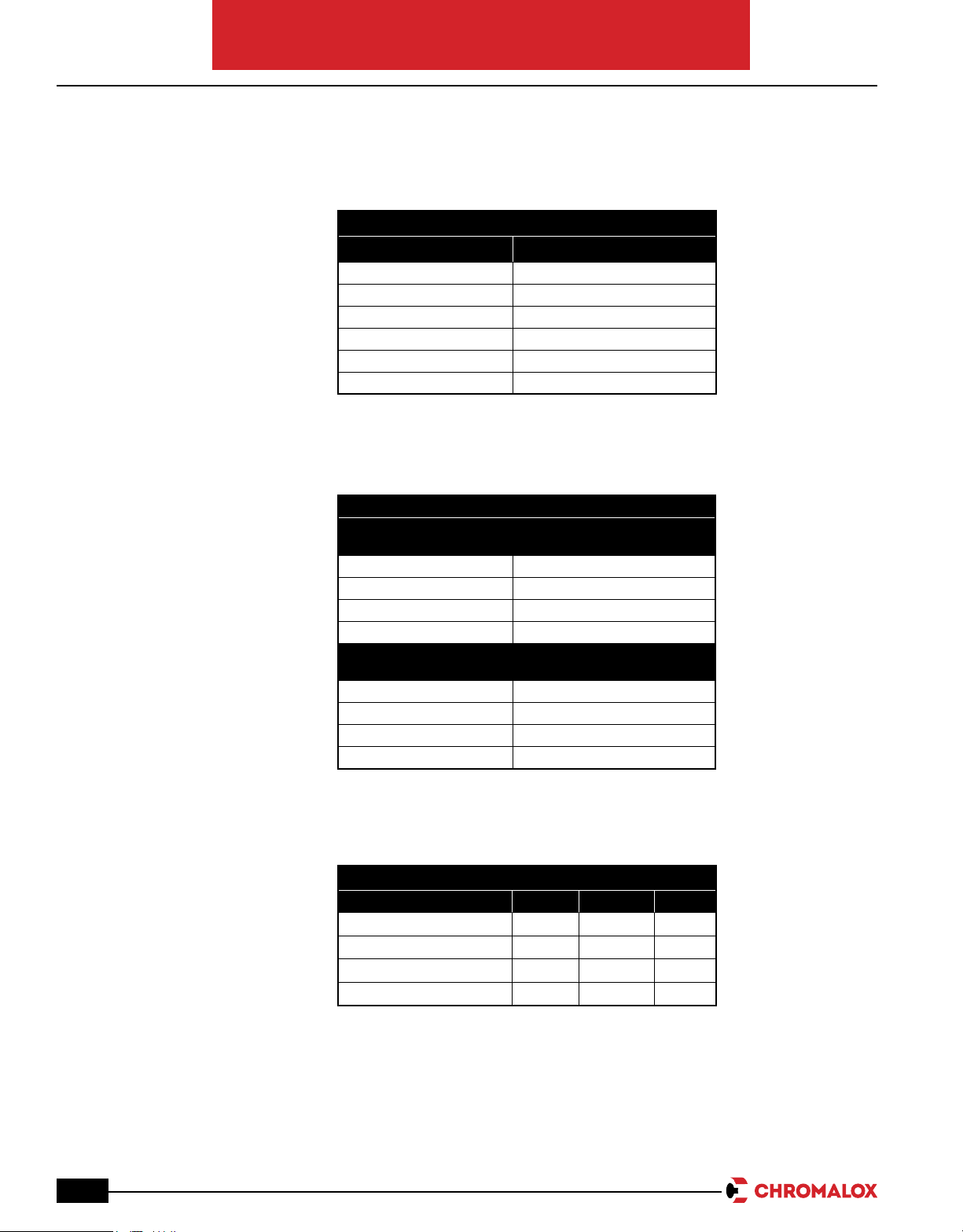

Insulation Requirement

Required thickness of fiberglass insulation is determined by nominal pipe size.

Fiberglass Insulation Thickness Selection

Pipe size (in) Insulation Thickness (in)

1/2 1

3/4 1

1 1

1 1/4 1

1-1/2 1-1/2

2 2

HWM Tracing Selection

To select the proper HWM cable for your applications, use the tables below.

Cable Selection

120V, 240V or 277V

Maintain Temperature (°F) Cable

105 HWM 5

115 HWM 10

125 HWM 10

140 HWM 10

208V

Maintain Temperature (°F) Cable

105 HWM 5

115 HWM 10

125 HWM 10

140 HWM 10

G-44

Maximum Circuit Length (Ft.)

Maximum Circuit Length ft

15A 20A 30A

HWM5-1CT 200 270 400

HWM5-2CT 400 540 800

HWM10-1CT 130 155 220

HWM10-2CT 260 310 440

Loading...

Loading...