Chromalox HVH-04-83, HVH-02-21, HVH-04-21, HVH-04-23, HVH-04-71 Installation, Operation And Maintenance Manual

...Page 1

Chromalox

®

SERVICE REFERENCE

Installation, Operation

and

MAINTENANCE

DIVISION 4 SECTION HVH

SALES

REFERENCE

(Supersedes PF203-5)

161-305679-001

JANUARY, 2012

DATE

PF203-6

Type HVH Horizontal/Vertical Unit Heater

GENERAL

Heater Location Instructions:

Arrange units so their discharge air streams:

A. Are subjected to a minimum of interference from columns,

machinery and partitions.

B. Wipe exposed walls without blowing directly at them.

C. Are directed away from room occupants in comfort heating.

D. Are directed along the windward side when installed in a build-

ing exposed to a prevailing wind.

E. See additional mounting limitations in Table D.

Locate thermostat on interior partition walls or posts away from

cold drafts, internal heat sources and away from heater discharge air

streams.

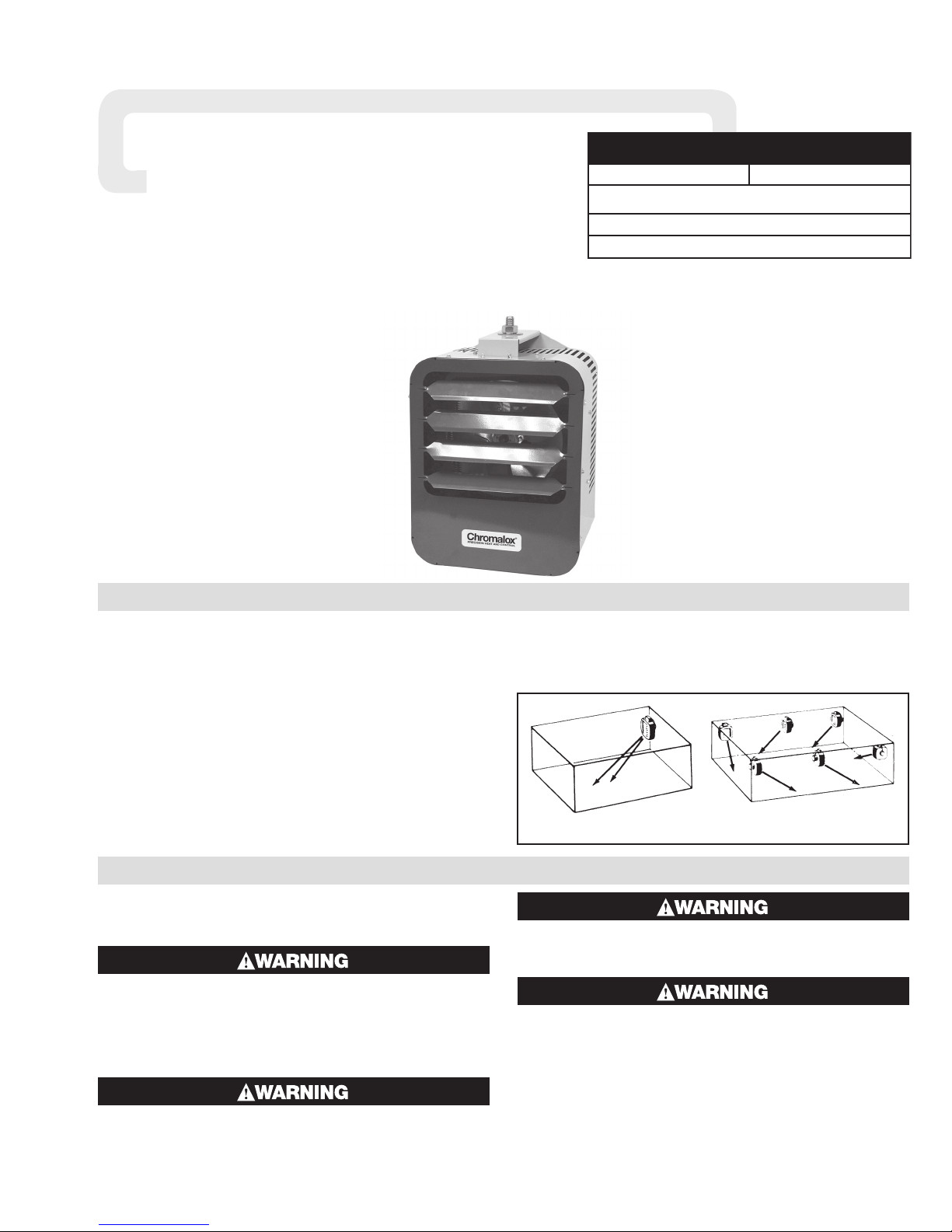

Small rooms can be heated by one unit heater. Where two walls

are exposed, the heater should be mounted as shown in Figure 1.

WARNING

Failure to understand and follow these installation instructions and

the “WARNING” notes therein may result in serious personal injury

from electrical shock, or from the heater falling due to faulty installation.

This heater is not intended for use in hazardous atmospheres where flammable vapors, gases, liquids or other

combustible atmospheres are present as defined in the

National Electric Code. Failure to comply can result in

explosion or fire. For these applications see PDS CXH-AEP (PF490).

ELECTRIC SHOCK HAZARD. Disconnect all power before

installing or servicing heater. Failure to do so could result in personal injury or property damage. Heater must

be installed or serviced by a qualified person in accordance with the National Electrical Code, NFPA 70.

Large rooms require multi-unit installation. Number and capacity

of units will be determined by volume of building and square feet of

floor area to be heated. Arrange units to provide perimeter air circulation where each unit supports the air stream from another.

Exposed

Exposed

Exposed

Figure 1 - Single and Multi Unit Mounting

This heater is not intended for use in exposed outdoor,

marine, or wash-down environments or in areas where

corrosive liquids or fumes exist under normal conditions.

ELECTRIC SHOCK HAZARD. Any installation involving

electric heaters must be performed by a qualified person

and must be effectivley grounded in accordance with the

National Electrical Code to eliminate shock hazard.

Do not mount mercury type thermostat directly on unit. Vibration

could cause heater to malfunction.

The heater must be mounted at least 7’ above the floor to prevent

accidental contact with the heating elements or fan blade which could

cause injury.

Keep at least 5’ clearance in front of the heater. Refer to Table D

for side, top and back clearance requirements.

Exposed

Exposed

Exposed

© 2012 Chromalox®, Inc.

Page 2

WARNING (cont’d.)

The ceiling mounting structure and the anchoring provisions must

be of sufficient strength to support the combined weight of the heater

and mounting bracket. (Refer to Table B for weights of heater and

bracket.)

The wall or mounting surface, and the anchoring provisions

must be capable of supporting the combined weight of the heater and

mounting brackets cantilevered from the mounting surface. (Refer to

Table B for weights of heater and brackets and for cantilevered force

expressed in foot-pounds.)

Fan blade rotation must be checked. If airflow is not moving out

through the louvers, interchange any two of the three customer power

leads on three-phase units only.

Specifications – Table A

Model Volts Watts Phase Amps BTU

HVH-02-81 208 2,667 1 12.8 8,850 16-1/8 13 10 —— 10

HVH-02-21 208/240 2000/2,667 1 11.1* 8,850 16-1/8 13 10 —— 10

HVH-02-71 277 2,667 1 9.6 8,850 16-1/8 13 10 —— 10

HVH-04-81† 208 4,000 1 19.2 13,661 16-1/8 13 10 —— 10

HVH-04-83† 208 4,000 3 11.2 13,661 16-1/8 13 10 30A (1) 12

HVH-04-21† 208/240 3,000/4,000 1 16.7* 13,661 16-1/8 13 10 —— 10

HVH-04-23† 208/240 3,000/4,000 3 9.6* 13,661 16-1/8 13 10 30A (1) 12

HVH-04-71 277 4,000 1 14.5 13,661 16-1/8 13 10 —— 10

HVH-04-43 480 4,000 3 4.8 13,661 16-1/8 13 10 30A (1) 11

HVH-05-81† 208 5,000 1 24.0 17,076 16-1/8 13 10 —— 10

HVH-05-83† 208 5,000 3 13.8 17,076 16-1/8 13 10 30A (1) 12

HVH-05-21† 208/240 3,750/5,000 1 20.8* 17,076 16-1/8 13 10 —— 10

HVH-05-23† 208/240 3,750/5,000 3 12.1* 17,076 16-1/8 13 10 30A (1) 12

HVH-05-71 277 5,000 1 18.2 17,076 16-1/8 13 10 —— 10

HVH-05-43 480 5,000 3 6.0 17,076 16-1/8 13 10 30A (1) 13

HVH-07-81† 208 7,500 1 36.1 25,598 20-5/8 17-1/8 12-3/4 50A (1) 12

HVH-07-83 208 7,500 3 20.9 25,598 20-5/8 17-1/8 12-3/4 30A (1) 12

HVH-07-21† 208/240 5,625/7,500 1 31.1* 25,598 20-5/8 17-1/8 12-3/4 30A (1) 12

HVH-07-23 208/240 5,625/7,500 3 18.1* 25,598 20-5/8 17-1/8 12-3/4 30A (1) 12

HVH-07-71 277 7,500 1 27.2 25,598 20-5/8 17-1/8 12-3/4 30A (1) 12

HVH-07-43 480 7,500 3 9.0 25,598 20-5/8 17-1/8 12-3/4 30A (1) 13

HVH-10-81† 208 10,000 1 48.0 34,130 20-5/8 17-1/8 12-3/4 50A (1) 12

HVH-10-83 208 10,000 3 27.8 34,130 20-5/8 17-1/8 12-3/4 30A (1) 12

HVH-10-21† 208/240 7,500/10,000 1 41.7* 34,130 20-5/8 17-1/8 12-3/4 30A (1) 12

HVH-10-23 208/240 7,500/10,000 3 24.0* 34,130 20-5/8 17-1/8 12-3/4 30A (1) 12

HVH-10-43 480 10,000 3 12.0 34,130 20-5/8 17-1/8 12-3/4 30A (1) 13

HVH-12-83 208 12,500 3 34.8 42,663 20-5/8 17-1/8 12-3/4 50A (1) 12

HVH-12-23 208/240 9,375/12,500 3 30.1* 42,663 20-5/8 17-1/8 12-3/4 50A (1) 12

HVH-12-43 480 12,500 3 15.1 42,663 20-5/8 17-1/8 12-3/4 30A (1) 13

HVH-15-83 208 15,000 3 41.8 51,195 20-5/8 17-1/8 12-3/4 50A (1) 12

HVH-15-23 208/240 11,250/13,000 3 36.2* 51,195 20-5/8 17-1/8 12-3/4 50A (1) 12

HVH-15-43 480 15,000 3 18.1 51,195 20-5/8 17-1/8 12-3/4 30A (1) 13

HVH-20-23 208/240 14,758/19,500 3 47.0 66,534 20-5/8 17-1/8 14-1/16 50A (2) 15

HVH-20-43 480 19,500 3 23.5 66,534 20-5/8 17-1/8 14-1/16 50A (1) 14

HVH-20-63 600 19,500 3 18.8 66,534 20-5/8 17-1/8 14-1/16

HVH-25-23 208/240 18,720/24,900 3 60.0 84,959 29-3/16 26-1/16 14-5/8 50A (2) 15

HVH-25-43 480 25,000 3 30.2 85,300 29-3/16 26-1/16 14-5/8 50A (1) 14

HVH-25-63 600 25,000 3 24.1 85,300 29-3/16 26-1/16 14-5/8 50A (1) 14

HVH-30-23 208/240 22,400/29,900 3 72.1 102,019 29-3/16 26-1/16 14-5/8 50A (2) 15

HVH-30-43 480 30,000 3 36.2 102,360 29-3/16 26-1/16 14-5/8 50A (1) 14

HVH-30-63 600 30,000 3 29 102,360 29-3/16 26-1/16 14-5/8 50A (1) 14

HVH-35-23 208/240 25,600/34,000 3 81.9 116,008 29-3/16 26-1/16 14-5/8 50A (3) 15

HVH-35-43 480 34,000 3 41 116,008 29-3/16 26-1/16 14-5/8 50A (1) 14

HVH-35-63 600 34,200 3 33 116,690 29-3/16 26-1/16 14-5/8 50A (1) 14

HVH-40-23 208/240 28,000/37,400 3 90.1 127,609 29-3/16 26-1/16 14-5/8 50A (3) 16

HVH-40-43 480 37,400 3 45.1 127,609 29-3/16 26-1/16 14-5/8 50A (1) 14

HVH-40-63 600 37,500 3 36.2 127,950 29-3/16 26-1/16 14-5/8 50A (1) 14

HVH-45-23 208/240 33,700/44,800 3 107.9 152,858 29-3/16 26-1/16 14-5/8 50A (3) 16

HVH-45-43 480 44,800 3 54 152,858 29-3/16 26-1/16 14-5/8 50A (2) 15

HVH-45-63 600 45,200 3 43.6 154,222 29-3/16 26-1/16 14-5/8 50A (1) 14

HVH-50-23 208/240 38,400/50,000 3 123.1 174,353 29-3/16 26-1/16 14-5/8 50A (3) 16

HVH-50-43 480 50,000 3 61.6 174,353 29-3/16 26-1/16 14-5/8 50A (2) 15

HVH-50-63 600 50,000 3 49.5 175,036 29-3/16 26-1/16 14-5/8 50A (2) 15

* Note: 208V amperage is 86% of 240V value.

† These models can be field changed from single phase to three phase or three phase to single phase.

Table B – Weights of Heater & Bracket

WEIGHT (Lbs.) Heater and Brackets

Ceiling

Model

Weight

Weight Ft.-Lbs.

HVH-02 to HVH-05 27 25-1/2 48

HVH-15 to HVH-20 55 67-1/4 112

HVH-25, 30, 35 108 105 126.3

HVH-40, 45, 50 118 115 138.4

A

Height

2

B

Width

C

Depth

Std. Contactor

Rating (Qty.)

50A (1) 14

Wall

Wiring

Dia. Figure

Page 3

INSTALLATION

NOTICE – These heaters are designed for wall and ceiling mount.

Other modes of mounting void factory warranty.

Vertical Air Flow

1. Height above floor

A. It is recommended that the heater only be used with ceiling

heights of 12 feet or greater. Minimum spacing to ceiling is 6

inches, use 3/8-18” thread stock (supplied by others) as shown

in Figure 3.

B. Mimimum mounting height is 10 feet from floor to bottom of

heater.

2. Spacing to walls.

A. Side of case to wall 6”. Top or bottom of case to back wall is

10-1/4” (HVH-02 to HVH-05), 13” (HVH-15 to HVH-20) and

15-1/2” (HVH-25 to HVH-50).

CEILING (Vertical Airflow):

A. The heater can be rod mounted to the ceiling by installing four

(4) threaded mounting rods in the threaded holes located on the

top of the heater as shown in Figure 3. (Refer to Table C for

mounting rod thread size.)

B. Securely attach the four (4) mounting rods to the ceiling. (Re-

fer to Table D for wall and ceiling clearances, and Figure 2 for

mounting spacing specifications.)

ADDITIONAL THREADED

3/8-18 THREADED

MOUNTING HOLES

MOUNTING HOLES FOR

HVH-25 TO HVH-50

Figure 2 - Wall and Ceiling Clearance

XX

L2

CL

CL

TERMINAL BOX

ACCESS DOOR

Back Wall

Figure 3 - Rod Spacing

Table C — Rod Thread Type and Spacing Dimensions (inches) for

Vertical Discharge.

Rod

Unit

Thread Type

L1 L2 X

2-5 kW 3/8-16 2-7/8 7-1/8 3-3/4

7-1/2 - 20 kW 3/8-16 4-5/16 9-3/8 5-1/2

25 - 50 kW 3/8-16 8-15/16 14 9-15/16

Table D — Clearance Requirements (Vertical Discharge)

Mounting Limitations (In.)

Model

Back to Wall Side to Wall Top to Ceiling

HVH-02 Thru HVH-05 10-1/4 6 6

HVH-07 Thru HVH-20 13 6 6

HVH-25 Thru HVH-50 15-1/2 6 6

Horizontal Air Flow

1. Height above floor

A.

In areas where ceiling height is more that 12 feet, recommended

mounting height is approximately 10 feet to underside of heater.

Side Wall

L1

Dimensions – (In.)

TERMINAL BOX

ACCESS DOOR

Figure 4 - Heater Back View

KO FOR POWER WIRING

KO FOR CONTROL WIRING

Knockout Sizes

HVH-02 - 05 1/2” 3/4” (1)

HVH-07 - 20 1/2” 1” (1)

HVH-25 - 50 1-1/4” 2” (1)

B. For ceiling heights of 12 feet or less, maximum mounting

height is detemined by the use of the mounting bracket offered

for these heaters. Minimum spacing to ceiling is 7-3/4”. (See

Figure 5)

C. In either case, the mimimum mounting height is 7 feet from

floor to bottom of heater.

2. Spacing to adjacent walls.

A. Rear of case to back wall 2” minimum.

B. Side of case to side wall 6” minimum.

CEILING – Horizontal Airflow (See Figure 5):

The ceiling mounting bracket is fastened to the top of the heater using

the four (4) bolts supplied with the mounting bracket. The bracket is

then mounted to the ceiling using a 5/8” bolt (by others).

WALL – Horizontal Airflow (See Figure 6):

Wall mounting necessitates the use of both an adaptor mounting

bracket and a wall mounting bracket. First, attach the ceiling mounting

bracket to the heater. Then, attach the wall mounting bracket to the

wall using four 5/16” bolts and six 3/8” bolts (by others). Attach the

ceiling mounting bracket on the heater to the wall mounting bracket

using the 5/8” bolt provided.

3

Page 4

INSTALLATION (cont’d.)

The heater may be rotated to discharge in the desired direction.

Open and adjust louvers to desired position. See Figure 5 and 6 for

additional mounting details.

CEILING

V

CL OF BOLT

A

BACK OF HEATER

B

W= MINIMUM DISTANCE FROM WALL TO ALLOW FOR FULL 180˚ SWIVEL

Bracket

Model No.

HVC-1 16-1/8 13 10 8-3/8 5-3/4 7-3/4 9-3/4 12 4 HVH-02, 04, 05

HVC-2 20-5/8 17-1/8 12-3/4 10-3/4 6-3/4 7-3/4 13 12 8 HVH-07, 10, 12, 15

HVC-3 20-5/8 17-1/8 14-1/16 12-1/16 8-1/16 7-3/4 13-5/16 8 7 HVH-15 (600V), HVH-20

HVC-4 29-13/16 26-1/16 14-5/8 11-3/4 8-3/16 7-3/4 22-5/16 8-7/16 17 HVH-25, 30, 35, 40, 45, 50

N

C

Dimensions (in.)

CEILING

M

U

FOR SWIVEL MOUNTING

TO CEILING, USE ONE

5/8" LAG BOLT. FOR FIXED

MOUNTING TO CEILING, USE

FOUR 3/8" LAG BOLTS

WALL

W

Wt.

(Lbs.) Use WithA B C M N U V W

Figure 5 - Optional Ceiling Swivel Mounting Bracket

ADAPTOR

BRACKET

Figure 6 - Optional Wall Swivel Mounting Bracket

R

S

P

Q

T

Bracket

Model

No.

HVW1 16-1/16 18-7/8 7 5 17-5/8 3-3/4 HVH-02, 04, 05

HVW2 16-1/16 23-1/4 7 5 18-5/8 6-1/2 HVH-07, 10, 12, 15

HVW3 6 23-7/16 6-7/8 4-15/16 20-1/16 9 HVH-15 (600V), HVH-20

HVW4 8 32-13/16 10-3/8 8-1/2 22-7/16 14 HVH-25, 30, 35, 40, 45, 50

Dimensions (in.)

Bracket

Weight

(Lbs.) Use WithP Q R S T

4

Page 5

WIRING

ELECTRIC SHOCK HAZARD. Be sure electricity is

turned off at main switch first before wiring. Any installation involving electric heaters must be effectively grounded in accordance with the National Electrical

Code to eliminate shock hazard.

1. Use heater only on the voltage and frequency specified on the nameplate.

2. All wiring should be done in accordance with local codes and the

National Electrical Code by a qualified person as defined in the NEC.

3. Two knockouts are provided on the back of the heater for wire entry.

See Figure 4 for location of knockouts.

4. Branch circuit wire for connection to heater must be at least 60˚C

wire.

5. The bottom access door is hinged. There are two screws that must be

removed to gain access (Figure 3).

6. A ground wire or ground lug is provided near the power connection

point (ground Wire on HVH-02 to HVH-20 and ground lug on HVH25 to HVH-50).

7. Terminals on contactor or on line voltage terminal block are supplied

to be connected to accept the correct size power supply wire. Copper

rated at 600V and 60˚C is satisfactory for the heater branch circuit.

8. Electrical accessories, either kits or factory-installed options, are

shown connected by a dash line on the heater wiring diagram.

9. Wiring connections are to be made on designated wire leads as

shown in the wiring diagrams located inside the access door.

10. Louver adjustment (Do not attempt to adjust while heater is operational): Louvers have been preset at factory with the minimum

open angle. Decreasing the 45˚ angle may result in high temperatures and functioning of the over temperature control. To increase the

opening angle, grasp the left end of louver with the left hand using

the index finger and thumb. Grasp right end of louver with right hand

in the same manner. Twist louver to the desired position.

REMOTE SUMMER FAN SWITCH

(MANUAL SWITCH-LINE VOLTAGE). The wall switch is

packed in the wiring compartment. The remote fan switch is mounted

external and remote from the HVH unit heater. The voltage of the remote fan switch is the same as the supply voltage to the HVH heater.

1. Use 14 gauge copper, NEC Class 1, 600V rated insulated wire.

Wiring must meet all Local and NEC requirements for 480-volt

service.

2. Install the remote fan switch in standard wall box in any conve-

nient location that is protected from traffic or other accidental damage.

3. Connect the 14 gauge copper field wire to the switch lead wires

with suitable connectors.

Power

Disconnect

Switch

To

Power

Supply

See

Note 2

Notes:

1. This illustration shows wiring hook up for three phase service. Remove lead

wires marked L3 and S3 when using single phase power service.

2. For units without contactors, disconnect switch is to be wired to terminal block

on heater power.

3. Use copper supply wire only with this switch.

L1

L2

L3

Contactor

or Terminal

Block

S1

S2

S3

See Notes

Figure 8 - Power Disconnect Switch Wiring Diagram

Top of Heater

45˚ Min.

All Louvers

Figure 7 - Louver Adjustment

POWER DISCONNECT SWITCH

(Available as a kit or factory installed option). This switch disconnects the power to the power leads when the handle is turned to its off

position. Refer to Instruction Sheet PF207.

1. Use copper conductor supply wire only when connecting to the

power line. (See Figure 8.)

2. Connection to the switch pigtails should be made with compres-

sion connectors and the joint should be then well insulated.

3. Consult the local wiring code in your area.

SUMMER FAN SWITCH - Refer to Instruction sheet PF205 without relay, PF206 with relay.

(MOUNTED ON FRONT OF HEATER). When the switch handle is

pointing toward the Summer (Fan ON) position, the fan will run continuously. When the switch handle is pointing toward the WINTER (HEAT)

position, the fan will run only when the heating elements are hot.

REMOTE FAN SWITCH

480V + Heaters require an additional fan relay. (Available as a kit

or factory installed option and standard on heaters 20kW and above).

The wall switch is packed in the wiring compartment.

1. Use 18 gauge (min.) NEC Class 1, 600V wiring that meets all Lo-

cal and NEC requirements.

2. Install the wall switch in a standard wall box in any convenient

location that is protected from traffic or other accidental damage.

3. Connect the field wire to the switch lead wires with suitable con-

nectors.

OPTIONAL THERMOSTAT (HVH-TK) Refer to Instruction

Sheet PF204.

Heaters can be equipped with an optional thermostat of the Bulb

and Capillary type for automatic temperature control (Figure 8). The

thermostat controls the heating elements and fan simultaneously to

achieve set temperature.

The “Lo” setting of the thermostat is approximately 40˚F, and the

“Hi” setting is approximately 90˚F.

Chromalox

Figure 9 — Thermostat Location, Front View

5

Page 6

WIRING (cont’d.)

CONTROL VOLTAGE WIRING — EXTERNAL REMOTE

THERMOSTATS AND FAN SWITCHES

ELECTRIC SHOCK HAZARD. Be sure electricity is

turned off at main switch first before wiring. Any installation involving electric heaters must be effectively grounded in accordance with the National Electrical

Code to eliminate shock hazard.

1. Use 600 volt, NEC Class 1 insulated wiring with a minimum gage

of 18 for thermostats and minimum gauge of 14 for line voltage

motor switch (remote fan switch without relay).

2. The thermostat should be located in the area to be heated on an inside wall. The thermostat should not be exposed to drafts, sunlight,

radiation from hot objects, or in a direct line with the discharge

from the unit heater.

3. Install the thermostat approximately 5 feet above the floor line.

4. Install the remote fan switch in any convenient location that is pro-

tected from traffic or likely accidental damage.

5. Internal optional controls are shown on the unit heater wiring diagrams by a dash line.

Optional thermostat

built-in or field

installed

Blue

Blue

Motor

T1 T2 T3

L1 L2 L3

Terminal

Block

Figure 10

Optional disconnect switch

built-in or field installed

Cutout

Power

60 Hz

1Ø Element wiring

(Omit for 2 element

heaters)

Elements

Optional

Disconnect

switch

built-in

or field

installed

Motor

T1 T2 T3

L1 L2 L3

Power 60 Hz

See Note #2

Optional Thermostat

Built-in or Field Installed

3Ø Wiring

TO T1

TO T2

TO T3

Yellow

Blue

C1C2C3

Pink

Remove jumper wire when

thermostat is used

NOTES:

1. Omit "L3" wiring for 1ø heaters

2. 3ø Motors used on all 480V, 7.5KV or higher

Black

Sec

Red

Figure 11

Cutout

Optional

disconnect

switch

built-in

or field

installed

Motor

T1 T3T2

L2

L1 L3

Power 60 Hz

Optional

thermostat

built-in or

field installed

TO T1

TO T1

TO T2

TO T3

TO T3

TO T2

C1C3C2

Pink

Remove jumper wire

when thermostat

is used

Notes: 1 Omit "L3" wiring for 1ø heaters

Figure 12

Purple

Orange

3Ø Wiring

Cutout

TO T1

TO T2

1Ø Wiring

TO T1

TO T2

TO T1

TO T2

Optional

disconnect

switch

built-in

or field

installed

See Note #2

Motor

T2

T1

L1

L2

Power 60 Hz

Notes:

1. Omit "L3" wiring for 1ø heaters

2. 3Ø motors used on all 480V 7.5Kw or higher heaters.

All other heaters use 1ø motors.

Optional thermostat

built-in or field installed

TO T1

TO T1

TO T2

TO T3

TO T3

TO T2

T3

C1C3C2

L3

Remove jumper wire

when thermostat is used

Yellow

Pink

Figure 13

Blue

Black

Black/Red

3Ø Wiring

SEC

Cutout

TO T1

TO T2

1Ø Wiring

TO T1

TO T2

TO T1

TO T2

6

Page 7

Figure 14

Elements

3 Phase Wiring

Line

Fusing

Alternate 1PH Motor Wiring

Optional

Pliot

Light

Built in

or External

Disconnect

Switch

WIRING (cont’d.)

Capacitor

Fusing

Fusing

AR Cutout

Motor

Contactor

Transformer

40VA

Time Delay

Refer to

Nameplate for

XFMR Primary

(Input) and

Seconday

Control) Voltage.

Relay

Built In or Remote

Thermostat

Termnal Block

(Control)

Figure 15

Elements

3 Phase Wiring

Line

Fusing

3 Phase Wiring

Optional

Line

Fusing

Built in or External

Disconnect Switch

Elements

Alternate 1PH Motor Wiring

Pliot

Light

Capacitor

Fusing

Fusing

Motor

Contactor

Transformer

Capacitor

Fusing

40VA

AR Cutout

Time Delay

Relay

Refer to

Nameplate for

XFMR Primary

(Input) and

Seconday

Control) Voltage.

Built In or Remote

Thermostat

Termnal Block

(Control)

Line

Fusing

Figure 16

Line

Fusing

Built in or External

Disconnect Switch

Optional

Pliot

Light

Line

Fusing

Fusing

Built In or Remote

Thermostat

Termnal Block

(Control)

AR Cutout

Motor

Contactor

Transformer

80VA

Time Delay

Relay

Refer to

Nameplate for

XFMR Primary

(Input) and

Seconday

Control) Voltage.

7

Page 8

RENEWAL PARTS IDENTIFICATION

PRODUCT

TYPE KW VOLTS Ø CONTROL VOLTAGE

INTEGRAL

THERMOSTAT

INTEGRAL

DISCONN.

SWITCH

FAN ONLY

SWITCH

TIME

DELAY

POWER

ON PILOT

LIGHT

OUTLET

SCREEN

hhh – hh – h – h – hh – hh – h – hh – h – h – h

Code

No. kW Volts Phase

HVH-02-81 2.67 208 1 118-305631-001 193-302912-001 112-302997-001

HVH-02-21 2.67 208/240 1 118-305631-002 193-302912-001 112-302997-001

HVH-02-71 2.67 277 1 118-305631-003 193-302120-001 112-130367-001

HVH-04-81 4 208 1 118-305631-001 193-302912-001 112-302997-001

HVH-04-83 4 208 3 118-305631-001 193-302912-001 112-302997-001

HVH-04-21 3/4 208/240 1 118-305631-002 193-302912-001 112-302997-001

HVH-04-23 3/4 208/240 3 118-305631-002 193-302912-001 112-302997-001

HVH-04-71 4 277 1 118-305631-003 193-302120-001 112-130367-001

HVH-04-43 4 480 3 118-305631-003 193-302912-003 112-302997-001

HVH-05-81 5 208 1 118-305631-004 193-302912-001 112-302997-001

HVH-05-83 5 208 3 118-305631-004 193-302912-001 112-302997-001

HVH-05-21 3.75/5 208/240 1 118-305631-005 193-302912-001 112-302997-001

HVH-05-23 3.75/5 208/240 3 118-305631-005 193-302912-001 112-302997-001

HVH-05-71 5 277 1 118-305631-006 193-302120-001 112-130367-001

HVH-05-43 5 480 3 118-305631-007 193-302912-003 112-302997-001

HVH-07-81 7.5 208 1 118-305659-007 193-302912-004 112-130367-002

HVH-07-83 7.5 208 3 118-305659-007 193-302912-004 112-130367-002

HVH-07-21 5.6/7.5 208/240 1 118-305659-008 193-302912-004 112-130367-002

HVH-07-23 5.6/7.5 208/240 3 118-305659-008 193-302912-004 112-130367-002

HVH-07-71 7.5 277 1 118-305659-009 193-302120-004 112-130367-002

HVH-07-43 7.5 480 3 118-305659-010 193-302912-005 112-130367-002

HVH-10-81 10 208 1 118-305659-001 193-302912-004 112-130367-002

HVH-10-83 10 208 3 118-305659-001 193-302912-004 112-130367-002

HVH-10-21 7.5/10 208/240 1 118-305659-002 193-302912-004 112-130367-002

HVH-10-23 7.5/10 208/240 3 118-305659-002 193-302912-004 112-130367-002

HVH-10-43 10 480 3 118-305659-003 193-302912-005 112-130367-002

HVH-12-83 12.5 208 3 118-305659-004 193-302912-004 112-130367-002

HVH-12-23 9.4/12.5 208/240 3 118-305659-005 193-302912-004 112-130367-002

HVH-12-43 12.5 480 3 118-305659-006 193-302912-005 112-130367-002

HVH-15-83 15 208 3 118-305659-007 193-302912-004 112-130367-002

HVH-15-23 11.2/15 208/240 3 118-305659-008 193-302912-004 112-130367-002

HVH-15-43 15 480 3 118-305659-010 193-302912-005 112-130367-002

HVH-20-23 19.8 208/240 3 118-305762-019 193-302912-004 112-130367-002

HVH-20-43 19.8 480 3 118-305762-009 193-302912-005 112-130367-002

HVH-20-63 19.8 600 3 Check with Factory Check with Factory Check with Factory

HVH-25-23 25.0 208/240 3 118-305762-017 193-302120-037 112-045422-016

HVH-25-43 25.0 480 3 118-305762-020 193-302120-011 112-045422-016

HVH-25-63 25.0 600 3 118-305762-016 193-302912-026 112-045422-016

HVH-30-23 30.0 208/240 3 118-305762-013 193-302120-037 112-045422-016

HVH-30-43 30.0 480 3 118-305762-014 193-302120-011 112-045422-016

HVH-30-63 30.0 600 3 118-305762-015 193-302912-026 112-045422-016

HVH-35-23 33.3 208/240 3 118-305762-011 193-302120-037 112-045422-013

HVH-35-43 33.3 480 3 118-305762-012 193-302120-011 112-045422-013

HVH-35-63 33.3 600 3 118-305762-010 193-302912-026 112-045422-013

HVH-40-23 37.5 208/240 3 118-305762-017 193-302120-037 112-045422-013

HVH-40-43 37.5 480 3 118-305762-020 193-302120-011 112-045422-013

HVH-40-63 37.5 600 3 118-305762-016 193-302912-026 112-045422-013

HVH-45-23 45.0 208/240 3 118-305762-013 193-302120-037 112-045422-013

HVH-45-43 45.0 480 3 118-305762-014 193-302120-011 112-045422-013

HVH-45-63 45.0 600 3 118-305762-015 193-302912-026 112-045422-013

HVH-50-23 50.0 208/240 3 118-305762-011 193-302120-037 112-045422-013

HVH-50-43 50.0 480 3 118-305762-010 193-302120-011 112-045422-013

HVH-50-63 50.0 600 3 118-305762-012 193-302912-026 112-045422-013

Element

Part No.

Motor

Part No.

Fan

Part No.

8

Page 9

-0

-0

OUTLET SCREEN

OUTLET

SCREEN

-0

LIGHT

POWER

ON PILOT

PILOT LIGHT

TIME DELAY

-0

RENEWAL PARTS IDENTIFICATION

0 = No Pilot Light 0 = No Outlet Screen

P = 24V P/N 213-072380-029 S = 2-5 kW P/N 247-305642-001

TIME

DELAY

SWITCH

FAN ONLY

SWITCH

INTEGRAL

DISCONN.

INTEGRAL

THERMOSTAT

DISCONNECT

INTEGRAL

P = 120V P/N 213-072380-007 S = 7-20 kW P/N 247-305642-002

-0

SWITCH

-00

THERMOSTAT

00 = No Thermostat 0 = No Disconnect Switch

TL = SPST P/N 300-049197-003 D = 50A P/N 292-303472-007

TL = DPST P/N 300-049197-004 D = 80A P/N 168-303598-007

TH = SPST P/N 300-049197-001 D = 100A P/N 168-303598-008

TH = DPST P/N 300-049197-002

FAN ONLY SWITCH

D0 = No Disconnect Switch 0 = No Time Delay Relay

FI = 3PST Switch P/N 292-057673-001 R = 24V Relay P/N 072-071847-040

FE = 3PST Switch P/N 292-057673-001 R = 120V Relay P/N 072-071847-041

FI = 24V Motor Relay P/N 072-123534-075

FI = 120V Motor Relay P/N 072-123534-064

Miscellaneous Parts

Thermostat Knob 169-049278-001

Instruction Sheets

1. Internal Thermostat PF204

2. Internal/External Summer Fan Switch PF205

3. Internal/External Summer Fan Switch W/Relay PF206

4. Disconnect Switch PF207

Limited Warranty:

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

-00

TYPE KW VOLTS Ø CONTROL VOLTAGE

PRODUCT

hhh – hh – h – h – hh – hh – h – hh – h – h – h

CONTROL VOLTAGE

Ø

VOLTS

kW

0

-0

-00

7 30 = 24V Transformer P/N 315-304252-004

2, 4, 7, 8 00 = No Contactor

2, 4, 8 30 = 24V Transformer P/N 315-304252-002

2, 4, 7, 8 30,31 = 24V 35A Contactor P/N 072-306110-001

2, 4, 7, 8 30,31 = 24V 50A Contactor P/N 072-306110-002

2, 4, 7, 8 32,33 = 120V 35A Contactor P/N 072-306110-007

7 32 = Transformer P/N 315-304252-003

2, 8 34 = 208/240V 35A Contactor P/N 072-306110-013

2, 4, 8 32 = Transformer P/N 315-304252-001

2, 4, 7, 8 32,33 = 120V 50A Contactor P/N 072-306110-008

9

Please refer to the Chromalox limited warranty applicable to this product at

Cutout Switch

2.6 through 5 kW 300-024413-001

7.5 through 15 kW 300-024413-002

7 35 = 277V 35A Contactor P/N 072-306110-019

7 35 =277V 50A Contactor P/N 072-306110-020

2, 8 34 = 208/240V 50A Contactor P/N 072-306110-014

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...