Page 1

Heating Cable

Heat Tracing Products

Application & Selection

Guidelines

Step 1 — Collect Required

General Product Summary

This section is designed to assist you in

determining the appropriate cable for use in

your application.

Step 1 — Collect Required Application Data

and Determine Heat Loss

Step 2 — Choose the cable that best meets

your specific application parameters based

on the summary. Consideration of application

temperature, exposure temperature, application requirements and environmental ratings

should be made.

Step 3 — Select Heating Cable Wattage Rating

Step 4 — Determine Total Cable Required

Step 5 — Determine Circuits and Circuit

Protection

Step 6 — Select Appropriate Accessories

Application Data & Determine

Heat Loss

Application data required can be split into two

categories. The first is the heat loss data. This

includes:

• Maintenance Temperature

• Minimum Ambient Temperature

• Pipe Size

• Insulation Type (or K factor)

• Insulation Thickness

• Indoor/Outdoor Installation

• Maximum Expected Wind Speed

• Required Safety Factor.

Refer to the Technical section of this catalog,

“Determining Heat Energy Requirements —

Pipe & Tank Tracing” for details on

performing heat loss calculations. For Commercial Freeze Protection, please see Cable

Selection Tables in this section.

The second category of data required is the

application and environmental conditions. This

includes:

• Maximum Exposure Temperature

(Power Off Condition)

• Circuit Length Considerations

• Available Voltage

• Hazardous Area Requirements

• Type of Pipe (Plastic or Metal)

• Chemical Exposure

• Fire Resistance.

Step 2 — Select the Cable

Choose the cable that best fits your specific

application parameters and wattage requirements.

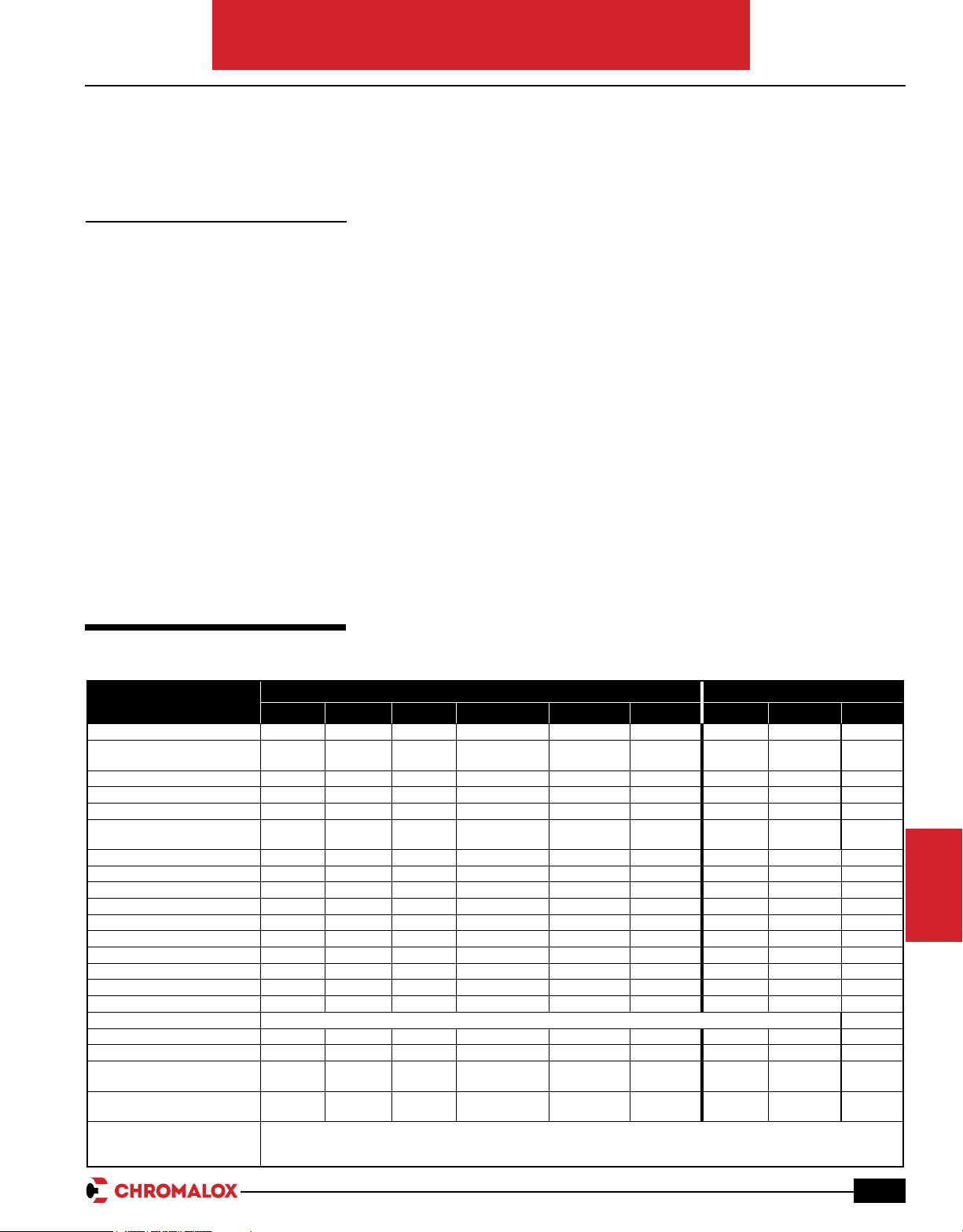

Heat Tracing Product Features

Industrial Commercial

Features

Max. Maintenance Temp. (°F) 150 225 302 320 302 900 100 50 225

Max. Exposure Temp. (°F)

Power Off

Max. W/Ft. 10 15 20 12 12 50 8 12 15

Max. Circuit Length (Ft.) 95-660 55-750 150-750 225-900 7,500 330-1,000 180-660 135-540 500-800

Buss Wire Size 16 16 16 12 16,14,12,10 N/A 16 16 16

Voltages

Hazardous Ratings Yes Ye s Yes Ye s Yes Yes No No No

Usable on Plastic Pipe Yes No No No No No Ye s Ye s Yes

Cut-to-Length in Field Ye s Yes Ye s Ye s Ye s No Ye s Ye s Ye s

Field Splicable Yes Yes Ye s Ye s Ye s No Ye s Ye s Ye s

Can be Overlapped Yes Ye s Ye s No No No Ye s Ye s Ye s

Output Varies with Temp. Ye s Ye s Yes No No No Yes Yes Ye s

Varies Output Along Length Yes Ye s Ye s No No No Ye s Ye s Ye s

Design of System Simple Simple Simple Simple Involved Involved Simple Simple Simple

Installation of System Easiest Easiest Easiest Simple Simple Involved Easiest Easiest Easiest

Fire Resistance Fair Fair Fair Fair Fair Excellent Fair Fair Fair

Chemical Resistance

Size (Max. In.) .435x.185 .435x 185 .435x.185 .435x.235 .435x.185 0.4 .435x.185 .435x.185 .435x.185

Accessories DL/EL/U D/UL DL/U DL/EL/U U DL/EL/U RG Access. DL/U

Monitor Wire Available

Applications

SRL SRP SRM/E CWM SLL Alloy 825 MI SRF SRF-RG HWM

185 275 420 400 450 1,100 185 185 275

120,

208-277

See Corrosion Guide, next page

Yes Ye s

FL,PL

FL = Freeze Protection

FH = Freeze Protection, High Exposure Temp.

PL = Process Maintenance, Low Temperature

120,

208-270

FL,FH,

PL,PH

120,

208-277

Contact

Factory

FL,FH,

PL,PH

120,

208-277, 480

Contact

Factory

FL,FH,

PL,PH

120-600 Up to 600

No No No No Yes

FL,FH,

PL,PH

PH = Process Maintenance, High Temperature

RG = Roof and Gutter De-icing

HWM = Hot Water Maintenance

FL,FH,

PL,PH

120,

208-277

FL RG HWM

120,

208-277

120,

208-270

PRODUCTS

HEAT TRACING

G-5

Page 2

Heating Cable

Heat Tracing Products

Application & Selection Guidelines (cont’d.)

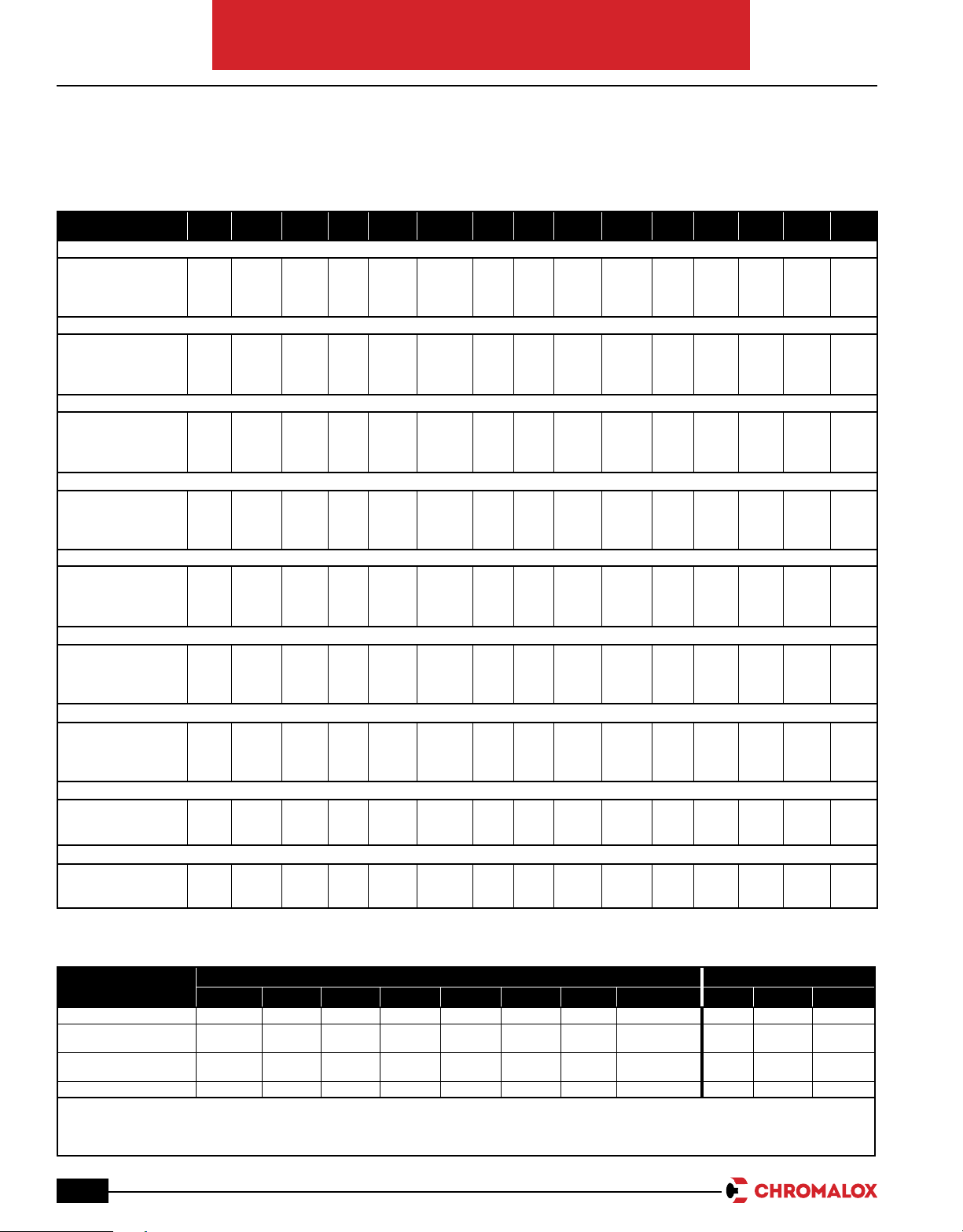

Agency Approvals

Area SRL-C SRL-CR SRL-CT HSRL SRM/E-C SRM/E-CT SRP HSRM CWM-C CWM-CT MI SRF-C SRF-CR SRF-RG HWM

Ordinary Area

UL

Factory Mutual

CSA

ATEX

Class 1 Div 2, Groups B,C,D

UL

Factory Mutual

CSA

ATEX

Class II Div 2, Groups F,G

UL

Factory Mutual

CSA

ATEX

Class III Div 2

UL

Factory Mutual

CSA

ATEX

Class 1 Div 1, Groups B,C,D*

UL

Factory Mutual

CSA

ATEX

Class II Div 1, Groups F,G

UL

Factory Mutual

CSA

ATEX

Class III Div 1

UL

Factory Mutual

CSA

ATEX

Zone 2 and Zone 22

Factory Mutual

CSA

ATEX

Zone 1 and Zone 21

Factory Mutual

CSA

ATEX

*ClassI,DivisionI,GroupsB,C&D-UL,CSA,FM-ContactyourLocalChromaloxSalesofcefordesignassistance.

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓ ✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓✓✓

✓ ✓

✓✓✓

✓✓✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

Corrosion Guide to Select Proper Cable Construction

Industrial Commercial

Exposure To

Moisture C, CR, CT C, CT C, CT CT CT C, CT CT Yes C, CR Yes C, CT

Aqueous Solutions of

Inorganic Compounds

Liquids Organic

Chemicals

Acids or Bases CT CT CT CT CT CT CT No No No CT

Note — This is a recommendation guide. Chromalox cannot warrant any Electric Heat Trace against failure by sheath degradation if such failure

is the result of operating conditions beyond the control of the heater manufacturer. It is the responsibility of the purchaser to make the

ultimate choice of sheath material based on knowledge of the chemical composition of the corrosive solution, character of materials

entering the solution, and controls which maintains the process.

G-6

SRL SRM/E SRP HSRL HSRM CWM SLL Alloy 825 MI SRF SRF-RG HWM

CR, CT CT CT CT CT CT CT No No No CT

CT CT CT CT CT CT CT Yes No No CT

Page 3

Heating Cable

Pipe Temperature (˚F)

Heat Output (W/Ft.)

0

4

12

16

20

24

8

30 50 70 90 110 130 150 170 190 210 230 250

20 W/Ft.

15 W/Ft.

10 W/Ft.

8 W/Ft.

5 W/Ft.

Cable Output vs.

Temperature

270 290

300

Heat Tracing Products

Application & Selection

Guidelines (cont’d.)

Required Jacket Material

Select the appropriate jacket configuration for

the desired level of mechanical and corrosive chemical protection. The CR over-jacket

option can be used when additional mechanical protection is desired. The CR over-jacket

option is required when the cable can be

exposed to aqueous inorganic chemicals. The

CT over-jacket option is required when the

cable can be exposed to organic chemicals or

strong corrosives. Use Corrosion Guide above

to determine the correct jacket material option

for the cable type selected.

Step 3 — Select Heating

Cable Wattage Rating

After calculating the heat loss

in the pipe and adjusting for any

application deviations, you may

determine which cable rating

to use. If you have selected a

self-regulating cable you must

adjust the output based on

maintenance temperatures,

using the Thermal Output

Rating Graphs shown on the individual product pages, select

the lowest cable rating that will

provide the pipe maintenance temperature. For Example: A

15 W/Ft. SRM/E cable @ 150°F

will output approximately

10 W/Ft. Multiple passes or runs

of cable may be required to

provide sufficient output per

foot calculated in Step 1. This is

accomplished with parallel runs

of cable or spiraling. Contact

your Local Chromalox Sales office.

Cable Output vs. Temperature

Step 4 — Determine Total Length of

Cable Required

The total amount of heating cable is

determined by adding the total footage of

pipe to be traced and adding for allowances

for the components such as flanges, valves,

pipe supports; then, multiply by the total

number of runs or Wrap Factor determined in

Step 3.

(Total Feet of Traced Pipe + Cable Allowance

for Components) x # of Runs = Total Cable

Length)

Step 5 — Determine Circuits &

Circuit Protection

Circuit protection depends on the breaker

size being used and the start-up temperature.

The National Electric Code (NEC 1996)

requires the use of ground fault protection

breakers for heating cable. Refer to the

specific data of the individual heat trace cable

to determine maximum circuit lengths. To

determine the number of circuits required for

each pipe, divide the total cable length found

in Step 4 by the maximum circuit length found

in the individual cable data charts. Round up

to the next higher number.

Number of Circuits = Cable Length

Maximum Circuit Length

Pipe Component Cable Allowance Estimation

Component Cable Allowance Factor (Ft.) x # Components Total Additional Cable

Flange Pair 1.5 x

Pipe Support 2.0 x

ButteryValve 2.5 x

Ball Valve 2.7 x

Globe Valve 4.0 x

Gate Valve 5.0 x

Example: Pipe: 150 feet

Valves: 1 globe valve

Pipe Supports: 2

Flanges: 2

Total Cable Length = [150 + (1 x 4) + (2 x 2) + (2 x 1.5)] x 2 runs

= 161 feet x 2 runs

= 322 feet

PRODUCTS

HEAT TRACING

G-7

Page 4

Heating Cable

Heat Tracing Products

Application & Selection Guidelines (cont’d.)

Design of Multiple Runs when Heat Requirements

Exceed Cable Output Ratings

Insulation

Sensors

Multiple Straight Runs

Heating Cable

Step 6 — Select Controls & General

Application Accessories

Chromalox provides a wide range of termination accessory and control options for your

heat tracing systems needs.

Accessory options range from ordinary area

under the insulation kits in our EL series all the

way through connections and terminations for

Division 1 hazardous areas in our HL series.

The accessories carry a full complement of

third party approvals from UL, Factory Mutual,

Canadian Standards, ATEX and IECex.

Controls range from Thermostats for both ambient air and pipe/tank sensing applications to

WeatherTrace power distribution and controls

panels through our IntelliTrace line of distribution, monitoring and control panels. Whether

your project is a few lines of freeze protection

or a few hundred lines of process piping we

have the right control option for your needs.

Spiral Run

Accessory Descriptions

U Series

• Designed for Ordinary and Hazardous Area

use in Industrial applications

• Integrated design allows for quick cable

termination

• Line carries worldwide approvals including

ATEX and IECex

• Reduced parts count results in fast installation times

• Line includes:

• Power Connection

• Multi Entry Connection (for splice, tee or

multiple power to 3 cables)

• Above Insulation End Seal

• Below Insulation End Seal

• Lighted End Seal

• Ambient Thermostat

• Line Sensing Thermostat

• Lighted End Seal

Thermostats also serve as power connection

for cable - eliminating need for extra power

connection box.

DL Series

• Designed for Ordinary and Hazardous Area

use in Industrial Applications

• Integrated design allows for fast installation

• Box design allows easy access for field wiring, maintenance and trouble shooting

• CSA, Factory Mutual and UL approved for

ordinary and Hazardous area use (Div. 2)

• Line Includes

• Power Connection

• Splice and Tee (connect up to 3 cables)

• Below Insulation End Seal

• Lighted End Seal (ordinary area use only)

• Ambient Thermostat

• Line Sensing Thermostat

• Thermostats also serve as power connection

for cable - eliminating need for extra power

connection box.

G-8

Page 5

Heating Cable

Heat Tracing Products

Application & Selection Guidelines (cont’d.)

EL Series

• Designed for use in ordinary areas for both

commercial and industrial applications

• Low profile designs allow for ease of insulation around connections

• Kits include standard electrical terminations

and heat shrink products familiar to most

installers

• Low parts count allows fast termination of

cables

• Third Party Approvals through UL, Factory

Mutual and CSA.

• Line Includes

• Junction Box

• Pipe Stand off with sealing grommets

and cable boots

• Heat shrink splice and tee kits

• Heat Shrink end caps

HL Series

• Specifically designed for use in Division 1

hazardous areas

• Corrosion Resistant housing made of high

strength cast aluminum

• Reduced parts count for fast installation

• Small profiles for ease of insulation

• Line Includes

• Power Connection

• Splice Kit

• Tee Kit

• End Seal Kit

• Add on Signal lights for End Seal and

Power Connection

Controls Descriptions

DL Controls

The DL Series temperature controls are available in four models to handle a broad range

of applications. Models include two ambient

sensing and two line sensing thermostats.

These high quality models combine On/Off

temperature control and cable power connection in one affordable, convenient easy to

install package. The line includes two 22 amp

capable models for Ordinary Area installations

and two 11 amp capable hermetically sealed

models for Division 2 hazardous area applications. Products carry UL, Factory Mutual and

CSA approvals.

EL Controls

The EL controls line contains ambient and

line sensing controllers for use in Division

1 and Division 2 areas. All products switch

22 amps and come in NEMA 4x and NEMA 7

rated enclosures. Two models are available in

dual output form. All capillaries are nontoxic

oil filled available in 8 and 10 foot lengths.

Products carry UL, Factory Mutual and CSA

approvals.

WeatherTrace Control and Distribution

Panels

The Chromalox FPAS, FPASM, FPLS, and

FPLSM series panels offer power distribution, ground fault protection, individual circuit

alarming, with options for both line sensing

and ambient sensing control. Line sensing is

accomplished in conjunction with U SERIES,

DL SERIES or EL SERIES thermostats. Ambient sensing can be accomplished with thermostats or optional Chromalox solid state 1604

series temperature controllers. The panels

are housed in NEMA 4 enclosures for indoor/

outdoor applications. NEMA 4X 304 stainless

steel enclosures may be selected as an option

for more harsh environments. The standard

models are available in 12,18,20,30 and 42

position panel boards with 100 and 225 amp

bus ratings in single and three phase configurations. Branch circuit breakers are available

in 20, 25, 30 and 40 amp single pole and two

pole configurations with 30mA ground-fault

equipment protection. Options for Z-purge

systems for hazardous area installation are

available. Sentinel monitoring system is available for alarm indication when a circuit loses

power. Common alarm available for interface

to building management systems. Panels are

built in a UL 508 certified manufacturing plant

and carry UL and cUL approvals.

DTS Digital Thermostat

The DTS-HAZ is a single circuit controller

which switches 30 Amps at 100-277 Vac

in Class I, Division 2 areas. It employs SSR

on/off control, soft start feature, programmable paramater values, AC or DC alarm and

large LED display. It comes complete with a

standard pipe stand or optional wall mount as

well as an RTD sensor. All of this is housed in

a 6" x 6" enclosure, wich facilitates all wiring

needs.

IntelliTRACE

The lTC is a 1 or 2 circuit microprocessorbased temperature controller, switching 40

Amps per circuit at 100-277 Vac, and may be

used in either freeze protection or process

temperature control applications. The ITC's

compact 10" x 8" x 6" NEMA 4X enclosure

facilitates all of the electrical connections and

it features a high resolution TFT display, PID

or On/Off SSR control, selectable soft start

program, dual RTD sensor input per circuit,

current load and GFEP monitoring. All process

variables may be monitored both locally and

remotely. The lTC is designed for line or ambient sensing heat trace applications in hazardous (Class I, Division 2) or non-hazardous

areas.

Should the lTC unit realize a failed sensor, the

controller automatically switches into a user

adjustable manual output duty cycle. This controller provides LED indication of load, power

and alarm status for each circuit, has front

panel capacitive touch user interface buttons

and comes complete with heavy gage stainless

steel mounting brackets.

IntelliTRACE Control, Monitoring and

Distribution Panels

The IntelliTRACE ITAS and ITLS Series is a

micro-processor based Control/Monitoring

and Power Management and Distribution system for Heat Trace Applications. The ITAS and

ITLS Series has models suitable for ordinary

as well as Class I, Division 2 areas and will

manage 6-72 circuits

The ITAS and ITLS Control Panel Series provides alarms for high / low temperatures, high/

low current, ground fault leakage and sensor

faults.

The 40 Amps per circuit capacity, the Integral

Circuit Panel and the Soft Start feature save

significant time, installation and maintenance

costs.

The customizable I/O (Sensor) Mapping, the

remote monitoring capability and the wireless

communication option provide desirable process management flexibility options.

®

ITC Series

SELF-REGULATING

G-9

Loading...

Loading...