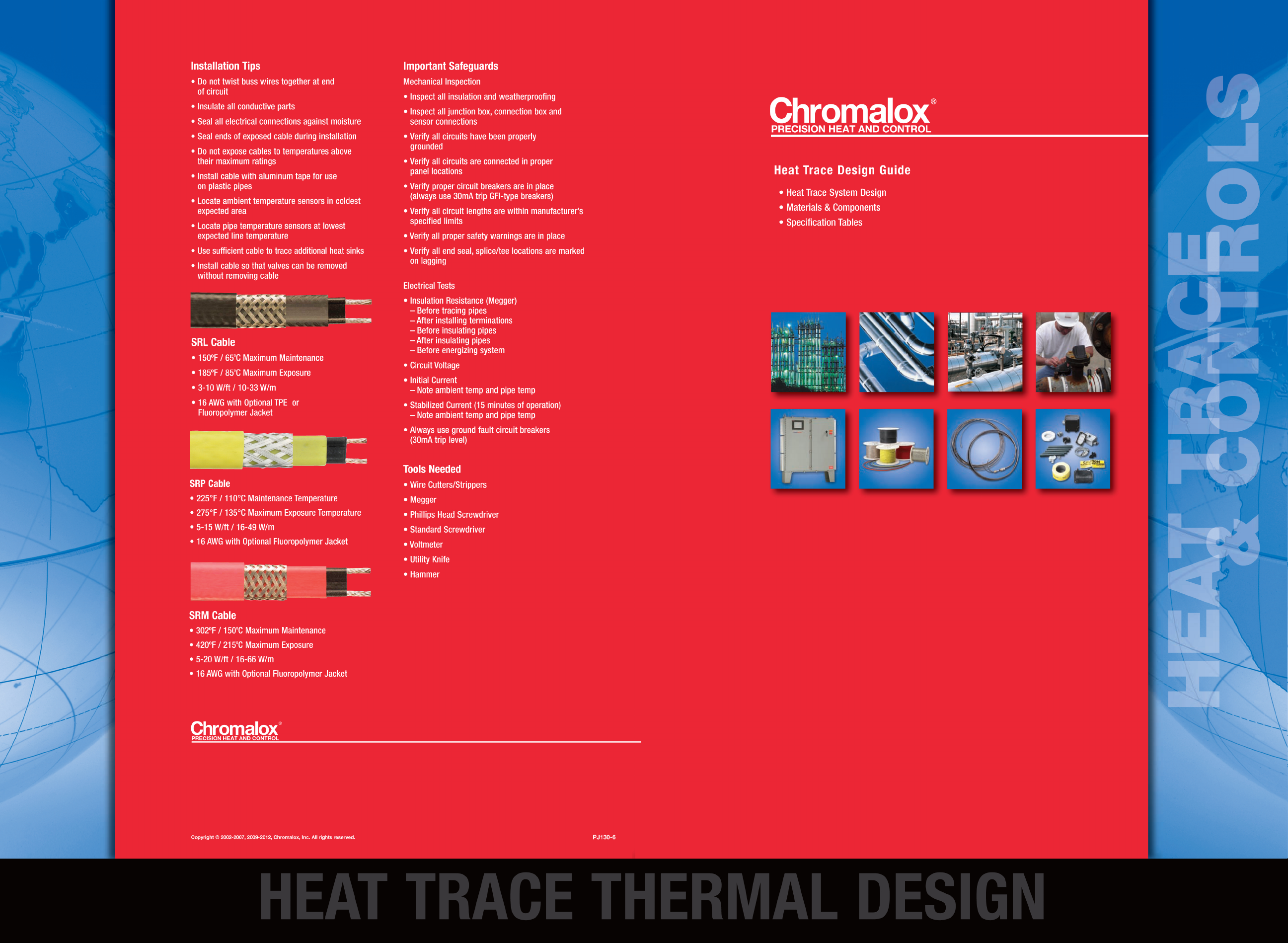

Page 1

Page 2

Insulation

Factor

Pipe Insulation TypePipe Insulation Type

Insulation

Factor

Glass fiber (ASTM C547) 1.00

Calcium silicate (ASTM C533) 1.48

Cellular glass (ASTM C552) 1.48

Rigid cellular urethane (ASTM C591) 0.64

Foamed elastomer (ASTM C534) 1.16

Mineral fiber blanket (ASTM C553) 1.16

Expanded perlite (ASTM C610) 1.90

A

Pipe Temperature (ºF)

Maintenance Temperature

0 10 20 30 50 60 70 80 90 100 110 120 130 140 150

Thermal Output (W/ft)

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

4.88

SRL10 & HSRL10

SRL8 & HSRL8

SRL5 & HSRL5

SRL3 & HSRL3

Cable Output

versus

Temperature

40

0 10 20 30 50 60 70 80 90 100 110 120 130 140 15040

Pipe Temperature (ºF)

SRL10 & HSRL10

Thermal Output (W/ft)

9

8

7

6

5

4

3

2

1

0

SRL8 &

HSRL8

SRL5 & HSRL5

SRL3 & HSRL3

Cable Output

versus

Temperature

Pipe Temperature (ºF)

Heat Output (W/ft)

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

15 W/ft

10 W/ft

5 W/ft

Cable Output

versus

Temperature

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230

0 50 100 150 200 250 300

Pipe Temperature (ºF)

SRM/E20 &

HSRM20

Power Output (W/ft)

24

20

16

12

8

4

0

SRM/E15 &

HSRM15

SRM/E10 &

HSRM10

SRM/E8& HSRM8

SRM/E5& HSRM5

SRM/E3& HSRM3

Cable Output

versus

Temperature

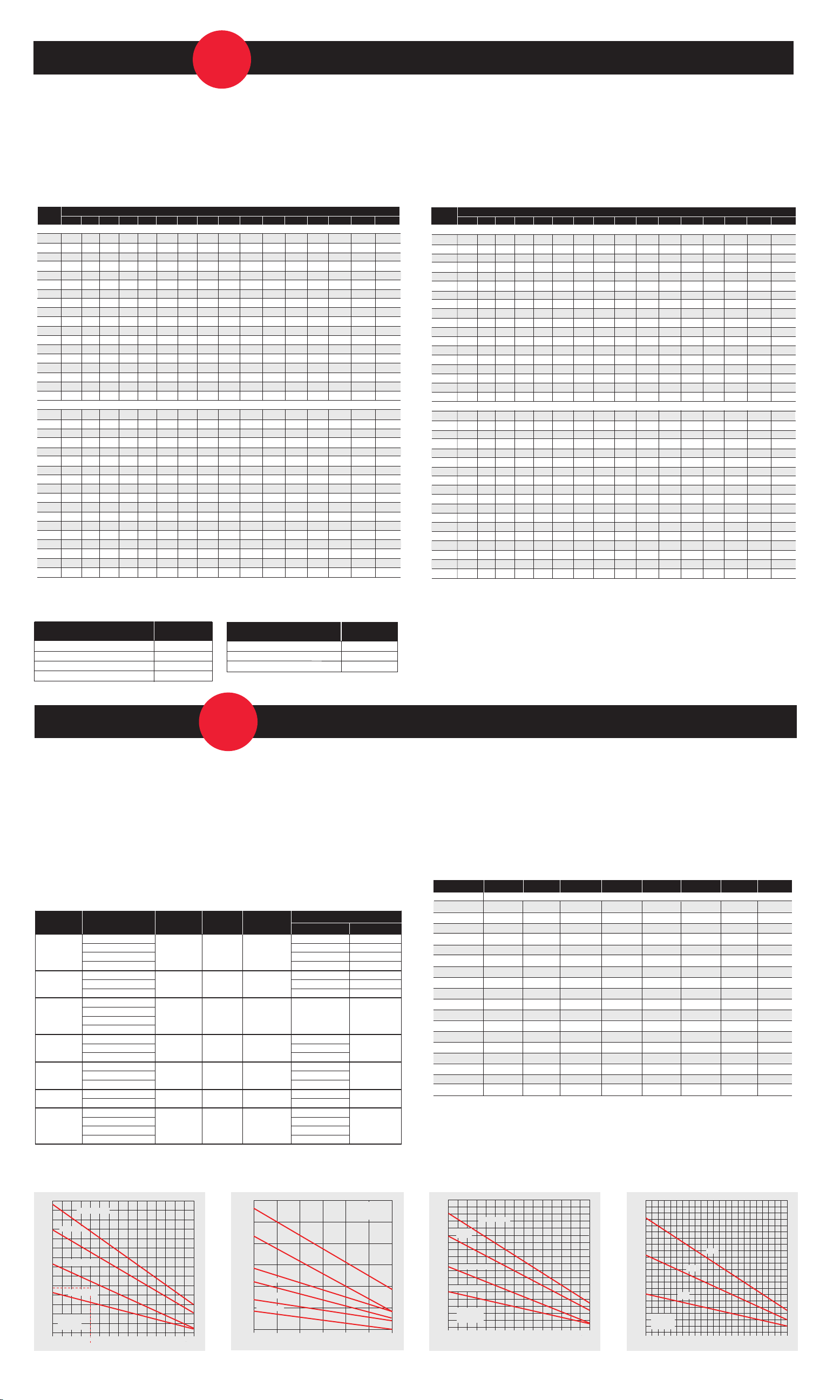

Pipe Heat Loss Calculations

1.Basic Heat Loss: After determining the difference between the ambient and desired pipe maintenance

temperature, T

, use Table 1 to figure the basic heat loss for the pipe size and insulation thickness.

m

2.Insulation Adjustment: Using Table 2, find the type of insulation being used and its insulation factor.

Table 1 Pipe Heat Loss Q

Nominal

Pipe Size,

in. (ID)

DegºF 40ºF 50ºF 60ºF 70ºF 80ºF 90ºF 100ºF 120ºF 140ºF 160ºF 180ºF 200ºF 220ºF 240ºF 260ºF

1

/2" W/ft 1.4 1.8 2.1 2.5 2.8 3.2 3.5 4.2 5.1 5.9 6.6 7.7 8.5 9.2 10.0

3

/4" W/ft 1.6 2.0 2.4 2.8 3.2 3.6 4.0 4.8 5.9 6.7 7.6 8.8 9.7 10.6 11.4

1" W/ft 1.8 2.3 2.8 3.2 3.7 4.1 4.6 5.5 6.8 7.7 8.7 10.1 11.1 12.1 13.2

11/2" W/ft 2.4 3.1 3.7 4.3 4.9 5.5 6.1 7.3 9.0 10.2 11.5 13.4 14.8 16.1 17.4

2" W/ft 2.8 3.5 4.1 4.8 5.5 6.2 6.9 8.3 10.1 11.6 13.0 15.2 16.7 18.2 19.7

21/2" W/ft 3.2 4.0 4.8 5.6 6.4 7.2 8.0 9.6 11.8 13.4 15.1 17.6 19.4 21.1 22.9

3" W/ft 3.7 4.7 5.6 6.5 7.4 8.4 9.3 11.2 13.7 15.6 17.6 20.5 22.5 24.6 26.6

4" W/ft 4.6 5.8 6.9 8.1 9.2 10.4 11.5 13.8 16.9 19.3 21.7 25.3 27.8 30.4 32.9

6" W/ft 6.4 8.0 9.6 11.2 12.8 14.4 16.0 19.2 23.5 26.9 30.2 35.2 38.7 42.2 45.8

8" W/ft 8.1 10.1 12.1 14.1 16.2 18.2 20.2 24.2 29.7 33.9 38.2 44.4 48.9 53.3 57.8

10" W/ft 9.9 12.4 14.8 17.3 19.8 22.2 24.7 29.6 36.3 41.5 46.7 54.3 59.8 65.2 70.6

12" W/ft 11.6 14.5 17.4 20.3 23.2 26.1 29.0 34.8 42.6 48.7 54.8 63.8 70.2 76.6 82.9

14" W/ft 12.6 15.8 19.0 22.1 25.3 28.4 31.6 37.9 46.5 53.1 59.7 69.5 76.5 83.4 90.4

16" W/ft 14.3 17.9 21.5 25.1 28.7 32.3 35.9 43.0 52.7 60.2 67.8 78.9 86.8 94.6 102.5

18" W/ft 16.0 20.1 24.1 28.1 32.1 36.1 40.1 48.1 58.9 67.4 75.8 88.2 97.0 105.9 114.7

20" W/ft 17.7 22.2 26.6 31.0 35.4 39.9 44.3 53.2 65.1 74.4 83.7 97.5 107.2 117.0 126.7

22" W/ft 19.4 24.3 29.1 34.0 38.8 43.7 48.5 58.2 71.3 81.5 91.7 106.7 117.4 128.0 138.7

24" W/ft 21.1 26.4 31.6 36.9 42.2 47.4 52.7 63.2 77.5 88.5 99.6 115.9 127.5 139.1 150.7

1

/2" W/ft 1.1 1.4 1.7 2.0 2.2 2.5 2.8 3.5 4.1 4.7 5.5 6.2 6.8 7.4 8.0

3

/4" W/ft 1.2 1.6 1.9 2.2 2.5 2.8 3.1 3.9 4.6 5.2 6.1 6.8 7.5 8.2 8.9

1" W/ft 1.4 1.8 2.2 2.5 2.9 3.2 3.6 4.5 5.3 6.0 7.1 7.9 8.7 9.5 10.3

11/2" W/ft 1.8 2.3 2.8 3.2 3.7 4.1 4.6 5.8 6.8 7.7 9.1 10.1 11.1 12.1 13.2

2" W/ft 2.1 2.6 3.1 3.6 4.2 4.7 5.2 6.6 7.6 8.7 10.3 11.4 12.6 13.7 14.9

21/2" W/ft 2.4 3.0 3.5 4.1 4.7 5.3 5.9 7.4 8.7 9.9 11.7 13.0 14.3 15.6 16.9

3" W/ft 2.7 3.4 4.1 4.8 5.4 6.1 6.8 8.6 10.0 11.4 13.5 15.0 16.5 18.0 19.4

4" W/ft 3.3 4.2 5.0 5.8 6.6 7.5 8.3 10.5 12.2 13.9 16.4 18.3 20.1 21.9 23.7

6" W/ft 4.5 5.7 6.8 7.9 9.0 10.2 11.3 14.2 16.6 19.0 22.4 24.9 27.3 29.8 32.3

8" W/ft 5.6 7.1 8.5 9.9 11.3 12.7 14.1 17.8 20.7 23.7 27.9 31.0 34.1 37.2 40.3

10" W/ft 6.8 8.0 10.3 12.0 13.7 15.4 17.1 21.5 25.1 28.7 33.9 37.6 41.4 45.1 48.9

12" W/ft 8.0 10.0 12.0 14.0 16.0 18.0 20.0 25.2 29.4 33.6 39.6 44.0 48.4 52.8 57.2

14" W/ft 8.7 10.9 13.0 15.2 17.4 19.5 21.7 27.3 31.9 36.5 43.0 47.7 52.5 57.3 62.1

16" W/ft 9.8 12.3 14.8 17.2 19.7 22.1 24.6 31.0 36.2 41.3 48.7 54.1 59.5 64.9 70.4

18" W/ft 11.0 13.7 16.4 19.2 21.9 24.7 27.4 34.5 40.3 46.0 54.3 60.3 66.3 72.3 78.4

20" W/ft 12.1 15.1 18.1 21.1 24.2 27.2 30.2 38.1 44.4 50.7 59.8 66.4 73.1 79.7 86.4

22" W/ft 13.2 16.5 19.8 23.1 26.4 29.7 33.0 41.6 48.5 55.4 65.3 72.6 79.9 87.1 94.4

24" W/ft 14.3 17.9 21.5 25.1 28.6 32.2 35.8 45.1 52.6 60.1 70.9 78.8 86.6 94.5 102.4

in W/ft Based on Temperature Differential and Insulation Thickness

P

Temperature DifferenceBetween Pipe and Ambient

1" Insulation Thickness

1.5" Insulation Thickness

3.Calculate Q

calculate the estimated heat loss, Q

4.Correct for Indoor Location/ Wind Speed: If location is indoors, multiply Q

: Multiply the basic heat loss figure from Table 1 by the adjustment factor from Table 2 to

F

, in watts per foot of pipe length.

F

by 0.9. Table 1 is based on

F

10% safety factor and 20 mph wind speed; add 5% margin for each 5 mph over 20 mph wind speed.

Nominal

Pipe Size,

in. (ID)

DegºF 40ºF 50ºF 60ºF 70ºF 80ºF 90ºF 100ºF 120ºF 140ºF 160ºF 180ºF 200ºF 220ºF 240ºF 260ºF

1

/2" W/ft 1.0 1.2 1.4 1.7 1.9 2.2 2.4 3.0 3.5 4.0 4.8 5.3 5.8 6.3 7.2

3

/4" W/ft 1.1 1.4 1.6 1.9 2.2 2.4 2.7 3.4 4.0 4.5 5.3 5.9 6.5 7.1 8.1

1" W/ft 1.2 1.5 1.8 2.1 2.4 2.7 3.0 3.8 4.4 5.0 5.9 6.6 7.3 7.9 9.0

11/2" W/ft 1.5 1.9 2.3 2.7 3.0 3.4 3.8 4.8 5.6 6.4 7.5 8.4 9.2 10.0 11.4

2" W/ft 1.7 2.2 2.6 3.0 3.4 3.9 4.3 5.4 6.3 7.2 8.5 9.5 10.4 11.4 12.9

21/2" W/ft 1.9 2.4 2.9 3.4 3.8 4.3 4.8 6.0 7.1 8.1 9.5 10.6 11.6 12.7 14.4

3" W/ft 2.2 2.8 3.3 3.9 4.4 5.0 5.5 6.9 8.1 9.2 10.9 12.1 13.3 14.5 16.4

4" W/ft 2.6 3.3 4.0 4.6 5.3 5.9 6.6 8.3 9.7 11.1 13.1 14.5 16.0 17.4 19.7

6" W/ft 3.6 4.5 5.3 6.2 7.1 8.0 8.9 11.2 13.1 15.0 17.6 19.6 21.5 23.5 26.6

8" W/ft 4.4 5.6 6.7 7.8 8.9 10.0 11.1 14.0 16.3 18.6 22.0 24.4 26.9 29.3 33.2

10" W/ft 5.3 6.7 8.0 9.3 10.6 12.0 13.3 16.8 19.6 22.3 26.3 29.3 32.2 35.1 39.8

12" W/ft 6.2 7.8 9.3 10.9 12.4 14.0 15.5 19.5 22.8 26.0 30.7 34.1 37.5 40.9 46.3

14" W/ft 6.7 8.4 10.1 11.8 13.4 15.1 16.8 21.2 24.7 28.2 33.3 37.0 40.7 44.4 50.2

16" W/ft 7.6 9.5 11.3 13.2 15.1 17.0 18.9 23.8 27.8 31.8 37.4 41.6 45.7 49.9 56.5

18" W/ft 8.4 10.5 12.6 14.7 16.8 18.9 21.0 26.5 30.9 35.3 41.6 46.2 50.8 55.4 62.8

20" W/ft 9.2 11.6 13.9 16.2 18.5 20.8 23.1 29.1 34.0 38.8 45.7 50.8 55.9 61.0 69.1

22" W/ft 10.1 12.6 15.2 17.7 20.2 22.7 25.3 31.8 37.1 42.4 50.0 55.6 61.1 66.7 75.5

24" W/ft 11.0 13.7 16.4 19.2 21.9 24.7 27.4 34.5 40.3 46.0 54.3 60.3 66.3 72.3 81.9

609.6 mm W/m 36.1 44.9 53.8 63.0 71.9

1

/2" W/ft 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.5 2.9 3.4 4.0 4.4 4.8 5.5 6.0

3

/4" W/ft 0.9 1.1 1.3 1.5 1.8 2.0 2.2 2.8 3.2 3.7 4.4 4.8 5.3 6.1 6.67

1" W/ft 1.0 1.3 1.5 1.8 2.0 2.3 2.5 3.2 3.7 4.2 5.0 5.5 6.1 6.9 7.5

11/2" W/ft 1.2 1.5 1.8 2.1 2.4 2.7 3.0 3.8 4.4 5.0 5.9 6.6 7.3 8.3 9.0

2" W/ft 1.3 1.7 2.0 2.3 2.6 3.0 3.3 4.2 4.9 5.5 6.5 7.3 8.0 9.1 9.9

21/2" W/ft 1.5 1.9 2.2 2.6 3.0 3.3 3.7 4.7 5.4 6.2 7.3 8.1 9.0 10.2 11.1

3" W/ft 1.7 2.1 2.5 2.9 3.4 3.8 4.2 5.3 6.2 7.1 8.3 9.2 10.2 11.6 12.6

4" W/ft 2.0 2.5 3.0 3.5 4.0 4.5 5.0 6.3 7.4 8.4 9.9 11.0 12.1 13.8 15.0

6" W/ft 2.6 3.3 3.9 4.6 5.2 5.9 6.5 8.2 9.6 10.9 12.9 14.3 15.7 17.9 19.4

8" W/ft 3.2 4.0 4.8 5.6 6.4 7.2 8.0 10.1 11.8 13.4 15.8 17.6 19.4 22.1 23.9

10" W/ft 3.8 4.8 5.7 6.7 7.6 8.6 9.5 12.0 14.0 16.0 18.8 20.9 23.0 26.2 28.4

12" W/ft 4.4 5.5 6.5 7.6 8.7 9.8 10.9 13.7 16.0 18.3 21.6 24.0 26.4 30.1 32.6

14" W/ft 4.7 5.9 7.1 8.3 9.4 10.6 11.8 14.9 17.3 19.8 23.4 26.0 28.6 32.6 35.3

16" W/ft 5.3 6.7 8.0 9.3 10.6 12.0 13.3 16.8 19.6 22.3 26.3 29.3 32.2 36.7 39.8

18” W/ft 5.9 7.4 8.8 10.3 11.8 13.2 14.7 18.5 21.6 24.7 29.1 32.3 35.6 40.6 44.0

20" W/ft 6.4 8.1 9.7 11.3 12.9 14.5 16.1 20.3 23.7 27.0 31.9 35.4 39.0 44.4 48.1

22" W/ft 7.0 8.8 10.5 12.3 14.0 15.8 17.5 22.1 25.7 29.4 34.7 38.5 42.4 48.3 52.3

24" W/ft 7.6 9.5 11.3 13.2 15.1 17.0 18.9 23.8 27.8 31.8 37.4 41.6 45.7 52.2 56.5

Temperature Difference Between Pipe and Ambient

2" Insulation Thickness

3" (76.2 mm) Insulation Thickness

3” Insulation Thickness

Table 2

Insulation Adjustment Factors

B

Chromalox Cable Selection

1.Select Heating Cable Family: Based on the maximum maintenance temperature rating, maximum

exposure temperature rating, and area classification, select the heating cable family from Table 3. (See

Chromalox Heat Trace Cable Product Information Sheets for cable construction options, voltage ratings,

and wattage outputs available.)

2.Select Thermal Output Rating:

(a) For Metal Pipes – Use Figures 1, 2 or 4

(b) For Plastic Pipes – Use Figure 3 by finding the intersection of the calculated heat loss, Q

maintenance temperature, Tm. Select the cable with a thermal output that equals or exceeds QFat Tm.

Table 3

Heating Cable

Family

SRL

(Self-Regulating

Low Temperature)

SRM/E

(Self-Regulating

Medium

Temperature)

SRP

(Self-Regulating

Medium

Temperature)

HSRL

(H-Self-Regulating

Low Temperature)

HSRM

(H-Self-Regulating

Medium

Temperature)

CWM

(ConstantWattage)

MI (Mineral

Insulated)

NOTE: It is the responsibility of the facility manager or engineer to determine the classification of an area where heat trace will be installed. The factory can help determine a suitable

cable based on the information provided.

Figure 1

Heating Cable Families

Area

Classification

Ordinary

Class I, Div.2, Gr. B, C, D CSA, FM, (Gr.A, CSA Only) GOST, Cenelec,CE, ATEX

Class II, Div.2, Gr. E, F,G CSA, FM, (Gr. E, CSA Only) GOST, Cenelec,CE

Class III, Div.2 FM Only GOST,Cenelec,CE, ATEX

Ordinary

Class I Div.2, Gr. A, B, C, D CSA, FM, (Gr.A, CSA Only) GOST, Cenelec,CE, ATEX

Class II, Div.2, Gr. F, G CSA Only GOST,Cenelec,CE, ATEX

Ordinary

Class I, Div.2, Gr. B, C, D

Class II, Div.2, Gr. F, G

Class III

Class I, Div.1, Gr. B, C, D

Class II, Div.1, Gr. E, F,G CSA, FM

Class III, Div.1 CSA, FM

Class I, Div.1, Gr. B, C, D

Class II, Div.1, Gr. E, F,G CSA, FM

Class III, Div.1 CSA, FM

Ordinary

HazardousArea, Consult Factory

Ordinary

Class I, Div.2, Gr. B, C, D CSA, FM

Class II, Div.2, Gr. E, F,G CSA, FM

Class III CSA, FM

Pipe

Material

Plastic/Metal 150ºF / 65ºC 185ºF / 85ºC

Metal Only 302ºF / 150ºC 420ºF / 215ºC

Metal Only 225ºF / 110ºC 275ºF / 135ºC

Plastic/Metal 150ºF / 65ºC 185ºF / 85ºC

Metal Only 302ºF / 150ºC 420ºF / 215ºC

Metal Only Consult Factory 392ºF / 200ºC

Metal Only Consult Factory 1,100ºF / 595ºC

Maximum

Maintenance

Temperature

SRL & HSRL – Thermal Output

Ratings on Insulated Metal Pipe

Maximum Exposure

Temperature

(Power Off)

Figure 2

U.S. Other

UL, CSA, FM GOST, Cenelec,CE, ATEX

UL, CSA, FM GOST, Cenelec,CE, ATEX

UL, CSA, FM

Pending

CSA, FM

CSA, FM

UL, CSA

CSA, FM

SRM/E & HSRM – Thermal Output

Ratings on Insulated Metal Pipe

, and pipe

F

Approvals

GOST,Cenelec,CE, ATEX

Pending

3.Determine Total Cable Length: In addition to pipe length, in-line components such as valves, flanges,

and pipe supports require additional heat tracing to maintain T

cable length required by combining the pipe length with the additional lengths needed for all the

other components.

Additional Cable Lengths Required for In-Line Components

Globe Valve

on Pipe Size)

Ball Valve

Butterfly Valve

ft

Table 4

Piping Size

1

in. 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.30

2

/

3

in. 1.50 1.00 1.00 1.00 1.50 1.00 1.00 0.30

4

/

1 in. 2.00 1.00 1.00 1.00 1.50 1.00 1.00 0.30

1

1

in. 2.50 1.50 1.50 1.50 2.00 2.00 2.00 0.30

2

/

2 in. 2.50 2.00 2.00 2.00 2.00 2.00 2.00 0.30

1

2

in. 2.50 2.00 2.00 2.00 2.00 2.00 2.00 0.30

2

/

3 in. 3.00 2.50 2.50 2.50 2.00 2.00 2.00 0.50

4 in. 4.00 3.00 3.00 3.00 2.50 2.50 2.50 0.50

6 in. 5.00 3.50 3.50 3.50 2.50 2.50 2.50 0.80

8 in. 7.00 4.00 4.00 4.00 2.50 2.50 2.50 0.80

10 in. 8.00 4.50 4.50 4.50 3.00 3.00 3.00 0.80

12 in. 9.00 5.00 5.00 5.00 3.00 3.00 3.00 0.80

14 in. 10.00 5.50 5.50 5.50 3.00 3.00 3.00 1.00

16 in. 11.00 6.00 6.00 6.00 3.50 3.50 3.50 1.00

18 in. 12.00 7.00 7.00 7.00 3.50 3.50 3.50 1.00

20 in. 13.00 7.50 7.50 7.50 3.50 3.50 3.50 1.00

22 in. 13.00 7.50 7.50 7.50 3.50 3.50 3.50 1.00

24 in. 15.00 8.00 8.00 8.00 4.00 4.00 4.00 1.00

Figure 3

Based on Pipe IPS (Ir

Gate Valve

SRL & HSRL – Thermal Output Ratings

on Plastic Pipe with Aluminum Tape

. See Table 4. Calculate the total

m

Shoe Support

Figure 4

Hanger Support

SRP – Thermal Output Ratings

on Insulated Metal Pipe

Sleeper Support

Flange Pair

Page 3

Metallic Pipe

Fiberglass Tape

FT-3

Self Regulating

Heating Cable

• Low Temperature

SRL, HSRL, SRF

• Medium Temperature

SRM/E, SRP, HSRM

Self Regulating

Heating Cable

• Low Temperature

SRL, HSRL, SRF

• Medium Temperature

SRM/E, SRP, HSRM

Fiberglass Tape

FT-3

For multiple heaters place

control sensor 90˚ from nearest

heater or centered between

equally spaced heaters.

Control

Sensor

45˚

Thermal

Insulation

Top

Weatherproof

Jacket

Cable located at nominal

45˚ below horizontal

centerline.

Cable located at nominal

45˚ below horizontal

centerline on either side.

45˚

Top

90˚

Top

45˚

Heating Cable/Sensor Location

Self Regulating

Heating Cable

• Low Temperature

SRL, HSRL, SRF

• Medium Temperature

SRM/E, SRP, HSRM

Pipe Support

3 in. / 75 mm Typical

Metal Pipe

Support Shoe

Fiberglass Tape

FT-3

Step 1

Step 2

Self Regulating Heating Cable

• Low Temperature SRL, HSRL, SRF

• Medium Temperature SRM/E, SRP, HSRM

Metallic Pipe

Weatherproof Jacket

Thermal Insulation

Fiberglass Tape

FT-3

Self Regulating

Heating Cable

• Low Temperature

SRL, HSRL, SRF

• Medium Temperature

SRM/E, SRP, HSRM

Step 1

Start tracing at the end of the pipe and work your way back to spool.

Step 3

Metal Pipe

Spool

Metal Pipe

Self Regulating Heating Cable

• Low Temperature

SRL, HSRL, SRF

• Medium Temperature

SRM/E, SRP, HSRM

Fiberglass Tape

FT-3

Fiberglass Tape

FT-3

Step 2

Leave a loop of cable at heat sinks such as

valves, pipe supports and flange sets. use

FT-3 fiberglass tape to secure cable to pipe

at 18 in. / 455 mm intervals.

Plastic

Pipe

Self Regulating

Heating Cable

• Use Low Temperature

SRL, HSRL, SRF Cable

Aluminum Tape

AL-1

Plastic Pipe Installation

Note: Aluminum tape must be used under or

over heating cable to spread heat transfer.

Fiberglass Tape

FT-3

Fiberglass Tape

FT-3

Heating Cable

Insulation

Pipe Strap

Caution

Labels

Ask about Chromalox Class 1 Div.1

Cables & Accessories as well as a full

line of High-Temperature Cables.

Copyright © 2002-2005, 2009-2012, Chromalox, Inc. All rights reserved.

Electric Heat Trace

Quick Install

Guide

Quick Install Guide is a specification

tool only. Always refer to proper

installation instructions when

installing heat trace cable.

CONTROL SYSTEMS

DTS-HAZ

Digital ThermoStat / Power Connection

Line- or Ambient-Sensing

UAS

Ambient-Sensing

UBC

Line-Sensing

• 0˚-225˚F / 0˚-107˚C

temperature rating

• 120-480 VAC, 22A

switching capability

• Freeze protection

applications

• 0˚-400˚F / 0˚-205˚C

set points

• 120-480 VAC, 22A

switching capability

• Freeze protection

applications

• Ordinary or hazardous areas

(Class 1, Division 2)

• -45˚-485˚F/-43˚-252˚C programmable

• 100-277 VAC, 30A SSR, soft start,

large LED display

• Freeze protection & process temperature

maintenance applications

Combination Single Point Temperature Controls &

Power Connection Boxes

• 1 to 4, 6 to 72 loops

• Fully wired. GFI, current, temperature,

and sensor alarm/monitoring

• Owner sensor mapping, soft start,

user-friendly touchscreen HMI

• Up to 40 loops

• Pre-wired and assembled

monitoring and distribution (saves

time on installation)

• Includes the Sentinel monitoring

system

Installation Tips

• Temporarily position cable on

pipe and equipment to ensure

proper distribution.

• Leave a loop of cable at heat

sinks such as valves, pipe

supports and flange sets. Use

FT-3 fiberglass tape to secure

cable to pipe at 18 in. / 455 mm

(nom) intervals using recommended method.

• Always observe minimum

bend radius.

Power Connection Box

(UPC)

Above Insulation

Cable End Seal

(UES)

Below Insulation

Cable End Seal

(RTES)

Multiple Entry

Connection

(UMC)

and sensor alarm/monitoring

t

s

Now suitable for

Class1,Division2areas!

Loading...

Loading...