Page 1

PN401

FXTH

161-051300-001

FEBRUARY, 2008

4

and

Installation, Operation

RENEWAL PARTS IDENTIFICATION

Chromalox

®

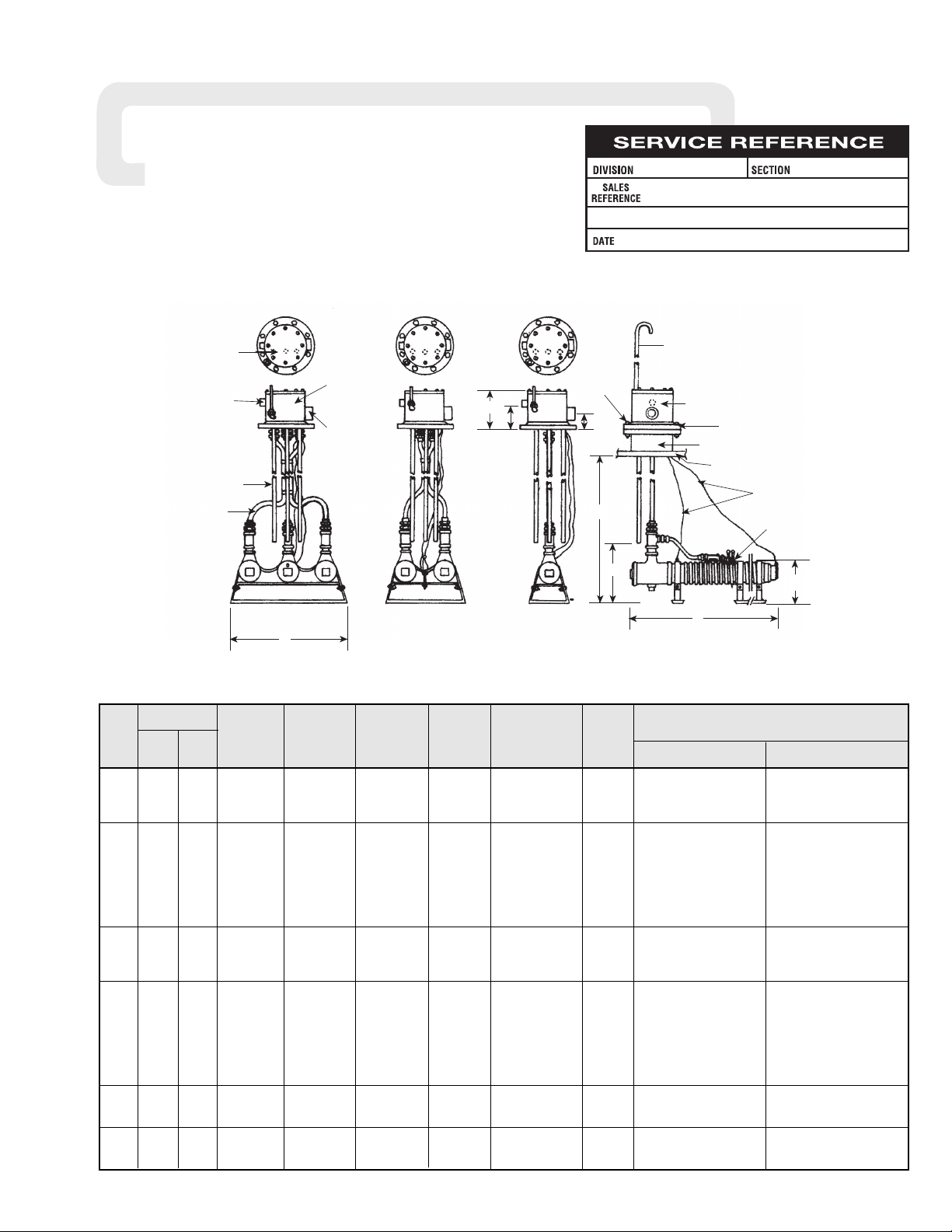

Chromalox Type FXTH Flexible Tank Heater

Amp / Tube

Catalog Number of Recommended

Minimum Heater Heater No. Tubes Approx

OCC or WCC Control Centers

Manhole Length Width and Catalog Net Wt.

kW 240 480 Size (In.) B C Circuits Number* Lbs. 240V 480V

*Suffix letters with FXTH Catalog Number indicate modification from standard as follows:

V= Voltage, W= Wattage, A= change in riser length, R= low temperature alarm contactor, D= temperature indicator and XX = special.

Thermowell

3/4” NPT

Thermowell

Riser

Three Tube

Heater Assembly

Two Tube

Heater Assembly

Single Tube

Heater Assembly

Heater

Terminal

Housing

2-1/2” NPT

6-1/4”

2”

Vent Tube

Notes:

1. Min. fluid Depth for safe heater operation is 12”.

2. 5/8” - 11 x 1 in. long hex head bolts. 8 required.

Heater Terminal Housing

Gasket (Furnished)

Manhole Adapter (Optional)

Customer Manhole Cover

Lifting Cables

Overtemperature

Sensor

C

9-3/16”

14’

B

8”

12”

Bolts. See

Note 2

6 15 7 14 12’3-3/4” 5-1/4 1 FXTH-11206 79 (OCC or WCC)-15-213 WCC-10-413

8 19 10 14 15’3-3/4” 5-1/4 1 FXTH-11508 97 WCC-25-213 WCC-10-413

10 24 12 14 15’3-3/4” 5-1/4 1 FXTH-11510 97 WCC-25-213 WCC-15-413

12 29 14 14 15’3-3/4” 5-1/4 1 FXTH-11512 97 WCC-30-213 WCC-15-413

10 24 12 14 20’3-3/4” 5-1/4 1 FXTH-12010 127 WCC-25-213 WCC-15-413

12 29 14 14 20’3-3/4” 5-1/4 1 FXTH-12012 127 WCC-30-213 WCC-15-413

15 36 18 14 20’3-3/4” 5-1/4 1 FXTH-12015 127 WCC-40-213 WCC-20-413

18 43 22 14 27’1” 5-1/4 1 FXTH-12718 170 WCC-45-213 WCC-25-413

21 51 25 14 30’1” 5-1/4 1 FXTH-13021 190 WCC-55-213 WCC-30-413

24 58 29 14 32’1” 5-1/4 1 FXTH-13224 205 WCC-60-213 WCC-30-413

27 65 33 14 35’1” 5-1/4 1 FXTH-13527 225 WCC-70-213 WCC-35-413

30 72 36 14 40’1” 5-1/4 1 FXTH-14030 250 WCC-75-213 WCC-40-413

12 15 7 18 12’3-3/4” 10-1/4 2 FXTH-21212 157 WCC-15-223 WCC-10-423

16 19 10 18 15’3-3/4” 10-1/4 2 FXTH-21516 194 WCC-25-223 WCC-10-423

20 24 12 18 15’3-3/4” 10-1/4 2 FXTH-21520 194 WCC-25-223 WCC-15-423

24 29 14 18 15’3-3/4” 10-1/4 2 FXTH-21524 194 WCC-30-223 WCC-15-423

20 24 12 18 20’3-3/4” 10-1/4 2 FXTH-22020 253 WCC-25-223 WCC-15-423

24 29 14 18 20’3-3/4” 10-1/4 2 FXTH-22024 253 WCC-30-223 WCC-15-423

30 36 18 18 20’3-3/4” 10-1/4 2 FXTH-22030 253 WCC-40-223 WCC-20-423

36 43 22 18 27’1” 10-1/4 2 FXTH-22736 340 WCC-45-223 WCC-25-423

42 51 25 18 30’1” 10-1/4 2 FXTH-23042 380 WCC-55-223 WCC-30-423

48 58 29 18 32’1” 10-1/4 2 FXTH-23248 405 WCC-60-223 WCC-30-423

54 65 33 18 35’1” 10-1/4 2 FXTH-23554 440 WCC-70-223 WCC-35-423

60 72 36 18 40’1” 10-1/4 2 FXTH-24060 500 WCC-75-223 WCC-40-423

18 15 7 24 15’3-3/4” 15-1/4 3 FXTH-31218 236 WCC-15-233 WCC-10-433

30 24 12 24 15’3-3/4” 15-1/4 3 FXTH-31530 291 WCC-25-233 WCC-15-433

36 29 14 24 15’3-3/4” 15-1/4 3 FXTH-31536 291 WCC-30-233 WCC-15-433

30 24 12 24 20’3-3/4” 15-1/4 3 FXTH-32030 370 WCC-25-233 WCC-15-433

36 29 14 24 20’3-3/4” 15-1/4 3 FXTH-32036 370 WCC-30-233 WCC-15-433

45 36 18 24 20’3-3/4” 15-1/4 3 FXTH-32045 370 WCC-40-233 (OCC or WCC)-20-433

© 2010 Chromalox, Inc.

Specifications – Type FXTH

Page 2

GENERAL

UNCRATING AND HANDLING OF HEATER

The Chromalox FXTH Flexible Tank Heater is designed for heating viscous liquids in large steel, concrete or fibrous glass tanks with

normal manhole entry. Standard equipment with every heater

includes flexible pipe and 14’ riser(s), two lifting cables, 4” high

sludge legs and a 50-250° non-indicating thermostat with well,

overtemperature probe and weatherproof terminal housing.

The Control Center OCC (NEMA XII, oil and dust-tight construction) or WCC (NEMA IV, weather-resistant construction) is

designed for controlling the temperature of the viscous liquids by regulating the FXTH's on-off cycle. It is mounted remotely with standard

components consisting of a NEMA XII or NEMA IV enclosure with

vertical wall mounted brackets and hasp and staple for padlocking.

Electrical components include: Failsafe overheat device, master circuit-breaker, contactor(s), relay(s), selector switch, pilot lights, fuses

and a 120-volt control circuit transformer.

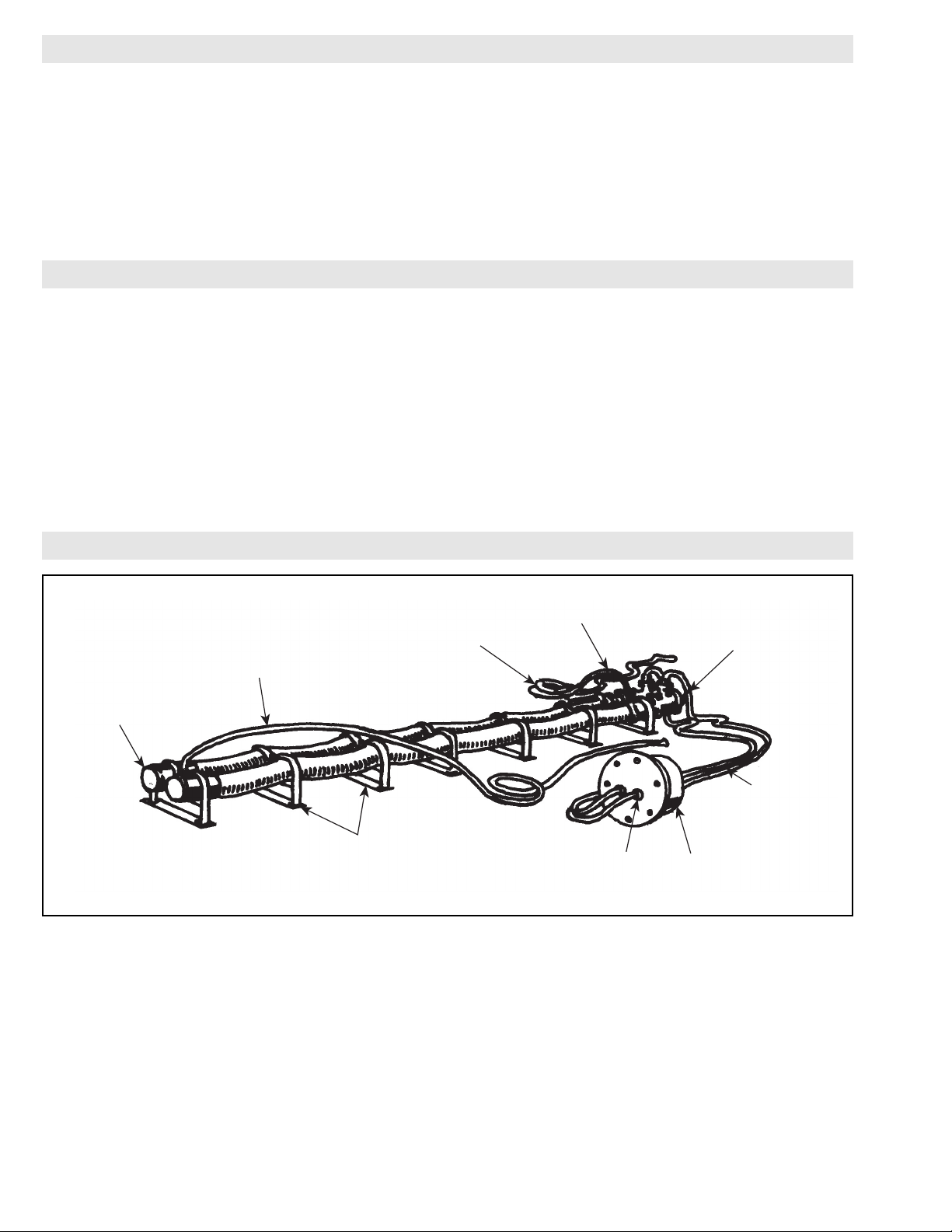

IMPORTANT-Before attempting to uncrate or install the FXTH

heater, read and understand all of the following instructions. Proper

handling is absolutely necessary to obtain satisfactory operation. All

electrical connections are to be made by a qualified electrician. To

avoid excessive separation, stratification, sludge formation, etc., in

your FXTH heated storage tank, consult a qualified oil supplier

regarding selection and blending of fuel oils.

Heater Front End

Front Lifting Cable

Overtemperature

Probes

Rear Lifting Cable

Heater

Back End

Flexible

Risers

Terminal Housing

Riser Unions

Sludge Leg Base Plates

1. Mechanical

The heater assembly has undergone a rigorous leak test just prior

to shipment from the factory. Visually inspect all joints and flex

tube surfaces to insure no mechanical damage has incurred during

shipping. Contact carrier if heater shows signs of damage. Do not

attempt to install heater if damage is evident. Do not attempt to

tighten or remove any of the threaded fittings in the flexible tube

assembly. If the sealing performed at the factory has been broken.

the unit must undergo another complete leak test supervised by an

Authorized Chromalox Serviceman before installing in tank.

2. Electrical

A. Open control unit cover and examine electrical components

for any damage which may have been incurred during shipment. Contact carrier and report any damage noted.

B. CAUTION: Retighten all electrical connections and mounted

components which may have loosened during shipment.

PRE·INSTALLATION CHECK OF HEATER

NOTE: Inspect shipping crates before opening. Contact the carrier if

damage is evident.

1. Check to see that all components are included. FXTH immersion

heaters are shipped as subassemblies consisting of (a) flexible

heater with riser tubes, (b) terminal housing, (c) thermowells and

vent tube, and (d) control unit (if ordered).

2. To unpack flexible heater, keep crate in upright and horizontal

position when removing heater. Only top boards of crate need to

be removed.

3. When lifting heater assembly, do not bend heater to radius less

than 22". Heaters should be flexed in vertical plane only. This is

a plane perpendicular to the sludge leg base plates. Bending in

horizontal plane can damage internal ceramic insulators.

4. Use several people to lift heater - the number depends on the

length and weight of the heater. As a guide, four men should be

used to lift and handle a dual tube 20 ft. unit.

5. Do not put any stress on the flexible riser tubes. These are not

designed for supporting weight. The unit must be lifted by either

the 3" heater tubes or the steel lifting cables furnished with heater

and located at both ends of heater. See Figure A.

6. Set heater in upright position on flat surface. Avoid any lateral

bending.

CAUTION: Never drop heater or subject it to mechanical shock.

Figure A

2

Page 3

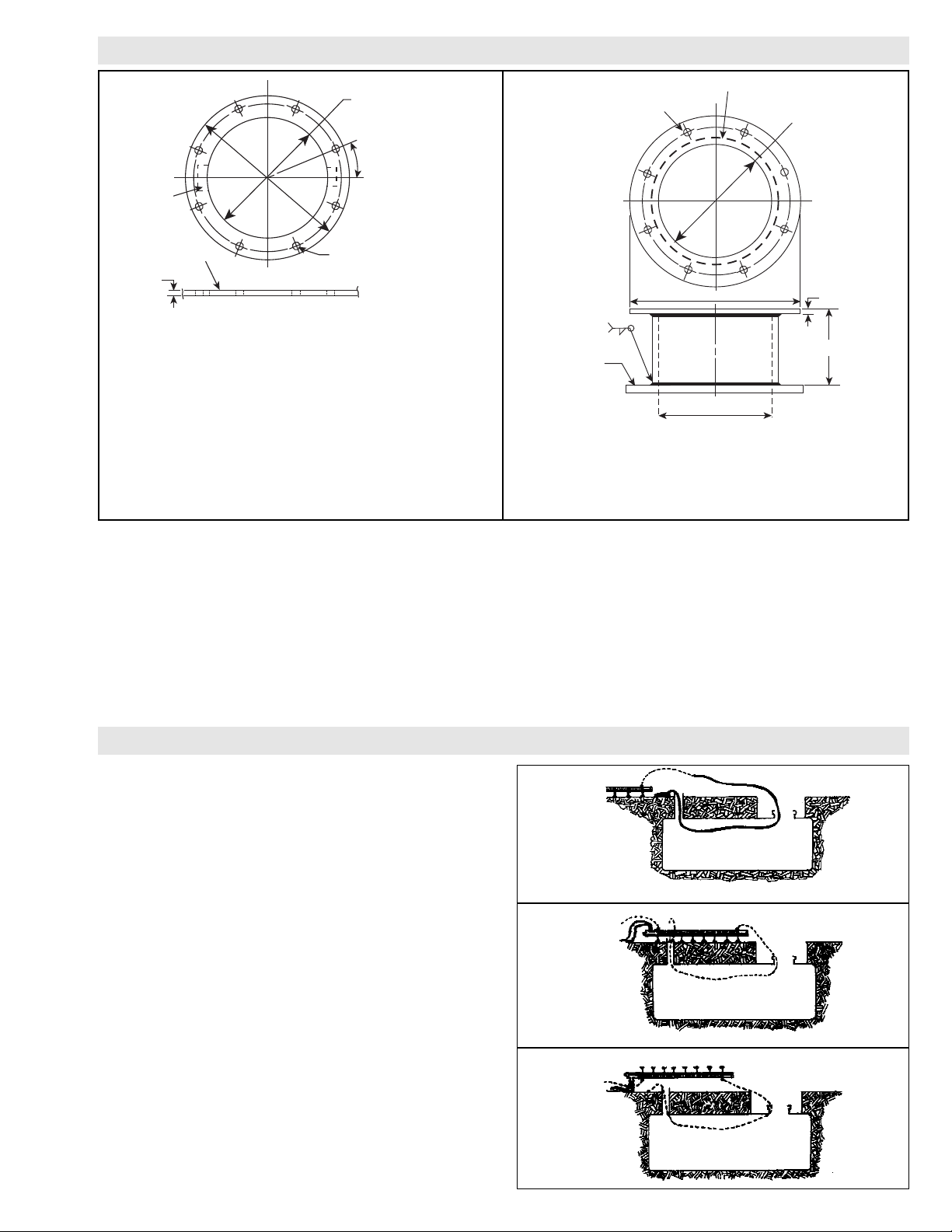

PREPARATION OF TANK TO RECEIVE HEATER

INSTALLATION OF HEATER ASSEMBLY IN TANK

Manhole Cover

3/8” Min.

8 - 3/8” - 11 Drilled and

Tapped Equally Spaced

Holes on 11-3/4” B.C.

22-1/2”

9-1/2” ± 1/4” Dia. Hole

By Customer

Conduit

Opening

13” Dia.

(See Note 1)

By Customer

Figure B

Figure C

Machining of Manhole Cover to Receive

FXTH Immersion Heater Terminal Box

1. Surface on top side of Tank Cover must be suitable for good gasket seating. The 13"

dia. area containing the gasket seat must be free of loose scale and rust and shall have

a maximum surface roughness of 250 RMS.

2. Bolt hole orientation to axis of storage tank is not important.

Machining of Manhole Cover to Receive

FXTH Immersion Heater Adapter Assembly

1. This Dimension is for Storage Tank Clearance Hole.

1. Double check internal dimensions of tank to be sure heater legs

will stand straight on portion of tank bottom to its full length

when in its operating position.

2. Remove any obstructions which may interfere with proper instal-

lation of heater into tank.

3. Clean manhole area to eliminate dirt and water which can be

picked up by heater during its insertion into tank.

4. Time the installation so oil level in tank is half full or less. This

will greatly facilitate insertion and positioning of heater.

5. Check sludge in bottom of tank to ensure it does not interfere with

operation of heater. Standard FXTH heaters are supplied with 4”

sludge legs. Sludge in excess of 3” must be removed before

installing heater. Sludge must not touch the corrugated heating

surface of the immersion unit.

6. Check point of tank suction to make sure it is 12” or more off bot-

tom of tank. This will insure a minimum liquid level of 12” and

prevent heater from being uncovered while in operation. The

heater must not be energized unless it is completely submerged.

7. Machine manhole cover per Figure B or install optional terminal

housing manhole adapter to manhole cover or storage tank per

Figure C. All welds must be liquid tight.

DANGER: Hazard of Fire. If adapter is to be welded directly into

tank, remove flammable liquids, and vent all combustible gases or

vapors from storage tank before performing welding operations.

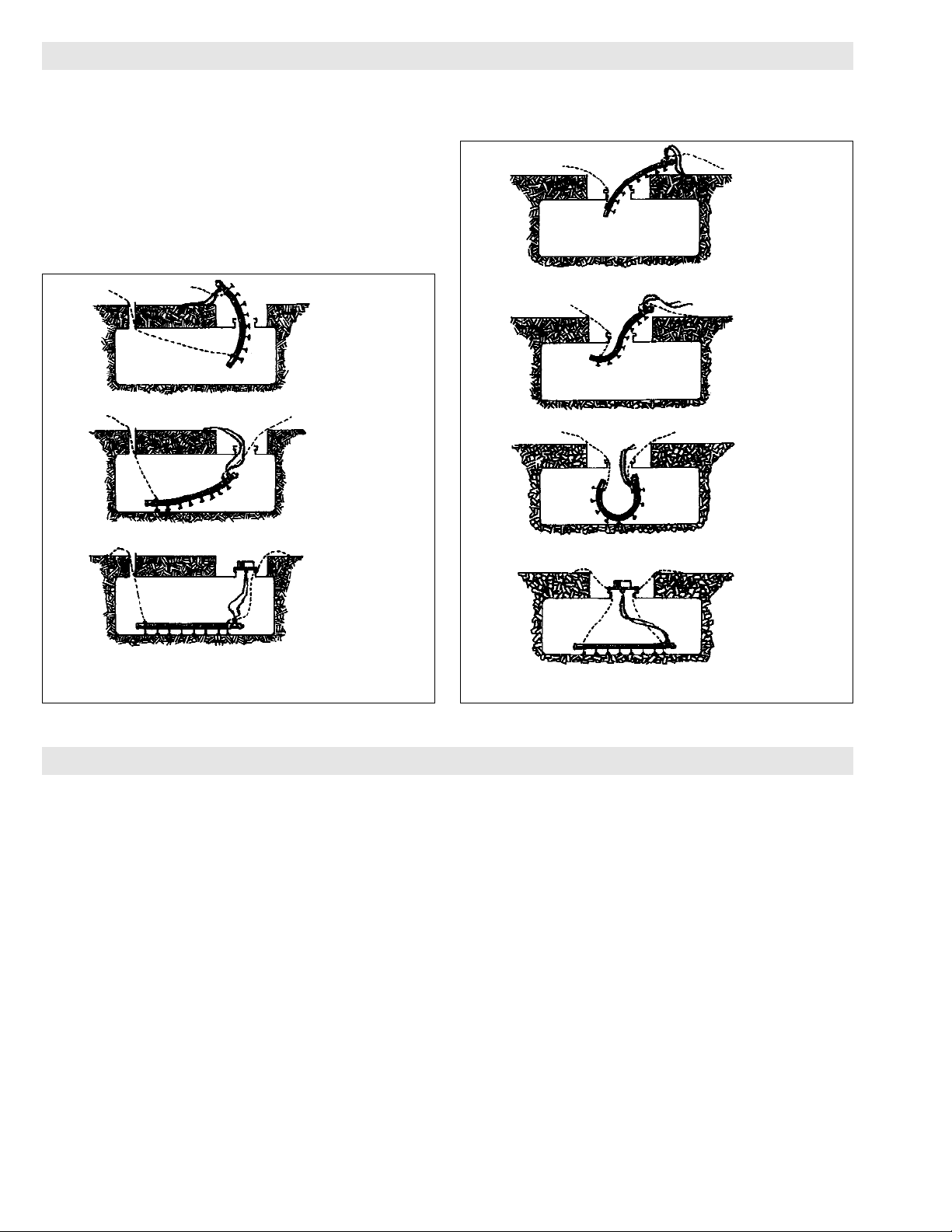

1. If tank is type with manhole located near end of tank rather than

in center, install a temporary pulling cable at far end of tank

through any available port such as (l) fill pipe, (2) suction port, (3)

auxiliary manhole, etc., and thread the cable through the tank and

out the manhole to be used for installing the heater. The pulling

cable will be used to pull front lifting cable through auxiliary port

and then pulling cable is disconnected. See Figure D.

2. Align heater assembly along centerline of tank having rear end

(riser end) of assembly farthest from manhole. Note: On tanks

with manhole near end rather than in center heater assembly

should be placed on side of manhole farthest from end of tank.

See Figure E.

3. Tie the riser(s) with rope or suitable line at a point just below the

union on riser(s). Anchor rope to any convenient nearby anchoring point. Length of rope should be sufficient to allow riser(s) to

be inserted into tank just inside manhole but not below oil level.

CAUTION: If oil gets into riser, it will cause failure of the heating element.

4. Carefully turn heater over, feet upward, taking care it is flexed in

only the one plane. (See Figure F.) Support must be maintained on

riser end of heater to avoid overstressing riser(s) until heater is

lowered into tank.

Manhole Cover Adapter Assy.

13-1/2” O.D.

8 - 3/8” - 11 Drilled and

Tapped Equally Spaced

Holes on 11-3/4” B.C.

3/4”

9-1/2” ± 1/4” Dia. Hole

By Customer

By Customer

1/4”

Manhole Cover

8”

9-1/4” ± 14” By Customer

Figure D

Figure E

Figure F

3

Page 4

INSTALLATION OF HEATER ASSEMBLY IN TANK (cont’d.)

5. Begin lowering heater into tank as per Figure G, Step 1 thru 3

(end manhole) or Figure H, Step 4 thru 7 (center manhole). Once

the heater has touched bottom, use pulling wire (front lifting

cable) to pull heater toward far end of tank.

6. Before lowering back end of heater, visually gage the remaining

length of heater to be laid down, to be certain an equal amount of

clearance is allowed at both ends of tank. Back end of heater is

lowered into place using rear lifting cable. CAUTION: NEVER

USE RISERS TO SUPPORT HEATER TUBES.

7. Where additional heater assemblies are to be installed in the same

manhole, follow same procedure, being careful not to interfere

with risers or cable on the initial heater.

NOTE: In tanks where the configuration does not allow following

the above procedure, or in above ground tanks, ask for Factory recommendations for installation of heater.

Figure G – Tanks with Manholes Near End

Step 1

Step 2

Step 3

Figure H – Tanks with Center Manhole

Step 4

Step 5

Step 6

Step 7

INSTALLATION OF FXTH TERMINAL HOUSING

A. Position manhole cover adjacent to manhole. Very carefully untie

rope from anchoring point and pass it through (1) manhole gasket,

(2) opening in manhole cover, and (3) terminal housing gasket.

Securely refasten rope to anchoring point. Do not allow riser

end(s) to fall into oil, or permanent damage will result to the

heater. Bolt down manhole cover using a suitable gasket sealant if

required to obtain water-tight seal.

B. Pull riser(s) upward into position next to terminal housing. Wrap

teflon tape on threaded riser connections and fasten into underside

of terminal housing. Unused connections on bottom of housing

will already contain flush plugs. Attach lifting cables to ring on

under side of terminal housing.

C. Bolt terminal housing to manhole cover or manhole cover

adapter, again using suitable gasket cement. If manhole cover is

machined per Figure B, be sure to install copper gasket washers

under bolt heads. Position housing so conduit connections are in

the most convenient position for your particular installation.

Connect all riser leads to terminals, following markers on wires

and terminals referring to wiring diagram Figure J.

D. Install power leads from terminal housing to control center. See

Specifications Table, Page I for amperages to determine wire and

conduit size as determined by the National Electric Code.

E. To install thermostat wells, insert closed end of the well into brass

fitting in bottom of terminal housing. Push well completely to

bottom of tank. A preliminary measurement from manhole level

to tank bottom will aid proper insertion. The well may first hit the

heater. It is then necessary to manipulate the well so that it will

glance off the rounded heater surface and extend to tank bottom.

Mark side of tube at the swage fitting and then pun upward several feet to working level. Using a tube cutter, cut the tube at a

point exactly 7” below the mark. Once the tube is cut, be extremely careful the tube is not allowed to drop through fitting and into

tank. Partially tighten fitting so this cannot happen. Position the

upper end of well 5” off top of tube fitting, then firmly tighten the

fitting. Insert bushing (located in shipping bag inside of terminal

housing) into top of well. This will prevent burrs on tube from

cutting the bulb or capillary of thermostat. Repeat this procedure

until all wells are installed. There can be as many as three wells;

(1) Thermostat, (2) Temperature Indicator, (3) Low Limit Alarm.

F. Install thermostat mounting plate. Make sure thermowells are

aligned with openings in plate and over-temperature leads from

riser are brought through plate. Fasten plate into position.

4

Page 5

INSTALLATION OF HEATER ASSEMBLY IN TANK (cont’d.)

G. Carefully unwind and straighten thermostat capillary tube. The

capillary must be reasonably straight. Be absolutely certain the

bulb is seated at bottom of well. Carefully coil any excess capillary and position next to thermostat and away from electrical connections. Repeat same procedure if low limit alarm is provided.

Attach wire for overtemperature sensor to terminals.

NOTE: Over-temperature control is located in the Chromalox

Control Center. If heater is supplied without control center, be

sure to obtain an over-temperature control for a positive thermistor, otherwise heater will be without over-temperature protection.

H. If the low temperature thermostat is being used, connect annunci-

ator leads directly to terminals on this thermostat and provide an

independent power source. The switch rating is; 20 amp @ 115V,

15 amp @ 230V, pilot duty 125VA.

I. If temperature indicator is employed, wire in accordance with

Figure J. Use wire size as recommended for connecting to control

center.

J. Install control wiring through 3/4" conduit connection as indicat-

ed on page 1. Leave lid off' terminal housing until operational

check is completed. Install breather tube on the outside of the terminal box as shown on page 1, Make sure top of tube is at least

12" above the drainage water level. CAUTION: All conduit connections to terminal housing must be sealed to prevent entry of

any water, water vapor or condensation into terminal housing.

Breather tube length may be cut to shorten height, or extended for

higher flood levels by using 3/8” compression tube coupling and

3/8” tubing, as desired between formed breather tube and elbow

fitting on side of terminal housing.

Temperature

Indicator (Optional)

Low Temp. Alarm

Contacts (Optional)

Non-Indicating

Temp. Control

4

Overtemp.

Probes

Terminal

Block

8

7

6

5

8

7

6

5

8

7

6

5

4

3

2

1

Terminal

Block

Overtemp.

Control

1CR

1CR

2 TDR

1 TDR

Heat

Htr. Contactor #1

#1 Time Delay Relay(15 Sec.)

#2 Time Delay Relay(30 Sec.)

Heat

Heater Contactor #2

Heat

Heater Contactor #3

Overtemp.

Control Relay

Power On

X2

X1

G

ISS

Off - On

Control

H4 H2

H3

H1

H4

H2

H3

H1 H4

H2

H3

H1

240V

480V

BL1

BL2

BL3

CL1

CL2

CL3

Ground

C3

C2

3

2

C1

1

AL1

AL2

AL3

Terminal

Blocks

Fuses

Circuit

Breaker

L1

L2

L3

IL3

IL2

IL1

1 TDR

2

3

2 TDR

1CR

A1

A2

Audible Alarm

(Optional)

Thermistors located on heater with leads in conduit riser.

One thremistor per heater tube.

1 Heater

3 Heaters

2 Heaters

1. Contactor “1 CON” and no fuses are supplied on single stage models.

2. Used on two stage models - fuses “3FU thru 8FU” - Contactor

“2 Con” - Time delay relay “1TDR” - Pilot light “3LT”.

3. Used on three stage models - fuses “3FU thru 11FU” - Contactor

“2 Con & 3 Con” - Time delay relay “1TDR & 2TDR” - Pilot

lights “3LT and 4LT”.

4. Termistor connections: Necessary Jumpers - Factory Wired

NOTES:

F8

F3

F4

F5

F6

F7

C3

R

A

C2

A

C1

A

F2

F1

F10

F11

F9

OCC & WCC Control Center

5

Figure J

Page 6

ELECTRICAL AND OPERATIONAL CHECKS

A. Having circuit breaker and power switch in “off” position, make

sure proper voltage supplied matches voltage of control panel and

elements.

B. Adjust controlling thermostat in terminal housing to a 50°F read-

ing. Increase setting until thermostat switch just “clicks”. This

setting is to be used for initial heater checkout.

C. Turn circuit breaker to “on” and note green power light coming

on. Turn on power switch and note first amber light will come on,

and then subsequent amber light(s) as explained in Section.

D. Observe control panel as heater goes through several heating

cycles. A cycle is determined when all amber lights are off. Cycle

interval can vary widely depending on amount of oil in tank.

However, the thermostat has been set to keep the cycle time to a

minimum.

E. Turn off circuit breaker and power switch, then re-set thermostat

to desired setting for normal operation. The thermostat contains a

factory adjusted stop which prevents settings above 150°F.

F. If low temperature alarm feature is provided, set this control 10°

to 15°F below the control thermostat setting.

G. Installation of terminal housing lid and gasket (with proper gasket

sealant) completes the check-out procedure.

H. If any difficulties are encountered during the installation and

check-out, call your local Chromalox Representative or

Chromalox Product Service.

INSTALLATION OF REMOTE CONTROL CENTER

CAUTION: Hazard of electric shock. Any installation involving

electric must be grounded to earth to eliminate shock hazard.

1. A safe maximum temperature limit on control cabinet compo-

nents is 125°F. Choose a mounting location not in direct sunlight

or exposed to any other source of excessive heat. If the panel must

be mounted in direct sun, a sun shield must be employed.

2. Install proper control and power wiring to control center as per

Figure J. Power lines are to be sized for the particular heater load.

Double check to insure proper grounding procedures have been

followed for heaters and control panel.

3. Available inside control panel are connections A and A1 which

provide for an over-temperature alarm; such as, horn, bell, etc., to

be mounted remotely as required. These terminals are rated at

50VA, 120V.

4. Electrical

A. CAUTION: Hazard of severe shock. Make sure circuit

breaker and panel switch are in “off” position.

B. Make knockouts in control cabinet which are desired for final

wiring installation.

C. Connect leads from riser(s) to identified terminals shown on

Figure J.

D. TEMPORARY WIRING TO SIMULATE ACTIVATION OF

CONTROL CIRCUIT.

1. Jumper terminals S to S

1

.

2. Connect overtemperature control leads to terminals 5, 6, 7

or 8 as shown on Figure J.

3. Connect green ground wire lead from riser(s) to grounding

lug in control box and from control box to a suitable

ground.

4. Connect power cable of proper voltage to input of control

box.

5. Secure control box door, then place circuit breaker in “on”

position and energize heater with panel switch. Start with

45 second time interval and increase until a definite rise in

temperature on each heater tube can be felt with the bare

hand. NOTE: Adjustable time delay(s) in multi-stage units

have been preset at factory to provide steps for energizing

individual circuits.

6. Observe green light (which indicates “power”) when clos-

ing circuit breaker, first amber light with panel switch "on"

and subsequent amber light(s) (if any) at approximately 15

second intervals.

7. Have qualified electrician, using an amprobe, check amper-

age in individual heater leads to insure uniform amperage.

8. Turn circuit breaker to “off” position and remove tempo-

rary jumper from terminals Sand S

1

6 240 15 1 OCC-15-213 WCC-15-213 24 20 8 64

8 240 25 1 OCC-25-213 WCC-25-213 24 20 8 65

12 240 30 1 OCC-30-213 WCC-30-213 24 20 8 65

15 240 40 1 OCC-40-213 WCC-40-213 24 20 8 66

18 240 45 1 OCC-45-213 WCC-45-213 30 24 8 89

21 240 55 1 OCC-55-213 WCC-55-213 30 24 8 91

24 240 60 1 OCC-60-213 WCC-60-213 30 24 8 91

27 240 70 1 OCC-70-213 WCC-70-213 30 24 8 96

30 240 75 1 OCC-75-213 WCC-70-213 30 24 8 96

12 240 15 2 OCC-15-223 WCC-15-223 30 24 8 84

16 240 25 2 OCC-25-223 WCC-25-223 30 24 8 86

24 240 30 2 OCC-30-223 WCC-30-223 30 24 8 86

30 240 40 2 OCC-40-223 WCC-40-223 30 24 8 91

36 240 45 2 OCC-45-223 WCC-45-223 42 30 8 126

42 240 55 2 OCC-55-223 WCC-55-223 42 30 8 128

48 240 60 2 OCC-60-223 WCC-60-223 42 30 8 128

54 240 70 2 OCC-70-223 WCC-70-223 42 30 8 135

60 240 75 2 OCC-75-223 WCC-75-223 42 30 8 135

18 240 15 3 OCC15-233 WCC-15-233 36 30 8 113

30 240 25 3 OCC-25-233 WCC-25-233 36 30 8 120

36 240 30 3 OCC-30-233 WCC-30-233 36 30 8 125

45 240 40 3 OCC-40-233 WCC-40-233 36 30 8 127

6 480 10 1 OCC-10-413 WCC-10-413 24 20 8 64

8 480 15 1 OCC-15-413 WCC-15-413 24 20 8 64

15 480 20 1 OCC-20-413 WCC-20-413 24 20 8 64

18 480 25 1 OCC-25-413 WCC-25-413 24 20 8 64

21 480 30 1 OCC-30-413 WCC-30-413 24 20 8 64

27 480 35 1 OCC-35-413 WCC-30-413 24 20 8 64

30 480 40 1 OCC-40-413 WCC-30-413 24 20 8 64

12 480 10 2 OCC-10-423 WCC-10-423 30 24 8 84

20 480 15 2 OCC-15-423 WCC-15-423 30 24 8 84

30 480 20 2 OCC-20-423 WCC-20-423 30 24 8 84

36 480 25 2 OCC-25-423 WCC-25-423 30 24 8 89

42 480 30 2 OCC-30-423 WCC-30-423 30 24 8 91

54 480 35 2 OCC-35-423 WCC-35-423 30 24 8 91

60 480 40 2 OCC-40-423 WCC-40-423 30 24 8 96

18 480 10 3 OCC-10-433 WCC-10-433 36 30 8 113

36 480 15 3 OCC-15-433 WCC-15-433 36 30 8 113

45 480 20 3 OCC-20-433 WCC-20-433 36 30 8 113

Catalog Number Dimensions

Max. No.

OCC WCC Inches

Approx.

Max. Amps Per of Dust and Oil Weatherproof Net Wt.

kW Volts Circuit Circuits Tight Models Models H W D Lbs.

Specifications – OCC and WCC Control Center (All Phases)

6

Page 7

OPTIONAL EQUIPMENT

Temperature Indicators (Suffix “D”)

(FXTH Heater Assembly and Control Center will have

suffix "D" e.g. FXTH-11206D, WCG15-213D)

MOUNTING

Temperature indicators are balanced for accurate reading in a normal

vertical position unless specified otherwise. All pyrometers labeled

"shielded meter" may be used in any type of panel with little or no

effect on calibration. Those labeled "non-magnetic" must be used

only on aluminum, plastic, wood or other non-magnetic panels. They

will read low if mounted in a steel panel. Pyrometers which are

labeled "magnetic" are intended for installation on steel panels. A

steel compensating ring is normally supplied where panel material is

not specified. Discard the ring when mounting on a steel panel. If the

pyrometer is used on a non-magnetic panel, the steel ring must be

used. Be sure the slit in the ring is at the top of the meter barrel and

the ring is pushed as far forward as it will go.

THERMOCOUPLE SELECTION AND CALIBRATION

Each pyrometer is marked on the dial with the type of thermocouple

and the total external resistance for which it is calibrated. Use of any

other type of thermocouple or one with a higher resistance than

marked will result in incorrect readings. (Type J thermocouples are

normally used.) All standard pyrometers are calibrated for 10 ohms

external thermocouple resistance and are provided with a 10 ohm calibrating resistor bobbin. (Non-standard pyrometers are usually calibrated for the specific external resistance ordered and no resistor bobbin is supplied.) This resistor bobbin must be adjusted so the total

resistance of the thermocouple and the bobbin add up to 10 ohms in

order to maintain calibration accuracy. Therefore, for a 5 foot, 20

gauge, iron-constantan thermocouple, the resistance of the thermocouple would be approximately 1.75 ohms and this resistance must be

subtracted from the calibrating bobbin. Each turn of the wire on the

resistor bobbin represents 0.5 ohms and for this example, 3-1/2 turns

would be removed. The total resistance of the thermocouple plus the

resistor bobbin would then add up to 10 ohms. For other values of

thermocouple resistance, simply remove more or less turns to adjust

for the total value of external resistance marked on the pyrometer

dial.

It is very important the resistor wire be properly soldered after

adjusting.

NOTE: When Thermocouples with external resistance higher than 10

ohms will be used, a special pyrometer will be required. The use of

other than thermocouple wire for leads or extensions may result in

improper ambient compensation.

ABBREVIATED TABLE OF THERMOCOUPLE RESISTANCE

The table lists the resistance in ohms per pair-foot for various types

of commonly used thermocouples for a number of different gauges of

wire. By using this table, it is necessary only to measure the length of

the thermocouple, knowing the type and gauge, to determine its

approximate resistance. (Actual measurement of the thermocouple

resistance is preferred to using the table.)

8 .0215 .0184 .0365

10 .0341 .0293 .0580

12 .0542 .0466 .0922

14 .0863 .0741 .1470

16 .1370 .1180 .2330

18 .2180 .1870 .3710

20 .3570 .2980 .5900

22 .5510 .4690 .9370

24 .8770 .7530 1.490

26 1.390 1.200 2.370

28 2:220 1.910 3.770

30 3.520 3.030 5.980

Ohms Per Pair - Foot

Iron/Constantan Copper/Constantan Chromel/Alumel

Gauge B & S (Type J) (Type T) (Type K)

CHROMALOX TYPE TMC 7-DAY TIMER

TMC 7-day Calendar, Electric Dial Timer is used to provide automatic start-up/off-on control of large tank heaters or could be set up

for non-peak operation. Standard features: 7-day calendar dial permits different on/off schedules on different days of week. 2 to 14

replaceable trippers for up to 4 on/off operations per day, up to 28

on/off operations per week. 3 hour minimum on or off time; 21 hour

maximum on or off time. Independent 4-pole design allows SPST,

DPST, SPDT, switching. Manual on/off lever transfers switch operation without disturbing daily or weekly preset schedule. Heavy duty

synchronous motor suitable for operation between -40°F and +140°F.

Switch slider bar assures positive switching. Heavy duty terminals

accommodate up to AWG No.8 wire.

OPERATION

“Off” Setting - de-energizes the entire zone control circuit, thus de-

energizing all heating-cooling equipment in the zone. This setting can

be used for extended summer shutdowns, etc.

“Automatic” Setting - allows the Day-Night Clock Panel to cycle

the control system according to the program clock dial tripper settings.

To Set Trippers - Refer to picture for typical setup of a Seven Day

Program. Two trippers must be used for each day; an “A” tripper for

switching from “Night Setback” to “Day Operation” and a “B” tripper for switching from “Day Operation” to “Night Setback”.

CAUTION: To set the correct day and time at beginning of initial

start-up, ROTATE THE PROGRAM CLOCK DIAL CLOCKWISE

ONLY. DO NOT ATTEMPT TO TURN POINTER!

Adjusting and Maintenance of Time Switch:

1. Periodically check trippers to insure that they are tightly fastened

to Program Clock dial. CAUTION: TIGHTEN TRIPPERS WITH

FINGERS ONLY!

2. Rotate Program Clock dial CLOCKWISE one hour in Spring to

adjust for daylight saving time (in areas where required). In Fall,

carefully rotate clock dial CLOCKWISE approximately one full

turn to reset at correct day and time for standard time. Check all

trippers to insure they have not moved during rotation.

3. The Program Clock motor is permanently lubricated. Lubrication

of other parts is not required.

4. The Program Clock switch contacts are factory set and need no

field adjustment.

4 Pole

TMC71 311-057070-001 Seven Day 120 2 N.O. 40

2 N.C.

Renewal Volts

Model Part No. Operation 60 Hz Switch Amps

7

Page 8

FXTH-11206 6 063-115244-004 063-115244-002

FXTH-11508 8 063-115244-003 063-115244-004

FXTH-11510 10 063-115244-005 063-115244-006

FXTH-11512 12 063-115244-009 063-115244-010

FXTH-12010 10 063-115244-007 063-115244-008

FXTH-12012 12 063-115244-011 063-115244-012

FXTH-12015 15 063-115244-013 063-115244-014

FXTH-12718 18 063-115244-015 063-115244-016

FXTH-13021 21 063-115244-017 063-115244-018

FXTH-13224 24 063-115244-019 063-115244-020

FXTH-13527 24 063-115244-021 063-115244-022

FXTH-14030 30 063-115244-023 063-115244-024

FXTH-21212 12 063-115244-001 (2) 063-115244-002 (2)

FXTH-21516 16 063-115244-003 (2) 063-115244-004 (2)

FXTH-21520 20 063-115244-005 (2) 063-115244-006 (2)

FXTH-21524 24 063-115244-009 (2) 063-115244-010 (2)

FXTH-22020 20 063-155244-007 (2) 063-115244-008 (2)

FXTH-22024 24 063-115244-011 (2) 063-115244-012 (2)

FXTH-22030 30 063-115244-013 (2) 063-115244-014 (2)

FXTH-22736 36 063-115244-015 (2) 063-115244-016 (2)

FXTH-23042 42 063-115244-017 (2) 063-115244-018 (2)

FXTH-23248 48 063-115244-019 (2) 063-115244-020 (2)

FXTH-23554 54 063-115244-021 (2) 063-115244-022 (2)

FXTH-24060 60 063-115244-023 (2) 063-115244-024 (2)

FXTH-31218 18 063-115244-001 (3) 063-115244-002 (3)

FXTH-31530 30 063-115244-005 (3) 063-115244-006 (3)

FXTH-31536 36 063-115244-009 (3) 063-115244-010 (3)

FXTH-32030 30 063-115244-007 (3) 063-115244-008 (3)

FXTH-32036 36 063-115244-011 (3) 063-115244-012 (3)

FXTH-32045 45 063-115244-013 (3) 063-115244-014 (3)

240 Voltage 480

Catalog No. kW Element Part Number Element Part Number

RENEWAL PARTS IDENTIFICATION

REPLACEMENT PARTS FOR OCC AND WCC CONTROL CENTER

What the Catalog Number means:

FXTH – 2 12 12 WCC – 10 - 423

1 2 3 4 1 2 345

1 – Flexible Tank Heater 1 – OCC - Oil Tight & Dust Tight Control Center

2 – Number of Tubes WCC - Weatherproof Control Center

3 – “B” Dimension 2 – Maximum Amperage per Circuit

4 – kW Rating 3 – Maximum Voltage 2 - 240, 4 - 480, 6 - 600

4 – Number of Circuits

5 – Phase

-----------------------------------------------------------------------------------------------------------------------------------------

Modified FXTH Standard Heater (FXTH-32036A)

Voltage................................................V Wattage.........................................W

Change in Riser Length......................................................................................A

Low Temp. Alarm Contacts ................................................................................R

Temperature Indicator.........................................................................................D

WCC

Voltage .............................................................................................................V

Audible Alarm .................................................................................................H

Time Clock.......................................................................................................T

Temperature Indicator .....................................................................................D

All Others .....................................................................................................XX

Common Parts Part Number

Terminal Housing Manhole adapter.................................... 306-115694-001

Manhole adapter Flange ..................................................... 121-115692-001

Manhole adapter Housing................................................... 065-115693-001

Flange Gasket ..................................................................... 132-115515-001

Housing Gasket .................................................................. 132-113661-001

Thermostat ......................................................................... 300-115621-001

Thermocouple Probe .......................................................... 309-121168-001

Circuit Breaker Handle (150 Amps or less) ........................ 139-071820-000

Circuit Breaker Handle (151 Amps to 225 Amps)............... 139-071820-010

Pilot Light - Red ................................................................. 213-120816-005

Amber ............................................................................ 213-120816-001

Green ............................................................................ 213-120816-002

Plexiglass Window ............................................................. 207-121061-001

Alarm ................................................................................. 385-122101-001

Selector Switch (WCC only) ............................................... 292-120827-002

Selector Switch (OCC only) ................................................ 292-120827-001

Moto-gard Overtemp. Control ............................................ 300-115550-001

Control Relay 300V, 10A, 3 Pole......................................... 072-120451-001

Time Clock - 7-day ............................................................. 311-057070-001

Pyrometer........................................................................... 308-051161-001

NEMA - IV Seal on Circuit Breaker Handle ......................... 139-071820-013

Note: Number in ( ) indicates quantity of same part number used.

Qty. Description Part Number

OCC or WCC-10-413, 480V, 1-3ø, 6 & 8 kW

1 Circuit Breaker, 480V, 15 Amp, 3 pole........................104-071818-017

1 Contactor, 600V, 20 Amp, 3 pole................................072-120812-005

2 Fuses, 1/2 (F1 and F2) ...............................................128-114696-010

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-10-423, 480V, 2-3ø, 12 & 16 kW

1 Circuit Breaker, 480V, 25 Amp, 3 pole........................104-071818-019

2 Contactors, 600V, 20 Amp, 3 pole..............................072-120812-005

2 Fuses, FNQ 6/10 (F1 and F2)......................................128-114696-005

6 Fuses, KTK-15 (F3 thru F8) ........................................128-047763-002

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay........................................................311-115540-001

OCC or WCC-10-433, 480V, 3-3ø, 18 kW

1 Circuit Breaker, 480V, 30 Amp, 3 pole........................104-071818-020

3 Contactors, 600V, 20 Amp, 3 pole..............................072-120812-005

9 Fuses, KTK-15 (F3 thru F11) ......................................128-047763-002

1 Transformer 250VA ....................................................315-048507-024

2 Relay Time Delay........................................................311-115540-001

2 Fuse FNQ 6/10 (F1 and F2) ........................................128-114696-005

Qty. Description Part Number

OCC or WCC-15-213, 240V, 1-3ø, 6 kW

1 Circuit Breaker, 240V, 20 Amp, 3 pole........................104-071818-003

1 Contactor, 600V, 20 Amp, 3 pole................................072-120812-005

2 Fuses, FNQ 8/10 (F1 and F2)......................................128-114696-011

1 Transformer, 150VA ...................................................315-048507-018

OCC or WCC-15-223, 240V, 2-3ø, 12 kW

1 Circuit Breaker, 240V, 40 Amp, 3 pole........................104-071818-007

2 Contactors, 600V, 20 Amp, 3 pole ............................072-120812-005

2 Fuses, FNM8/10 (F1 and F2) .....................................128-114696-012

6 Fuses, KTK-20 (F3 thru F8) ........................................128-047763-002

1 Time Delay Relay........................................................311-115540-001

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-15-233, 240V, 3-3ø, 18 kW

1 Circuit Breaker, 240V, 60 Amp, 3 pole........................104-071818-010

3 Contactors, 600V, 20 Amp, 3 pole..............................072-120812-005

9 Fuses, KTK-20 ............................................................128-047763-002

1 Transformer, 250VA ...................................................315-048507-024

2 Time Delay Relay........................................................311-115540-001

2 Fuse FNM 1- 4/10.......................................................128-114696-013

8

Page 9

REPLACEMENT PARTS FOR OCC AND WCC CONTROL CENTER (cont’d.)

Qty. Description Part Number

OCC or WCC-15-413, 480V, 1-3ø, 10 & 12 kW

1 Circuit Breaker, 480V, 20 Amp, 3 pole........................104-071818-018

1 Contactor, 600V, 20 Amp, 3 pole................................072-120812-005

2 Fuses, FNQ 1/2 (F1 and F2)........................................128-114696-010

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-15-423, 480V, 2-3ø, 20 & 24 kW

1 Circuit Breaker, 480V, 40 Amp, 3 pole........................104-071818-022

2 Contactors, 600V, 20 Amp, 3 pole..............................072-120812-005

2 Fuses, FNQ 6/10 (F1 and F2)......................................128-114696-005

6 Fuses, KTK-20 (F3 thru F8) ........................................128-047763-003

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay........................................................311-115540-001

OCC or WCC-10-433, 480V, 3-3ø, 30 kW

1 Circuit Breaker, 480V, 50 Amp, 3 pole........................104-071818-024

3 Contactors, 600V, 20 Amp, 3 pole ............................ 072-120812-005

9 Fuses, KTK-20 (F3 thru F11) ......................................128-047763-002

1 Transformer, 250VA....................................................315-048507-024

2 Time Delay Relay........................................................311-115540-001

2 Fuses, FNQ 6/10 (F1 and F2)......................................128-114696-005

Qty. Description Part Number

OCC or WCC-25-233, 240V, 3-3ø, 30 kW

1 Circuit Breaker, 240V, 100 Amp, 3 pole......................104-071818-014

3 Contactors, 600V, 30 Amp, 3 pole ............................072-120812-005

9 Fuses, KTK-30 (F3 thru F11) ......................................128-047763-005

1 Transformer, 250VA....................................................315-048507-024

2 Time Delay Relay........................................................311-115540-001

2 Fuses, FNM 1- 4/10 (F1 and F2).................................128-114696-013

OCC or WCC-25-413, 480V, 1-3ø, 18 kW

1 Circuit Breaker, 480V, 30 Amp, 3 pole........................104-071818-020

1 Contactor, 600V, 30 Amp, 3 pole................................072-120812-001

2 Fuses, FNQ V2 (F1 and F2).........................................128-114696-010

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-25-423, 480V, 2-3ø, 36 kW

1 Circuit Breaker, 480V, 60 Amp, 3 pole........................104-071818-025

2 Contactors, 600V, 30 Amp, 3 pole..............................072-120812-001

2 Fuses, FNQ 4/10 (F1 and F2)......................................128-114696-010

6 Fuses, FRS-35 (F3 thru F8) ........................................128-121133-063

1 Transformer, 150VA ...................................................315-048507-018

1 Time Delay Relay........................................................311-115540-001

OCC or WCC-15-433, 480V, 3-3ø, 36 kW

1 Circuit Breaker, 480V, 70 Amp, 3 pole........................104-071818-026

3 Contactors, 600V, 20 Amp, 3 pole..............................072-120812-005

9 Fuses, KTK-20 (F3 thru F11) ......................................128-047763-003

1 Transformer, 250VA....................................................315-048507-024

2 Time Delay Relay .......................................................311-115540-001

2 Fuses, FNQ 6/10 (F1 and F2)......................................128-114696-005

OCC or WCC-30-213, 240V, 1-3ø, 12 kW

1 Circuit Breaker, 240V, 40 Amp, 3 pole .......................104-071818-007

1 Contactor, 600V, 30 Amp, 3 pole............................... 072-120812-005

2 Fuses, FNQ 8/10 (F1 and F2)......................................128-114696-011

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-20-413, 480V, 1-3ø, 15 kW

1 Circuit Breaker, 600V, 25 Amp, 3 pole........................104-071818-019

1 Contactor, 600V, 20 Amp, 3 pole................................072-120812-005

2 Fuses, FNQ V2 (F1 and F2).........................................128-114696-010

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-30-223, 240V, 2-3ø, 24 kW

1 Circuit Breaker, 240V, 80 Amp, 3 pole........................104-071818-012

2 Contactors, 600V, 30 Amp, 3 pole..............................072-120812-001

2 Fuses, FNM 8/10 (F1 and F2) .....................................128-114696-012

6 Fuses, FRN (F3 thru F8) .............................................128-121133-077

1 Time Delay Relay........................................................311-115540-001

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-20-423, 480V, 2-3ø, 30 kW

1 Circuit Breaker, 480V, 50 Amp, 3 pole........................104-071818-024

2 Contactors, 600V, 20 Amp, 3 pole..............................072-120812-005

2 Fuses, FNQ 6/10 (F1 and F2)......................................128-114696-005

6 Fuses, KTK-25 (F3 thru F8) ........................................128-047763-004

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay .......................................................311-115540-001

OCC or WCC-30-233, 240V, 3-3ø, 36 kW

1 Circuit Breaker, 600V, 125 Amp, 3 pole......................104-071818-045

3 Contactor, 600V, 30 Amp, 3 pole................................072-120812-005

9 Fuses, FRN 40 (F3 thru F11) ......................................128-121133-077

1 Transformer, 250VA....................................................315-048507-024

2 Relays, Time Delay .....................................................311-115540-001

2 Fuses, FNM 1- 4/10 (F1 and F2).................................128-114696-013

OCC or WCC-20-433, 480V, 3-3ø, 45 kW

1 Circuit Breaker, 480V, 70 Amp, 3 pole........................104-071818-026

3 Contactors, 600V, 20 Amp, 3 pole..............................072-120812-005

9 Fuses, KTK-25 (F3 thru F11) ......................................128-047763-004

1 Transformer, 250VA....................................................315-048507-024

2 Time Delay Relay .......................................................311-115540-001

2 Fuses, FNQ 6110 (F1 and F2).....................................128-114696-005

OCC or WCC-30-413, 480V, 1-3ø, 21 & 24 kW

1 Circuit Breaker, 480V, 40 Amp, 3 pole........................104-071818-022

1 Contactor, 600V, 30 Amp, 3 pole................................072-120812-001

2 Fuses, FNQ V2 (F1 and F2).........................................128-114696-010

OCC or WCC-25-213, 240V, 1-3ø, 3 & 8 & 10 kW

1 Circuit Breaker, 240V, 30 Amp, 3 pole........................104-071818-005

1 Contactor, 600V, 30 Amp, 3 pole................................072-120812-005

2 Fuses, FNQ 8/10 (F1 and F2)......................................128-114696-011

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-30-423, 480V, 2-3ø, 42 kW

1 Circuit Breaker, 480V, 70 Amp, 3 pole .......................104-071818-026

2 Contactor, 600V, 30 Amp, 3 pole................................072-120812-001

2 Fuses, FNQ 4/10 (F1 and F2)......................................128-114696-010

6 Fuses, FRS-40 (F3 thru F8) ........................................128-121133-064

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay....................................................... 311-115540-001

OCC or WCC-25-223, 240V, 2-3ø, 16 & 20 kW

1 Circuit Breaker, 240V, 70 Amp, 3 pole........................104-071818-011

2 Contactors, 600V, 30 Amp, 3 pole..............................072-120812-001

2 Fuses, FNM 8/10 (F1 and F2) .....................................128-114696-012

6 Fuses, KTK-30 (F3 thru F8) ....................................... 128-047763-005

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay........................................................311-115540-001

OCC or WCC-30-423, 480V, 2-3ø, 48 kW

1 Circuit Breaker, 480V, 80 Amp, 3 pole........................104-071818-027

2 Contactors, 600V, 30 Amp, 3 pole..............................072-120812-001

2 Fuses, FNQ 4/10 (F1 and F2)......................................128-114696-010

6 Fuses, FRS-45 (F3 thru F8) ........................................128-121133-065

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay........................................................311-115540-001

9

Page 10

REPLACEMENT PARTS FOR OCC AND WCC CONTROL CENTER (cont’d.)

Qty. Description Part Number

OCC or WCC-35-413, 480V, 1-3ø, 27 kW

1 Circuit Breaker, 480V, 45 Amp, 3 pole........................104-071818-023

1 Contactor, 600V, 60 Amp, 3 pole................................072-120812-002

2 Fuses, FNQ V2 (F1 and F2).........................................128-114696-010

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-35-423, 480V, 2-3ø, 54 kW

1 Circuit Breaker, 480V, 90 Amp, 3 pole .......................104-071818-028

2 Contactors, 600V, 60 Amp, 3 pole..............................072-120812-002

2 Fuses, FNQ 4/10 (F1 and F2)......................................128-114696-010

6 Fuses, FRS-50 (F3 thru F8) ........................................128-121133-066

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay........................................................311-115540-001

OCC or WCC-40-213, 240V, 1-3ø, 15 kW

1 Circuit Breaker, 240V, 50 Amp, 3 pole........................104-071818-009

1 Contactor, 600V, 60 Amp, 3 pole............................... 072-120812-002

2 Fuses, FNQ 8/10 (F1 and F2)......................................128-114696-011

1 Transformer, 150VA....................................................315-048507-018

Qty. Description Part Number

OCC or WCC-55-213, 240V, 1-3ø, 21 kW

1 Circuit Breaker, 240V, 70 Amp, 3 pole........................104-071818-011

1 Contactor, 600V, 60 Amp, 3 pole................................072-120812-002

2 Fuses, FNQ 8/10 (F1 and F2)......................................128-114696-011

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-55-223, 240V, 2-3ø, 42 kW

1 Circuit Breaker, 600V, 150 Amp, 3 pole .....................104-071818-046

2 Contactors, 600V, 60 Amp, 3 pole..............................072-120812-002

2 Fuses, FNM 8/10 (F1 and F2) .....................................128-114696-012

6 Fuses, FRN-70 (F3 thru F8) .......................................128-121133-081

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay .......................................................311-115540-001

OCC or WCC-60-213, 240V, 1-3ø, 24 kW

1 Circuit Breaker, 240V, 80 Amp, 3 pole........................104-071818-012

1 Contactor, 600V, 60 Amp, 3 pole................................072-120812-002

2 Fuses, FNQ 8/10 (F1 and F2)......................................128-114696-011

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-40-223, 240V, 2-3ø, 30 kW

1 Circuit Breaker, 240V, 100 Amp, 3 pole......................104-071818-014

2 Contactors, 600V, 60 Amp, 3 pole..............................072-120812-002

2 Fuses, FNM 1- 4/10 (F1 and F2).................................128-114696-013

6 Fuses, FRN-45 (F3 thru F8)........................................128-121133-078

1 Time Delay Relay........................................................311-115540-001

1 Transformer, 250VA....................................................315-048507-024

OCC or WCC-60-223, 240V, 2-3ø, 48 kW

1 Circuit Breaker, 600V, 150 Amp, 3 pole......................104-071818-046

2 Contactors, 600V, 60 Amp, 3 pole..............................072-120812-002

2 Fuses, FNM 8/10 (F1 and F2) .....................................128-114696-012

6 Fuses, FRN-80 (F3 thru F8)........................................128-121133-082

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay........................................................311-115540-001

OCC or WCC-40-233, 240V, 3-3ø, 45 kW

1 Circuit Breaker, 600V, 150 Amp, 3 pole .....................104-071818-046

3 Contactors, 600V, 60 Amp, 3 pole ........................... 072-120812-002

9 Fuses, FRN 45 (F3 thru F11) ......................................128-121133-078

1 Transformer, 250VA....................................................315-048507-024

2 Time Delay Relay .......................................................311-115540-001

2 Fuses, FNM 1-4/10 (F1 and F2)..................................128-114696-013

OCC or WCC-70-213, 240V, 1-3ø, 27 kW

1 Circuit Breaker, 240V, 90 Amp, 3 pole........................104-071818-013

1 Contactor, 600V, 100 Amp, 3 pole..............................072-120812-003

2 Fuses, FNQ 8/10 (F1 and F2)......................................128-114696-011

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-40-413, 480V, 1-3ø, 30 kW

1 Circuit Breaker, 480V, 50 Amp, 3 pole........................104-071818-024

1 Contactor, 600V, 60 Amp, 3 pole................................072-120812-002

2 Fuses, FNQ 1/2 (F1 and F2)........................................128-114696-010

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-70-223, 240V, 2-3ø, 54 kW

1 Circuit Breaker, 600V, 175 Amp, 3 pole .....................104-071819-019

2 Contactors, 600V, 100 Amp, 3 pole ..........................072-120812-003

2 Fuses, FNM 1-1/8 (F1 and F2)....................................128-114696-020

6 Fuses, FRN-90 (F3 thru F8)........................................128-121133-083

1 Transformer, 250VA....................................................315-048507-024

1 Time Delay Relay........................................................311-115540-001

OCC or WCC-40-423, 480V, 2-3ø, 60 kW

1 Circuit Breaker, 480V, 100 Amp, 3 pole......................104-071818-029

2 Contactors, 600V, 60 Amp, 3 pole..............................072-120812-002

2 Fuses, FNQ 4/10 (F1 and F2)......................................128-114696-010

6 Fuses, FRS-35 (F3 thru F8) ........................................128-121133-063

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay........................................................311-115540-001

OCC or WCC-75-213, 240V, 1-3ø, 30 kW

1 Circuit Breaker, 240V, 100 Amp, 3 pole......................104-071818-014

1 Contactor, 600V, 100 Amp, 3 pole..............................072-120812-003

2 Fuses, FNQ 8/10 (F1 and F2)......................................128-114696-011

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-45-213, 240V, 1-3ø, 18 kW

1 Circuit Breaker, 240V, 60 Amp, 3 pole........................104-071818-010

1 Contactor, 600V, 60 Amp, 3 pole................................072-120812-002

2 Fuses, FNQ 8/10 (F1 and F2)......................................128-114696-011

1 Transformer, 150VA....................................................315-048507-018

OCC or WCC-72-223, 240V, 2-3ø, 60 kW

1 Circuit Breaker, 600V, 200 Amp, 3 pole......................104-071819-020

2 Contactors, 600V, 100 Amp, 3 pole .......................... 072-120812-003

2 Fuses, FNM 1-1/8 (F1 and F2)....................................128-114696-020

6 Fuses, FRN-100 (F3 thru F8) .....................................128-121133-084

1 Transformer, 250VA....................................................315-048507-024

1 Time Delay Relay........................................................311-115540-001

OCC or WCC-45-223, 240V, 2-3ø, 36 kW

1 Circuit Breaker, 600V, 125 Amp, 3 pole......................104-071818-045

2 Contactors, 600V, 60 Amp, 3 pole..............................072-120812-002

2 Fuses, FNM 8/10 (F1 and F2) .....................................128-114696-012

6 Fuses, FRN-60 (F3 and F8..........................................128-121133-080

1 Transformer, 150VA....................................................315-048507-018

1 Time Delay Relay........................................................311-115540-001

10

Page 11

11

Page 12

1347 HEIL QUAKER BLVD., LAVERGNE, TN 37086

Phone: (615) 793-3900 www.chromalox.com

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...