Page 1

Installation Instructions

DH and DHOC

Electric Duct Heaters

PF503

161-562766-001

1

February 2015

Page 2

Table of Contents

Section Page

General ...............................................................................................................................3

Installation .......................................................................................................................... 3

Mounting ............................................................................................................................6

Wiring ................................................................................................................................10

Operation .........................................................................................................................11

Maintenance ....................................................................................................................11

Heater Bundle Removal and Replacement ................................................................... 11

Replacement Parts .......................................................................................................... 12

Troubleshooting ............................................................................................................... 13

2

Page 3

DH and DHOC Electric Duct Heaters

General

Read and understand all instructions before installing, servicing or operating product. Failure

to do so could result in personal injury or property damage.

These heaters are designed to be installed in either a

horizontal or vertical duct in one of the six positions

shown in figure 12. The heater is constructed with individual metal sheath fintube elements mounted to a

heavy gauge metal terminal box.

Due to the various options and materials available,

check the nameplate attached to the heater terminal

box with the catalog number designation system before installing to insure the heater you received conforms to your specification.

Please read these directions carefully to insure all limitations are properly observed and all wiring and controls are properly installed and connected.

IMPORTANT - Observe at least one complete heating cycle operation before leaving the installation.

FIRE/EXPLOSION HAZARD. This heater is not

intended for use in hazardous atmospheres

where flammable vapors, gases, liquids or

other combustible atmospheres are present as

defined in the National Electrical Code. Failure

to comply can result in personal injury or property damage.

ELECTRIC SHOCK HAZARD. Any installation

involving electric heaters must be performed

by a qualified person and must be effectively grounded in accordance with the National

Electrical Code to eliminate shock hazard.

ELECTRIC SHOCK HAZARD. Disconnect all

power before installing or servicing heater.

Failure to do so could result in personal injury

or property damage. Heater must be installed

or serviced by a qualified person in accordance

with the National Electrical Code, NFPA 70.

Installation

Limitations: Must be in accordance with one of the

following: Standards of the National Fire Protection

Association for the installation of Air Conditioning and

Ventilating Systems of other than Resident Type (Pamphlet 90A) or Residential Type Warm Air Heating and

Air Conditioning Systems (Pamphlet 90B).

NOTE: The minimum distances shown are limitations.

Wherever possible, locate as far away from these limits as practical. In any case, this distance with any required airflow correction must be sufficient to accomplish even air flow at a velocity equal to, at least, the

minimum stated on the heater nameplate.

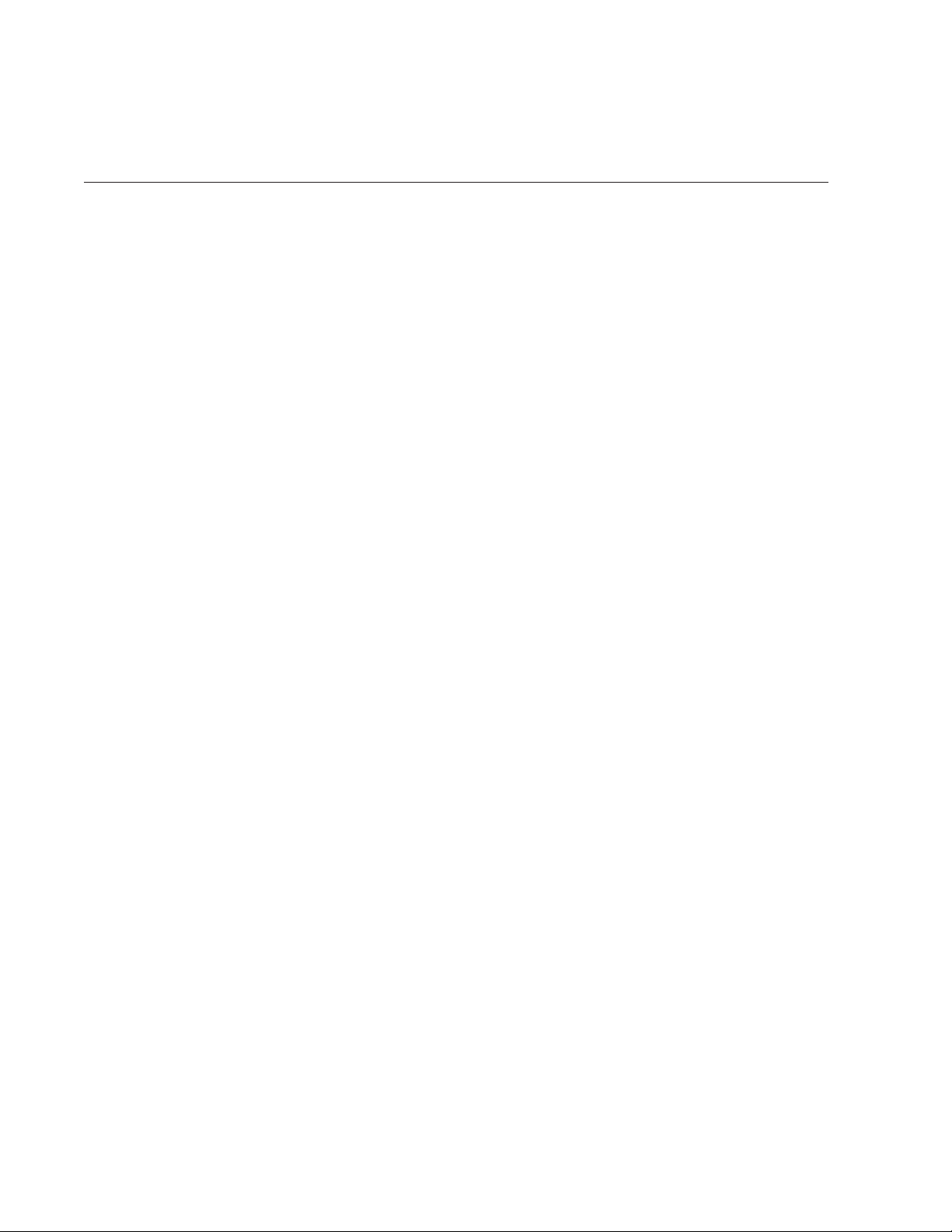

1. Installation near heat pump, central air conditioner,

filters or humidifier. (Refer to Figure 1).

Duct Heater

Air

Flow

4 Ft.

Min.

Heat Pump,

Central Air Conditioner,

Filters or Humidifier

Figure 1

3

Page 4

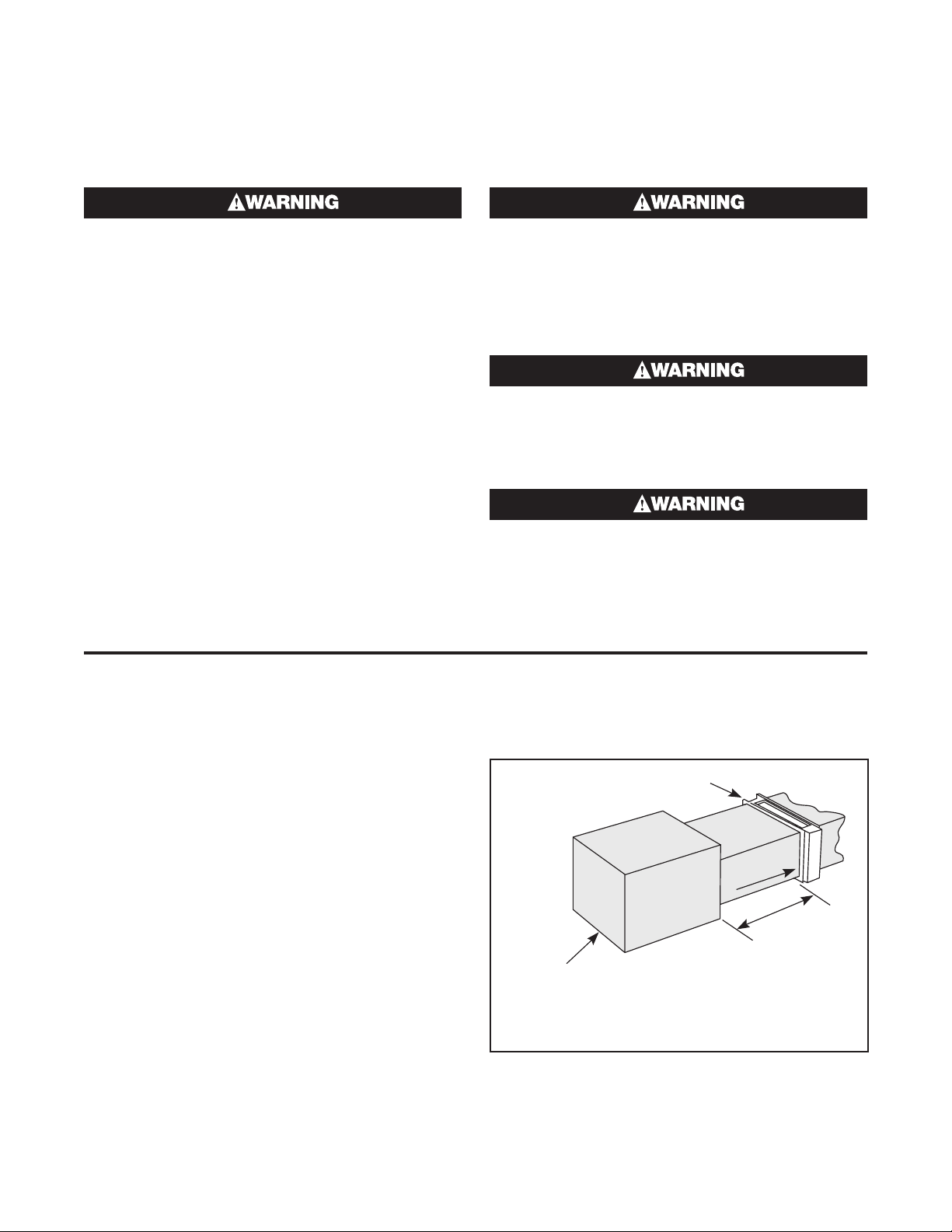

2.

Installation near air handler discharge. (Refer to Fig. 2).

Duct Heater

Air

Flow

5. Installation with duct transitions in some air distribution systems, the duct heater may be considerably larger than the ductwork and the duct area

must be increased by a sheet metal transition. The

slope of the transformation piece on the upstream

side of the equipment is limited to 30° as indicated

in Fig. 5. On the leaving side, the slope should not

be more than 45°.

4 Ft.

Min.

Air Handler

Figure 2

3. Installation in branch duct take-off. (Refer to Fig. 3).

Air Flow

4 Ft. Min. Straight Section

Duct Heater

Figure 3

4.

Installation near turns. (Refer to Fig. 4). If heater must

be installed closer than 4 feet from the downstream

side of a turn, turning vanes must be installed in the

turn. The turning vanes will straighten out the air

flow so it will be uniform over the face of the heater.

2 Ft.

Min.

30"

Air

Flow

Max.

30°

4 Ft. Min.

45°

Duct Heater

45°

Max.

4 Ft. Min.

Figure 5

6.

Do not insulate control or terminal box. (Refer to Fig. 6).

External

Insulation

Top of Duct

Duct Heater

Leave Control

Box Uninsulated

Figure 6

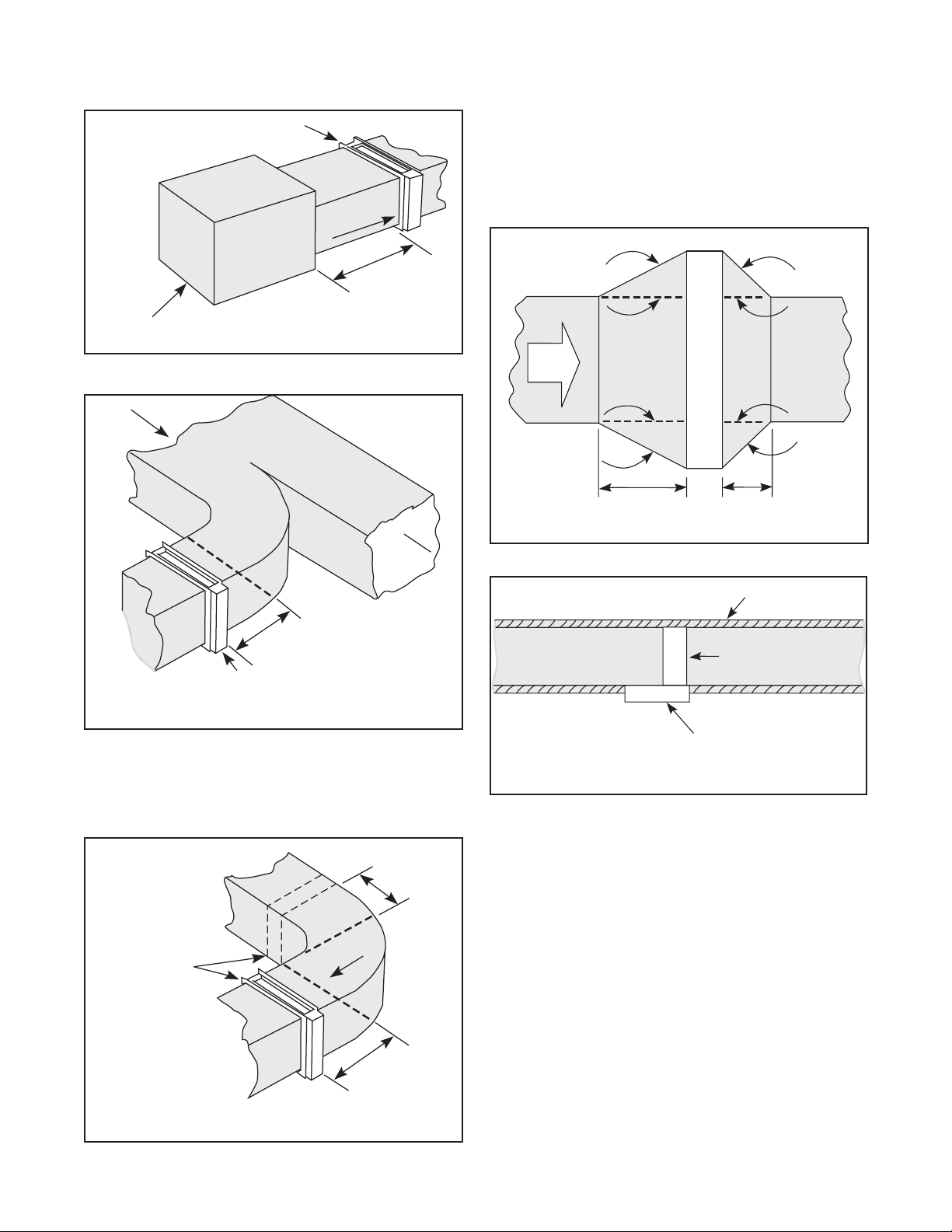

7. Installation in duct larger than heater. For installa-

tion where the duct dimensions exceed the insert

type heater dimensions, the area beyond the heater

dimensions must be filled with wire mesh, expanded or perforated sheet metal of 50% open area as

shown in Figure 7. This will maintain a uniform air

velocity across the face of the duct.

Duct Heater

Here or Here

Air Flow

4 Ft.

Min.

Figure 4

4

Page 5

Inner Baffle

Insert Type

Duct Heater

Perforated Metal

(50% Open Area)

Flexible Duct

(Must be suitable

for 195°F)

Air

Flow

4 Ft.

Min.

Figure 8

Duct Heater

Remove Bracket and

Use Sheetmetal Screws

Thru Same Holes into Duct.

Oversized Duct

Figure 7

8. Installation with flexible duct. Where a duct heater

must be installed near a flexible duct connection,

be certain that a 4’ minimum distance between the

duct heater and the flexible connector exists and

that the connector is suitable for 195°F temperature. (Refer to Fig. 8).

9. Do not install duct heater outdoors. Duct heaters

cannot be installed with rooftop equipment where

they are exposed to the weather.

10.

Installation with dampers or filters. Maintain at least

4’ distance between duct heater and damper, filter

frames, or other similar obstructions. (Refer to Fig. 9).

4 Ft.

Min.

Damper

Duct

Heater

Air Flow

Top of Duct

Figure 9

Clearance: Zero clearance between duct heater and

combustible materials such as wood is permissible.

However, adequate clearance must be provided around

terminal box for proper ventilation and future service accessibility.

5

Page 6

Air Flow

Flow through duct heater must never drop below the

minimum air velocity shown on duct heater nameplate.

If the air handling system includes filters, they must be

cleaned whenever necessary in order to maintain air

flow above the minimum, otherwise poor temperature

control and discomfort will result.

If air flow is poorly distributed within the duct, deflector

vanes must be added to provide correction.

The minimum air velocities shown on the nameplate

are not to be considered average readings. Do not add

various velocities taken across the face of the duct,

find an average value, and compare it to the minimum

velocity shown on the heater nameplate.

The minimum air velocity refers to any point along the

face of the duct heater when checking duct velocities,

no velocity can be below that sown on the heater nameplate (remembering inlet air temperature). Velocities are

best checked with an anemometer, taking numerous

readings along the horizontal and vertical centerline

of the duct heater at the location prior to installation

Example: 500 FT./MIN. Minimum Air Velocity

on Heater Nameplate.

Velocity

Profile

Ft./Min.

RIGHT:

600

500 400x

700 800

600 900

900 600

700 700

600 200x

500 300x

500 Ft./Min.

Minimum

Velocity

Profile

Ft./Min.

WRONG:

200x

400x

9 4500 =

500 Ft./Min

Average

or slightly up stream from the heater after installation.

(Refer to Figure 10). Large ducts will require additional

readings taken at locations in addition to the centerline.

Duct Heater

Air Flow

Incoming Air Temperature: Incoming air temperature

entering the duct heater must not exceed 100°F.

Velocity

Profile

Figure 10

Mounting

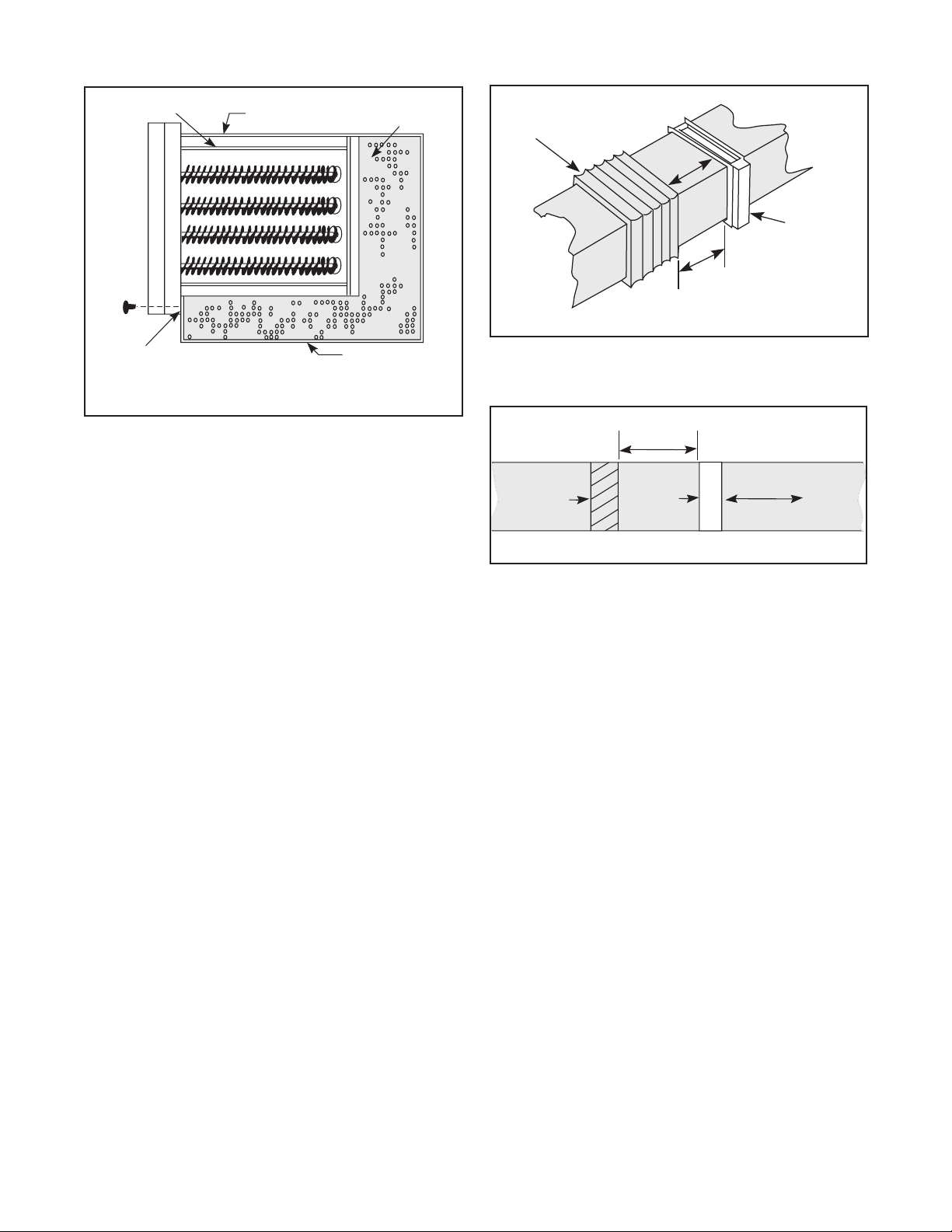

Multiple Duct Heaters: Up to six duct heaters may be

combined into a heating bank as shown in Figure 11.

When called for on order, brackets will be furnished for

fastening flange type duct heaters together to form a

bank. Heater will be coded for proper assembly in the

field.

Two to six duct heaters (with flange) may be installed in

a horizontal or vertical duct.

Heaters must be mounted in the position designated

by arrows on the heater frame. (Refer to Figure 12).

The heater terminal box on vertical duct installations

can be located on any side of the duct but for horizontal duct installation the terminal box must be on the

side of the duct.

Figure 11

6

Page 7

Figure 12

Airflow

Left

Airflow

Right

Airflow

Right

Airflow

Left

Horizontal duct with panel

extended in left direction

Airflow

Up

Airflow

Down

Vertical duct with panel extended

in Upward direction

Airflow

Right

Airflow

Left

Horizontal duct with panel extended

in RIGHT direction

Airflow

Up

Airflow

Down

Vertical duct with panel extended

in DOWNWARD direction

Airflow

Left

Airflow

Right

Bottom mount in horizontal duct with

panel extended in LEFT direction

Bottom mount in horizontal duct with

panel extended in RIGHT direction

7

Page 8

Mounting

Mounting Procedure

(Flanged heaters with control box)

1. At heater location, cut out a section of duct, or a

new construction lay out duct work to accommodate dimensions of heater.

2. Form mounting flanges on cut edges of duct as

shown in Figure 13. Omit flange in side when terminal box overhangs.

3. Position heater in duct and attach duct lip to heater

flanges with sheet metal screws.

4. Attach control box to duct with sheet metal screws

through the mounting holes provided inside the

control box.

NOTE: Where necessary, make provision to support

weight of heater. Any part of heater flange may be

drilled for attaching hanger straps or duct.

5. Where necessary, joint between duct and heater

flange may be sealed with silicone gaskets or silicone sealant.

Double

Lip

3/4"

Control

Box

Sheet Metal

Screws

Mounting

Holes

3/4"

W

Figure 13

Self-Adhesive Gasket

Supplied with Heater and

Installed by Customer

Duct

D

W

H

Sheet Metal

Screws

H

Mounting Procedure

(Insert heaters with control box)

NOTE: Insert or slip-in type duct heaters are designed

to be inserted into existing duct and require a rectangular hole of proper size to be cut. The heater frame is

manufactured with a specified duct height (H in figure

14) and a standard depth (D in figure 14). If the frame

does not match the specified dimensions contact a

Chromalox representative.

1. Measure the height and width of the heater frame

and note (H and D per figure 14).

2. The next step is to cut out the rough opening. Cut a

rectangle in the duct with dimensions H x (D - 1.5”).

Remove the sheet metal. (See figure 14A)

3. With the rough opening cut and the sheet metal removed, cut the remaining 3/4 and fold over sides to

create support tabs. (See figure 14A).

4. Attach control box to duct with sheet metal screws

through the mounting holes provided inside the

control box and through the brackets on the top

and bottom of heater.

5. Where necessary, make provision to support weight

of heater and terminal box.

3/4"

Control

Box

Sheet Metal

Screws

Mounting

Holes

Cut 3/4” and fold

over to create tab

Double

Lip

Self-Adhesive Gasket

Supplied with Heater and

Installed by Customer

Duct

Figure 14

D

W

D

H

H

Cut 3/4” and fold

over to create tab

H

W

Cut out and remove

shaded area H x (D-1.5”)

Figure 14a

8

Page 9

Mounting Procedure

(Flanged heaters with compact terminal box)

1. At heater location, cut out a section of duct, or on

new construction lay out duct work to accommodate dimensions of heater.

2. Form mounting flanges on cut edges of duct as

shown in Figure 15.

3. Position heater in duct and attach duct lip to heater

flanges with sheet metal screws.

NOTE: Where necessary, make provision to support

weight of heater. Any part of heater flange may be

drilled for attaching hanger straps or duct.

4. Attach control box to duct with sheet metal screws

through the mounting holes provided inside the

control box.

5. Where necessary, joint between duct and heater

flange may be sealed with silicone gasket or sealant.

Mounting Procedure

(Insert heaters with compact terminal box)

NOTE: Insert or slip-in type duct heaters are designed

to be inserted into existing duct and require a rectangular hole of proper size to be cut. The heater frame is

manufactured with a specified duct height (H in figure

16) and a standard depth (D in figure 16). If the frame

does not match the specified dimensions contact a

Chromalox representative.

1. Measure the height and width of the heater frame

and note (H and D per figure 16).

2. The next step is to cut out the rough opening. Cut a

rectangle in the duct with dimensions H x (D - 1.5”).

Remove the sheet metal. (See figure 16A)

3. With the rough opening cut and the sheet metal removed, cut the remaining 3/4 and fold over sides to

create support tabs. (See figure 16A).

4. Attach control box to duct with sheet metal screws

through the mounting holes provided inside the

control box and through the brackets on the top

and bottom of heater.

5. Where necessary, make provision to support weight

of heater and terminal box.

Double

Lip

3/4"

Sheet Metal

Screws

Mounting

Holes

3/4"

Sheet Metal

Screws

Mounting

Holes

3/4"

Double

Lip

Cut 3/4” and fold

over to create tab

W

Figure 15

Self-Adhesive Gasket

Supplied with Heater and

Installed by Customer

Duct

W

Figure 16

D

Self-Adhesive Gasket

Supplied with Heater and

Installed by Customer

Duct

D

W

H

Sheet Metal

Screws

W

H

H

D

H

Cut 3/4” and fold

over to create tab

H

Cut out and remove

shaded area H x (D-1.5”)

Figure 16a

9

Page 10

Wiring

ELECTRIC SHOCK HAZARD. Disconnect all

power before installing or servicing heater.

Failure to do so could result in personal injury

or property damage. Heater must be installed

or serviced by a qualified person in accordance

with the National Electrical Code, NFPA 70.

ELECTRIC SHOCK HAZARD. Any installation

involving electric heaters must be performed

by a qualified person and must be effectively grounded in accordance with the National

Electrical Code to eliminate shock hazard.

1. Connect heater only to the voltage, frequency and

phase specified on the nameplate.

2. All wiring should be done according to local and

National Electric Codes.

3. Make supply connections to marked heater terminals using wire suitable for 75°C. (Type RH-RW or

equivalent). In addition, the supply wires must be

rated to supply a minimum of 125% of the total amperage load required by the Duct Heater.

4. Connect field wiring to the Duct Heater using the

Wiring Diagram provided with the heater.

5. Conduit attachment to heater:

a. Ensure that conduit size used matches the

knock-out size(s) provided on Duct Heater

b. Run conduit(s) to conduit knock-out(s) on Duct

Heater

c. Remove knock-out(s) with a punch and hammer.

d. Install conduit to knock-out hole.

6. If the heater does not include a main circuit breaker

or a disconnect switch, a remote disconnect must

be provided (see N.E.C. 424.65).

7. Any wiring that is connected to the secondary

(control) wiring of the Duct Heater is required to be

N.E.C. class 1 (see National Electric Code, Article

725).

Wiring Diagram

The appropriate wiring diagram will be supplied with

each heater.

Field Wire/Conduit Sizing (based on 125% of total heater amperage)

1PH 3PH

1.4 2.5 2.9 3.3 4.3 5.0 10.0 14 1/2 1/2 12

1.8 3.1 3.6 4.2 5.4 6.2 12.5 12 1/2 1/2 15

2.5 4.4 5.0 5.8 7.6 8.7 17.5 10 1/2 1/2 21

3.8 6.7 7.7 8.9 11.5 13.3 26.6 8 1/2 3/4 32

4.7 8.1 9.4 10.8 14.1 16.2 32.4 6 3/4 3/4 39

6.1 10.6 12.2 14.1 18.4 21.2 42.4 4 3/4 1 51

7.2 12.5 14.4 16.6 21.6 24.9 49.9 3 1 1 60

8.3 14.4 16.6 19.1 24.9 28.7 57.4 2 1 1-1/4 69

9.4 16.2 18.7 21.6 28.1 32.4 64.8 1 1-1/4 1-1/4 78

10.8 18.7 21.6 24.9 32.4 37.4 74.8 1/0 1-1/4 1-1/2 90

12.6 21.8 25.2 29.1 37.8 43.6 87.3 2/0 1-1/4 1-1/2 105

14.4 25.0 28.8 33.2 43.2 49.9 99.8 3/0 1-1/2 2 120

16.6 28.7 33.1 38.2 49.7 57.4 114.7 4/0 2 2 138

18.4 31.8 36.7 42.4 55.1 63.6 127.2 250 2 2-1/2 153

20.5 35.6 41.0 47.4 61.6 71.1 142.2 300 2 2-1/2 171

22.3 38.7 44.6 51.5 67.0 77.3 154.6 350 2-1/2 2-1/2 186

24.1 41.8 48.2 55.7 72.4 83.6 167.1 400 2-1/2 3 201

27.4 47.4 54.7 63.2 82.1 94.8 189.6 500 2-1/2 3 228

30.2 52.4 60.5 69.8 90.8 104.8 209.5 600 3 3-1/2 252

33.1 57.4 66.2 76.5 99.4 114.7 229.5 700 3 3-1/2 276

35.3 61.2 70.6 81.4 105.9 122.2 244.4 800 3 3-1/2 294

Wire Size

(AWG or

kcmil)

Conduit Size

Heater

Amps120 208 240 277 208 240 480 1ph 3ph

10

Page 11

Operating Instructions

Heater Start-up:

1. Close the duct heater’s door and ensure that the

latch has engaged by pulling on the door. The door

should not open unless a tool is used to disengage

the latch.

2. Turn on the blower or fan for the ductwork that contains the duct heater.

3. Ensure that the Air Velocity on the downstream side

of the duct heater matches the Minimum Air Velocity stamped on the duct heater’s nameplate. The

minimum airflow requirement shall be met at any

point over the face of the heater.

4. Turn Selector Handle on the duct heater to the

“ON” position. -Note: A small amount of smoke will

usually be emitted from the duct heater when first

initialized. This is from dust that has built up on the

elements and is normal and should only last for a

few seconds.

5. Verify that adequate heat is coming from ductwork

vents.

Maintenance

ELECTRIC SHOCK HAZARD. Disconnect all

power before installing or servicing heater.

Failure to do so could result in personal injury

or property damage. Heater must be installed

or serviced by a qualified person in accordance

with the National Electrical Code, NFPA 70.

Heater Shut-Down:

1. With the blower or fan still running, turn the Selector

handle on the duct heater to the “OFF” position.

2. Verify that the air coming out of the ductwork vents

is not heated.

3. Do not turn off the blower or fan until at least 15

minutes after the heater has turned off.

4. Verify that the duct heater outer surfaces have

cooled down to at least 110°F before touching.

5. Disconnect all power to the duct heater before

opening the duct heater’s door.

1. Periodically clean terminals and terminal covers of

dust and corrosion to maintain good electrical connections and to permit rapid heat dissipation. Use

airblast, and be careful to avoid damage to mica

insulation.

2. At least once a year check for loose terminal connections. Tighten as necessary. Torque to 30 in-lbs.

Heater Bundle Removal

& Replacement

ELECTRIC SHOCK HAZARD. Disconnect all

power before installing or servicing heater.

Failure to do so could result in personal injury

or property damage. Heater must be installed

or serviced by a qualified person in accordance

with the National Electrical Code, NFPA 70.

ELECTRIC SHOCK HAZARD. Any installation

involving electric heaters must be performed

by a qualified person and must be effectively grounded in accordance with the National

Electrical Code to eliminate shock hazard.

1. If there is more than one bank of elements on the

heater, drill out rivets from the back side of the duct

heater that are holding the heating bank that is to

be replaced in place.

11

Page 12

2. Remove wiring from terminal pins of heater bank.

3. Remove thermal cutouts if they are attached to the

bank that needs to be replaced.

4. Remove screws around the outside of the heating

bank that hold the heating bank to the housing.

Replacement Parts

Description Part Number Rating

Heating Element Bank Contact sales

303472019 40 amps

Disconnect Switch

Power Fusing Contact sales

Transformer Fusing Contact sales

Contactors

Transformer Contact sales

Air ow switch 051947001

Automatic Reset Thermal Cutout 306600007

Manual Reset Thermal Cutout 306600008

Pilot Light

303472020 60 amps

303472021 80 amps

303472022 100 amps

306110002 24 V

306110008 120 V

304688001 24 V

304688002 120 V

12

Page 13

Duct Heater Troubleshooting Guide

Problem Causes Solution

Won’t Power On

(no heat)

Not Enough

Heat

Too Much Heat

Field power wires not

connected properly

Fuse(s) have blown or

breaker has tripped

Automatic Reset Cutout

has tripped

Manual Reset Cutout has

tripped

Air Flow Switch has

tripped

Wires have shorted out Shut down the heater per the Heater Shut Down section of the In-

Loose or unconnected

internal wires

Incorrect Voltage Check the rated voltage for the heater provided on the nameplate.

Fuse(s) have blown Check resistance of fuses using a Multimeter to ensure continuity.

Failed Element(s) Shut down the heater per the Heater Shut Down section of the In-

Loose or unconnected

wire terminals

Incorrect Voltage Check the rated voltage for the heater provided on the nameplate.

Improper sizing (kw) Verify that the heater KW provided is adequate for the applica-

Incorrect Voltage Check the rated voltage for the heater provided on the nameplate.

Connect wires per the Wiring section of the Installation & Operating Manual (IOM)

Check resistance of fuses using a Multimeter to ensure continuity.

Replace any blown fuses.

Wait for 30 minutes. The Automatic Cutout should reset and the

heater should begin working again. If not, disconnect wires from

the cutout and use a Multimeter to test for continuity across the

cutout.

Shut down the heater per the Heater Shut Down section of the

Installation & Operating Manual. Open the terminal box and push

the reset button on the manual reset (near the label "PUSH TO

RESET") and start up the heater per the Heater Startup section

of the Installation & Operating Manual. If the heater still does not

function, disconnect wires from the cutout and use a Multimeter

to test for continuity across the cutout. If there is still no continuity

after pushing the button, the cutout needs to be replaced.

Ensure that adequate flow is being provided to the heater per the

Air Velocity requirements stamped on the Nameplate.

stallation & Operating Manual. Open the terminal box and check

for each wire for continuity.

Shut down the heater per the Heater Shut Down section of the Installation & Operating Manual. Open the terminal box and check

wire terminals for proper connection.

Check supply voltage & verify that it matches the nameplate.

Replace any blown fuses.

stallation & Operating Manual. Open the terminal box and use an

ohmmeter to check for resistance across each element. All coils

should have the same resistance. If the heating element is broken

there will generally be either zero or infinite resistance. Replace

any heating banks with broken coils.

Shut down the heater per the Heater Shut Down section of the Installation & Operating Manual. Open the terminal box and check

wire terminals for proper connection.

Check supply voltage & verify that it matches the nameplate.

tion. Ensure that the blower output, when measured downstream

of the duct heater, matches the Air Velocity requirement that is

stamped on the nameplate.

Check supply voltage & verify that it matches the nameplate.

13

Page 14

Problem Causes Solution

Contactor

Chatter

Terminals

Heating Up

Pilot Lights

don’t turn on

Incorrect Control Voltage

Input

Incorrect wire size to

heater

Loose Wiring Connection Tighten wire connections on all terminals.

Light bulb burnt out Replace pilot light

Loose Wiring Connection Check wire connections on all control circuit terminations.

Check the rated control circuit voltage for the heater provided

on the nameplate. Check supply control voltage & verify that it

matches the nameplate.

Check supply wiring size. Wiring sizing should conform to N.E.C.

424.3(b).

© 2015 Chromalox, Inc.

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Chromalox, Inc.

2150 N. Rulon White Blvd.

Odgen, UT 84404

1-800-368-2493

www.chromalox.com

14

Loading...

Loading...