Page 1

Chromalox

®

DIVISION 4 SECTION

CVEP

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation, Operation

and

RENEWAL PARTS IDENTIFICATION

PF457-8

JUNE, 2010

(Supersedes PF457-7)

161-302639-001

GENERAL

INSTALLATION

NOTICE: Carefully remove heater from carton and check for

shipping damage. Any damage claims should be entered

immediately with the carrier.

Type CVEP Convection Heaters are designed for use in Class

I, Div I hazardous environments. Units without control options

are suitable for areas classified as Groups B, C & D. Units with

built-in controls can be supplied for groups C and D or B, C and

D. Refer to classification stamped on heater nameplate.

FIRE/EXPLOSION HAZARD.

To prevent ignition of hazardous atmospheres, this heater should not be installed in

areas where vapors or gases having an ignition temperature less than 280˚C (536˚F)(T2A) at 1.8kW, 3.6kW, 4.5kW,

7.6kW, 9.0kW or 180˚C (356˚F)(T3A) at 1.6kW, 3.2kW,

4.0kW are present.

These heaters must not be operated in ambient temperatures exceeding 40˚C (104˚F).

1.

Connect air heaters to the same line voltage as on heater nameplate.

2. Heaters can be mounted individually end to end.

3. Heaters can be mounted directly on any type of surface masonry,

concrete, block, plastered walls, metal framework, etc.-using

appropriate hardware.

4. All controls such as thermostat and contactor, when required must

have the same explosion-proof rating as heater.

5. Do not install one unit above the other.

6. Units are mounted a minimum of 8” above the floor.

7. Heaters are mounted on wall in a horizontal position with termi-

nal end at right. Never recess heater into wall.

8. NOTE: Article 500 of the National Electric Code (NEC) out-

lines requirements for installation of electrical equipment in hazardous (Classified) locations.

9. All unit electrical installation fittings, conduit, wiring and seals

must meet NEC and local codes for hazardous locations. External

line fusing or circuit breaker protection is required.

10. Failure to understand and follow these installation instructions

and the “WARNING” notes contained therein may result in

severe personal injury, death or substantial property damage.

ELECTRIC SHOCK HAZARD. Any installation

involving electric heaters must be performed by a

qualified person and must be effectively grounded

in accordance with the National Electrical Code to

eliminate shock hazard.

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do so

could result in personal injury or property damage.

Heater must be installed by a qualified person in accordance with the National Electrical Code, NFPA 70.

1. Remove front panel by removing screws.

2. Locate desired heater position on wall.

3. Locate mounting holes for rear panel. Rear panel must be a mini-

mum of 8” from the floor.

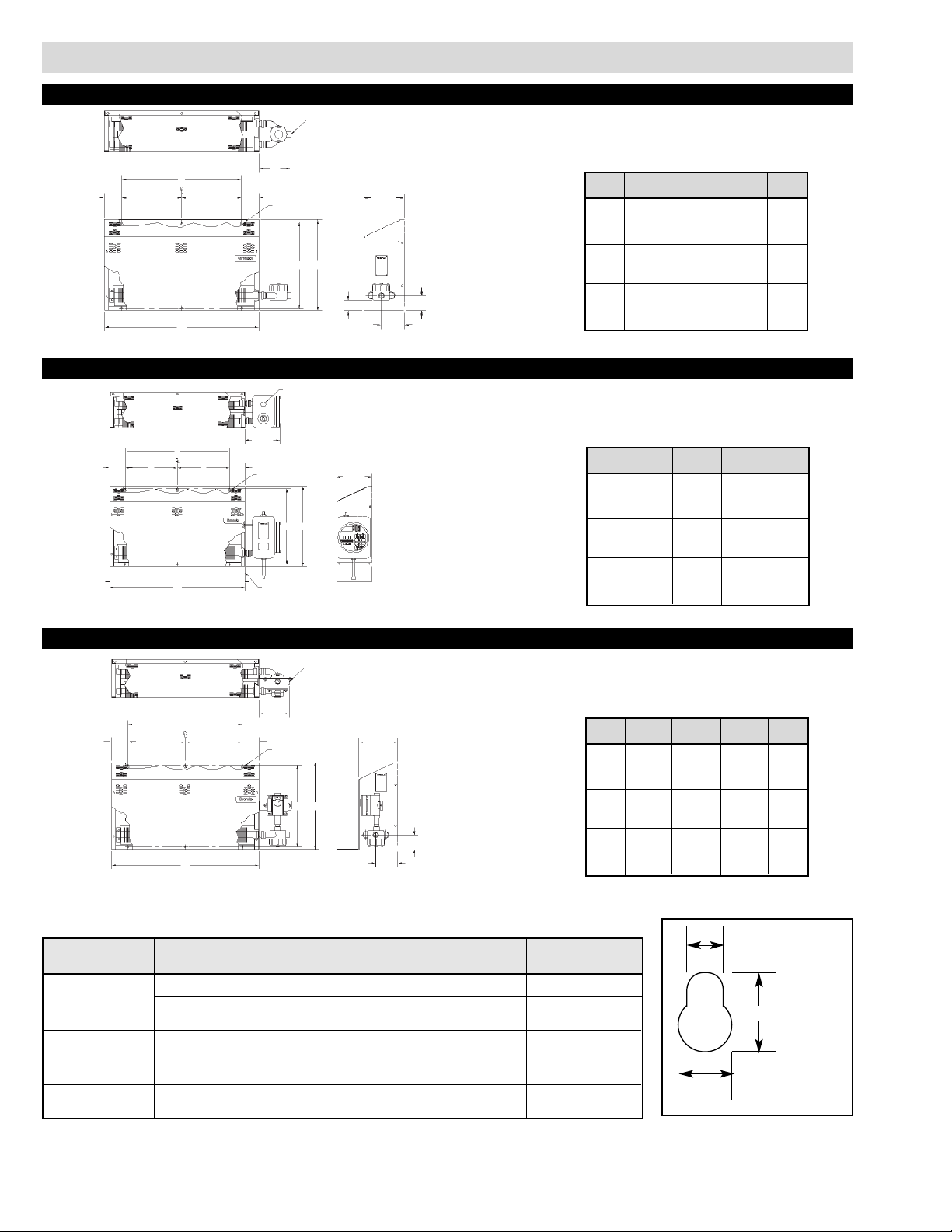

4. Refer to Figure 1A, 1B or 1C for mounting hole layout for each

cabinet size.

5. Drill a pilot hole in wall mounting surface at each mounting hole

location. Use a convenient small size drill.

6. Drill the mounting holes in accordance with size in Table 1. Insert

anchors where applicable.

7. Fasten rear panel to wall with screws noted in Table 1.

8. Replace front panel and screws.

FIRE HAZARD. Never operate heater with front panel

off. Adequate air flow across heating elements

requires the front panel to be in place. The heating

elements could overheat causing equipment damage

or personal injury.

Type CVEP-C

Convection Air Heater for Hazardous Locations

© 2010 Chromalox, Inc.

Page 2

kW A B C D

1.6

1.8 34 20 7

3.6

3.2

58 32 16 13

7.6

4.0

4.5 70 48 24 11

9.0

10

INSTALLATION

Dimensions (In.)

CVEP MODELS WITHOUT CONTROLS — GROUPS B, C AND D

Dimensions (In.)

CVEP MODELS WITH BUILT-IN CONTROLS — GROUPS B, C AND D

Dimensions (In.)

CVEP MODELS WITH THERMOSTAT ONLY — GROUPS C AND D

2

Type of Mounting ** Accessory Screw Size to Fit

Surface Hardware Screw Type Drill Size and Type Mtg Hole Size

Concrete Block

Ackerman Rd. Hd. Mach. Steel 1/2” Masonry † 1/4” x 20 x.............lg

Masonry

Lead Anchor

Rd. Hd. Mach Steel or Pan Hd.

5/16” Masonry † # 1/4” x .................lg

Metal (Self Tapping)

Wood Studs — — Wood or Metal (Self Tapping) — — † # 1/4” x .................lg

Plaster wall Hollow or

— — Toggle Bolt #7 Twist † # 1/4” x .................lg

Similar Type

* Metal Beam, Nuts

Rd. Hd. Mach. Steel #7 Twist † 1/4” x 20 x.............lg

Channel, etc. Washers

Table 1 — Suggested Heater Mounting Screws — Types and Sizes

*If clearance permits use washer, lockwasher and nut; otherwise drill and tap to these lengths add thickness of beam, washers, nut, etc.

**If mounting structure permits. Except plastered hollow walls explosive type anchors can be used. Suggested size noted in Table and/or

sketches be used to determine size of anchors.

†Select overall length of screw to provide a minimum penetration of 1 inch into base wall material.

1/2

7/8

5/16

Mounting Hole

Detail “A”

Figure 1A

Figure 1B

Figure 1C

kW A B C D

1.6

1.8 34 20 7

3.6

3.2

58 32 16 13

7.6

4.0

4.5 70 48 24 11

9.0

10

kW A B C D

1.6

1.8 34 20 7

3.6

3.2

58 32 16 13

7.6

4.0

4.5 70 48 24 11

9.0

10

7/8

3/4" Conduit Entrance

7

D

See Detail "A"

8-15/16

D

C

C

B

19

20-1/16

A

2-3/8

5-1/16

3-3/8

1" Conduit Entrance

8-7/8

D

See Detail "A"

C

C

D

19

20-1/16

8-15/16

A

B

Feet are Optional

Primarily Used to Protect

Thermowell During Shipping

and Installation

3/4" Conduit Entrance

7

D

See Detai "A"

C

C

D

19

20-1/16

8-15/16

5-1/16

3-3/8

A

2-3/8

Page 3

WIRING

ELECTRIC SHOCK HAZARD. Any installation

involving electric heaters must be performed by a

qualified person and must be effectively grounded

in accordance with the National Electrical Code to

eliminate shock hazard.

1. All wiring should be done in accordance with local codes and

the National Electrical Code by a qualified person as defined in

the NEC.

CAUTION: Use copper conductors only.

2. Rough-in-line-wiring to unit in manner approved for hazardous

locations. (See warning below.)

3.

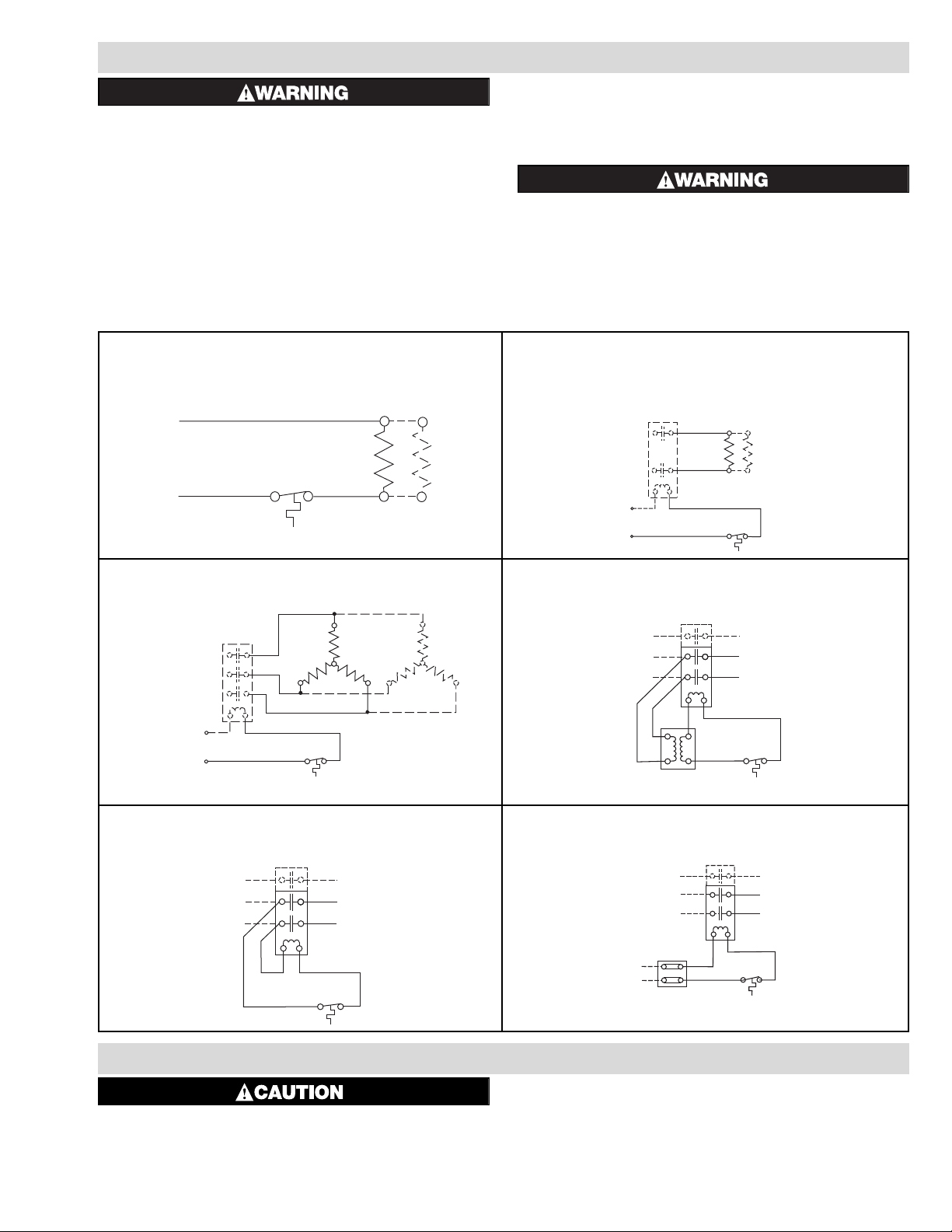

Wire per diagrams 1 through 6 based on the rating and control

options listed in table 2. Refer to table 3 for amperage specifications.

4. Remove cover of conduit box for connections. Use either opening

and plug the other with the plug provided.

5. In single phase units the heaters must be wired in parallel, com-

bining L1 to L1, L2 to L2 and for 3 phase unit, L3 to L3.

6. Re-assemble cover with a minimum of 7 turns.

FIRE/EXPLOSION HAZARD.

(Group B atmospheres)

To prevent ignition of Group B atmospheres, conduit

runs must not exceed 3/4” in size and all conduit

runs 1/2” size and larger must have a sealing fitting

connected within 2”, 6” or 18” of the terminal enclosure depending on the exact model. For correct

placement, refer to data located on the enclosure

label.

OPERATION

The system designer is responsible for the safety

of this equipment and should install adequate

back-up controls and safety devices with their

electric heating equipment. Where the consequences of failure could result in personal injury or

property damage, back-up controls are essential.

1. Do not operate heater at voltages in excess of that stamped on

the heater since excess voltage will shorten heater life and

cause high element temperatures which may exceed allowable

temperatures of operation in a hazardous atmosphere.

3

Elements

Optional Thermostat

Built-In or Ext. Supplied

Single Phase — No Controls, 120-277V

& Heater Amps < 22A

Diagram 1

Diagram 3

Diagram 5

Diagram 2

Diagram 4

Diagram 6

Elements

Optional Thermostat

Built-In or Ext. Supplied

Single Phase — No Controls, Volts > 277V

& 120–277V When Heater Amps > 22A

External

Contactor

Control

Voltage

Elements

Optional Thermostat

Built-In or Ext. Supplied

External

Contactor

Control

Voltage

Three Phase – No Controls

Optional Thermostat

Built-In or Ext. Supplied

Contactor

Transformer

Element Wiring

1 PH or 3 PH

Single or Double

Element

Single or Three Phase

With Controls — Contactor & Transformer

Optional Thermostat

Built-In or Ext. Supplied

Contactor

Line

Voltage

Control

Voltage

Element Wiring

1 PH or 3 PH

Single or Double

Element

Single or Three Phase

With Controls — Contactor & Line Voltage Control

Optional Thermostat

Built-In or Ext. Supplied

Contactor

Element Wiring

1 PH or 3 PH

Single or Double

Element

Single or Three Phase With Controls —

Contactor & External Supplied Control Voltage

Terminal

Block

External

Supplied

Control

Voltage

Page 4

MAINTENANCE

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage. Heater must be installed by a qualified person in accordance with the National Electrical

Code, NFPA 70.

1. Before activating for next heating season, vacuum or use com-

pressed air to remove accumulated dust or lint, which otherwise

may restrict proper air flow.

2. Periodically check all electrical connections and retighten to avoid

electrical wiring difficulties.

3. Check to ensure terminal cover is tightly closed, before energiz-

ing.

4

Sealed, Heavy duty Finned

Element assembly.

Explosion Proof

Junction Box

for Field wiring

Mounting Holes

ELEMENT REPLACEMENT

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property damage.

1. Disconnect power from circuit.

2. Remove cover from junction box and disconnect element wiring.

3. Remove front panel by removing screws.

4. Loosen aluminum coupling connecting element to junction box.

5. Remove screws and bracket holding element end opposite junc-

tion box.

6. Disconnect aluminum coupling connection element to junction

box.

7. Remove element from cabinet.

8. Install element in reverse sequence.

Page 5

RENEWAL PARTS IDENTIFICATION

MANUFACTURER MODEL NUMBER BREAKDOWN

(located on unit nameplate)

CVEP-C 36 2 1 30 42

5

Model

CVEP Explosion Proof Convection Heater

Temperature Rating

CVEP-C Code kW ID Number ˚F ˚C (BTU)

16 1.6 T3A 356 180 5,500

18 1.8 T2A 536 280 6,150

32 3.2 T3A 356 180 11,000

36 3.6 T2A 536 280 12,300

40 4.0 T3A 356 180 13,600

45 4.5 T2A 536 280 15,350

76 7.6 T2A 536 280 25,930

90 9.0 T2A 536 280 30,700

Code Voltage Maximum kW Allowable

1 120 1.8

2 240 9.0

3 380 9.0

4 480 9.0

5 415 9.0

6 575 9.0

7 277 9.0

8 208 9.0

9 600 9.0

Code Phase

11Ø

3 3Ø (Not available in 120, 277V)

Control Combination

Code Contactor Transformer

Coil Secondary

00 None None

30 24 Volt 24 Volt

31 24 Volt None

32 120 Volt 120 Volt

33 120 Volt None

34 208/240 Volt None

35 277 Volt None

Code Temperature Control

00 None

40 Thermostat 40 - 90˚F

Group B, C & D

42 Thermostat Group C & D

50 - 90˚F

Page 6

TABLE 2 — TEMPERATURE SPECIFICATIONS

DIMENSIONS REPLACEMENTS ELEMENTS REQUIREMENTS

Temperature Rating T3A 356˚F (180˚C) Common To Units W & W/O Suffix B

kW BTU Volts Phase Amps Model Width A Height B Depth C Wt. (Lbs.) Element P/N Qty.

1.6 5,500 208 1 7.7 CVEP-C-16-81 34” 20-1/16” 8-15/16” 58 003-304650-002 2

1.6 5,500 208 3 4.4 CVEP-C-16-83 34” 20-1/16” 8-15/16” 58 003-304650-005 2

1.6 5,500 240 1 6.7 CVEP-C-16-21 34” 20-1/16” 8-15/16” 58 003-304650-096 2

1.6 5,500 240 3 3.8 CVEP-C-16-23 34” 20-1/16” 8-15/16” 58 003-304650-006 2

1.6 5,500 277 1 5.8 CVEP-C-16-71 34” 20-1/16” 8-15/16” 58 003-304650-004 2

1.6 5,500 480 1 3.3 CVEP-C-16-41 34” 20-1/16” 8-15/16” 58 003-304650-091 2

1.6 5,500 480 3 1.9 CVEP-C-16-43 34” 20-1/16” 8-15/16” 58 003-304650-009 2

1.6 5,500 575 3 1.6 CVEP-C-16-63 34” 20-1/16” 8-15/16” 58 003-304650-010 2

3.2 11,000 208 1 15.4 CVEP-C-32-81 58” 20-1/16” 8-15/16” 94 003-304650-023 2

3.2 11,000 208 3 8.9 CVEP-C-32-83 58” 20-1/16” 8-15/16” 94 003-304650-026 2

3.2 11,000 240 1 13.3 CVEP-C-32-21 58” 20-1/16” 8-15/16” 94 003-304650-097 2

3.2 11,000 240 3 7.7 CVEP-C-32-23 58” 20-1/16” 8-15/16” 94 003-304650-027 2

3.2 11,000 277 1 11.6 CVEP-C-32-71 58” 20-1/16” 8-15/16” 94 003-304650-025 2

3.2 11,000 480 1 6.7 CVEP-C-32-41 58” 20-1/16” 8-15/16” 94 003-304650-093 2

3.2 11,000 480 3 3.8 CVEP-C-32-43 58” 20-1/16” 8-15/16” 94 003-304650-030 2

3.2 11,000 575 3 3.2 CVEP-C-32-63 58” 20-1/16” 8-15/16” 94 003-304650-031 2

4.0 13,600 208 1 19.2 CVEP-C-40-81 70” 20-1/16” 8-15/16” 112 003-304650-045 2

4.0 13,600 208 3 11.1 CVEP-C-40-83 70” 20-1/16” 8-15/16” 112 003-304650-048 2

4.0 13,600 240 1 16.7 CVEP-C-40-21 70” 20-1/16” 8-15/16” 112 003-304650-046 2

4.0 13,600 240 3 9.6 CVEP-C-40-23 70” 20-1/16” 8-15/16” 112 003-304650-049 2

4.0 13,600 277 1 14.4 CVEP-C-40-71 70” 20-1/16” 8-15/16” 112 003-304650-047 2

4.0 13,600 480 1 8.3 CVEP-C-40-41 70” 20-1/16” 8-15/16” 112 003-304650-094 2

4.0 13,600 480 3 4.8 CVEP-C-40-43 70” 20-1/16” 8-15/16” 112 003-304650-052 2

4.0 13,600 575 3 7.0 CVEP-C-40-63 70” 20-1/16” 8-15/16” 112 003-304650-053 2

Temperature Rating T2A 536˚F (280˚C)

kW BTU Volts Phase Amps Model Width A Height B Depth C Wt. (Lbs.) Element P/N Qty.

1.8/3.6 6,150/12,300 208 1 8.7/17.3 CVEP-C-18/36-81 34” 20-1/16” 8-15/16” 46/58 003-304650-034

1 or 2

1.8/3.6 6,150/12,300 208 3 5.0/10.0 CVEP-C-18/36-83 34” 20-1/16” 8-15/16” 46/58 003-304650-038

1 or 2

1.8/3.6 6,150/12,300 240 1 7.5/15.0 CVEP-C-18/36-21 34” 20-1/16” 8-15/16” 46/58 003-304650-098

1 or 2

1.8/3.6 6,150/12,300 240 3 4.3/8.7 CVEP-C-18/36-23 34” 20-1/16” 8-15/16” 46/58 003-304650-039

1 or 2

1.8/3.6 6,150/12,300 277 1 6.5/13.0 CVEP-C-18/36-71 34” 20-1/16” 8-15/16” 46/58 003-304650-036

1 or 2

1.8/3.6 6,150/12,300 480 1 3.8/7.5 CVEP-C-18/36-41 34” 20-1/16” 8-15/16” 46/58 003-304650-037

1 or 2

1.8/3.6 6,150/12,300 480 3 2.2/4.3 CVEP-C-18/36-43 34” 20-1/16” 8-15/16” 46/58 003-304650-042

1 or 2

1.8/3.6 6,150/12,300 575 3 1.8/3.6 CVEP-C-18/36-63 34” 20-1/16” 8-15/16 46/58 003-304650-043

1 or 2

7.6 25,930 208 1 36.5 CVEP-C-76-81 58” 20-1/16” 8-15/16” 94 003-304650-055 2

7.6 25,930 208 3 21.1 CVEP-C-76-83 58” 20-1/16” 8-15/16” 94 003-304650-058 2

7.6 25,930 240 1 31.7 CVEP-C-76-21 58” 20-1/16” 8-15/16” 94 003-304650-099 2

7.6 25,930 240 3 18.3 CVEP-C-76-23 58” 20-1/16” 8-15/16” 94 003-304650-059 2

7.6 25,930 277 1 27.4 CVEP-C-76-71 58” 20-1/16” 8-15/16” 94 003-304650-057 2

7.6 25,930 480 1 15.8 CVEP-C-76-41 58” 20-1/16” 8-15/16” 94 003-304650-095 2

7.6 25,930 480 3 9.1 CVEP-C-76-43 58” 20-1/16” 8-15/16” 94 003-304650-062 2

7.6 25,930 575 3 7.6 CVEP-C-76-63 58” 20-1/16” 8-15/16” 94 003-304650-063 2

4.5/9.0 15,350/30,700 208 1 21.6/43.3 CVEP-C-45/90-81 70” 20-1/16” 8-15/16” 87/112 003-304650-065

1 or 2

4.5/9.0 15,350/30,700 208 3 12.5/25.0 CVEP-C-45/90-83 70” 20-1/16” 8-15/16” 87/112 003-304650-069

1 or 2

4.5/9.0 15,350/30,700 240 1 18.8/37.5 CVEP-C-45/90-21 70” 20-1/16” 8-15/16” 87/112 003-304650-100

1 or 2

4.5/9.0 15,350/30,700 240 3 10.8/21.7 CVEP-C-45/90-23 70” 20-1/16” 8-15/16” 87/112 003-304650-070

1 or 2

4.5/9.0 15,350/30,700 277 1 16.2/32.5 CVEP-C-45/90-71 70” 20-1/16” 8-15/16” 87/112 003-304650-067

1 or 2

4.5/9.0 15,350/30,700 480 1 9.4/18.8 CVEP-C-45/90-41 70” 20-1/16” 8-15/16” 87/112 003-304650-068

1 or 2

4.5/9.0 15,350/30,700 480 3 5.4/10.8 CVEP-C-45/90-43 70” 20-1/16” 8-15/16” 87/112 003-304650-073

1 or 2

4.5/9.0 15,350/30,700 575 3 4.5/9.0 CVEP-C-45/90-63 70” 20-1/16” 8-15/16” 87/112 003-304650-074

1 or 2

6

Page 7

Model Front Rear Right Left Element

Any Voltage Cover Assembly Cover Assembly Side Panel Side Panel Support Bracket

CVEP-C-16/18/36 207-304644-101 207-304644-001 207-304644-201 304-304644-301 027-304646-001

CVEP-C-32/76 207-304644-102 207-304644-002 207-304644-201 304-304644-301 027-304646-001

CVEP-C-40/45/90 207-304644-103 207-304644-003 207-304644-201 304-304644-301 027-304646-001

Control Combination

Code Contactor Transformer

Coil Secondary

00 None None

30 24 Volt 24 Volt

31 24 Volt None

32 120 Volt 120 Volt

33 120 Volt None

34 208/240 Volt None

35 277 Volt None

Primary Secondary

Transformer

Voltage Voltage

208/240/480 24 315-304252-002

208/240/480 120 315-304252-001

277 24 315-304252-004

575 24 315-304252-005

277/575 120 315-304252-003

Code Thermostat

00 None

40 300-049197-003

42 300-113075-003

Contactor

Coil Voltage 30 Amp 50 Amp

24V 072-304551-001 072-304551-002

120V 072-304551-007 072-304551-008

208/240V 072-304551-013 072-304551-014

277V 072-304551-019 072-304551-020

7

REPLACEMENT PARTS

C V E P C kW Volts Phase Control Stat

* Included when unit is equipped with control(s).

Page 8

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

02 - 074

TA - Q4 - EF

Litho in U.S.A.

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...