Page 1

CTF-Xtra Single Phase Advanced SCR

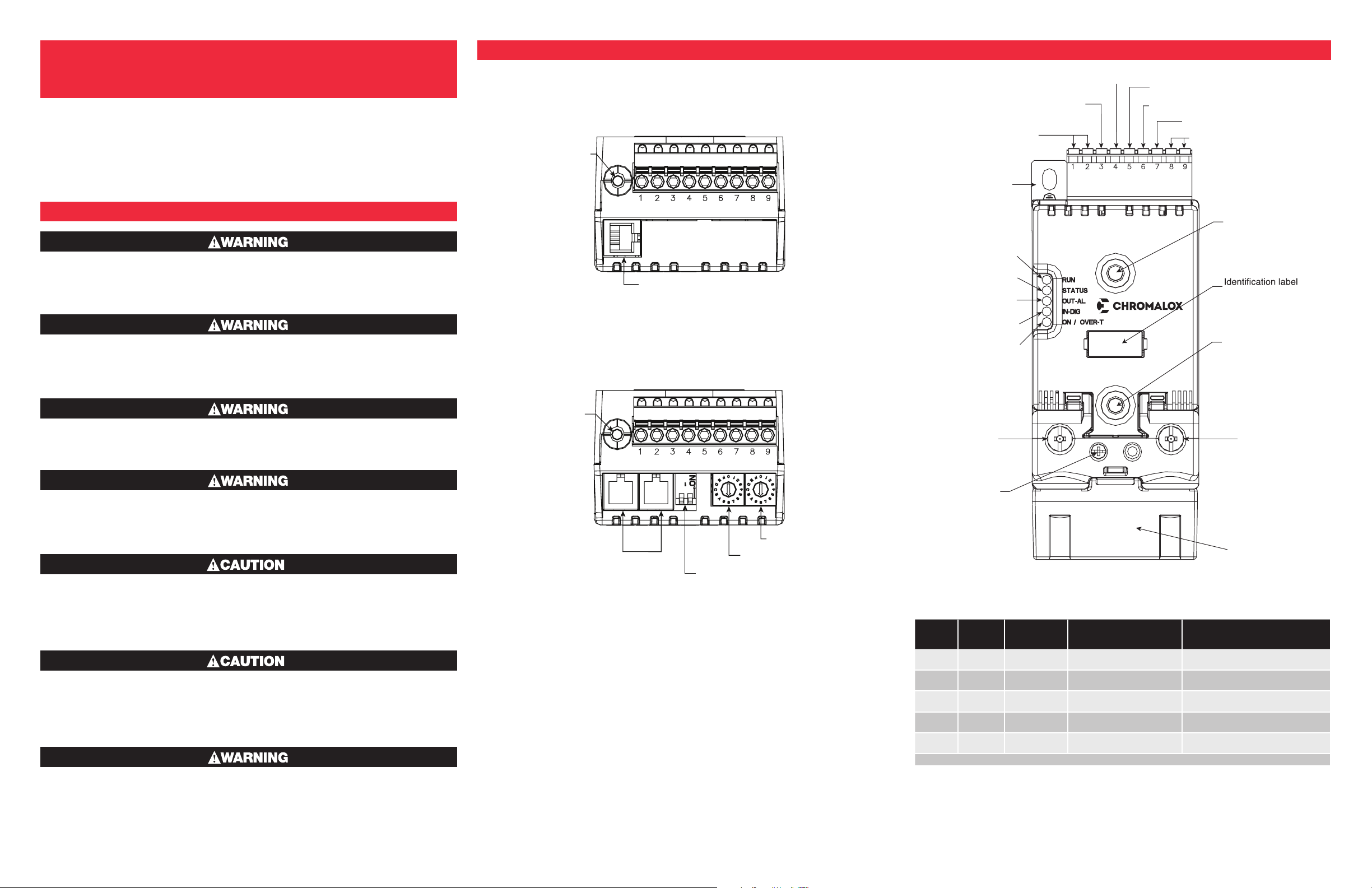

Top view

Key HB

RS485 serial line

Input control signal (+)

(GND)

Power Controller Quick Start Manual

0037-75560 (PK538)

This manual is intended to be a quick reference guide for basic installation requirements and an overview of the connections, wiring considerations, and general specifications for the CTF-Xtra Advanced SCR Power Controller. For complete installation, operation, programming and configuration, please refer to the following manuals:

PK535 CTF-Xtra Hardware Instruction Manual; PK534 CTF & CTF-Xtra Controller Programming Manual; PK537 C-PWR Configuration Software Manual. The most current

revisions may be found on the Chromalox website: www.chromalox.com.

2. INSTALLATION

Input & Output Connections: CTF-Xtra 25 – 60 Amp Models

Key HB

WITHOUT Modbus Option

Syncronous output for

Master/Slave connection

Alarm output

(solid state relay - HB option)

Earth Ground

Potentiometer output power supply (+5Vdc)

Digital input (PWM input)

Power supply terminal 24Vac/Vdc

J1

Power supply /control

connector

1. IMPORTANT SAFEGUARDS

ELECTRIC SHOCK HAZARD: Read and understand all instructions before

installing, servicing or operating this controller. Failure to do so could

result in equipment or property damage as well as personal injury and

even death.

HIGH VOLTAGE is used in the operation of this equipment; DEATH ON

CONTACT may result if personnel fail to observe safety precautions.

Learn the areas containing high-voltage connections when installing or

operating this equipment.

Be careful not to contact high-voltage connections when installing or

operating this equipment. Before working inside the equipment, turn

power off and ground all points of high potential before touching them.

ELECTRIC SHOCK HAZARD: Any installation involving control equipment must be performed by a qualified person and must be effectively

grounded in accordance with the National Electrical Code or local governing electrical code/authority, to eliminate shock hazard.

The owner/installer must provide all necessary safety and protection

devices and follow all current electrical wiring standards and regulations. Failure to do so may compromise the integrity of the controller

and/or cause product failure resulting in a safety risk to operational and

service personnel.

This controller utilizes a heat sink which is designed to cool the unit

during operation. Under no circumstance should air flow around the

controller be compromised in any way. Failure to do so may result in the

overheating of the controller, product failure, product temperatures and

even fire.

During continuous operation, the heat sink can reach very high temperatures, and keeps a high temperature even after the unit is turned

off due to its high thermal inertia.

J2

TTL port for

Port Configuration

Yellow Led (Status digital input)

Top view

WITH Modbus Option

Address x 1

J3, J4

RJ10 connectors

Switch for

serial line

Installation Wiring Note:

Use the extra rapid fuses as indicated in the CTF-Xtra Hardware Instruction

Manual PK535, according to the wiring schematic examples and controller rating.

Additionally, the applications with solid state units require a safety automatic switch

to disengage the load power line during certain alarm events.

EMC Filter

EMC Filters are required in Phase Angle firing mode. The filter model and current level depend

on the configuration and load used. The power filter MUST be connected as close as possible

to the CTF. You can use a filter connected between the power line and CTF or an LC group

connected between the CTF output and the load.

Address x 10

Fixing screw

at heatsink

Green Led (RUN)

Yellow Led (STAT US)

Red Led (Alarm output HB)

Led: Green = SCR ON

Yellow = Temperature OVER

1/L1

LINE connection

3/L2

Reference connection

of line voltage

Fixing screw

at heatsink

2/T1

LOAD connection

Over Voltage Protector

Recommended Wire Gauges

CTF-Xtra

Current

Level Terminal Cable Wire Wire Terminal Tightening Torque / Tool

1/L1, 2/T1, PE4 mm

25A

1/L1, 2/T1, PE10 mm

40A

1/L1, 2/T1, PE10 mm

50A

1/L1, 2/T1, PE16 mm

60A

-

NOTE: Cables must be Copper “Stranded Wire” or “Compact-Stranded Wire” type with max. operating temp. 60/75°C

3/L2

(Ref. Vline)

0.25 ...2.5 mm

2

10 AWG

2

7 AWG

2

7 AWG

2

5 AWG

23...14 AWG

Wire terminal / Eye D. 6mm 2.5 Nm / Phillips screwdriver PH2 - PH3

Wire terminal / Eye D. 6mm 2.5 Nm / Phillips screwdriver PH2 - PH3

Wire terminal / Eye D. 6mm 2.5 Nm / Phillips screwdriver PH2 - PH3

Wire terminal / Eye D. 6mm 2.5 Nm / Phillips screwdriver PH2 - PH3

2

Wire stripped for 8 mm or

with tag terminal

0.5 ...0.6 Nm / Flat-head screwdriver tip

0.6 x 3.5 mm

Page 2

3. INSTALLATION CONSIDERATIONS: DIMENSIONS & WEIGHTS, MOUNTING & SPACING REQUIREMENTS 4. DERATING CURVES

W

L

25 25

22.5

20

40

40

35

30

15

20

25

30

35

40

45

0 40 45 50

60 60

55

5050 50

45

40

30

35

40

45

50

55

60

65

70

0 40 45 50

Current (Amps)

Enclosure / Ambient Temperature ˚C

CTF-025 & CTF-040

Current (Amps)

Enclosure / Ambient Temperature ˚C

CTF-050 & CTF-060

Dimensions in Inches (mm)

Minimum Spacing Requirements

CTF-Xtra 25 (Without Fan)

CTF-Xtra 40 (With Fan)

CTF-Xtra 50 (With Fan)

CTF-Xtra 60 (With Fan)

3.1 (80)

0.7 (18.5)

5 (127)

1.2 (30)

3.9

(100)

Rear Panel Mounting Template

1.3

(32)

Depth: 5.6 (143)

CTF-Xtra 25: 2.1 lbs (970 g)

CTF-Xtra 40, 50: 2.4 lbs (1,100 g)

Fan

Overvoltage Protector

Depth: 5.6 (143)

Weight: 3.3 lbs (1,500 g)

1.3

(32)

Model

CTF 25A/40A/50A 4.4 (112) 1.7 (44)

CTF 60A 4.4 (112) 4.4 (113)

5. GENERAL TECHNICAL DATA & SPECIFICATIONS 6. FUSES & FUSE HOLDERS

LOAD, FIRING, DIAGNOSTICS & RATINGS

CATEGORY OF USE

(Tab. 2 EN60947-4-3)

Trigger Mode

Feedback Mode

Max rated voltage 480 Vac

Work voltage range 90 - 530 Vac

Non-repetitive voltage 1200 Vp

Rated Frequency 50/60Hz Auto-Synchronization

Rated Current, AC51 - AC55b Resistive Load

(@ 40˚C contin. service)

Rated current AC56A permitted trigger modes:

ZC, BF/DOT with DT (Delay Trigger), PA with

softstart (@ Tamb = 40 °C)

Maximum Surge Current (t = 10 ms) A 400A 520A 520A 1150A

Maximum I

Critical dV/dt Off-state (minimum) 1,000 V/µs

Nom. Impulse Voltage 4 KV

Nominal SCCR

2

t for fusing (blowout) A2s 450 1,800 1,800 6,600

AC 51 resistive or low inductance loads

AC 55b infrared lamps

AC 56a: transformer loads

PA - Load management by adjusting the firing angle (only configuration

single-phase or delta open)

ZC - Zero Crossing with constant cycle time (settable in range 1-200sec)

BF - Burst Firing, or D.O.T. with variable cycle time optimized min.

HSC - Half Single Cycle corresponds to Burst Firing that includes ON and

OFF half-cycles.

Useful for reducing flicker with short-wave IR loads (applied only to singlephase resistive or 3-phase 6-wire open delta loads).

2

V, V

: Voltage feedback proportional to RMS voltage value on load

(useful to compensate possible variations in line voltage).

I, I2: Current feedback: bound to RMS current value on load to compensate

variations in line voltage and/or variations in load impedance.

P: Power feedback: proportional to real power value on load (useful to keep

constant values of electrical power assigned regardless of load impedance

or line voltage variations).

CTF MODEL CTF-025 CTF-040 CTF-050 CTF-060

25A 40A 50A 60A

20A 32A 40A 50A

WARNING: Max. Permissable inductance loop

5 KA / 480 V

impedance is 500 µh

Diagnostics

Options

Diagnostic

Power Supply CTF 25-60 A: 24 Vac 50-60 Hz / Vdc ± 25%, max 3 VA

Power Supply for

external fan (only for

CTF-120A model)

Signals

Load Type

& Connection

Protection IP20

Ambient Temp.

Storage Temp. -20˚C to 70˚C (-4˚F to 158˚F)

Relative Humidity 20…85% RH non-condensing

Ambient Cond. for use Indoor use, altitude up to 2000 m

Installation DIN Rail EN50022 or panel with screws

Installation

Requirements

Detection of shorted load circuit, absence of line voltage, HB alarm (partial break

of load)

- Timed Soft-Start firing ramp, with or without peak current control

- Soft-Start firing ramp (specific for infrared lamps)

- Timed shut-off ramp

- Limitation of RMS current in load

- 0-90° Delay-Triggering for firing inductive loads in ZC & BF/DOT modes.

- SCR in short circuit (presence of current with OFF control)

- Absence of SCR current when under load.

- Overtemperature alarm

Current read

• HB alarm: interrupted or partially interrupted load

• Automatic calibration of HB alarm setpoint starting from current value in load

• Alarm for load in short circuit or overcurrent

Voltage read

• No line voltage

24 Vdc ± 10%, max 200mA

5 leds: RUN: run state of CPU

STATUS: operating state

ALARM: state of alarm output

DIGITAL INPUT: state of digital inputs

ON / OVER-TEMP.: state of SCR power / Alarm for overheating

Single phase load, Independent single-phase load in open delta 3-phase load;

3-phase load (star without neutral or closed triangle) w/ 2-leg control

0 to 50˚C (32 to 122˚F) (Per EN 60947-4-3 § 7.1.1: Average Temperature over 24

hour period shal not exceed 35˚C (95˚F)

Installation category II, pollution level 2, double isolation (only for model >120A):

- Max. temp. of air surrounding device 40°C; for temp. >40°C refer at derating

curves

- Device type: “UL Open Type”

FUNCTION

OPTIONS

GENERAL DATA

CTF Model

CTF-25 25A 390 A²s 6W 10x38 FWC25A10F 0024-07815 0024-12124 30A@600V 32A@690V

CTF-40 50A 1,600 A²s 9.5W 22x58 FWP50A22F 0024-07816 0024-12199 100A@600V 125A@690V

CTF-50 50A 1,600 A²s 9.5W 22x58 FWP50A22F 0024-07816 0024-12199 100A@600V 125A@690V

CTF-60 63A 3,080 A²s 11W 22x58 FWP63A22F 0024-07817 0024-12199 100A@600V 125A@690V

CTF Model

All Models 1A N/A N/A 10x38 KTK-1 0024-01113 0024-12124 30A@600V 32A@690V

Length

In. (mm)

Fuse Rating,

Fuse Rating,

Width

In. (mm)

Amps I

Amps I

2

t

2

t

Power

Dissipation Fuse Size

Power

Dissipaton Fuse Size

2

t Extra Rapid Fuses Fuse Holder

I

Manufacturer’s

Model Code Part No. Part No.

Instrument Fuse Fuse Holder

Manufacturer’s

Model Code Part No. Part No.

Fuse Holder

Rating (UL)

Fuse Holder

Rating (UL)

Fuse Holder

Rating (IEC)

Fuse Holder

Rating (IEC)

PK538

0037-75560

© 2016 Chromalox, Inc.

June 2016

Loading...

Loading...