Page 1

Components

Components

Overview

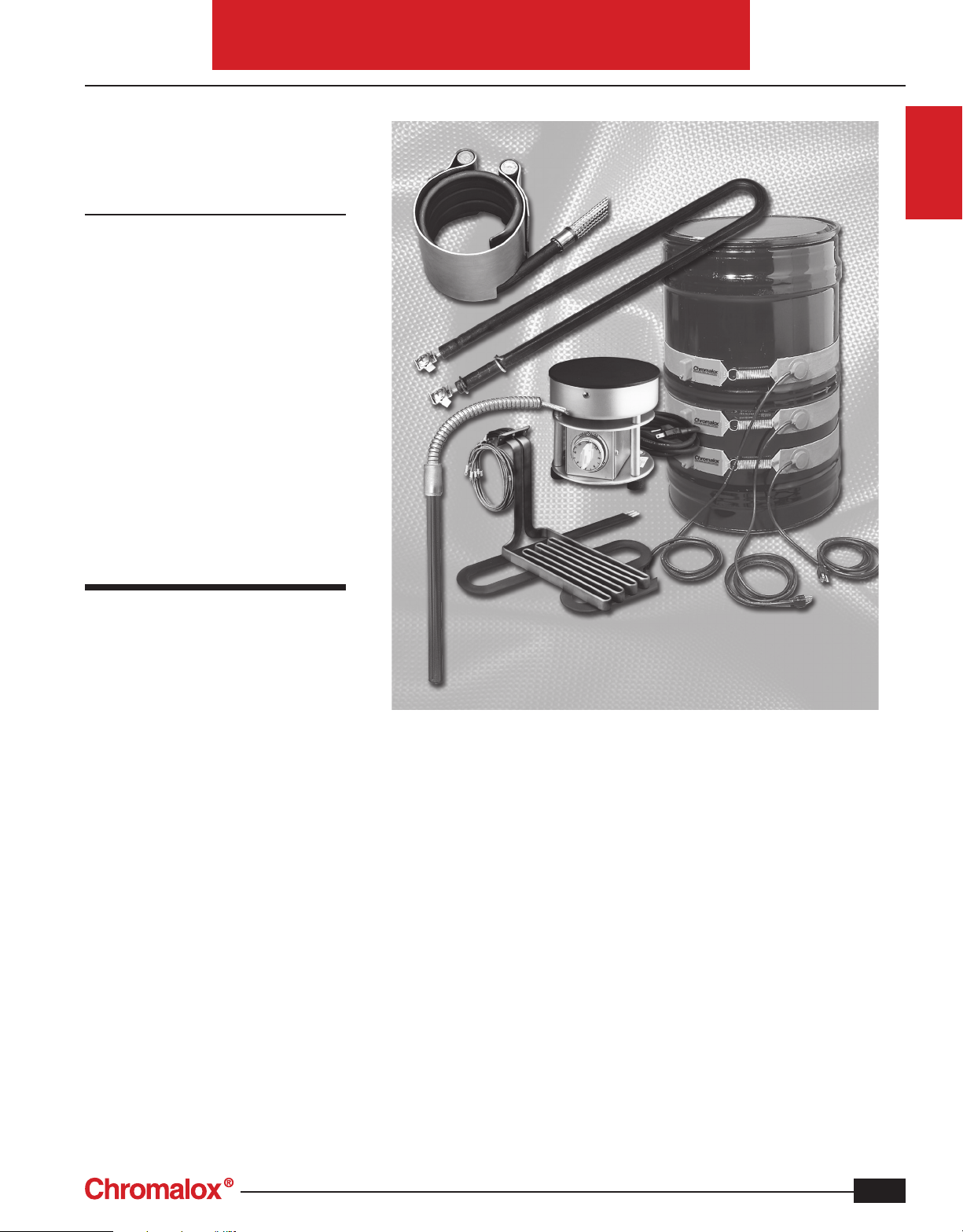

Component Heaters include the

basic types of heating elements:

• TubularElements

• ThinBladeHeaters

• StripHeaters

• Ring&DiscHeaters

• Band&NozzleHeaters

• CartridgeHeaters

• FlexibleHeaters

• SpecialtyHeaters

heaters

component

Component heaters may be used by

themselves to solve many heating problems. They may also be incorporated into

more complex heating systems, providing a

complete thermal solution for your heating

requirements.

Chromalox carries the widest selection of

standard component heaters in many shapes,

sizes and wattages. Chromalox is the “First

Choice for Thermal Solutions”.

Applications

With component heaters, most often the shape

and size will be the determining factor in most

heater applications. Brief descriptions of each

heater type follow, with selection guidelines

that lead to a detailed description on individual

product pages.

Tubular heating elements perform exceptional heat transfer by conduction, convection

or radiation to heat liquids, air, gases and

surfaces. In most heater assemblies, tubular

element design configurations vary — round,

triangular, flat press and formed. Bends are

made to customer requirements Custom built

from 0.200" to 0.475" diameters, a multitude

of sheath materials with sheath temperature

capabilities up to 1600°F, watt densities to fit

many applications and up to 600 volts. Available with over 20 optional terminations and

many stocked accessories.

Thin blade heater elements provide more

surface area than standard tubular elements to

offer greater wattage or lower watt densities.

Select from many sheath materials with watt

densities to 75 W/in

as high as 1200°F. Heating elements can be as

long as 120" and are capable of being formed

into many configurations for heating via immersion, direct surface contact or convection.

Three wire construction within the element

provides uniform heating. Available in single

or 3-phase current terminations with a 120 to

240 volt range.

2

and sheath temperatures

A-1

Page 2

Components

Application Guidelines

Applications (cont’d.)

Strip/Ring/Disc heating elements are rugged and easy to install for heat transfer by

conduction or convection to heat liquids, air,

gases and surfaces with sheath temperatures

up to 1600°F and watt densities to 35 W/in

Common applications include drying, melting,

baking and curing. Strip heater sizes range

from 0.5" wide to 2.5" and lengths to 72"

long. Heaters bolt or clamp to many surfaces.

Nested ring heaters can provide concentrated

heat in small areas. Select from many sheath

materials, termination styles, operating temperatures, sizes, voltages, wattage ratings and

mounting devices.

2

.

Components

Band heaters grip tightly to cylindrical surfaces to supply uniform heat transfer, critical

to the heater life. Chromalox band heaters

are flexible and come in one or two-piece

construction for easy installation and removal.

They accommodate diameters as small as

15/16" and as large as 20" and are capable of

reaching sheath temperatures up to 1600°F.

Stainless steel braids and conduit protect

terminations and resist contamination. Completely customize your heater by specifying

exact physical dimensions, material, electric

ratings and terminations.

Cartridge heaters are high efficiency heating

elements. Diameters of cartridge heaters range

from 0.25" to 1.25". Watt densities from 25

2

W/in

to 200 W/in2 and sheath temperatures to

1600°F. Optional end seals resist contaminants

and moisture from entering inside the heater.

Chromalox provides a variety of sizes, wattage

ratings, voltages and protective features to

meet many challenging applications.

Flexible heaters are very versatile and provide

solutions to a vast number of low-to-medium

temperature applications. Heaters are manufactured with rugged light-weight materials

providing chemical and moisture resistance

with operating temperatures to 390°F. Wire

elements are durable and wound precisely

within the structure for optimal performance.

A variety of electrical, shape and contour fittings to meet many specifications.

A-2

Loading...

Loading...