Chromalox CMX-250-4, CMX-250-24, CMX-250-4C, CMX-250-18C, CMX-250-9C Installation & Operation Manual

...Page 1

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Installation & Operation Manual

Circulating Water

Temperature Control System

i

Thermal Devices, Inc. Mount Air

PQ450

161-123417-036

March 2019

, Maryland USA www.thermaldevices.com

Page 2

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Table of Contents

Contents Page Number

Section 1 Getting Started ......................................................................................................................................1

Section 2 Installation .............................................................................................................................................. 4

Section 3 Temperature Control Operation ........................................................................................................... 9

Section 4 System Operation ................................................................................................................................ 10

Section 5 Diagnostics .......................................................................................................................................... 11

Section 6 Maintenance ........................................................................................................................................12

Section 7 Troubleshooting ................................................................................................................................... 17

Section 8 Specifications ...................................................................................................................................... 18

Appendix A CMX Closed Loop to Open Loop Cooling Conversion ................................................................. 19

Appendix B CMX Open Loop to Closed Loop Cooling Conversion ................................................................. 20

Appendix C CMX 2104 Controller Information .................................................................................................. 23

Thermal Devices, Inc. Mount Air

ii

, Maryland USA www.thermaldevices.com

Page 3

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Section 1 – Getting Started

Installation Instructions

Read and understand all instructions in this

user’s manual and the associated temperature

control instruction manual before attempting

to install or operate system.

Introduction

Congratulations on purchasing the Chromalox CMX

Series microTHERM™ Temperature Control System.

This system has been thoroughly engineered, carefully

built, and fully tested to assure years of service.

The CMX can be operated at a maximum temperature of 250°F at a minimum pressure of 30psi. CMX180 models do not require minimum pressure. Water

temperature is maintained by a microprocessor-based

temperature controller which applies heating and cooling as needed. Heat is applied by a long-life, INCOLY

sheathed heater. Cooling is either via direct injection, in

an open loop, or through a closed loop heat exchanger.

Every system is equipped with an automatic vent that

removes unwanted air from the system during operation, and an ASME pressure relief valve that is factoryset to 125 psi (150 psi with 7.5 hp motor.) A pressure

switch ensures adequate water pressure in the system

to help prevent pump cavitation and steam buildup on

the heater elements, which can shorten the lives of the

heater and pump. The switch is factory-set to 20 psi.

This switch is not included on CMX-180 models.

®

Electrical and hydraulic components are located in

distinctly separate areas in the system to better manage heat buildup and prevent component damage.

The pump housing, heater, and cooling chambers are

single cast pieces, designed to drastically reduce the

chance of leaks and provide ease of service and maintenance. Standard casters make it easy to move the

system from machine to machine.

Power requirements for the system are 240 or 480

volts, 3 phase, 60 cycle, and 4.5 to 24 kW. See the system nameplate for the appropriate voltage and wattage

ratings.

The System Photo and Control Panel Illustrations, on

the following pages, show the CMX and identifies all

key components.

Thermal Devices, Inc. Mount Air

1

, Maryland USA www.thermaldevices.com

Page 4

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

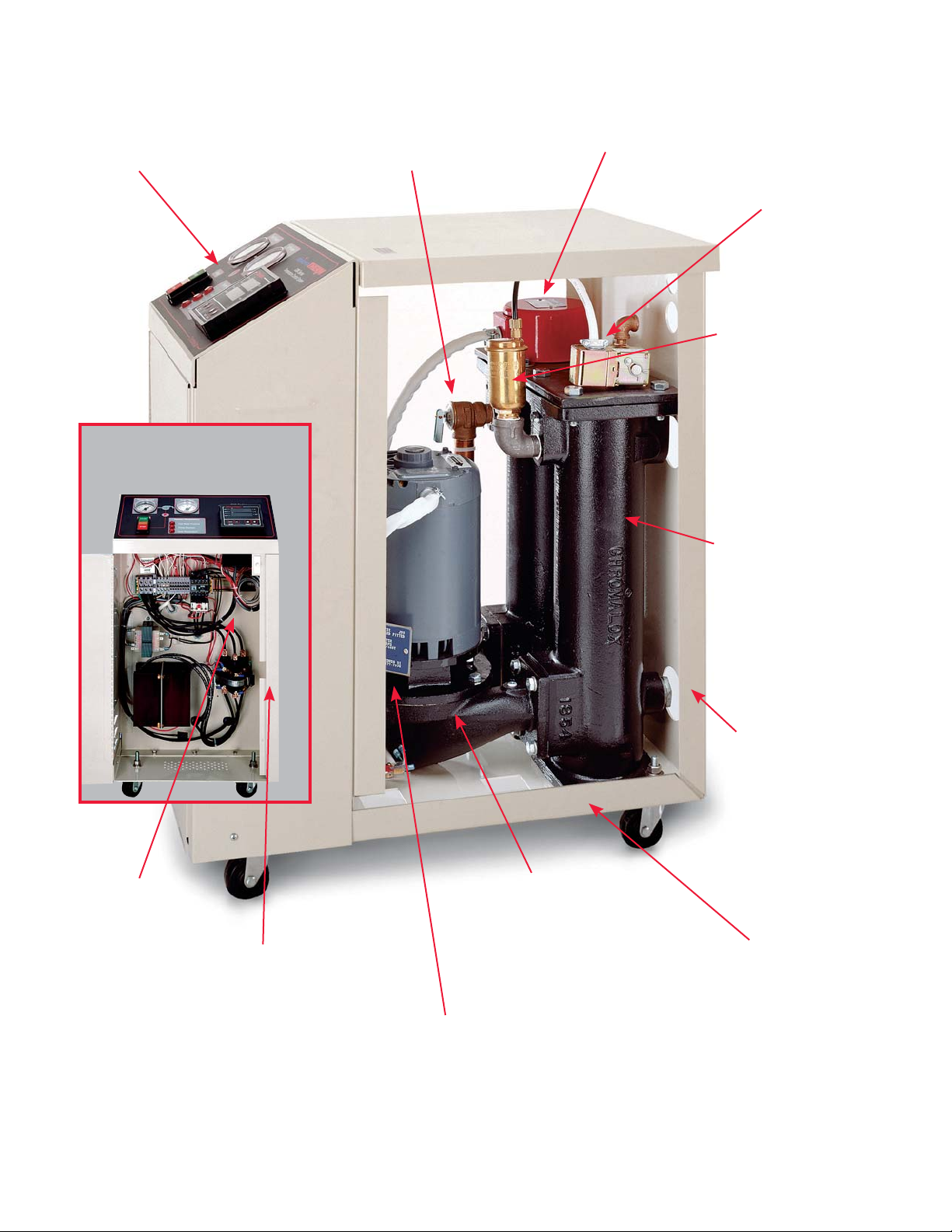

Figure 1.1 System Photo (Side View)

Operating temperatures of 50° to 250°F

for a wide variety of applications.

Internal system configuration separates

electronics from mechanical systems,

reducing heat buildup and providing

a safer operating system.

ASME pressure relief valve opens if system pressure exceeds 125 psi, ensuring

safe operation.

High watt density, INCOLOY

Chromalox® heating elements.

Integral solenoid valve for precise temperature control and

optimum flow.

®

sheath

Automatic air purge cycle

removes accumulated air

from water lines.

Standard 3.8 sq. ft. heat exchanger (closed loop cooling)

Pump overload circuit protects

systems from damage in event

of excessive current draw in

the motor.

Long-life mercury contactor switches

heater power for millions of cycles and

quiet, trouble-free operation.

Thermal Devices, Inc. Mount Air

Cabinet design allows

access to all components without removing

a single fastener.

Custom cast pump for optimum flow,

minimum leakage and long life.

Compact, rugged cabinet fits into tight

spaces. Rolling casters allow easy

transfer between locations.

Low pressure switch disables system when

supply pressure is low, preventing cavitation in

pump and protecting the system.

2

, Maryland USA www.thermaldevices.com

Page 5

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

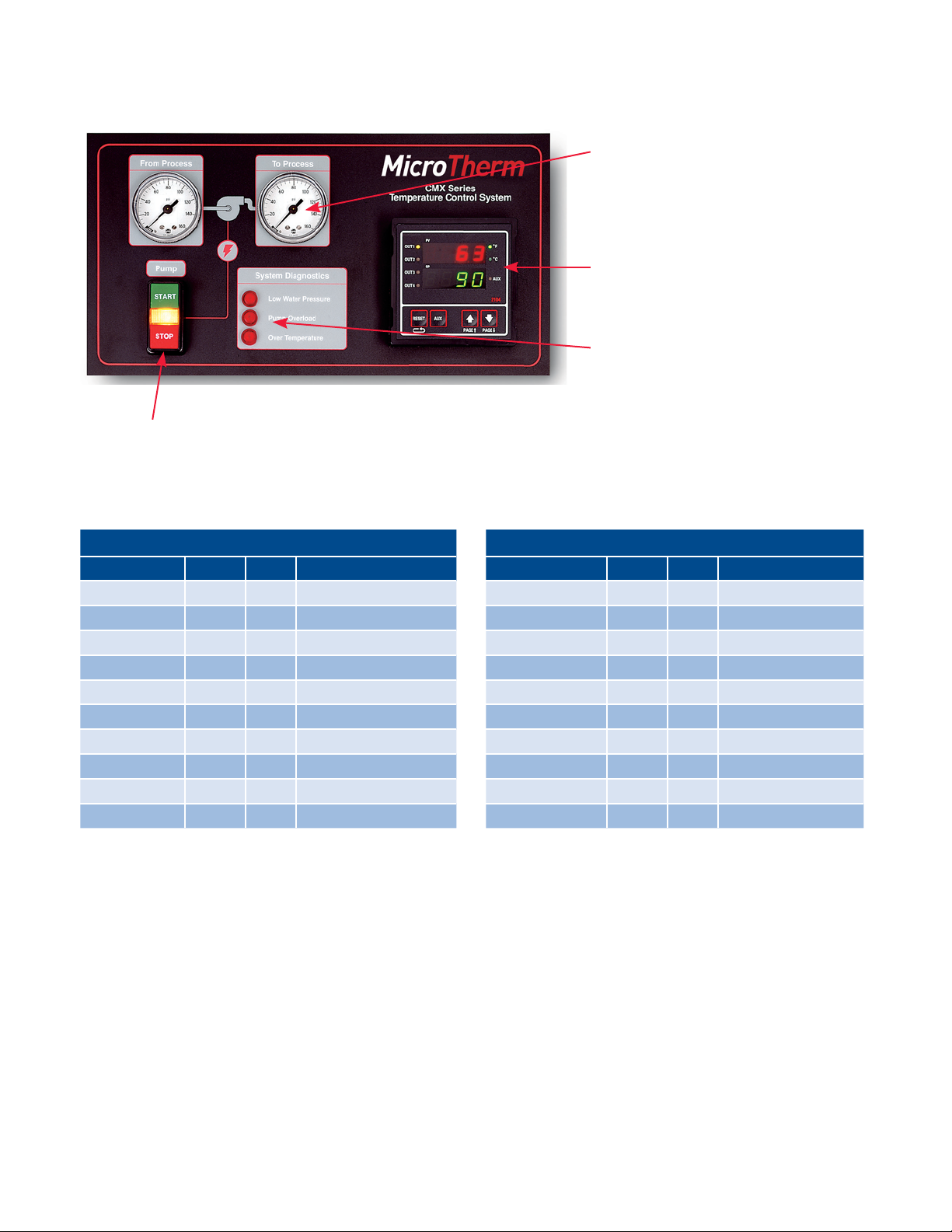

Figure 1.2 Control Panel

Pump START/STOP Pushbuttons

Du al p re ssu re g au ge s s implif y mo ni to rin g o f b ot h

to process and from process pressures.

Chromalox’s Temperature and Process Controller

features separate PID algorithms for heat and

cool control modes, dual display of setpoint and

process temperatures, and simple configuration

parameters with alphanumeric cues. Optional

digital communications expand microTHERM’s

application flexibility. (Controller model supplied

may vary from picture)

Diagnostic Indicators allow you to constantly

monitor microTHERM’s performance, giving you

early detection of potential problems before they

occur and simplifying maintenance.

Ordering Information

Open Loop Cooling

Model kW Volts Total Amperage

CMX-250-4 4.5 240 13.6

CMX-250-4 4.5 480 6.8

CMX-250-9 9 240 24.5

CMX-250-9 9 480 12.2

CMX-250-12 12 240 31.7

CMX-250-12 12 480 15.8

CMX-250-18 18 240 46.1

CMX-250-18 18 480 23.1

CMX-250-24 24 240 60.5

CMX-250-24 24 480 30.3

Closed Loop Cooling

Model kW Volts Total Amperage

CMX-250-4C 4.5 240 13.6

CMX-250-4C 4.5 480 6.8

CMX-250-9C 9 240 24.5

CMX-250-9C 9 480 12.2

CMX-250-12C 12 240 31.7

CMX-250-12C 12 480 15.8

CMX-250-18C 18 240 46.1

CMX-250-18C 18 480 23.1

CMX-250-24C 24 240 60.5

CMX-250-24C 24 480 30.3

Thermal Devices, Inc. Mount Air

3

, Maryland USA www.thermaldevices.com

Page 6

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Section 2 – Installation

Before Open-Loop Hydraulic Installation:

Before proceeding with the installation of the openloop system, please take note of the following important information:

1. Reduced diameter fittings may be used if they do

not reduce flow rate and increase pressure drop

significantly. Galvanized steel unions are recommended at all connections.

2. If water pressure falls below 20 psi, a pressure

switch will interrupt pump motor and heater operation. Use an external water pressure regulator

and back pressure relief valve or regulator, set at

maximum 125 psi (150 psi with 7.5 hp motor) connected in the external fill line, to reduce excessive

water pressure. Not provided on CMX-180 models.

HAZARD OF EXPLOSION, FIRE AND SCALDING

BURNS.

The water feed line on both open and closed

loop systems must not have any obstructions

which could prevent expanding water from

backing up into the feed line.

Do not use oils or other synthetic heat transfer fluids. This system is for use with water or

ethylene glycol and water mixture for freeze

protection only as the heat transfer fluid.

When installing system, allow sufficient room

to remove the heater element and other serviceable items when necessary. 18 inches

clearance on sides of unit recommended.

If the water source is a potable water source,

a back flow preventer and back pressure relief

valve/regulator should be installed and may be

required by local code. Do not install a check

valve only on the fill line. The inability of the

system to flow back into the fill line can lead

to excessive pressure. Back pressure relief is

required.

To avoid excessive pressures, do not connect

any valves or obstructions which could prevent

free discharge from relief valve in a safe manner. Route line so water drains completely. Do

not allow drain to freeze or corrode shut.

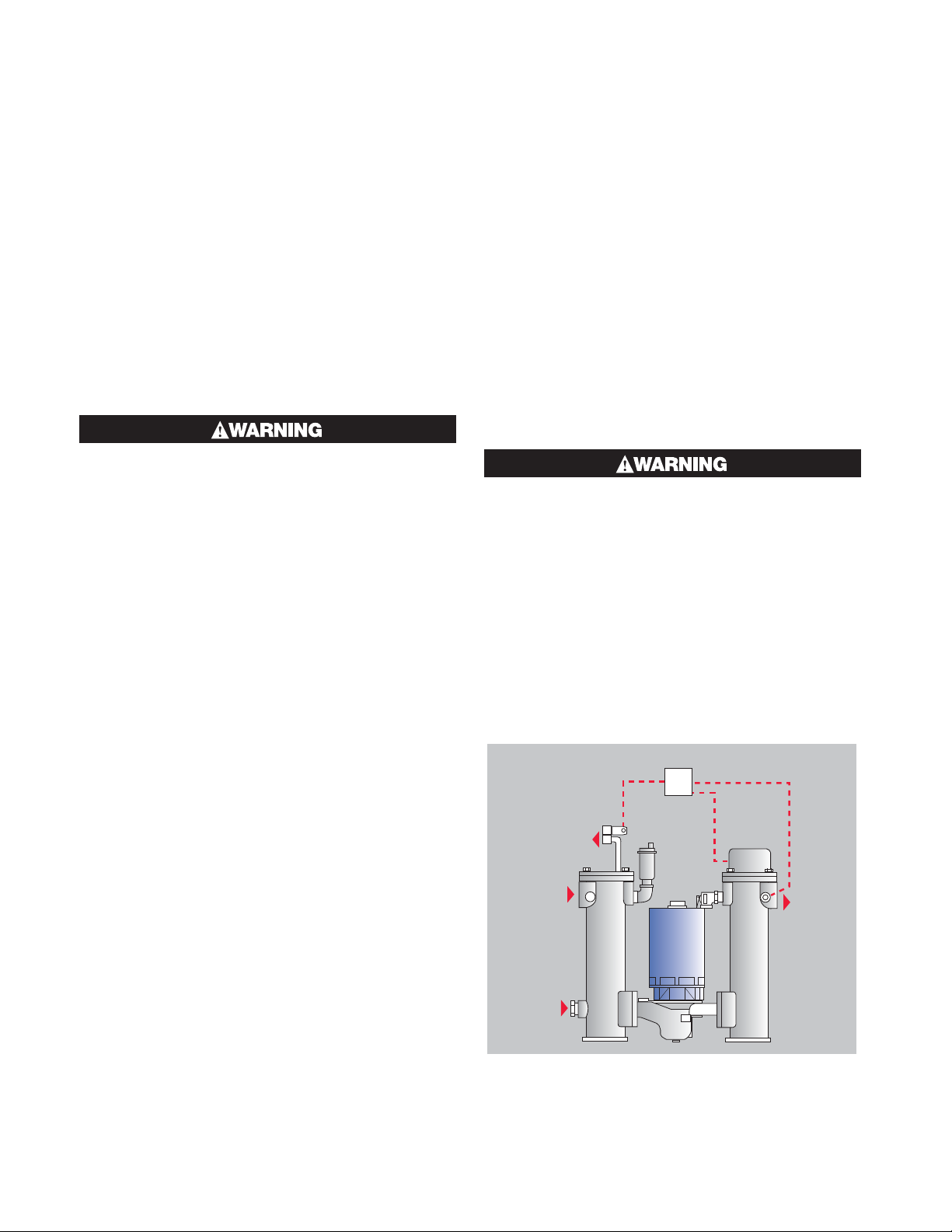

Hydraulic Installation, Open Loop:

1. Locate the unit as close as possible to the controlled process in order to minimize pressure

drops. Make sure the unit is sitting on a solid, level

foundation.

2. Using 1 1/4” NPT or larger schedule 40 pipe (flexible hose suitable for 150 psi and 250°F minimum

service conditions can be used), connect the 1

1/4” NPT “FROM PROCESS” and “TO PROCESS”

ports to the mold, mold manifold, or other process.

3. Pipe the entire system to minimize air pockets.

Provide air bleed valves at high points and drains

at low points.

4. Connect the plant water supply (30 psi to 80 psi)

to the unit’s 1/2” NPT “WATER SUPPLY/COOLING

INLET” port with suitable pipe or hose.

HAZARD OF EXPLOSION, FIRE AND SCALDING

BURNS.

Connect the 1/4” NPT port identified as “DRAIN

COOLING OUTLET” to an open or plant drain

that contains no valves or obstructions that

could impede discharge. Review the condition

of potential hot water or steam going down a

plant drain. Verify that local codes and materials are acceptable for this service.

Locate floor drain under unit. The air bleed and

relief valve may discharge hot water or steam

from the bottom of the unit. Do not locate materials that could be damaged by hot water or

steam adjacent to the unit.

Temperature Controller

Cooling

Valve

Drain/Cooling

(1/4 NPT)

From Process

(1-1/4 NPT)

Outlet

Auto

Air Bleed

Pressure

Relief

Valve

Pump and

Motor

Heater

Therocouple

Probe

To Process

(1-1/4 NPT)

Thermal Devices, Inc. Mount Air

Water Supply/

Cooling Inlet

(1/2 NPT)

Figure 2.1 Open-Loop System Piping

4

, Maryland USA www.thermaldevices.com

Page 7

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

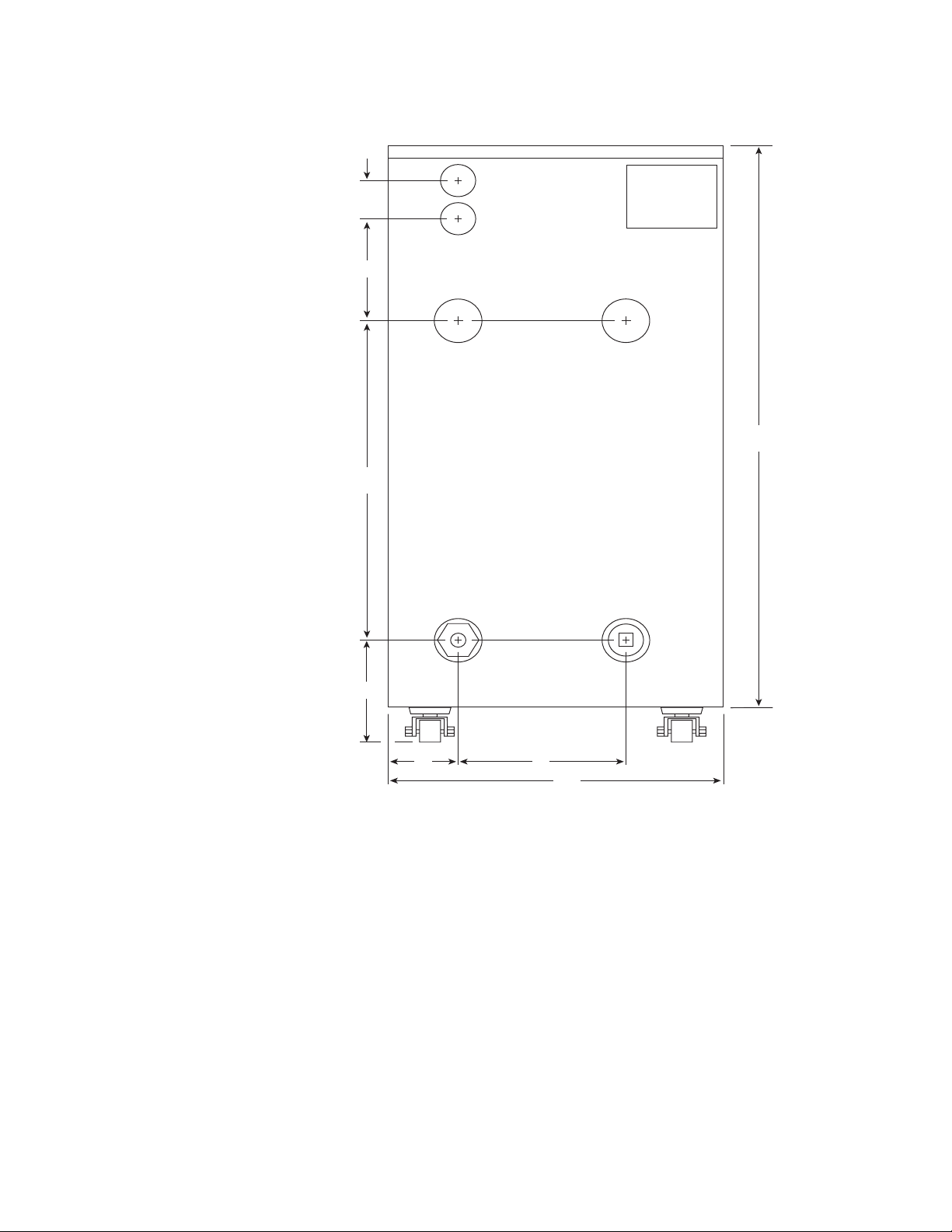

y

Figure 2.1 Open-Loop Cooling Piping Connections

1-7/8”

6"

12-5/16”

FROM PROCESS

WATER SUPPLY/

COOLING INLET

DRAIN/

COOLING OUTLET

TO

PROCESS

Chromalox

®

28-1/2”

6"

4"

7"

15"

Rear View

Note: Dimensions are nominal ± 3/8”

Thermal Devices, Inc. Mount Air

5

, Maryland USA www.thermaldevices.com

Page 8

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Before Closed-Loop Hydraulic Installation

Before proceeding with the installation of the Closedloop system, please take note of the following information:

1. Reduced diameter fittings may be used if they do

not reduce flow rate and increase pressure drop

significantly. Galvanized steel unions are recommended at all connections.

2. If water pressure falls below 20 psi, a pressure

switch will interrupt pump motor and heater operation. Use an external water pressure regulator

and back pressure relief valve or regulator set at

maximum 125 psi (150 psi with 7.5 hp motor) connected in the external fill line, to reduce excessive

water pressure. Not provided with CMX-180 models.

HAZARD OF EXPLOSION, FIRE AND SCALDING

BURNS. To avoid excessive pressures, do not

connect any valves or obstructions which could

prevent free discharge from relief valve in a

safe manner. Route line so water drains completely. Do not allow drain to freeze or corrode

shut.

Do not install a check valve on the fill line. The

inability of the system to flow back into the

fill line can lead to excessive pressure. If back

flow preventer or check valve is required, install back pressure regulator rated for 250°F

water with a pressure setting of 30 to 80 psi.

Back pressure regulator setting must be approximately 10 psi above water supply pressure to minimize water flow directly from supply to drain.

4. Connect the cooling water supply (30 psi to 80 psi)

to the unit’s 1/2” NPT “WATER SUPPLY/COOLING

INLET” port with suitable pipe or hose.

5. Connect the 1/4” NPT port identified as “COOLING OUTLET” to a cooling water return line or plant

drain that contains no valves or obstructions that

could impede discharge. Review the condition of

potential hot water going down a plant drain. Verify

that local codes and materials are acceptable for

this service. Temperature of discharge water could

reach 250°F and create steam at atmospheric

pressure.

Temperature Controller

Solenoid

Cooling Outlet

(1/2 NPT)

Water Supply/

Cooling Inlet

(1/2 NPT)

From Process

(1-1/4 NPT)

Valve

Auto

Air Bleed

Pressure

Relief

Valve

Pump and

Motor

Heater

Therocouple

Probe

To Process

(1-1/4 NPT)

Figure 2.3 Closed-Loop System Piping

Hydraulic Installation Closed-Loop

1. Locate the unit as close as possible to the controlled process in order to minimize pressure

drops. Make sure the unit is sitting on a solid, level

foundation.

2. Using 1 1/4” NPT or larger schedule 40 pipe (flexible hose suitable for 150 psi and 250°F minimum

service conditions can be used), connect the 1

1/4” NPT “FROM PROCESS” and “TO PROCESS”

ports to the mold, mold manifold, or other process.

3. Pipe the entire system to minimize air pockets.

Provide air bleed valves at high points and drains

at low points.

Thermal Devices, Inc. Mount Air

, Maryland USA www.thermaldevices.com

6

Page 9

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Figure 2.1 Open-Loop Cooling Piping Connections

S” and “TO PR

1-7/8”

6"

12-5/16”

COOLING OUTLET

WATER SUPPLY/

COOLING INLET

FROM PROCESS

PROCESS

TO

Chromalox

®

28-1/2”

6"

Thermal Devices, Inc. Mount Air

4"

7"

15"

Rear View

Note: Dimensions are nominal ± 3/8”

7

, Maryland USA www.thermaldevices.com

Page 10

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Electrical Installation

HAZARD OF ELECTRIC SHOCK. The heat transfer system must be grounded using grounding

means provided in control box and employing

wiring by a qualified electrician in accordance

with National Electric Code. Failure to comply

can result in electrical shock or electrocution.

HAZARD OF ELECTRIC SHOCK. Disconnect all

power before servicing the heat transfer system. Failure to comply can result in electrical

shock or electrocution.

Fusing or other over-current protection must be supplied to the system by the user.

The unit is completely wired when shipped. The only

wiring necessary is to the blue colored terminals L1,

L2, L3, and the green and yellow colored ground. To

make these connections:

4. Pump Rotation Check: With power off, check the

wiring connections by tugging on the lines. Tighten

all terminals in the control area. These can loosen

due to vibration in shipping.

5. Close the front electrical enclosure door. Pull the

top cover off of the heat transfer system and locate

the top of the pump motor.

6. With the supply water connected, and adequate

pressure present, Press the

tons in quick succession. Watch the rotation on the

pump motor to insure it matches the label on its

top.

7. If rotation is incorrect, disconnect power to the

system and swap any two of the supply lines. Repeat rotation check.

Close the front electrical enclosure door and

retighten the locking screw. This must be done

to limit access to high voltage components.

Failure to comply could lead to electric shock

or electrocution.

START

and

STOP

but-

Figure 2.5 Power Connection Terminals

1. Loosen the screw on the front electrical enclosure

door to unlock the latch.

2. Open the front electrical enclosure door. Using

90°C wire sized per National and local codes, run

each leg of the three phase supply power and

ground to the appropriate terminals as shown in

Figure 2.5.

3. A separate fused disconnect is required. Locate

this fused disconnect near the equipment. Codes

may require the location of disconnect in sight of

operation standing next to the equipment. Consult

applicable codes for details.

Control Voltage Fusing

Terminal block #1 (see Figure 2.5) contains a 120V fuse

for the control circuitry. This fuse protects the control

transformer and circuitry.

1. Should the fuse blow, an indicator will light on the

terminal block.

2. Disconnect power from the system.

3. Determine the cause of the blown fuse.

4. Replace with an equivalent fuse.

5. Reconnect power.

Thermal Devices, Inc. Mount Air

8

, Maryland USA www.thermaldevices.com

Page 11

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Section 3 – Temperature Control Operations

Figure 3.1 Control Panel Layout

START/STOP Pushbuttons

START

Press

pump.

Indicator will illuminate while

pump is running. Press

STOP

to start the

to stop the pump.

Status and Diagnostic Indicators

System shuts down if any red diagnostic indicator is

illuminated.

Low Water Pressure:

• System water pressure is below 20 psi.

(Disabled on CMX-180 models)

Pump Overload:

• Pump has drawn too much current.

Over Temperature:

• System temperature has exceeded 260°F.

Most CMX units shipped from 1995 through 2018 will

have been equipped with a Chromalox model 2104

temperature controller. For these units, please reference the 2104 Quick Info Manual or Instruction Manual

0037-75276 for complete technical details.

For specific controller Set-up Parameters, please refer

Chromalox Manual PQ445-5

Most CMX units shipped from 2019 and onward will

have been equipped with a Chromalox model 4081

(standard controller) or 4082 (advanced controller). For

these units, please reference the 4081 & 4082 Quick

Start Manual, Document PK531 (0037-75563) or Instruction manual PK532-1 (0037-75562) for complete

technical details.

Temperature Control

Actual controller supplied may vary from picture.

Below is a list of the most common controller setups,

with additional details available in Appendix C

CMX-250, Contactor – Dwg. 223-123625-053

CMX-275, Contactor – Dwg. 223-123625-052

CMX-250, SCR – Dwg. 223-123625-055

CMX-275, SCR – Dwg. 223-123625-058

CMX-250, Heat-Only – Dwg. 223-123625-057

CMX-275, Heat-Only – Dwg. 223-123625-059

Thermal Devices, Inc. Mount Air

9

, Maryland USA www.thermaldevices.com

Page 12

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Section 4 – Operation

On both open Closed-loop systems, turn on water and insure the water supply lines are free

of obstructions BEFORE energizing the heater.

Such obstructions could prevent the thermal

expansion of water from backing up into this

line, thereby increasing system pressure until

the relief valve opens.

Note: This system is equipped with an ASME

safety pressure relief valve (factory preset at

125 psi or 150 psi with 7.5 hp motor).

1. Apply power to the system via the remote discon-

nect. The temperature controller and “LOW WATER

PRESSURE” diagnostics light should illuminate.

2. Open supply-water line and process valving to al-

low system to fill. Auto air bleed will remove air from

the system. Any remote air bleed valves should be

opened to remove air from process and associated

piping.

3. “LOW WATER PRESSURE” diagnostic light should

go out when the system is filled and has reached

20 psi. The system will not start when light is illuminated.

4. Adjust the temperature setpoint to the desired lev-

el.

5. Assure that Pump Rotation Check was performed

per instructions on page 12.

6. Start the pump by pressing on the front panel. The

pump indicator light will illuminate.

7. Once temperature has stabilized at the setpoint

level, review controllability of the system. If the

temperature is fluctuating at an unacceptable level,

consult the temperature control instruction manual

for details on tuning the controller.

8. If the system temperature is below the current set-

point, heat will be applied by the controller to the

heater elements. If the temperature is above the

setpoint, the cooling solenoid will open (open and

closed loop) to reduce the system temperature.

down to prevent release of hot fluid.

Note: This is a PID type controller and cycling of the

heat and cool can be expected below and above setpoint.

9. For system shutdown, lower the setpoint to 90°F or

lower, Allow the system to cool to this temperature

level.

10. Press to de-energize the pump and disable the

system.

11. Disconnect power to the unit.

Do not leave system unattended in a HOT electrical condition; and do not leave system unattended in HOT environmental conditions.

Operating systems at temperatures above

140°F will create surface temperatures on

pipes that can cause burns. Precautions should

be taken to prevent operator contact with hot

pipes. Also, bleed valves should be locked

Thermal Devices, Inc. Mount Air

, Maryland USA www.thermaldevices.com

10

Page 13

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Section 5 – Diagnostics

Figure 5.1 Diagnostic Indicators

HAZARD OF ELECTRIC SHOCK. Disconnect

system power, if the Pump Overload Indicator

is illuminated. Hazard of electric shock or electrocution. Disconnect all power and piping to

the system.

After the system power is disconnected, solve the

electrical current problem. To put the pump back online, open the front electrical enclosure and press the

pump reset switch (See Figure 5.2, Overload Switch).

Diagnostic Functions

All diagnostic functions will shut down the system and

require the operator to remedy the problem before it

can be restarted.

Low Water Pressure Indicators

The pump, heater, and cooling will not operate while

the pressure is low. The Low Water Pressure Indicator will illuminate when the system pressure is below

20 psi. This warning system is designed to reduce the

possibility of pump cavitation and boiling on the heater

element at higher operating temperatures. Disabled on

CMX-180 models.

Pump Overload Indicator

The Pump Overload Indicator will illuminate when the

pump draws too much current. Low line voltage, single

phase power input, and a seized pump motor are all

possible causes for pump overload.

Figure 5.2 Pump Reset Switch

Close the front electrical enclosure door and

retighten the locking screw. This must be done

to limit access to high voltage components.

Failure to comply could lead to electric shock

or electrocution.

Over Temperature Indicator

If the system temperature exceeds 260°F (127°C), the

Over Temperature Indicator will illuminate. When the

system temperature drops below 260°F*, press RE-

SET on the controller face. The controller will not reset

until the temperature is below 260°F*.

*

190°F on CMX-180 model(s)

Thermal Devices, Inc. Mount Air

11

, Maryland USA www.thermaldevices.com

Page 14

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Section 6 – Maintenance

ELECTRIC SHOCK AND BURN HAZARD. Disconnect all power before servicing or performing

maintenance to the system. Do not attempt to

service system while it is operating or while

hot. Failure to comply can result in:

a. Electric shock.

b. Burns from hot heating elements, piping,

and hot oil or water.

c. Injury from operating or rotating pump and

motor.

Maintenance is to be performed by qualified

personnel only. Thoroughly read and understand these instructions. Consult the factory if

you have any questions.

Shut Down

To take the unit out of service, the following steps must

be done in sequence:

1. Set the temperature controller setpoint to 90°F or

lower. Allow to cool.

2. Turn off power to the unit. The controller will turn

off.

3. Turn off the water supply to the unit.

4. Disconnect electrical supply to the unit.

5. Carefully bleed pressure from the system by loosening a pipe fitting.

Draining

Drain the unit before taking it out of service for a period of time, or if it is exposed to freezing temperatures

while out of service.

1. To drain the unit completely, move it to an inclined

position with the front of the system raised.

2. Remove the lower plugs on cast chambers (see

Figure 6.1, Chamber Photo).

Remove these

plugs

Figure 6.1 Chamber Photo

System may be pressurized. Use extreme care

while removing piping. Disconnect water supply, drain and process connections.

6. Drain all water from the system.

Thermal Devices, Inc. Mount Air

, Maryland USA www.thermaldevices.com

12

Page 15

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Heater Removal/Replacement

HAZARD OF ELECTRIC SHOCK. Disconnect all

power and piping to system.

1. Disconnect all power to the system.

2. Bleed pressure and drain all water from the system.

3. Remove top panel.

4. Remove red top cover on the heater (see Figure

6.2, Heater/Chamber Photo).

5. Note location of wires on the heater, then remove

wires (L1, L2, L3).

6. Loosen compression fitting on the heater power

supply cable.

Figure 6.2 Heater/Chamber Photo

7. Remove cable from the heater.

8. Unbolt the heater (4 bolts) and remove.

9. Remove Bussing from old heater and re-install on

replacement heater, using the same orientation.

10. Replace heater and reverse procedure.

Close the front electrical enclosure door and

retighten the locking screw. This must be done

to limit access to high voltage components.

Failure to comply could lead to electric shock

or electrocution.

Remove Top Panel

Remove Top Cover

on Heater

Thermal Devices, Inc. Mount Air

13

, Maryland USA www.thermaldevices.com

Page 16

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Pump Removal/Replacement

HAZARD OF ELECTRIC SHOCK. Disconnect all

power and piping to system.

1. Disconnect all power to the system.

2. Bleed pressure and drain all water from the system.

3. Remove top and side panels.

4. Remove pump motor wiring cover panel (2 screws).

5. Note location of pump motor wires and remove.

6. Loosen and remove vent line (see Figure 6.3, Motor

Vent Line).

7. Remove bolts holding pump motor to the casting

(4 bolts), and lift motor out of casting.

8. Remove impeller and install new mechanical seal

and impeller on the new motor.

9. Place new motor in system and bolt down.

10. Replace vent line and tighten.

11. Reconnect wires and replace wiring cover and side

panels.

12. Reconnect the system.

13. Perform Pump Rotation Check (see Section 2,

page 12).

14. Replace top panel.

Heat Exchanger Removal/Replacement

(Closed loop system)

1. Disconnect all power to the system.

2. Bleed pressure and drain all water from the system.

3. Remove top panel.

4. Remove cover on the cooling solenoid (see Figure

6.4, Heat Exchanger).

5. Disconnect “COOLING INLET” and “COOLING

OUTLET” piping.

6. Disconnect copper tubing connected to the heat

exchanger.

7. Unbolt the heat exchanger and remove (4 bolts).

8. Place new heat exchanger in system and bolt

down.

9. Reconnect “COOLING INLET” and “COOLING

OUTLET” piping.

10. Reconnect wires to the cooling solenoid.

11. Reconnect copper tubing.

12. Replace cover on cooling solenoid and top panel.

13. Replace system water and reconnect the system.

Close the front electrical enclosure door and

retighten the locking screw. This must be done

to limit access to high voltage components.

Failure to comply could lead to electric shock

or electrocution.

Close the front electrical enclosure door and

retighten the locking screw. This must be done

to limit access to high voltage components.

Failure to comply could lead to electric shock

or electrocution.

Heater Element

Housing

Pump/Motor Vent Line

Figure 6.3 Motor Vent Line

Motor

Pump Housing

Top Panel

Figure 6.4 Heat Exchanger

Cooling Solenoid

Heat Exchanger

Thermal Devices, Inc. Mount Air

14

, Maryland USA www.thermaldevices.com

Page 17

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Replacement Heating Elements and Contactors

MicroTHERM Model Replacement Parts

Open Loop Closed Loop Voltage Heating Element Heater Contactor

CMX-4 CMX-4C 240 155-554807-523 072-057576-050

CMX-4 CMX-4C 480 155-554807-523 072-057576-050

CMX-9 CMX-9C 240 155-554807-512 072-057576-050

CMX-9 CMX-9C 480 155-554807-512 072-057576-050

CMX-12 CMX-12C 240 155-554807-524 072-057576-050

CMX-12 CMX-12C 480 155-554807-524 072-057576-050

CMX-18 CMX-18C 240 155-554807-519 072-057576-051

CMX-18 CMX-18C 480 155-554807-519 072-057576-050

CMX-24 CMX-24C 240 155-554807-515 072-057576-051

CMX-24 CMX-24C 480 155-554807-515 072-057576-050

Replacement Parts Common to All Models

Identification # Part Name Part Number

1 3/4 HP Motor 240V/480V 193-121843-227

2 Solenoid Valve 344-121780-012

3 Pressure Relief Valve 344-048419-004

4 Automatic Air vent 344-053181-001

5 Pressure Gauge 130-118661-021

6 Pressure Switch 292-121927-028

7 Pump Mechanical Seal 251-121946-019

8 Heat Exchanger Bundle (Closed Loop) 353-123367-002

9 Heater/Cooling Gasket (2 total) 132-146012-020

10 Thermocouple 309-121759-063

11 Switch, Start/Stop

Switch Indicator Bulb

12 Diagnostic Indicator Light (3 total) 213-122066-041

13 Motor Contactor 240/480V 072-123534-064

14 Auxillary Motor Contact Block 071-122886-055

15 Motor Thermal Overload 240V

Motor Thermal Overload 480V

16 Transformer 240/480V 315-303786-001

17 Caster (4 total) 375-123425-003

18 Control Voltage Fuse 128-123445-005

19 Heater Contactor See table above

292-122882-043

213-122066-034

359-122078-096

359-122078-095

These parts may vary for non-catalog items.

Please consult your local Chromalox representative. (800-443-2640 or www.chromalox.com)

15

Thermal Devices, Inc. Mount Air

, Maryland USA www.thermaldevices.com

Page 18

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Figure 6.6 Replacement Parts Identification

From Process

5

12

Pump

START

ST

OP

CONNECT

_____VOLT

SUPPLY

HERE

System Diagnostics

Low Water Pressure

Pump Overload

Over Temperature

13

19

FUSE

1F

To Process

5

Temperature Control System

Chromalox

HEAT

COOL

OUT3

OUT4

RESET AUX

15

AUX. CONTACT BLOCK

1M

CMX Series

®

PV

SP

Chromalox

PAGE

F

C

AUX

PAGE

®

17

TRANSFORMER

MOTOR CONTACTOR

MOTOR THERMAL

OVERLOAD

16

HEATER

CONTACTOR

20

14

1C

Thermal Devices, Inc. Mount Air

16

, Maryland USA www.thermaldevices.com

Page 19

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Section 7 – Troubleshooting

Troubleshooting Guide - For qualified personnel only. See warnings in earlier sections.

Symptom Probable Cause Correction

Unit will not start, control

display does not light.

Control display lights, unit

will not start

Unit stops while running

Low Water Pressure

Indicator Illuminated

Pump Overload Indicator

illuminated

Over Temperature

Indicator illuminated

Unit runs but fails to

pump.

1. Unit not wired correctly. 1. Check wiring.

2. Disconnect switch OFF. 2. Turn disconnect ON.

3. Blown fuse. 3. Check customer disconnect fuses and

120V fuse on terminal block (blown fuse indicator will light if fuse is blown).

4. Wrong voltage. 4.

1. Cooling water off, or below 20

psi. (CMX-250 models only)

2. Pump Motor Overload 2. Determine problem and press pump reset.

3. System above temperature

limit of 260°F. (190˚F on CMX180 Models)

1. Cooling water drops below 20

psi

2. Pump motor overload 2. Determine problem and press pump reset.

3. System exceeds temperature

limit of 260˚F (190˚F on CMX-180

Models)

1. Cooling water drops below 20

psi (CMX-180 models)

1. Pump motor overload 1. Determine the problem and press pump

1. System above temperature

limit of 600°F.

1. Incoming phase reversed on

pump motor.

Check supply voltage & unit’s rated voltage.

1. Open cooling water valve, check to assure

pressure is above 30psi

3. Allow unit to cool below 260°F and press

RESET.

1. Check cooling water valve, check to assure above 30 psi

3. Allow unit to cool below 260°F and press

RESET.

1. Check that pressure is above 30 psi

reset button

1. Allow unit to cool below 550°F and press

reset on over temperature controller inside

the panel. See Section 5.

1. Swap any two legs on the incoming power.

Unit will not heat to

setpoint.

Unit will not cool to

setpoint.

If you continue to have problems with the system after review of the above issues, please contact Chromalox

Product Service at 800-443-2640.

Thermal Devices, Inc. Mount Air

1. Cooling valve stuck open. 1. Check for cooling water flow during heat

cycle.

2. Heater element failure. 2. Check current at heater contactor during

heating.

3. Heater output insufficient. 3. Excessive losses in process or incorrectly

sized unit for application.

4. Controller needs to be tuned. 4. Check factory MENU settings, Section 3 of

this manual. Refer to 2104 Controller Technical Manual, page 35, for further information.

1. Inadequate cooling water flow. 1. Open cooling water supply line more and

assure adequate pressure.

2. Cooling outlet obstructed. 2. Check cooling outlet for obstructions

3. Heater contactor fused

closed.

4. Controller needs to be tuned. 4. Check factory MENU settings, Section 3 of

17

3. Check voltage across contactor during

cooling cycle.

this manual. Refer to 2104 Controller Technical manual, page 35, for further information.

, Maryland USA www.thermaldevices.com

Page 20

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Section 8 – Specifications

Standard 3/4 HP Pump

Heating

Pump

Size (HP)

Nominal

Flow (gpm)

Capacity

(kW)

Standard

Voltages

3/4 30 4.5 240 or 480 1-1/4 NPT 1/4 NPT 29 height

3/4 30 9 240 or 480 1-1/4 NPT 1/4 NPT 29 height

3/4 30 12 240 or 480 1-1/4 NPT 1/4 NPT 25 depth

3/4 30 18 240 or 480 1-1/4 NPT 1/4 NPT 15 width

3/4 30 24 240 or 480 1-1/4 NPT 1/4 NPT 15 width

Optional Pump Sizes

Optional Pump Sizes

(HP)

Nominal Flow

(gpm)

1.5 40

350

560

7.5 80

Five Pump sizes are available for the flow rate

appropriate to your process application.

Ft.

PSI

180

78

160

69

61

140

52

120

43

100

80

35

26

60

17

40

9

20

0 20 40 60 80 100 120

3/4 HP

1.5 HP

U.S. Gallons Per Minute

3 HP

7.5 HP

5 HP

Process

Connection

dia. (Inches)

Drain/Supply

dia. (Inches)

Approximate

Optional Options

• Alternate Voltages: 208, 380, 575 VAC, 3 phase

• Expanded Open Loop Cooling: increased cooling

water flow

• Expanded Closed Loop Cooling: 6.3 sq. ft. heat

exchanger

• Solid State Power Control: SCR heater switching

• Surge Reduction valve: reduces water pressure

spikes

• Door Interlock: prevents operation with service

door open

• Digital Communications: for interface with ChromaSoft or remote PC/PLC systems

• IEC Style Contactor: for dry contact power switching

• Isolation Valve Kit: 1” ball valve for system isolation

Dimensions

(Inches)

Pump Capacity

Figure 8.1 - Pump Capacity

Thermal Devices, Inc. Mount Air

18

, Maryland USA www.thermaldevices.com

Page 21

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Appendix A

microTHERM CMX Closed Loop to Open Loop Cooling Conversion

Note: All warnings and cautions denoted

throughout this user’s manual also apply to the

modifications listed below. General instructions and specifications referring to the open

and closed loop systems apply to the fieldmodified units below.

New Material Required

1. 1/4” NPT Pipe Plug 1 piece 218-075439-036

2. 1/4” NPT x 1-1/2” Nipple 1 piece 198-122817-013

3. 1/4” NPT Elbow 1 piece 107-122815-001

4. 1/4” NPT Close Nipple 1 piece 198-122817-002

5. 1x1/2” NPT Reducer 1 piece 032-120942-019

6. Open loop cooling flange 1 piece 121-510702-017

Replacement Steps

Figures 1 and 2 show the layout of the cooling configuration for both closed and open loop cooling. These parts

are located on the top of the cooling chamber. Use pipe tape or other sealing compound when attaching threaded

connections.

This sheet details the steps taken and material required

to convert a Chromalox CMX microTHERM hot water

system from closed loop cooling to open loop cooling. The basic operation involves removing the heat exchanger bundle and replacing it with a flat plate. Please

contact the Chromalox Customer Service department

for more information and to order the necessary materials.

or

Figure A1 - Closed Loop Cooling

Note: Refer to Figures 3 and 4 for location of compo-

nents.

1. Remove (47) 3/8” copper tube and compression

fittings from heat exchanger and tee above pump

inlet.

2. Place 1/4” pipe plug into tee above pump inlet

where copper tube was connected.

3. Pop magnetic coil from top of (43) solenoid valve

and leave wired to system.

4. Remove (43) solenoid valve from top of heat exchanger and keep for reinstallation.

5. Remove four (9) bolts and lift (42) heat exchanger

from cooling chamber.

Thermal Devices, Inc. Mount Air

, Maryland USA www.thermaldevices.com

Figure A2 - Open Loop Cooling

6. Reuse rubber gasket and (9) bolts to attach new

(42) cooling flange to cooling chamber.

7. Attach new (40) 1-1/2” nipple to flange.

8. Attach (43) solenoid and magnetic coil to nipple.

9. Attach new (15) close nipple and new (39) elbow to

solenoid.

10. Replace 1” pipe plug from lower cooling chamber

port with 1 x 1/2” reducer.

11. Lower cooling chamber port becomes the new

cooling inlet.

19

Page 22

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Appendix B

microTHERM CMX Open Loop to Closed Loop Cooling Conversion

Note: All warnings and cautions denoted

throughout this user’s manual also apply to the

modifications listed below. General instructions and specifications referring to the open

and closed loop systems apply to the fieldmodified units below.

New Material Required

1. 1/4” NPT Tee 1 piece 299-122818-001

2. 1/2” NPT Tee 1 piece 299-122818-003

3. 1/4” NPT x 7/8” Nipple 1 piece 198-122817-002

4. 1/2” NPT x 3” Nipple 1 piece 198-122817-090

5. 1/2” NPT Street Elbow 1 piece 107-114567-005

6. Bush Reducer 1/2” x 1/4”NPT 2 pieces 032-121003-005

7. Compression Fitting, 1/4” NPT x 3/8” tube 2 pieces 119-114570-001

8. Tubing 3/8” copper 2 Feet 318-511965-001

9. Gasket 1 piece 132-146012-020

10. Heat Exchanger Tube Bundle 1 piece 353-123367-002

11. 1” NPT Pipe Plug 1 piece 218-075439-066

12. Labels 1 piece 170-122103-040

This sheet details the steps taken and material required

to convert a Chromalox CMX microTHERM hot water

system from open loop cooling to closed loop cooling.

The basic operation involves removing the flat plate

and replacing it with a heat exchanger bundle. Please

contact the Chromalox Customer Service department

(1-800-368-2493) for more information and to order the

necessary materials.

Replacement Steps

Figures 1, 2, 3 and 4 show the layout of the cooling configuration for both closed and open loop cooling. These

parts are located on the top of the cooling chamber. Use pipe tape or other sealing compound when attaching

threaded connections.

or

Figure B1 - Closed Loop Cooling

Note: Refer to Figures 3 and 4 for location of components.

Figure B2 - Open Loop Cooling

Thermal Devices, Inc. Mount Air

20

, Maryland USA www.thermaldevices.com

Page 23

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

DRAIN /

COOLING

OUTLET

FROM

PROCESS

WATER SUPPLY

COOLING

INLET

TO

PROCESS

Fig. 2

OPEN LOOP

COOLING

OUTLET

WATER

SUPPLY

COOLING

INLET

FROM

PROCESS

PROCESS

OPEN LOOP

Figure B3 - Open Loop Cooling

TO

Fig. 1

CLOSED LOOP

Figure B4 - Closed Loop Cooling

Thermal Devices, Inc. Mount Air

CLOSED LOOP

21

, Maryland USA www.thermaldevices.com

Page 24

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Installation Steps

1. Drain fluid from system and disconnect all power.

2. Fig. 2: Remove 1/4” NPT elbow (39), nipple (15)

and nipple (40) from solenoid valve and keep solenoid valve for reinstallation.

3. Fig. 2: Remove flange (42).

4. Fig. 3: Remove 1/4” coupling (30) from pump inlet nipple (31) and remove coupling from pressure

switch (29). Keep pressure switch for reinstallation.

5. Fig. 4: Install 1/4” NPT tee (14) on pump inlet nipple

(31), install compression fitting (46) in 1/4” NPT tee

(14). Reinstall pressure switch (29) into top of 1/4”

NPT tee (14).

6. Fig. 1: Install heat exchanger (42) using new gasket

and existing bolts.

7. Fig. 1: Install the following items onto the heat exchanger:

• 1/2” NPT street elbow (44)

• 1/2” NPT x 3” nipple (40)

• 1/2” NPT tee (38)

• 1/2” x 1/4” NPT bush reducers (45)

• 1/4” NPT x 7/8” nipple (39)

• compression fitting (46)

• solenoid valve (43) removed earlier

8. Fig. 1: Install 3/8” copper tubing (47) in compression fitting (46). Route tubing to compression fitting

(46) near pump inlet shown in Fig. 4. Do not kink

tubing.

9. Fig. 3: Remove the 1” x 1/2” NPT bush reducer (38)

from the bottom port on the inlet chamber.

10. Fig. 4: Install 1” NPT pipe plug (37) in bottom port

of the inlet chamber.

11. Fig. 3: Remove the following labels from the CMX

back panel:

• “Water Supply / Cooling Inlet” from bottom port

on inlet chamber

• “Drain / Cooling Outlet” from bottom heat ex-

changer opening

12. Fig. 4: Apply new labels (50) to CMX back panel:

• “Cooling Outlet” to top heat exchanger opening.

• “Water Supply / Cooling Inlet” to bottom heat ex-

changer opening.

13. Test all connections for leaks

Thermal Devices, Inc. Mount Air

22

, Maryland USA www.thermaldevices.com

Page 25

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

Appendix C

CMX-250, Heat Only 4081 Controller

Configuration Menu

Lock Code 10

Input Configuration Input 1 setup

Input Type J Thermocouple

Engineering Units ˚F

Decimal Point Position 1234

Scaled Input Lower Limit 32˚F

Scaled Input Upper Limit 260 °F

Cold Junction Compensation Enabled

Input Filter Time 2.0 sec

Control Configuration

Control Select Control Standard

Control Enable/Disable Control Enabled

Select Auto/Manual Control Automatic Control

Control Type SINGLE

Primary Control Action Reverse

PID set Use PID set 1

Set 1 Primary Pb 15°F

Set 1 Secondary Pb 10˚F

Set 11ntegral 0.01 s

Set 1 Derivative 20.0s

Set 1 overlap/deadband 5˚F

Manual Reset 0%

Anti windup limit 100

Primary Cycle Time 30.0 s

Secondary Cycle Time 10.0 s

Primary Power Lower Limi 0.00%

Primary Power Upper Limit 100.00%

Secondary Power Lower Limit 0.00%

Secondary Power Upper Limit 100.00%

Sensor Break Off

Set Point Lower Limit 32˚F

Set Point Upper Limit 250˚F

Set Point Ramp Rate Off

Main setpoint source Local Set point

Alternate Set Point Source Not Used

Main Set Point 250°F

Output Configuration

Output 1 Usage Unused

Output 2 Usage Primary

Output 3 Usage OR alarm-events reverse

OPR3 OR selection Alarms 1v

Output 3 Latch enable Enabled

Output 4 Usage UNUSED

Alarm Configuration Alarm 1

Alarm 1 Type Process High

Alarm 1 source universal input 1

Process High Alarm Value 260˚F

Process High Alarm Hysteresis 1˚F

Minimum Duration 15 sec

Power-Up Inhibit Alarm 1 Uninhibited

Communication Configuration

Modbus RTU Parity None

Modbus RTU Data Rate 19200

Serial Communication Enabled

Thermal Devices, Inc. Mount Air

23

, Maryland USA www.thermaldevices.com

Page 26

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

CMX-275, High Temperature 4081 Controller, Heat Only

Configuration Menu

Lock Code 10

Input Configuration Input 1 setup

Input Type J Thermocouple

Engineering Units ˚F

Decimal Point Position 1234

Scaled Input Lower Limit 32˚F

Scaled Input Upper Limit 285˚F

Cold Junction Compensation Enabled

Input Filter Time 2.0 sec

Control Configuration

Control Select Control Standard

Control Enable/Disable Control Enabled

Select Auto/Manual Control Automatic Control

Control Type SINGLE

Primary Control Action Reverse

PID set Use PID set 1

Set 1 Primary Pb 15˚F

Set 1 Secondary Pb 10˚F

Set 11ntegral 0.01 s

Set 1 Derivative 20.0s

Set 1 overlap/deadband 5˚F

Manual Reset 0%

Anti-windup limit 100

Primary Cycle Time 30.0 s

Secondary Cycle Time 10.0 s

Primary Power Lower Limit 0.00%

Primary Power Upper Limit 100.00%

Secondary Power Lower Limit 0.00%

Secondary Power Upper Limit 100.00%

Sensor Break Off

Set Point Lower Limit 32˚F

Set Point Upper Limit 275˚F

Set Point Ramp Rate Off

Main setpoint source Local Set point

Alternate Set Point Source Not Used

Main Set Point 275˚F

Output Configuration

Output 1 Usage Unused

Output 2 Usage Primary

Output 3 Usage OR alarm-events reverse

OPR3 OR selection Alarms 1v

Output 3 Latch enable Enabled

Output 4 Usage Unused

Alarm Configuration Alarm 1

Alarm 1 Type Process High

Alarm 1 source universal input 1

Process High Alarm Value 285˚F

Process High Alarm Hysteresis 1˚F

Minimum Duration 15 sec

Power-Up Inhibit Alarm 1 Uninhibited

Communication Configuration

Modbus RTU Parity None

Modbus RTU Data Rate 19200

Serial Communication Enabled

Thermal Devices, Inc. Mount Air

24

, Maryland USA www.thermaldevices.com

Page 27

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

CMX-275, High Temperature 4081 Controller with SCR

Configuration Menu

Lock Code 10

Input Configuration Input 1 setup

Input Type J Thermocouple

Engineering Units ˚F

Decimal Point Position 1234

Scaled Input Lower Limit 32˚F

Scaled Input Upper Limit 285˚F

Cold Junction Compensation Enabled

Input Filter Time 2.0 sec

Control Configuration

Control Select Control Standard

Control Enable/Disable Control Enabled

Select Auto/Manual Control Automatic Control

Control Type DUAL

Primary Control Action Reverse

PID set Use PID set 1

Set 1 Primary Pb 15˚F

Set 1 Secondary Pb 10˚F

Set 11ntegral 0.01 s

Set 1 Derivative 20.0s

Set 1 overlap/deadband 5˚F

Manual Reset 0%

Anti-windup limit 100

Primary Cycle Time 1 s

Secondary Cycle Time 10.0 s

Primary Power Lower Limit 0.00%

Primary Power Upper Limit 100.00%

Secondary Power Lower Limit 0.00%

Secondary Power Upper Limit 100.00%

Sensor Break Off

Set Point Lower Limit 32˚F

Set Point Upper Limit 275˚F

Set Point Ramp Rate Off

Main setpoint source Local Set point

Alternate Set Point Source Not Used

Main Set Point 275˚F

Output Configuration

Output 1 Usage Primary

Output 2 Usage Unused

Output 3 Usage OR alarm-events reverse

OPR3 OR selection Alarms 1v

Output 3 Latch enable Enabled

Output 4 Usage Secondary

Alarm Configuration Alarm 1

Alarm 1 Type Process High

Alarm 1 source universal input 1

Process High Alarm Value 285˚F

Process High Alarm Hysteresis 1˚F

Minimum Duration 15 sec

Power-Up Inhibit Alarm 1 Uninhibited

Communication Configuration

Modbus RTU Parity None

Modbus RTU Data Rate 19200

Serial Communication Enabled

Thermal Devices, Inc. Mount Air

25

, Maryland USA www.thermaldevices.com

Page 28

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

CMX-275, High Temperature 4081 Controller

Configuration Menu

Lock Code 10

Input Configuration Input 1 setup

Input Type J Thermocouple

Engineering Units ˚F

Decimal Point Position 1234

Scaled Input Lower Limit 32˚F

Scaled Input Upper Limit 285˚F

Cold Junction Compensation Enabled

Input Filter Time 2.0 sec

Control Configuration

Control Select Control Standard

Control Enable/Disable Control Enabled

Select Auto/Manual Control Automatic Control

Control Type DUAL

Primary Control Action Reverse

PID set Use PID set 1

Set 1 Primary Pb 15˚F

Set 1 Secondary Pb 10˚F

Set 11ntegral 0.01 s

Set 1 Derivative 20.0s

Set 1 overlap/deadband 5˚F

Manual Reset 0%

Anti-windup limit 100

Primary Cycle Time 30.0 s

Secondary Cycle Time 10.0 s

Primary Power Lower Limit 0.00%

Primary Power Upper Limit 100.00%

Secondary Power Lower Limit 0.00%

Secondary Power Upper Limit 100.00%

Sensor Break Off

Set Point Lower Limit 32˚F

Set Point Upper Limit 275˚F

Set Point Ramp Rate Off

Main setpoint source Local Set point

Alternate Set Point Source Not Used

Main Set Point 275˚F

Output Configuration

Output 1 Usage Unused

Output 2 Usage Primary

Output 3 Usage OR alarm-events reverse

OPR3 OR selection Alarms 1v

Output 3 Latch enable Enabled

Output 4 Usage Secondary

Alarm Configuration Alarm 1

Alarm 1 Type Process High

Alarm 1 source universal input 1

Process High Alarm Value 285˚F

Process High Alarm Hysteresis 1˚F

Minimum Duration 15 sec

Power-Up Inhibit Alarm 1 Uninhibited

Communication Configuration

Modbus RTU Parity None

Modbus RTU Data Rate 19200

Serial Communication Enabled

Thermal Devices, Inc. Mount Air

26

, Maryland USA www.thermaldevices.com

Page 29

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

CMX-250 STD Heat/Cool 4081/4082 Controller with SCR

Configuration Menu

Lock Code 10

Input Configuration Input 1 setup

Input Type J Thermocouple

Engineering Units ˚F

Decimal Point Position 1234

Scaled Input Lower Limit 32˚F

Scaled Input Upper Limit 260 °F

Cold Junction Compensation Enabled

Input Filter Time 2.0 sec

Control Configuration

Control Select Control Standard

Control Enable/Disable Control Enabled

Select Auto/Manual Control Automatic Control

Control Type DUAL

Primary Control Action Reverse

PID set Use PID set 1

Set 1 Primary Pb 15°F

Set 1 Secondary Pb 10˚F

Set 11ntegral 0.01 s

Set 1 Derivative 20.0s

Set 1 overlap/deadband 5˚F

Manual Reset 0%

Anti windup limit 100

Primary Cycle Time 1 s

Secondary Cycle Time 10 s

Primary Power Lower Limi 0.00%

Primary Power Upper Limit 100.00%

Secondary Power Lower Limit 0.00%

Secondary Power Upper Limit 100.00%

Sensor Break Off

Set Point Lower Limit 32˚F

Set Point Upper Limit 250˚F

Set Point Ramp Rate Off

Main setpoint source Local Set point

Alternate Set Point Source Not Used

Main Set Point 250°F

Output Configuration

Output 1 Usage Primary

Output 2 Usage Unused

Output 3 Usage OR alarm-events reverse

OPR3 OR selection Alarms 1v

Output 3 Latch enable Enabled

Output 4 Usage Secondary

Alarm Configuration Alarm 1

Alarm 1 Type Process High

Alarm 1 source universal input 1

Process High Alarm Value 260˚F

Process High Alarm Hysteresis 1˚F

Minimum Duration 15 sec

Power-Up Inhibit Alarm 1 Uninhibited

Communication Configuration

Modbus RTU Parity None

Modbus RTU Data Rate 19200

Serial Communication Enabled

Thermal Devices, Inc. Mount Air

27

, Maryland USA www.thermaldevices.com

Page 30

Thermal Devices, Inc. Mount Airy, Maryland USA www.thermaldevices.com

y

CMX-250 Stnadard, Heat/Cool 4081 Controller

Configuration Menu

Lock Code 10

Input Configuration Input 1 setup

Input Type J Thermocouple

Engineering Units ˚F

Decimal Point Position 1234

Scaled Input Lower Limit 32˚F

Scaled Input Upper Limit 260˚F

Cold Junction Compensation Enabled

Input Filter Time 2.0 sec

Control Configuration

Control Select Control Standard

Control Enable/Disable Control Enabled

Select Auto/Manual Control Automatic Control

Control Type DUAL

Primary Control Action Reverse

PID set Use PID set 1

Set 1 Primary Pb 15˚F

Set 1 Secondary Pb 10˚F

Set 11ntegral 0.01 s

Set 1 Derivative 20.0s

Set 1 overlap/deadband 5˚F

Manual Reset 0%

Anti-windup limit 100

Primary Cycle Time 30.0 s

Secondary Cycle Time 10.0 s

Primary Power Lower Limit 0.00%

Primary Power Upper Limit 100.00%

Secondary Power Lower Limit 0.00%

Secondary Power Upper Limit 100.00%

Sensor Break Off

Set Point Lower Limit 32˚F

Set Point Upper Limit 250˚F

Set Point Ramp Rate Off

Main setpoint source Local Set point

Alternate Set Point Source Not Used

Main Set Point 250˚F

Output Configuration

Output 1 Usage Unused

Output 2 Usage Primary

Output 3 Usage OR alarm-events reverse

OPR3 OR selection Alarms 1v

Output 3 Latch enable Enabled

Output 4 Usage Secondary

Alarm Configuration Alarm 1

Alarm 1 Type Process High

Alarm 1 source universal input 1

Process High Alarm Value 260˚F

Process High Alarm Hysteresis 1˚F

Minimum Duration 15 sec

Power-Up Inhibit Alarm 1 Uninhibited

Communication Configuration

Modbus RTU Parity None

Modbus RTU Data Rate 19200

Serial Communication Enabled

© 2019 Chromalox, Inc.

Thermal Devices, Inc. Mount Air

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Chromalox, Inc.

2150 N. Rulon White Blvd.,

Ogden, UT 84404

Phone: 1-800-368-2493

www.chromalox.com

28

, Maryland USA www.thermaldevices.com

Loading...

Loading...