Page 1

(Supersedes PQ400-8)

PQ400-9

3001H

161-048643-001

JULY, 2009

4

and

Installation, Operation

RENEWAL PARTS IDENTIFICATION

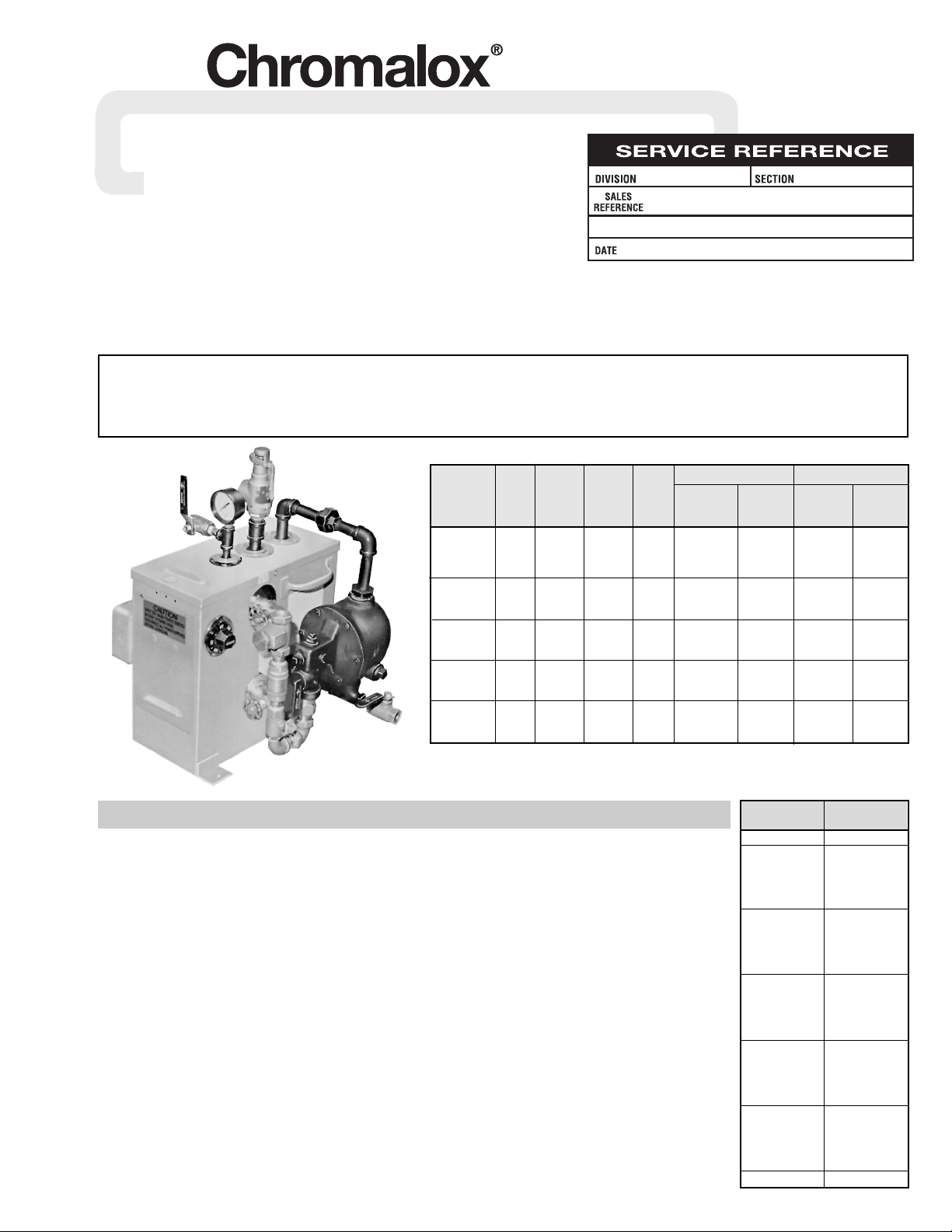

Type CMB Electric Steam Generator

0 – 90 PSI

© 2010 Chromalox, Inc.

Output

Single Phase Three Phase

Lbs./Hr. Power Power

Vol. AT † Amperes CCT. Amperes CCT.

Model kW (Gals.) 212°F Volts Drawn Diag. Drawn Diag.

3 1.6 9 120 25 1 NA NA

CMB-3A

3 1.6 9 208 14.4 2 8.3 3

3 1.6 9 240 12.5 2 7.2 3

3 1.6 9 480 6.3 2 3.6 3

6 6 18 208 28.8 4 16.7 8

CMB-6A 6 6 18 240 24 4 14.4 8

6 6 18 480 125 4 7.2 8

9 6 27 208 43.3 6 25 8

CMB-9A 9 6 27 240 37.5 5 21.7 8

9 6 27 480 18.8 4 10.8 8

12 6 36 208 57.7 7 33.3 8

CMB-12A 12 6 36 240 50 7 28.9 8

12 6 36 480 25 5 14.4 8

15 6 45 208 72.1 7 41.6 9

CMB-15A 15 6 45 240 62.5 7 36.1 8

15 6 45 480 31.2 5 18 8

Specifications —

GENERAL

WARNING: Hazard of Electric Shock. Any installa-

tion involving electric generators must be effectively grounded in accordance with the National

Electrical Code to eliminate shock hazard.

1. Locate unit on level floor or platform.

2. Connect water line to tagged fitting on the water control feeder.

3. The incoming water supply must be 10 pounds greater than the

operating pressure. Otherwise, a high pressure feed (pump)

must be used.

4. Wire unit following wiring diagrams supplied. (See recom-

mendations on safety switches and fusing.)

5. Connect steam line with an outlet valve to boiler steam outlet.

Chromalox recommends using a globe valve one pipe size

smaller than steam line to limit any pressure drops (surges) that

may occur during start-up.

6. Open all gauge valves and steam outlet valve. Keep drain valve

closed.

7. Turn on watter supply; water will reach operation level automatically.

8. Close steam outlet valves.

9. Set thermostat for desired steam pressure (see Table 1).

10. Turn boiler switch to ON position, pilot light will go on.

Generator will Build up to desired

pressure and shut off automatically.

11. Open steam outlet valves and

use steam as needed.

12. Generator should be blown

down daily (see Blowdown

instructions).

13. Chromalox generators are pretested before shipment. No internal

wiring or piping is required.

14. Substitution of components or

modification of wiring systems

without consult of manufacturer

voids the warranty.

15. Power must be off when generator is drained.

16. Purchaser should use a safety

switch between the main power

source and the steam generator.

The safety switch should use circuit breakers or fuses.

CMB-3A

† Assuming Feedwater at 50°F.

Note — All Models listed with Underwriters Laboratories Inc.

Gauge Pressure Temperature

(psig) (°F)

0 212

1 216

2 219

3 222

4 224

5 227

6 230

7 232

8 235

9 237

10 240

15 250

20 259

25 267

30 274

35 281

40 287

45 292

50 298

55 303

60 307

65 312

70 316

75 320

80 324

85 328

90 331

Table 1 —

Temperature-Pressure

Relationship for Steam

Boiler Serial # . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Power Circuit Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model # . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Control Circuit Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

National Board # . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Amps . . . . . . . . . . . . . . . Phase . . . . . . . . . . . Cy . . . . . . . . . . . . . . .

IMPORTANT – This data file contains the National Board Registration Certificate approving your generator. It must be kept near the generator at all times.

Page 2

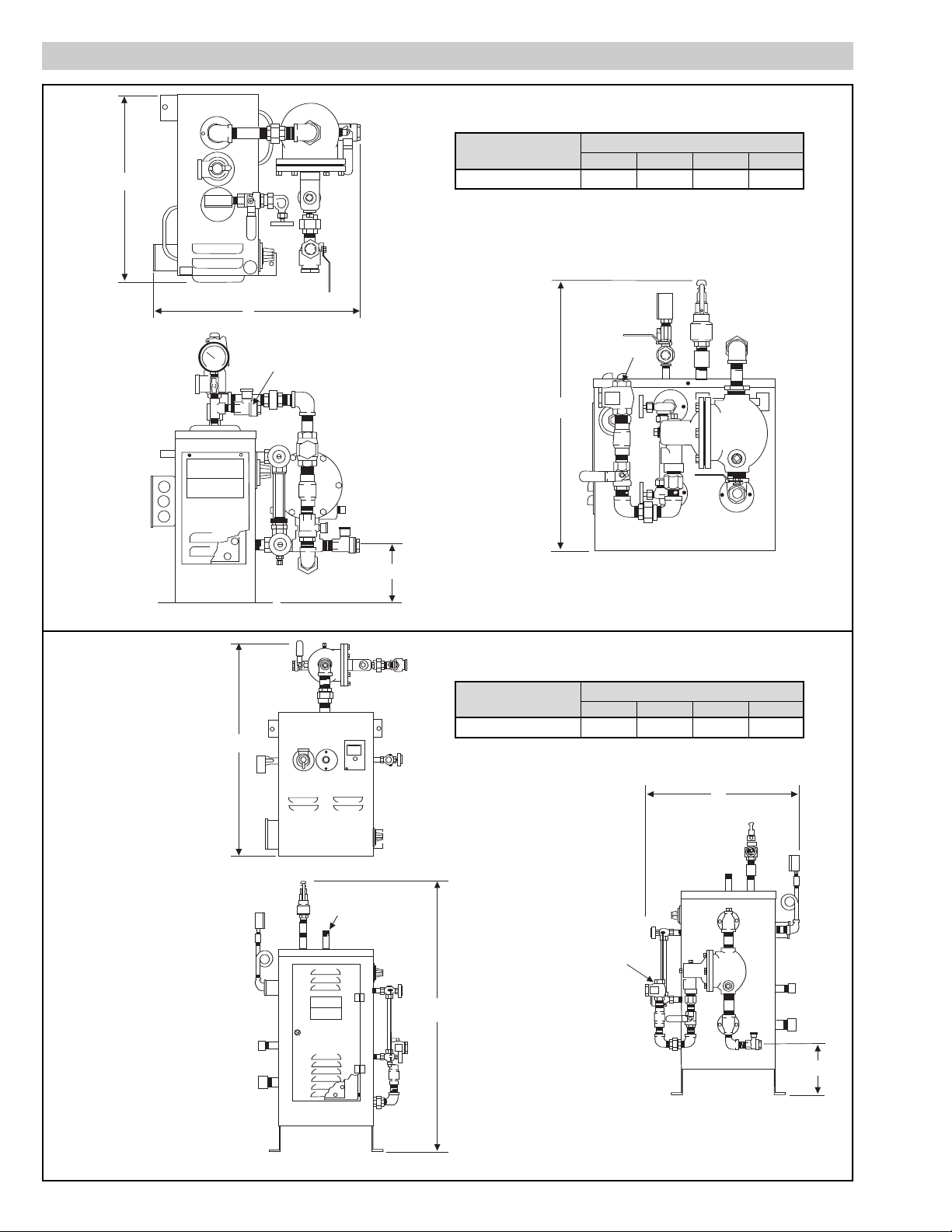

DIMENSIONS

Top View

C

B

D

A

Front View

Side View

®

CAUTION

1/4" NPT Outlet

1/2" NPT Inlet

Dimensions (In.)

Model A B C D

CMB-3 22-1/2 17-1/4 15 4-1/4

Dimensions (In.)

Model A B C D

CMB-6, 9, 12, 15 36-1/2 30 20 7

Top View

B

A

Front View

Rear View

D

C

®

CAUTION

1/2" NPT Outlet

1/2" NPT Inlet

Page 3

BLOWDOWN INSTRUCTIONS

Blowdown is an essential part of generator operation. It is the

best preventive maintenance you can give your generator and

will add years of life to the unit. Make sure that a blowdown

schedule is established and followed regularly.

In extremely hard water areas, blowdown may be necessary

once a day. In other areas, once each week may be sufficient. If

there is a particular problem which applies to your local water

condition, other than mineral content, take this into consideration

in determining what schedule is to be followed.

1. At the end of the working day turn the control switch to the

OFF position and close the watter supply valve.

2. If blowing down into a receptacle, allow the pressure to

decrease to 15-20 psi before opening the blowdown valve.

3. It is preferable to connect the blowdown valve directly into a

drainage system, if local codes permit. If this is allowed, the

generator can be discharged at operating pressure.

4. When discharge is complete and the generator is drained, close

the blowdown valve and open the water supply valve, allowing

the generator to fill to normal level.

5. Close wall-mounted safety switch.

6. If you have been supplied with a manual reset control (as

required in some states), the reset button on the control must be

pushed before generator will begin developing pressure.

CAUTION: Do not push reset until boiler has filled with water.

7. WARNING: The use of chemical cleaning compounds in

these generators voids the warranty, unless approved by the

manufacturer.

OPERATION

WIRING DIAGRAMS

Standard

1-3 kW, 120V

1 Ø

Diagram 1

1-3 kW, 208V-480V

1 Ø

1-3 kW, 208V-240V & 480V

3 Ø

Diagram 2 Diagram 3

Diagram 4

Diagram 6Diagram 5

Diagram 7 Diagram 8 Diagram 9

6 kW, 208V-480V, 1 Ø

9 kW, 480V, 1 Ø

9 kW, 230V-277V, 1 Ø

12-15 kW, 480V, 1 Ø

C

C

9 kW, 208V-220V, 1 Ø

12 kW, 277V, 1 Ø

40-47A

C

C

FU1

FU2

12 kW, 208V-240V, 1 Ø

15 kW, 208V-277V, 1 Ø

48A

C

C

FU1

FU2

C

C

FU3

FU4

6-15 kW, 208V-240V, 3 Ø

15 kW, 208V, 3 Ø

40A

C

FU1

C

C

FU2

FU3

From Power Circuit, Separate Source, or Transformer

C

W

B

R

Control Circuit Diagram

KEY

For All Units with Contactors

Contactor

Normally Open

Thermostat Switch

Black Lead

Red Lead

White Lead

C

B

R

W

120V 1Ph

Page 4

2150 N. RULON WHITE BLVD., OGDEN, UT 84404

Phone: 1-800-368-2493 www.chromalox.com

RENEWAL PARTS IDENTIFICATION

HEATING ELEMENTS

Description Part Number

3kW 120V 1PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300129-005

3kW 208V 1PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300129-008

3kW 240V 1PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300129-002

3kW 480V 1PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300129-037

3kW 208V 3PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300122-008

3kW 240V 3PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300122-009

3kW 480V 3PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300122-010

6kW 208V 1PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300129-022

6kW 240V 1PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300129-023

6kW 480V 1PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300129-027

6kW 208V 3PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300122-006

6kW 240V 3PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300122-001

6kW 480V 3PH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155-300122-004

9kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONTACT

12kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FACTORY

15kW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY VALVES

Description Part Number

Popoff 1/2” 100 PSIG . . . . . . . . . . . . . . . . . . . . . . . . . . 344-300032-004

Popoff 1/2” 15 PSIG . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-300032-001

MISCELLANEOUS VALVES AND GAUGES

Description Part Number

Float Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-300247-001

Check Valve 1/2” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276-118536-053

Ball Valve 1/4” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-121194-007

Ball Valve 1/2” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-121194-006

Ball Valve 1/4” T-Grip . . . . . . . . . . . . . . . . . . . . . . . . . . 344-300323-002

Gauge, 0-160 PSIG Dual Scale . . . . . . . . . . . . . . . . . . . 130-118661-001

Gauge, 0-30 PSIG Dual Scale . . . . . . . . . . . . . . . . . . . . 130-118661-013

Strainer 1/2” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351-118664-001

ELECTRICAL PARTS

Description Part Number

Rocker Switch with Pilot . . . . . . . . . . . . . . . . . . . . . . . . 292-053223-001

Contactor 40A 2 Pole . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-009

Contactor 40A 4 Pole (For 1Ph) . . . . . . . . . . . . . . . . . . 072-047913-022

Contactor 50A 2 Pole . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-003

Contactor 50A 3 Pole . . . . . . . . . . . . . . . . . . . . . . . . . . 072-047913-019

Thermostat — SPST 22A . . . . . . . . . . . . . . . . . . . . . . . 300-300330-001

Thermostat — DPST . . . . . . . . . . . . . . . . . . . . . . . . . . . 300-300176-001

Thermostat SPST 25A . . . . . . . . . . . . . . . . . . . . . . . . . . 300-300330-002

Fuse 50A 250V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-121133-079

Fuse 60A 250V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-121133-080

Fuse 40A 600V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-121133-064

Fuse 60A 600V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128-121133-067

Fuse Block 35-60A, 250V 2 Pole . . . . . . . . . . . . . . . . . 129-024494-005

Fuse Block 35-60A, 250V 3 Pole . . . . . . . . . . . . . . . . . 129-024494-006

Fuse Block 35-60A, 600V 1 Pole . . . . . . . . . . . . . . . . . 129-047445-003

Fuse Block 35-60A, 600V 2 Pole . . . . . . . . . . . . . . . . . 129-047445-001

Fuse Block 35-60A, 600V 3 Pole . . . . . . . . . . . . . . . . . 129-047445-002

Terminal Block, Control Circuit . . . . . . . . . . . . . . . . . . . 303-075444-001

Terminal Block, Power . . . . . . . . . . . . . . . . . . . . . . . . . 303-071809-001

SIGHT GLASS ASSEMBLIES

Description Part Number

Sight Glass Assy., Complete, CMB 3 . . . . . . . . . . . . . . 130-073287-003

Tubing Protector CMB 3 . . . . . . . . . . . . . . . . . . . . . . . . 374-056360-003

Valve Set CMB 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-120970-003

Sight Glass Tubing CMB 3 . . . . . . . . . . . . . . . . . . . . . . 374-121046-019

Sight Glass Assy., Complete, CMB 6-15 . . . . . . . . . . . . 130-073287-004

Valve Set CMB 6-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . 344-120970-002

Sight Glass Tubing CMB 6-15 . . . . . . . . . . . . . . . . . . . . 324-121046-020

Guard Rods (2) CMB 6-15 . . . . . . . . . . . . . . . . . . . . . . 242-121047-008

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...