Page 1

Circulation Heaters

Selection Guidelines

Circulation

Selecting a Circulation Heater

Selecting the proper circulation heater component requires critical engineering judgement

and careful evaluation of the application. After

determining the heat requirement for a specific

heat application, the proper selection of the

flange and vessel material, heating element

sheath material, and correct watt density is

critical to achieve long heater life. The ultimate

selection of equipment is determined by the

knowledge of the process and engineering

acumen of the designer or plant engineer. Consult the Technical section of this catalog for

circulation heater calculations and guidelines.

Application Factors

Heater selection is influenced by the following

parameters.

1 The heated medium, viscosity, specific

heat, density and corrosive properties.

2 The presence of contaminants in the

medium.

3 The corrosion resistant properties of the

heater sheath material.

4 The sheath watt density of the heating

elements — the watts per square inch, and

the flow rate of the heated medium.

Corrosion Policy

Chromalox will not warrant any electric heater

against failure by sheath corrosion if such

failure is the result of operating conditions beyond the control of the heater manufacturer. It

is the responsibility of the purchaser to make

the ultimate choice of sheath material based

on his knowledge of the chemical composition of the corrosive solution, character of

materials entering the solution, and controls

by which he maintains the process.

5 The vessel design and material — pressure

and temperature of the fluid being heated.

Circulation Heaters — Selection Guidelines

1 2 3 4 5

Solution or

Application

Water Clean Water pH6 to pH8 (Neutral) Copper 45 - 100 Galvanized Steel

Mild Solutions Process Water and Very Weak Solutions

Corrosive &

High Viscous

Solutions

Oil Low Viscosity Oils

Air, Gases

& Steam

Weak Solutions

Demineralized, De-ionized or Pure Water

Mildly Corrosive Solutions

More Severe Corrosive Solutions

Severely Corrosive Solutions

Medium Viscosity Oils

High Viscosity Oils (Fuel Oil)

Medium Temperatures to 750°F

High Temperatures to 1400°F

Heater Type

Alkaline or Acid Content

(Est. % by Volume)

pH5 to pH9 (2 - 3%)

5 - 6%

—

5 -15%

10 - 25%

30 - 60%

—

—

—

—

—

Sheath

Material

INCOLOY

INCOLOY

INCOLOY

INCOLOY

INCOLOY

INCOLOY

Steel

Steel

Steel

INCOLOY

INCOLOY

®

®

®

®

®

®

®

®

Watt Density

2

(W/In

) Vessel Material

45 - 86

45 - 75

45 - 75

20 - 25

20 - 25

10 - 20

20 - 25

10 - 20

5 - 15

20 - 25

10 - 20

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Steel

Steel

Steel

Steel

Stainless Steel

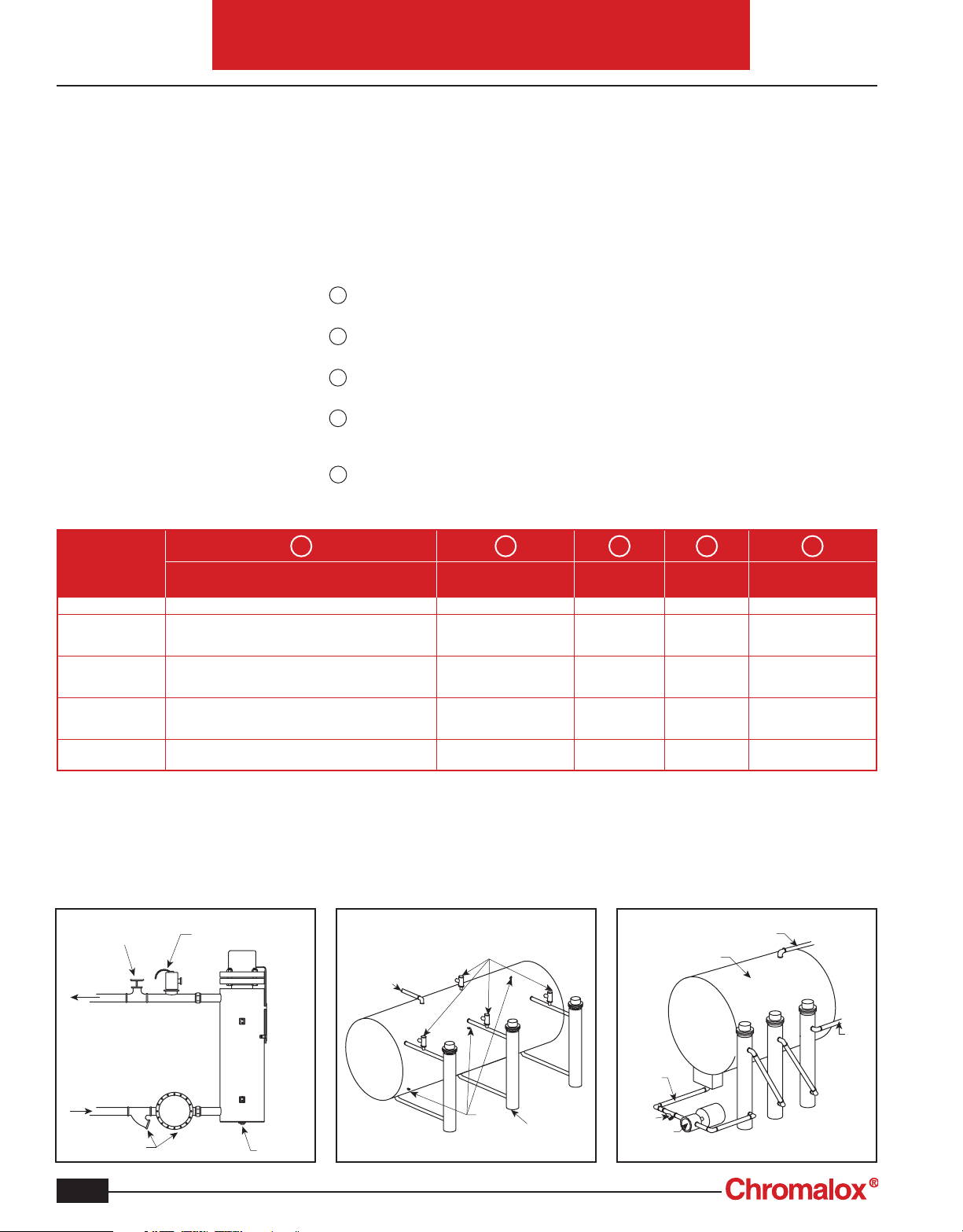

Typical Applications

Inline Heating — Where demands for heated

water or oil are nearly constant, circulation

heaters may be installed directly in the fluid

line, eliminating the need for storage tanks and

their related heat losses.

Shut Off Valve

Outlet to

Application

Inlet from

Storage Supply

Strainer

and Pump

(when used)

C-2

Pressure Relief Valve

Drain

Side Arm — Requirements of large storage

tanks can be satisfied by using a number of

circulation heaters, providing flexibility in temperature control and reducing power demand.

Pressure Relief Valves

Outlet

Thermostat

Bulbs

Drain

Closed-Loop Fuel Oil Heating —Require-

ments may be provided by a number of

circulation units individually adjustable to

temperature and fluid flow, reducing electrical

demand on your utility bill.

Return Line to Tank

Storage Tank

From Fuel

Oil Tank

Sump

Strainer

Pump

To Fuel

Oil Burner

Page 2

Circulation

Circulation Heaters

Selection Guidelines (cont'd.)

Circulation Heaters — Selection Guidelines

Application

Clean Water Copper/Steel

Clean Water

or Oil

Corrosive &

High Viscous

Solutions

Oil

Light

Medium

Heavy Steel/Steel 3 - 120

Steam, Air & Gas INCOLOY®/

Pre-engineered Packages — Wired & Skid Mounted C-34

ASME & Custom Engineering Specifications (SDS) C-35

Heater/Vessel

Material

or Brass

Copper/Galv.

Steel

INCOLOY®/

Galvanized

INCOLOY®/

Stainless

INCOLOY®/

CPVC

Steel/Steel 3 - 120

Steel

INCOLOY®/

Stainless

kW

Rating Feature Model Page

1.5 - 3 Booster NWHJR C-13

3 - 18

6 - 500

0.5 - 40 Field Adjustable NWHSRG C-14

6 - 200

2 - 30

1.5 - 3

30 - 120

20 - 70

30 - 50

0.5 - 3.0

3 - 350

2 - 200

Scr

ew Plug

Flanged

Flanged

Reduced Watt Density

Non-Metallic Body

Flanged

Baffled

Reduced W

Baffled

Low Flow

Flanged

Flanged

Baffled

att Density

NWH C-11

NWHIS

NWHOIS

CVCHS

NWHSR

NWHO

NWHOB

NWHOR

NWHORB

GCHCIS

GCHI

GCHIS

GCHISB

Codes & Standards

ASME Certification to Sections I, III, IV and

VIII, Division 1 or PED —Chromalox is the

leader in providing ASME (American Society of

Mechanical Engineers or PED) certification for

pressure vessel applications.

Underwriters Laboratories — UL Listing

available for many circulation heaters. Consult

your Local Chromalox Sales office.

ATEX Directive — Many Chromalox products

are approved for use in explosive atmoshpehere

Canadian Standards Association —CSA

certification available.

National Electrical Code (NEC and IEC) — All

Chromalox circulation heaters are built to allow

NEC installation requirements.

Special Features Available

Kilowatt Ratings —Large kilowatt circulation

heaters (500 kW and above) are available as

single chambers or with multiple chambers

in series. Skid mounting and integral control

panels are also available.

Vessel Construction — Chamber size available

in 10, 12, 14, 16, 18" and above for larger

kilowatt capacities.

Pressure Ratings — 150, 300, 400, 600, 900,

1,500 and 2,500 Lb. Class.

Materials — 304, 316, 321, 347 Stainless

Steel, INCONEL

®

and more.

Thermocouplescan be provided on element

sheath for overtemperature protection and/

or mounted in the outlet nozzle for process

control.

Inlet and Outlet Nozzles — Available with

flanged or threaded connections, smaller or

larger pipe sizes and different orientations.

Bafflesmounted on element bundle inside

chamber to increase fluid or gas velocity.

Terminal Standoffs in 4, 6 and 8" allow the

terminal enclosure housing and the field wiring connection to operate at lower temperatures in high temperature heaters. Standoffs

are frequently used in heat transfer and gas

heating applications.

Mounting Saddlesfor horizontally mounted

circulation heaters.

Weatherproof Insulation Jacket for outdoor

unprotected installations.

C-29

C-30

C-16

C-19

C-17

C-18

C-21

C-21

C-33

C-24

C-32

C-32

CIRCULATION

HEATERS

C-3

Loading...

Loading...