Circulation

Plate

Plate

Circulation Heaters

Terminal

Enclosures

• E1GeneralPurpose

• E2MoistureResistant/Explosion

Resistant

• E4MoistureResistant

• ConduitOpeningsMatched

totheNumberofCircuits

Applications

The versatility of electric heaters permits

them to be used in almost any conceivable

location indoors or outdoors, exposed to

the weather. Chromalox provides a variety of

electrical terminal enclosures to match the

unique requirements of virtually any environment.

Features

E1 General Purpose Enclosure —Suitable

for most indoor or protected commercial and

industrial applications.

E2 Combination Moisture Resistant and Explosion Proof Enclosures —Type E2 explo-

sion proof terminal enclosures are intended

for use in hazardous locations. Refer to the

following table for details.

Type E2 terminal enclosures are provided

with gaskets and are suitable for outdoor or

wet locations as well as hazardous areas.

E4 Moisture Resistant Enclosure —Suitable

for outdoor or wet locations. The terminal

covers are provided with water-tight gaskets

to seal the electrical terminals and connections from the environment.

Special Requirements for Electric

Heaters & Terminal Enclosures in

Hazardous Locations:

Wiring —The proper use of Type E2 terminal

enclosures on electric heaters located in hazardous areas requires that all electrical wiring

comply with National Electrical Code (NEC)

and IEC requirements for hazardous locations.

Maximum Temperatures —Safe operation in

a hazardous location requires the maximum

operating temperatures of all exposed surfaces of the heater including temperatures on the

outside of the vessel, piping, flanges, screw

plugs, enclosures and other heat conducting

parts be limited. The maximum surface temperature permitted in any hazardous location

is determined by the flammable liquids, vapors

or gases present. The end user or purchaser of

the electric heating equipment is responsible

for determining the proper classification of an

area and for providing Chromalox with hazardous area specifications and requirements for

proper equipment design. (NEC Articles 500

and 501 provide guidelines for evaluating and

classifying hazardous locations.)

Safety Devices — Approved pressure and/

or temperature limiting controls must be used

on electric heaters and heating elements to

ensure safe operation in the event of system

malfunctions.

Note 1 — Class I Group B locations include

Hydrogen gas. These areas require additional

conduit seals and thread engagement. Contact

your Local Chromalox Sales office for heaters

and terminal enclosures suitable for Class I

Group B hazardous locations.

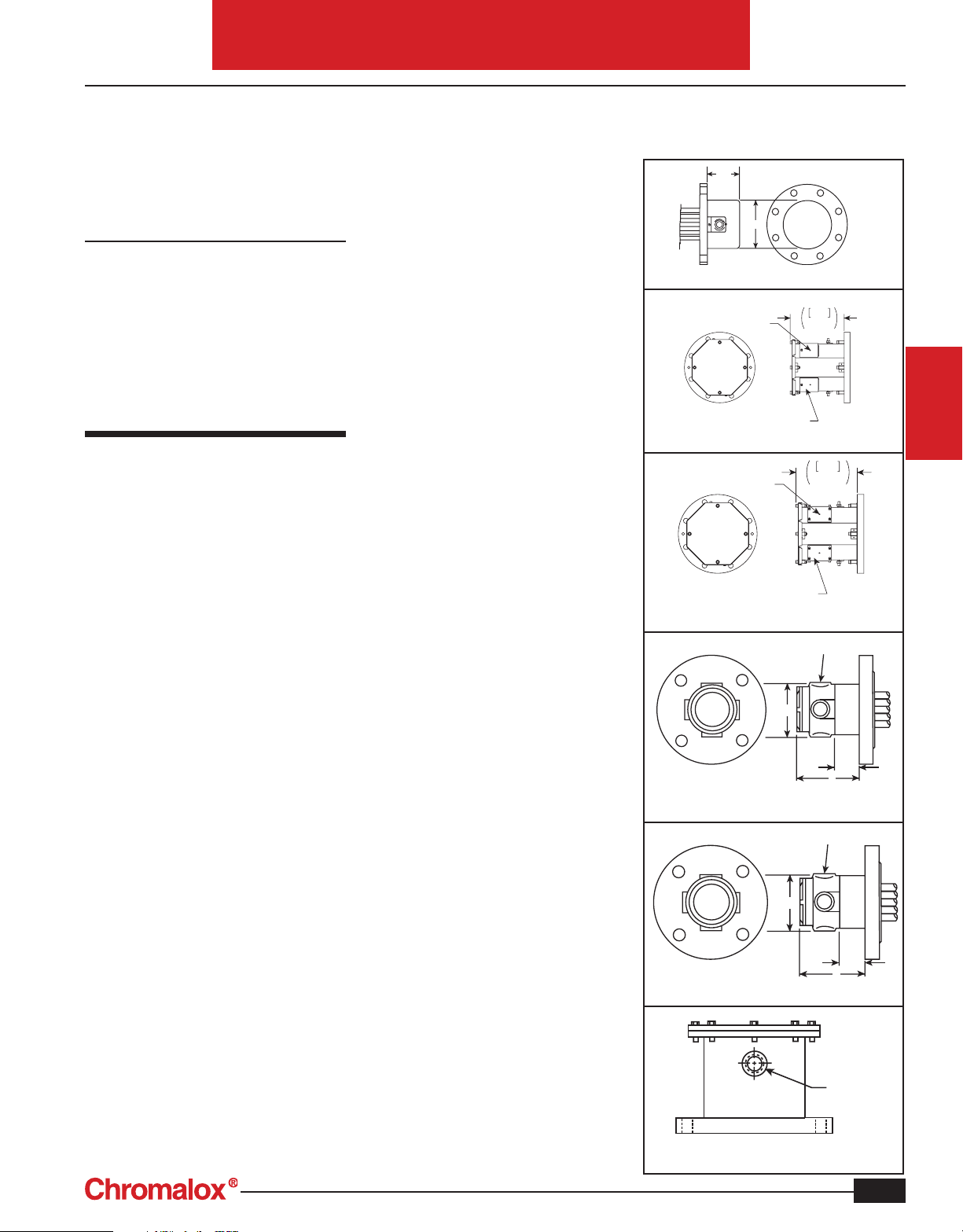

Typical Terminal Enclosures

3-1/2"

6-3/4"

E1 — General Purpose, for up to 5" Flange

Dimple for locating

chassis punched

conduit opening(s)

Removable

Service Entrance

E1 — General Purpose, for 6" and Larger Flange

Dimple for locating

chassis punched

conduit opening(s)

Removable

Service Entrance

E4 — Moisture Resistant Enclosure

with Gasket 6" and Larger

E4 — Moisture Resistant Enclosure

with Gasket up to 5" Flange

E2 — Explosion Proof Enclosure up to 5" Flange

3-3/4"

3-3/4"

263

10-3/8

267

10-1/2"

1" Conduit Outlet

1" Conduit Outlet

5

1-1/2"

1-1/2"

5

CIRCULATION

HEATERS

Conduit

E2 — Explosion Proof Enclosure

for 6" and Larger Flange

Hub

C-5

Circulation Heaters

Terminal

Enclosures

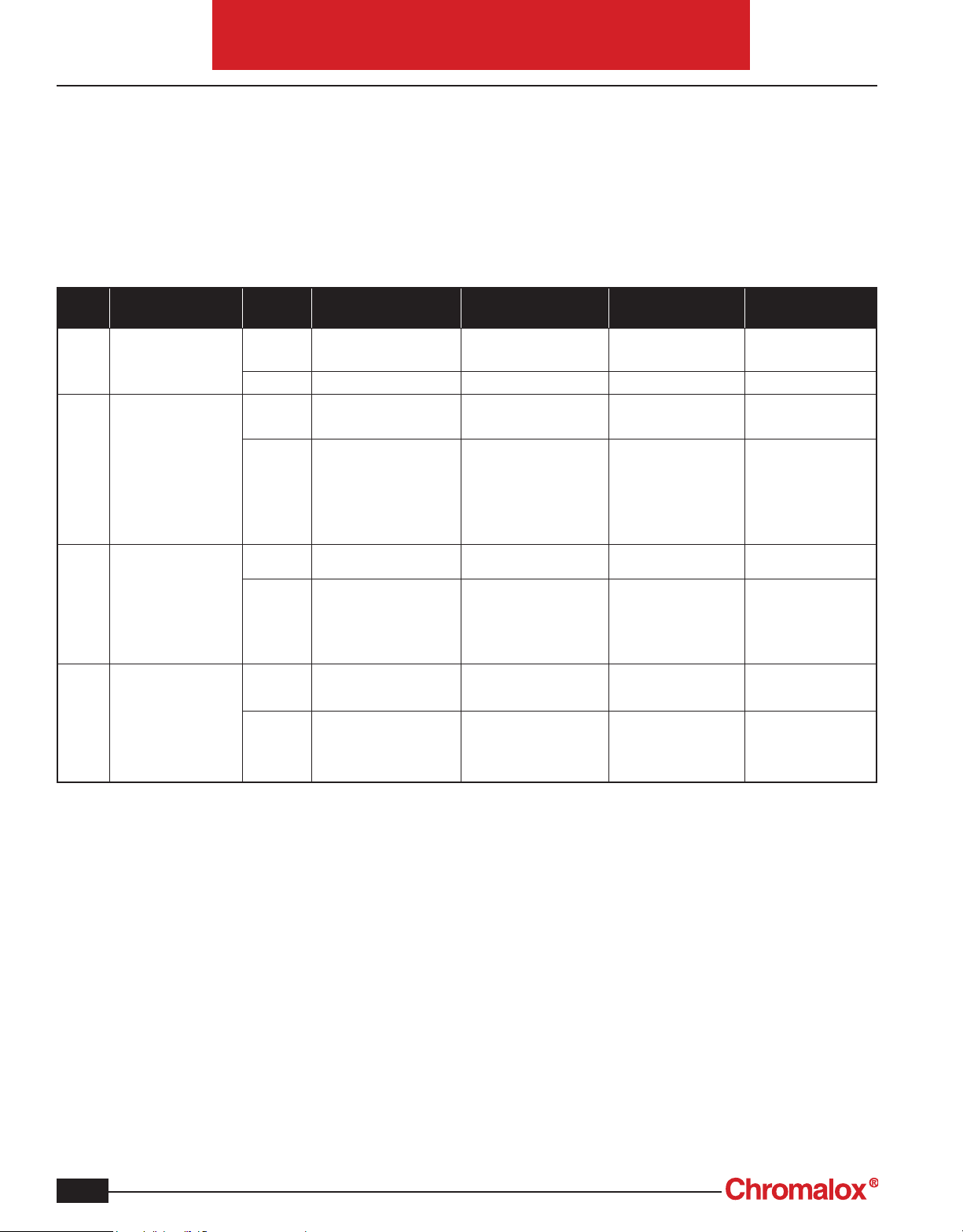

Third Party Specifications by Housing Style

Circulation

Model Purpose

E1 GeneralPurpose Generic

E4* MoistureResistant

E2 MoistureResistant/

E4

Flange

8"-12"

12"-18"

*WARNING: Addition of sparking devices such as a Thermostat to an E4 housing will annul hazardous area rating.

Note: Temps over T3

(200°C) require standoffs for third party

listing. Refer to IECex

& ATEX certifs. for

standoff dimensions

ExplosionProof

ExdIIB+H2T1toT6

Note:Temps over T4

(135°C) require standoffs for third party

listing. Refer to IECex

& ATEX certifs. for

standoff dimensions

MoistureResistant/

Size

3"-8"

ExplosionProof

ExdIIB+H2T1toT6

540°C,600°C

ATEX IIC Labeling

CFP4, CFP8, CFP12

Refer to European

Reference

Catalog

Agency (s)

Ratings General Duty Only General Duty Only General Duty Only General Duty Only

Generic

Agency (s)

Ratings Class I Div. 2,

Generic

Agency (s)

Ratings Class I, Div. 1

Generic

Agency (s)

Ratings II 2 G EEx de IIC T1 to

Designation(s)

NEMA 1, NEC

UL/CSAus

NEMA 4

UL / CSAus

Groups B, C, D

Groups E, F: 200°C

(T3)

Group G 165°C (T3B)

Class I Zone 2 AEx nA II

T1 to T6

CSAus CSA ATEX IECex

Groups B,C & D

Class II, Div. 1

Groups E, F & G

Class I Zone 1

AEx d IIB + H2 T1 to T6

North American

Canadian

Designation(s)

NEMA 1 IP32

CSA

NEMA 4

CSA

Class I Div. 2,

Groups B, C, D

Class II Division 2,

Groups E, F: 200°C

(T3)

Group G 165°C (T3B)

Class I Zone 2

Ex nA II T1 to T6

Class I, Div. 1

Groups B,C &D

Class II, Div. 1

Groups E, F & G

Class I Zone 1

Ex d IIB + H2 T1 to T6

European

Designation(s)

IP32

CE: Manufacturer’s

Declaration

IP66

CE: Manufacturer’s

Declaration

II 3 G Ex nA II T1 to T6 Ex nA II T1 to T6

I 2 G EEx d IIB+H2 T1

to T6

ITS

ATEX

T6, 540°C, 600°C

International

Designation(s)

CE: Manufacturer’s

Declaration

IP66

CE: Manufacturer’s

Declaration

Ex d IIB+H2 T1 to T6

IECex

Ex de IIC T1 to T6

540°C, 600°C

C-6

Circulation

Circulation Heaters

Terminal Enclosures

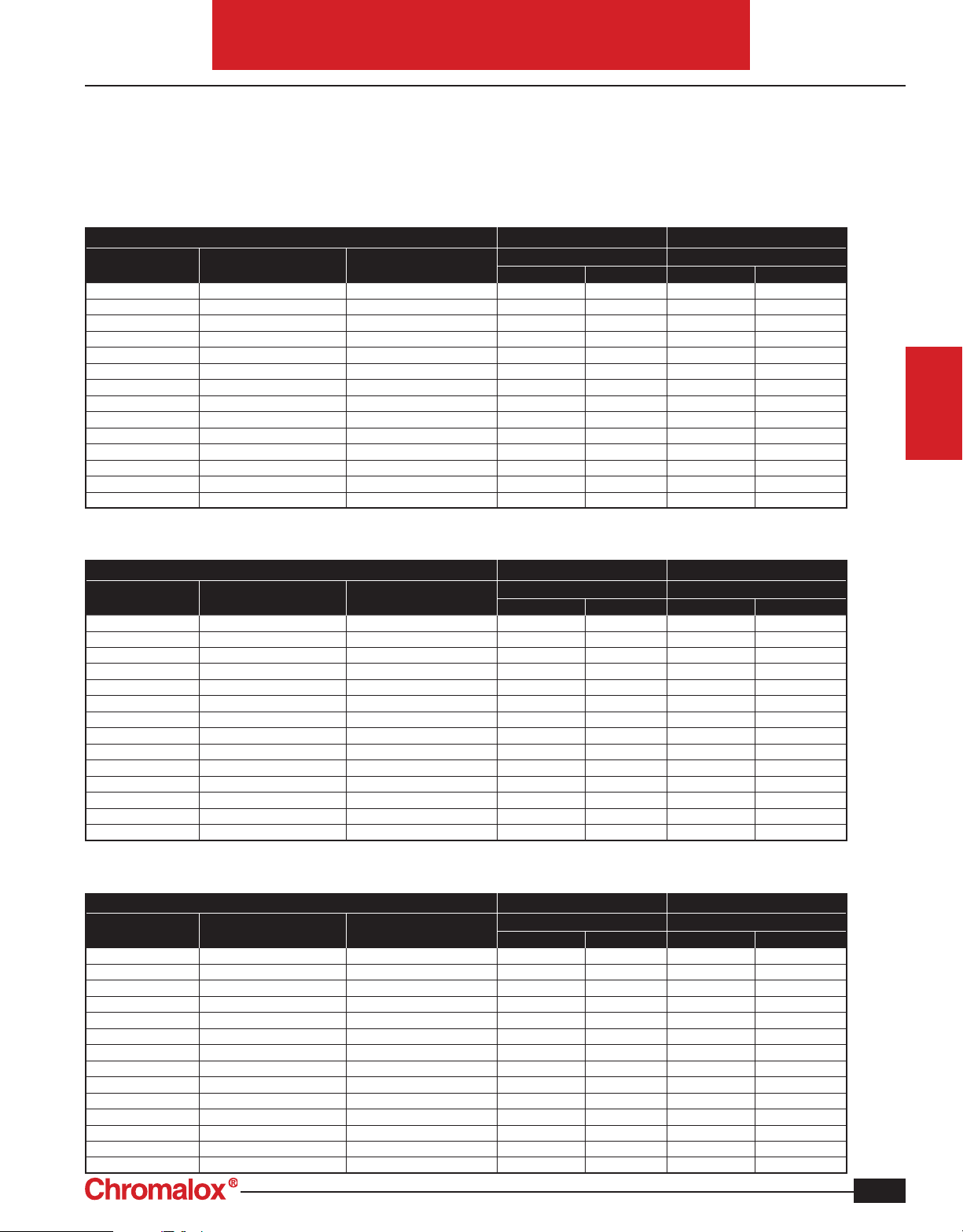

ATEX/IECEx/CSA Zone Classification Selection chart for terminal enclosure

standoff dimension based on 30°C rise over 40°C ambient

70°C Cable Supply

Temperature Code Wet Face Temperature: °F Wet Face Temperature: °C

T6 185 85 3 76 1 25

T5 212 100 3 76 2 50

T4A 248 120 5 127 3 76

T4 275 135 6 152 3 76

T3C 320 160 7.5 191 4 102

T3B 329 165 7.5 191 4 102

T3A 356 180 7.5 191 5 127

T3 392 200 9 229 5 127

T2D 419 215 9 229 5 127

T2C 446 230 9 229 6 152

T2B 500 260 10.5 267 6 152

T2A 536 280 10.5 267 6 152

T2 572 300 10.5 267 7.5 191

T1 842 450 13.5 343 9 229

Vertical Heater Orientation Horizontal Heater Orientation

Minimum Standoff Dimension Minimum Standoff Dimension

Inches mm Inches mm

CIRCULATION

HEATERS

ATEX/IECEx/CSA Zone Classification Selection chart for terminal enclosure

standoff dimension based on 10°C rise over 60°C ambient

70°C Cable Supply

Temperature Code Wet Face Temperature: °F Wet Face Temperature: °C

T6 185 85 9 229 6 152

T5 212 100 10.5 267 7.5 191

T4A 248 120 12 305 7.5 191

T4 275 135 12 305 7.5 191

T3C 320 160 12 305 7.5 191

T3B 329 165 12 305 9 229

T3A 356 180 13.5 343 9 229

T3 392 200 15 381 9 229

T2D 419 215 15 381 10.5 267

T2C 446 230 15 381 10.5 267

T2B 500 260 16.5 419 10.5 267

T2A 536 280 18 457 10.5 267

T2 572 300 18 457 10.5 267

T1 842 450 24 610 12 305

Vertical Heater Orientation Horizontal Heater Orientation

Minimum Standoff Dimension Minimum Standoff Dimension

Inches mm Inches mm

CSA Class and Division Classification Selection chart for terminal enclosure

standoff dimension based on 85°C rise over 40°C ambient

125°C Cable Supply

Temperature Code Wet Face Temperature: °F Wet Face Temperature: °C

T6 185 85 0 0 0 0

T5 212 100 0 0 0 0

T4A 248 120 0 0 0 0

T4 275 135 0 0 0 0

T3C 320 160 2 50 0 0

T3B 329 165 2 50 0 0

T3A 356 180 4 102 2 50

T3 392 200 4 102 2 50

T2D 419 215 4 102 2 50

T2C 446 230 4 102 2 50

T2B 500 260 6 152 4 102

T2A 536 280 6 152 4 102

T2 572 300 6 152 4 102

T1 842 450 7.5 191 6 152

Vertical Heater Orientation Horizontal Heater Orientation

Minimum Standoff Dimension Minimum Standoff Dimension

Inches mm Inches mm

C-7

Loading...

Loading...